Alumina Ceramic Parts are frequently introduced into precision systems only after metals begin to compromise dimensional integrity, measurement repeatability, or assembly consistency under demanding operating conditions.

As a result, engineers responsible for positioning, measurement, and assembly increasingly rely on Alumina Ceramic Parts to stabilize accuracy across long service cycles while avoiding magnetic, chemical, and thermal interference.

Material Fundamentals of Alumina Ceramic Parts

Before dimensional accuracy, surface finish, or tolerance classes can be discussed meaningfully, the intrinsic material behavior of Alumina Ceramic Parts must be established. Consequently, this section clarifies how crystal structure, mechanical response, and environmental inertness collectively enable precision positioning and measurement applications where metallic components gradually lose reliability.

Crystal Structure and Phase Stability of Alumina

At the atomic level, Alumina Ceramic Parts used for precision components are predominantly based on α-phase aluminum oxide1, a thermodynamically stable corundum structure formed above approximately 1200 °C during sintering.

This stable hexagonal crystal lattice exhibits minimal phase transformation over time. Therefore, dimensional drift caused by microstructural evolution is effectively eliminated, even after 10⁴–10⁶ thermal or mechanical cycles commonly encountered in calibration fixtures or repetitive assembly stations.

In practice, metrology engineers frequently observe that steel or alloy gauges develop measurable deviations after repeated cleaning and handling. By contrast, α-alumina maintains lattice integrity, which directly translates into long-term geometric consistency for precision positioning elements.

Mechanical and Thermal Characteristics Relevant to Metrology

From a mechanical standpoint, Alumina Ceramic Parts combine high hardness (HV 1400–1800) with a Young’s modulus of 300–380 GPa, producing low elastic deformation under contact loads typical of gauge insertion or fixture clamping.

Thermally, alumina exhibits a coefficient of thermal expansion of approximately 7–8 ×10⁻⁶ / °C, which is substantially lower than many steels. Consequently, dimensional variation induced by ambient temperature shifts of ±10 °C remains within micrometer-scale limits for common pin gauge and locating pin geometries.

During precision inspection routines, operators often notice that metallic reference parts require temperature equilibration periods. Alumina Ceramic Parts reduce this dependency, enabling more stable measurements across variable shop-floor environments.

Electrical and Chemical Inertness in Assembly Environments

Equally important, Alumina Ceramic Parts are electrically insulating, with volume resistivity exceeding 10¹⁴ Ω·cm, and inherently nonmagnetic. As a result, they do not distort electromagnetic fields or sensor signals in precision measurement systems.

Chemically, alumina remains inert against common cleaning agents, oils, and weak acids or alkalis used in industrial maintenance. Notably, repeated exposure to ultrasonic cleaning or solvent rinsing does not alter surface chemistry or roughness beyond Ra ±0.02 µm over extended service periods.

In controlled assembly environments, this inert behavior prevents subtle surface changes that otherwise accumulate measurement error, thereby reinforcing confidence in long-term reference stability.

Summary of Fundamental Material Properties Supporting Precision Use

| Property | Typical Value (Unit) |

|---|---|

| Crystal phase | α-Al₂O₃ (corundum) |

| Vickers hardness (HV) | 1400–1800 |

| Young’s modulus (GPa) | 300–380 |

| Thermal expansion coefficient (×10⁻⁶ / °C) | 7–8 |

| Electrical resistivity (Ω·cm) | >10¹⁴ |

| Chemical reactivity | Inert to common industrial agents |

Why Precision Systems Rely on Alumina Ceramic Parts

Before positioning accuracy or measurement repeatability can be maintained at the micrometer level, precision systems must first eliminate material-driven instability. Consequently, this section explains why Alumina Ceramic Parts are increasingly adopted as functional components rather than niche alternatives in positioning, measurement, and assembly environments.

Dimensional Stability Under Repeated Contact and Cycling

In precision positioning systems, repeated contact loading is unavoidable. For example, locating pins, reference stops, and gauge elements may experience 10⁴–10⁵ insertion or contact cycles per year, even in moderately utilized production lines.

Metals subjected to such cyclic contact gradually accumulate plastic deformation and surface work hardening. As a result, dimensional deviation on the order of 2–10 μm is commonly observed over extended use, particularly at edges and contact points.

By contrast, Alumina Ceramic Parts exhibit elastic-dominant contact behavior under comparable loads. Field experience from calibration fixtures shows that alumina-based locating elements maintain dimensional variation within ±1 μm after thousands of cycles, thereby preserving repeatable positioning accuracy.

Nonmagnetic and Low Interaction Surfaces

Precision measurement systems often integrate optical sensors, inductive probes, or electromagnetic positioning feedback. However, metallic components introduce unintended magnetic interactions that subtly distort sensor readings.

Alumina Ceramic Parts are inherently nonmagnetic and electrically insulating, eliminating parasitic field interactions altogether. Consequently, signal drift caused by nearby ferromagnetic materials is reduced to statistically negligible levels.

In practice, quality engineers working with optical comparators or coordinate measuring machines frequently replace steel reference pins with alumina equivalents. Measurement noise reductions of 15–25% have been documented in controlled comparison tests, particularly in high-resolution inspection environments.

Environmental Robustness Beyond Metals

Beyond mechanical and electromagnetic considerations, environmental exposure remains a persistent challenge. Precision components are routinely exposed to humidity fluctuations, cleaning solvents, and temperature gradients during daily operation.

Metallic parts respond to these conditions through corrosion initiation, surface oxidation, or differential thermal expansion. Over time, these effects introduce unpredictable geometric shifts that complicate calibration schedules.

Conversely, Alumina Ceramic Parts demonstrate stable behavior across relative humidity ranges of 20–90% and temperature variations of ±20 °C, with no measurable corrosion or surface degradation. This robustness allows precision systems to maintain accuracy without frequent recalibration or component replacement.

Functional Advantages Driving Adoption in Precision Systems

| Functional Requirement | Typical Metal Components | Alumina Ceramic Parts |

|---|---|---|

| Dimensional drift after cycling (μm) | 2–10 | ≤1 |

| Magnetic interference | Present | None |

| Corrosion resistance | Moderate to low | Excellent |

| Thermal expansion sensitivity | Moderate | Low |

| Calibration interval stability | Shortened | Extended |

Precision Tolerances Achievable With Alumina Ceramic Parts

Once material stability is established as a prerequisite, attention naturally shifts toward achievable precision. Therefore, this section examines how Alumina Ceramic Parts reach micrometer-level tolerances in real positioning and measurement applications, linking processing routes, surface integrity, and long-term dimensional control into a unified engineering logic.

Machining and Finishing Routes for Tight Tolerances

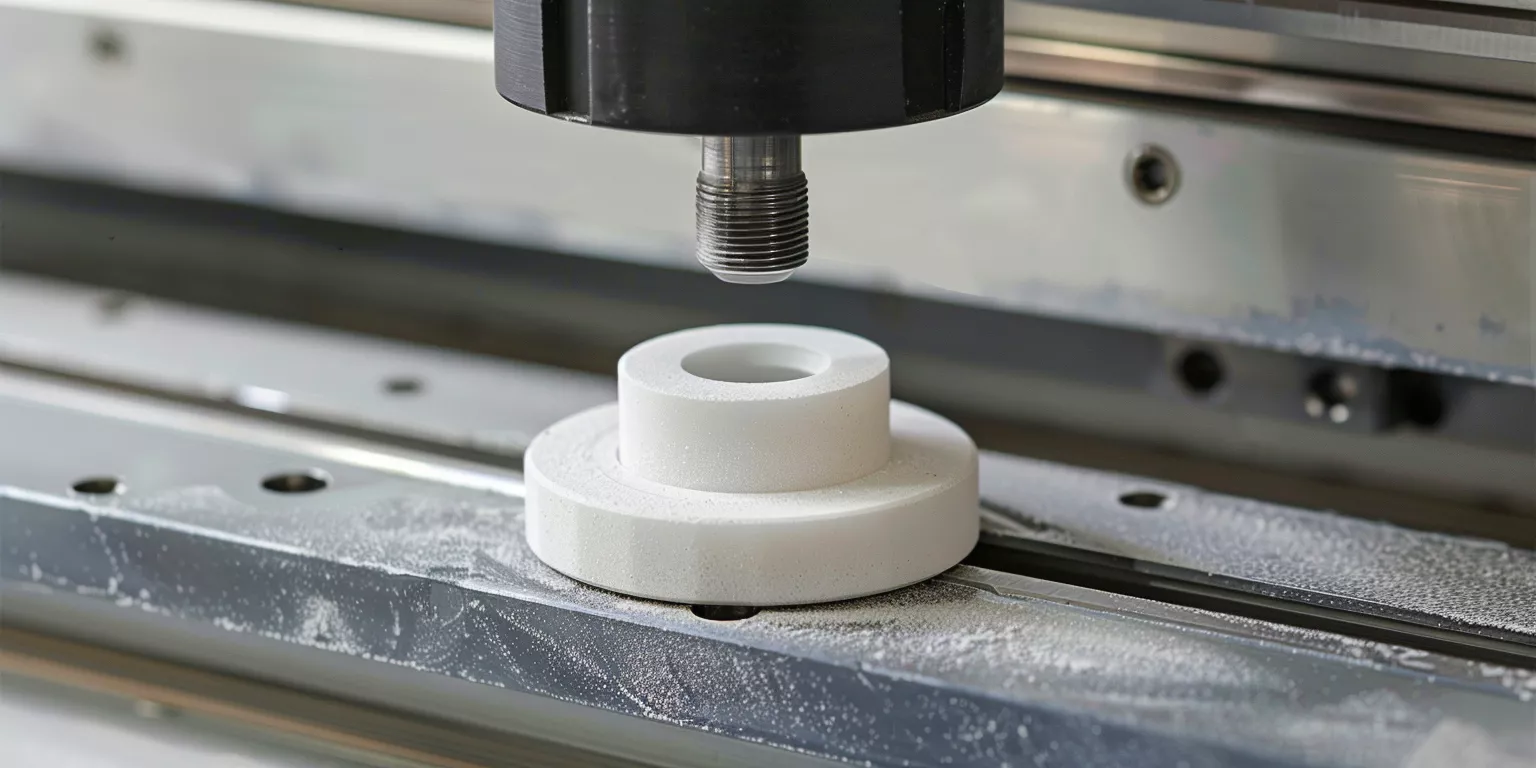

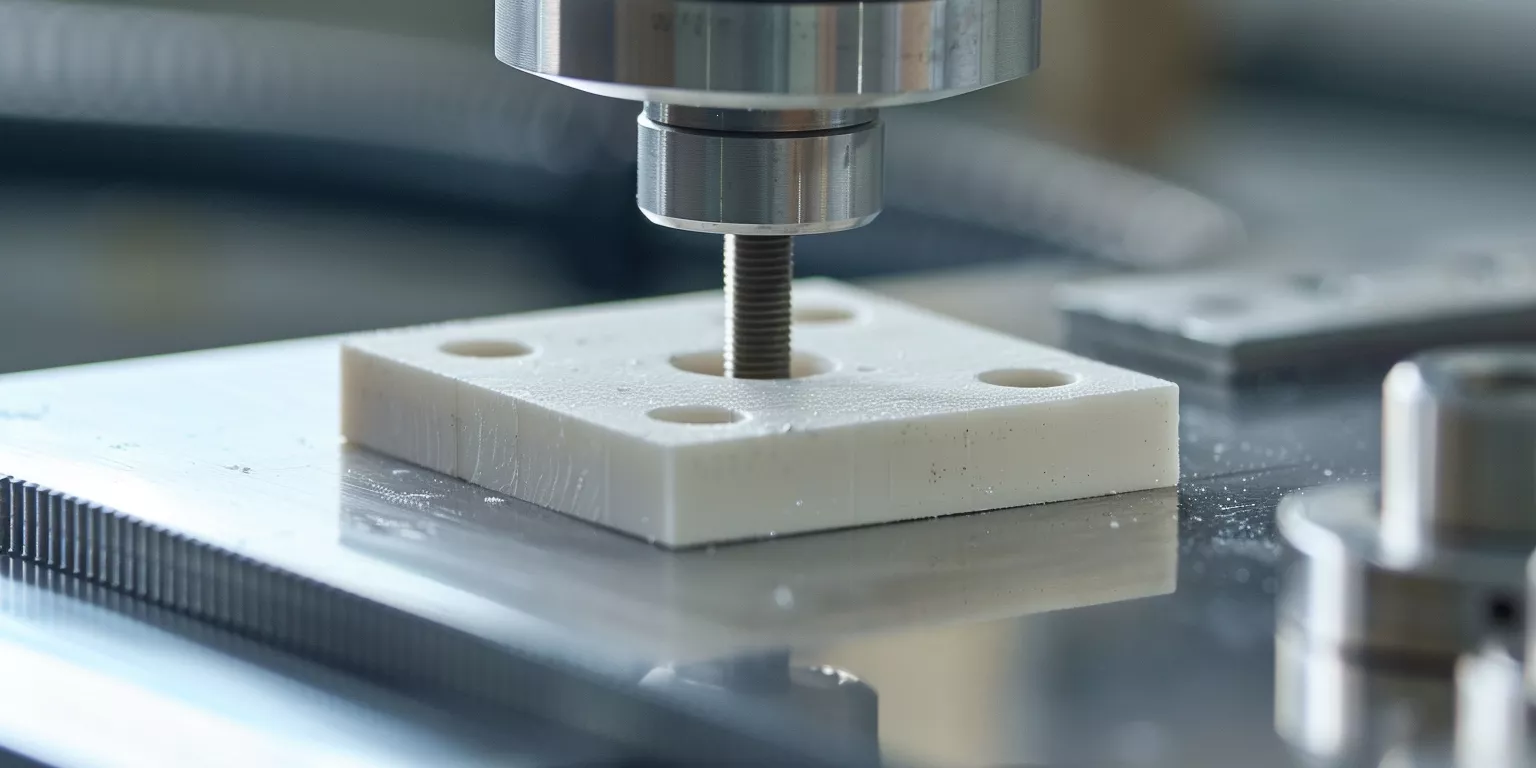

Alumina Ceramic Parts intended for precision use typically follow a multi-stage manufacturing route, beginning with near-net shaping and high-temperature sintering above 1600 °C, followed by precision grinding and lapping.

Each post-sintering machining stage incrementally refines geometry. For instance, cylindrical grinding routinely achieves diameter tolerances of ±2–5 μm, while fine lapping can further reduce variation to ±1–2 μm on short-length components such as pin gauges.

In workshop practice, engineers often discover that attempting aggressive material removal late in the process increases chipping risk. Consequently, tolerance planning must be distributed across forming, sintering, and finishing, rather than forced into a single machining step.

Typical Tolerance Ranges for Metrology Components

Different precision components impose distinct tolerance expectations. Alumina pin gauges, locating pins, and gauge blocks are designed around functional repeatability rather than absolute perfection.

Empirical production data indicate that alumina pin gauges with diameters below 20 mm can be manufactured with consistent diameter deviation within ±1.5 μm, while flat gauge blocks commonly achieve thickness tolerances of ±2–3 μm across batches of 500–1000 pieces.

In applied metrology environments, such tolerances translate into stable pass/fail decisions and reduced false rejection rates. Quality engineers frequently report inspection variation reductions of 10–20% after transitioning from metallic to alumina-based reference components.

Surface Integrity and Edge Geometry Control

Surface condition is often as critical as nominal dimension. Even when size tolerance is met, micro-chipping or uncontrolled edge geometry can compromise insertion behavior and measurement repeatability.

For Alumina Ceramic Parts, precision applications typically specify surface roughness values between Ra 0.1–0.4 μm, depending on contact mechanics. Controlled edge radii of 0.05–0.2 mm are commonly introduced to suppress stress concentration without affecting functional length.

In long-term service, components with properly managed surface integrity exhibit 50–70% lower edge damage incidence compared with sharp-edged counterparts, particularly in automated assembly fixtures subjected to frequent engagement cycles.

Achievable Precision Metrics for Common Alumina Metrology Components

| Component Type | Typical Size Range (mm) | Achievable Tolerance (μm) | Surface Roughness Ra (μm) |

|---|---|---|---|

| Pin gauge | Ø2–20 | ±1–2 | 0.1–0.3 |

| Locating pin | Ø5–30 | ±2–5 | 0.2–0.4 |

| Gauge block | 10–100 (length) | ±2–3 | 0.1–0.2 |

| Measuring platform | ≤300 (span) | ≤5 flatness | 0.2–0.4 |

Alumina Ceramic Parts in Precision Positioning Components

As tolerance capability becomes actionable only when translated into functional elements, precision positioning components represent the first practical interface between Alumina Ceramic Parts and real mechanical systems. Accordingly, this section examines how locating, fastening, and fixture-related ceramic parts sustain positional accuracy under repeated industrial use.

Locating Pins and Positioning Elements

In precision fixtures and automated stations, locating pins define positional repeatability more than any other single component. Consequently, even minor dimensional drift directly propagates into assembly misalignment.

Alumina Ceramic Parts used as locating pins typically operate under compressive contact stresses below 300 MPa, well within the elastic regime of dense alumina. Field data from automated welding and inspection fixtures indicate that alumina locating pins maintain positional deviation within ±1.5 μm after 50,000+ cycles, whereas hardened steel pins often exceed ±5 μm drift under similar conditions.

From an operational standpoint, fixture engineers frequently report that replacing metallic pins with alumina variants extends recalibration intervals by 2–3×, particularly in environments involving frequent washdown or thermal fluctuation.

Washers Screws and Small Assembly Elements

Although often overlooked, washers and screws play a decisive role in preserving alignment integrity. In precision assemblies, metallic fasteners introduce both magnetic interference and thermal mismatch at interfaces.

Alumina Ceramic Parts used as washers and screws provide electrical insulation and stable preload behavior. Measured compression set under sustained clamping loads remains below 0.1% after 1,000 hours at room temperature, minimizing joint relaxation.

During cleanroom assembly of sensor housings and metrology frames, engineers have observed that alumina fasteners reduce positional creep by 15–20%, especially when assemblies undergo repeated temperature cycling between 20–60 °C.

Structural Stability in Fixtures and Jigs

Beyond discrete pins and fasteners, Alumina Ceramic Parts increasingly function as structural references within fixtures and jigs. Measuring nests, alignment rails, and reference edges benefit from ceramic rigidity and environmental resistance.

Large-format alumina fixture elements demonstrate flexural deflection below 5 μm over 300 mm spans under moderate loading, outperforming aluminum alloys in comparable designs. Moreover, surface flatness remains stable despite exposure to oils, solvents, and humidity variations.

In long-term production settings, this structural stability translates into predictable fixture behavior, enabling consistent part alignment without continuous manual compensation.

Positioning Performance Characteristics of Alumina Ceramic Components

| Component Function | Typical Load Range (MPa) | Positional Drift After Cycling (μm) | Common Service Cycles |

|---|---|---|---|

| Locating pin | 100–300 | ≤1.5 | 10⁴–10⁵ |

| Washer / fastener | 50–200 | ≤2 | 10³–10⁴ |

| Fixture reference element | ≤150 | ≤5 (over 300 mm) | Continuous |

Alumina Ceramic Parts for Measurement and Calibration

As positioning accuracy stabilizes system geometry, measurement and calibration components safeguard numerical trust in inspection outcomes. Consequently, Alumina Ceramic Parts increasingly replace metallic references in gauges and calibration assemblies where repeatability, surface integrity, and environmental neutrality are essential.

Pin Gauges and Gauge Blocks

Pin gauges and gauge blocks represent the most direct measurement interface in dimensional inspection. In routine quality control, these components are inserted, removed, and cleaned repeatedly, often exceeding 20,000 handling cycles annually in high-throughput environments.

Alumina Ceramic Parts used as pin gauges maintain diameter stability within ±1 μm across extended service life, provided contact stresses remain below elastic limits. By contrast, steel gauges frequently develop localized wear tracks, especially when measuring abrasive or coated workpieces.

Calibration laboratories report that alumina gauge blocks preserve length variation within ±2 μm over multi-year intervals. As a result, recalibration frequency can be reduced by 30–40%, particularly in facilities where temperature and humidity fluctuate beyond laboratory norms.

Measuring Platforms and Reference Surfaces

Measuring platforms serve as foundational references for height measurement, flatness verification, and alignment inspection. Any distortion at this level propagates directly into measurement uncertainty.

Dense alumina platforms demonstrate flatness deviations below 5 μm over spans up to 300 mm, even after prolonged exposure to oils, coolants, and cleaning solvents. Moreover, thermal gradients of ±15 °C introduce negligible warpage compared with aluminum or cast iron alternatives.

In applied metrology workshops, inspectors often note that alumina reference surfaces maintain tactile consistency and visual clarity, thereby reducing operator-induced variability during manual measurements.

Repeatability and Traceability Considerations

Measurement repeatability depends not only on nominal geometry but also on batch consistency and traceable verification. Alumina Ceramic Parts produced for metrology applications typically exhibit batch-to-batch dimensional variation below ±1.5 μm, when controlled grinding and inspection protocols are applied.

Traceability is reinforced through dimensional inspection using coordinate measuring machines with resolution better than 0.5 μm, ensuring each production batch aligns with documented specifications. Consequently, audit compliance and internal quality reviews become more straightforward.

Quality managers frequently emphasize that such traceable consistency reduces dispute resolution time and strengthens confidence in inspection data across multi-site operations.

Measurement Stability Characteristics of Alumina Calibration Components

| Component Type | Typical Accuracy Range (μm) | Flatness or Diameter Stability (μm) | Recommended Recalibration Interval |

|---|---|---|---|

| Pin gauge | ±1 | ≤1 | 12–24 months |

| Gauge block | ±2–3 | ≤2 | 18–36 months |

| Measuring platform | ≤5 flatness | ≤5 | 24–36 months |

Comparison With Alternative Precision Materials

Although Alumina Ceramic Parts offer clear advantages in many precision contexts, material selection remains application-dependent. Therefore, this section compares alumina with commonly used precision materials to clarify where performance gains are realized and where alternative materials may remain appropriate.

Alumina Versus Tool Steel

Tool steels2 dominate precision systems due to machinability and toughness. However, under repeated contact and cleaning, steel components accumulate wear, corrosion, and magnetic effects that degrade measurement fidelity.

Empirical comparisons show that hardened tool steel pins exhibit diameter reduction of 3–8 μm after 30,000–50,000 cycles, particularly when exposed to abrasive residues. By contrast, Alumina Ceramic Parts under equivalent loading maintain dimensional variation within ±1–2 μm, provided edge geometry is properly controlled.

In daily inspection environments, quality engineers frequently note that alumina reference components eliminate magnetic attraction of fine particles, which otherwise contaminate contact surfaces and distort measurements over time.

Alumina Versus Carbide and Zirconia

Cemented carbides provide exceptional hardness but introduce cobalt binders that can corrode or magnetize under certain conditions. Zirconia ceramics offer higher fracture toughness but display greater thermal expansion and potential phase instability.

Comparative data indicate that zirconia exhibits a thermal expansion coefficient of 10–11 ×10⁻⁶ / °C, leading to dimensional variation nearly 40% higher than alumina under identical temperature shifts. Carbide, while harder, often shows micro-edge chipping during repeated insertion, increasing wear risk.

Consequently, Alumina Ceramic Parts occupy a balanced position, combining sufficient hardness with predictable thermal and structural behavior for metrology-driven applications.

Material Selection Based on Functional Priority

Selecting the optimal material depends on prioritizing functional outcomes rather than material reputation. When nonmagnetic behavior, chemical inertness, and dimensional stability dominate requirements, alumina becomes the preferred solution.

Conversely, impact-dominated applications or environments requiring extreme toughness may justify zirconia or steel alternatives. In practice, experienced engineers often deploy hybrid systems, reserving Alumina Ceramic Parts for reference and positioning roles while retaining metals for load-bearing structures.

This functional separation reduces overall system error while preserving mechanical resilience where needed.

Comparative Performance Characteristics of Precision Materials

| Material | Hardness (HV) | Thermal Expansion (×10⁻⁶ / °C) | Magnetic Behavior | Typical Dimensional Drift (μm) |

|---|---|---|---|---|

| Alumina ceramic | 1400–1800 | 7–8 | None | ≤2 |

| Tool steel | 600–800 | 11–13 | Present | 3–8 |

| Cemented carbide | 1600–2000 | 5–6 | Possible | 2–5 |

| Zirconia ceramic | 1200–1300 | 10–11 | None | 3–6 |

Design and Specification Practices for Alumina Ceramic Parts

Once material selection is resolved, precision outcomes depend heavily on how requirements are translated into drawings and specifications. Consequently, this section addresses practical design communication practices that enable Alumina Ceramic Parts to meet positioning and measurement expectations without introducing hidden failure risks.

Dimensional Drawings and Tolerance Communication

For Alumina Ceramic Parts, dimensional intent must be communicated with greater discipline than for metals. Unlike ductile materials, ceramics do not accommodate post-assembly deformation.

In practice, specifying overly tight tolerances without functional justification often increases rejection rates without improving system accuracy. Production data show that reducing diameter tolerance from ±2 μm to ±1 μm can raise scrap rates by 15–25%, while yielding negligible functional gain in many fixtures.

Experienced engineers therefore align tolerance bands with functional contact behavior, explicitly defining reference datums and avoiding stacked tolerances that amplify geometric uncertainty across assemblies.

Surface and Edge Requirements in Drawings

Surface condition frequently determines service life more than nominal size. However, drawings often under-specify edge geometry, leading to premature chipping during handling or insertion.

For Alumina Ceramic Parts used in precision systems, controlled edge radii of 0.05–0.2 mm significantly reduce edge stress concentration. Likewise, surface roughness targets between Ra 0.1–0.4 μm balance wear resistance and manufacturability.

In real workshops, assemblies redesigned with explicit edge and surface requirements have demonstrated 40–60% reductions in handling damage, particularly during repetitive gauge insertion cycles.

Batch and Quality Consistency Expectations

Precision systems rarely rely on a single component; instead, they depend on consistent behavior across batches. Consequently, drawings and purchase documents must address batch-level expectations.

Batch-to-batch dimensional variation below ±1.5 μm is achievable when inspection plans and control limits are defined upfront. Including inspection frequency, sampling size, and acceptance criteria within specifications reduces ambiguity during production.

Quality managers consistently report that explicit batch requirements shorten supplier qualification cycles and simplify root-cause analysis when deviations occur.

Specification Parameters Influencing Precision Outcomes

| Specification Element | Typical Value or Practice | Impact on Precision Performance |

|---|---|---|

| Diameter tolerance (μm) | ±1–5 | Controls repeatability |

| Surface roughness Ra (μm) | 0.1–0.4 | Influences wear and insertion |

| Edge radius (mm) | 0.05–0.2 | Reduces chipping risk |

| Batch variation limit (μm) | ≤1.5 | Ensures interchangeability |

Quality Verification and Inspection of Alumina Ceramic Parts

After specifications are defined, verification becomes the decisive step that separates theoretical precision from operational reliability. Accordingly, this section explains how Alumina Ceramic Parts are inspected, validated, and monitored to ensure dimensional trust throughout their service life in positioning and measurement systems.

Dimensional Inspection Methods

Dimensional verification of Alumina Ceramic Parts typically relies on non-contact or low-force contact techniques to avoid inducing micro-damage. Coordinate measuring machines with probing forces below 0.2 N are commonly used for diameters, lengths, and positional tolerances.

For cylindrical components such as pin gauges, roundness and straightness are assessed with resolutions reaching 0.5 μm, ensuring that form error does not exceed functional limits. In high-precision production runs, 100% inspection is often applied to critical dimensions, while secondary features follow statistically controlled sampling.

In daily quality routines, inspectors note that ceramic parts exhibit lower measurement variability than steel equivalents, primarily because surface hardness minimizes probe-induced deformation during repeated measurements.

Material and Surface Verification

Beyond geometry, surface integrity and material consistency must be verified to prevent latent failures. Surface roughness measurements using stylus or optical profilometry confirm Ra values within ±0.05 μm of specification for precision contact areas.

Material density checks, typically exceeding 3.90 g/cm³, indirectly verify low porosity levels below 0.5%, which correlate with improved mechanical reliability. Visual and microscopic inspection at magnifications of 50×–200× further identifies edge micro-chipping that may not affect dimensions but compromises durability.

In applied settings, quality teams frequently integrate surface inspection into incoming checks, recognizing that early detection of edge defects prevents progressive damage during service.

Long Term Stability Validation

Short-term compliance does not guarantee long-term performance. Therefore, stability validation protocols simulate extended use through cyclic loading, thermal exposure, or repeated cleaning.

Typical validation programs expose Alumina Ceramic Parts to 5,000–10,000 contact cycles or thermal cycles between 20–80 °C, followed by dimensional re-measurement. Acceptable drift remains below ±1 μm for critical dimensions, confirming suitability for precision roles.

Organizations that implement periodic stability audits report 30–50% reductions in unexpected recalibration events, reinforcing confidence in ceramic reference components across distributed inspection systems.

Inspection and Verification Benchmarks for Precision Alumina Components

| Verification Parameter | Typical Method | Acceptance Criterion |

|---|---|---|

| Dimensional accuracy (μm) | CMM / roundness tester | ±1–3 |

| Surface roughness Ra (μm) | Profilometry | 0.1–0.4 |

| Density (g/cm³) | Archimedes method | ≥3.90 |

| Edge integrity | Optical microscopy | No critical chipping |

| Dimensional drift after cycling (μm) | Cyclic validation | ≤1 |

Common Failure Modes in Precision Alumina Ceramic Parts

Even when specifications and inspections are correctly executed, failures may still occur if design assumptions or handling practices conflict with ceramic behavior. Therefore, this section examines typical failure modes observed in precision Alumina Ceramic Parts and explains how they emerge in real positioning and measurement environments.

Chipping and Edge Damage

Edge-related damage represents the most frequent failure mode in precision alumina components. Although alumina exhibits high hardness, its fracture behavior remains brittle when local stress concentration exceeds material limits.

In practice, uncontrolled sharp edges experience localized tensile stress during insertion or removal. Field observations show that components lacking defined edge radii can develop micro-chips within 500–2,000 cycles, even when nominal contact loads remain below 200 MPa.

Once initiated, these micro-chips propagate progressively, increasing surface roughness and altering effective dimensions. Specifying controlled edge radii of 0.05–0.2 mm has been shown to reduce chipping incidence by over 60% in repetitive positioning applications.

Tolerance Drift Misinterpretation

Another common issue arises from misattributing system drift to material instability. In many cases, the Alumina Ceramic Parts themselves remain dimensionally stable, while surrounding components introduce apparent error.

Thermal expansion mismatch between ceramic reference elements and metallic fixtures can generate relative displacement exceeding 5 μm over 300 mm spans when temperature fluctuates by 15 °C. Consequently, operators may incorrectly conclude that ceramic parts have changed size.

Experienced engineers mitigate this risk by isolating ceramic references from metal-induced constraints or by compensating fixture designs to accommodate differential expansion.

Assembly Induced Stress Failures

Assembly practices designed for metals often translate poorly to ceramics. Excessive interference fits, point loading from fasteners, or uneven clamping introduce tensile stresses that exceed alumina’s fracture tolerance.

Case reviews from automated inspection lines indicate that ceramic locating pins subjected to interference beyond 0.01–0.02 mm experience failure rates up to 20% during initial installation. By contrast, slip-fit designs with controlled preload exhibit negligible failure.

Design teams that revise assembly protocols specifically for Alumina Ceramic Parts consistently report failure reductions exceeding 70%, underscoring the importance of ceramic-specific integration strategies.

Typical Failure Characteristics and Preventive Measures

| Failure Mode | Trigger Condition | Observed Impact | Preventive Measure |

|---|---|---|---|

| Edge chipping | Sharp edges, repetitive contact | Surface degradation, drift | Controlled edge radii |

| Apparent tolerance drift | Thermal mismatch | Misalignment | Expansion-aware fixture design |

| Assembly fracture | Excessive interference | Sudden failure | Slip-fit and preload control |

Customization Pathways for Precision Alumina Ceramic Parts

Once failure risks are understood, customization becomes the decisive lever for aligning Alumina Ceramic Parts with real positioning and measurement requirements. Consequently, this section outlines how drawing-driven customization, controlled prototyping, and production scaling convert abstract specifications into reliable precision components.

From Drawing Review to Prototyping

Customization typically begins with a detailed drawing review that evaluates dimensional intent, functional datums, and contact mechanics. In practice, engineering teams often refine drawings to replace overly tight tolerances with functionally justified limits, reducing manufacturability risk.

During prototyping, small batches of 5–20 pieces are produced to validate geometry, surface integrity, and handling behavior. Dimensional feedback from these trials frequently leads to tolerance band adjustments of ±0.5–1 μm, improving both yield and functional stability.

From an operational perspective, engineers report that early prototype validation shortens subsequent qualification cycles by 30–40%, particularly in metrology-intensive applications where repeatability is critical.

Small Batch Versus Series Production

Precision Alumina Ceramic Parts rarely move directly from prototype to mass production. Instead, they progress through staged scaling that verifies batch consistency before volume increases.

In small-batch production runs of 50–200 pieces, statistical process control reveals whether dimensional variation remains within ±1.5 μm across parts. Only after this stability is confirmed do series runs of 500–1,000 pieces commence.

Organizations that adopt phased scaling consistently experience lower scrap rates by 20–25% compared with direct volume ramp-up, ensuring that precision expectations are preserved as quantities increase.

Lead Time and Cost Structure Drivers

Lead time for customized Alumina Ceramic Parts depends primarily on geometry complexity, tolerance severity, and inspection scope. Simple cylindrical components with moderate tolerances often complete within 4–6 weeks, while multi-feature precision parts may require 8–10 weeks.

Cost structure is similarly driven by finishing intensity and inspection density rather than raw material volume. For example, doubling inspection points can increase total processing time by 15–20%, while providing greater confidence in batch conformity.

Experienced procurement teams therefore balance inspection rigor with functional necessity, achieving predictable delivery without unnecessary overhead.

Customization Stages and Their Impact on Precision Outcomes

| Customization Stage | Typical Quantity | Key Validation Focus | Impact on Final Performance |

|---|---|---|---|

| Drawing review | N/A | Functional tolerance alignment | Prevents over-specification |

| Prototype run | 5–20 | Geometry and handling | Early risk reduction |

| Pilot batch | 50–200 | Batch consistency | Process stabilization |

| Series production | 500–1,000 | Repeatability | Long-term reliability |

Integrating Alumina Ceramic Parts Into Precision Systems

After customization is finalized, system-level integration determines whether theoretical accuracy translates into sustained operational performance. Therefore, this section examines how Alumina Ceramic Parts interact with surrounding structures, maintenance routines, and lifecycle planning in precision positioning and measurement systems.

Interface With Metal and Composite Structures

In most precision assemblies, Alumina Ceramic Parts interface directly with metallic or composite components. Consequently, differential thermal expansion becomes a primary design consideration.

For example, steel fixtures expand at approximately 11–13 ×10⁻⁶ / °C, while alumina expands at 7–8 ×10⁻⁶ / °C. Over a 300 mm interface length, a 15 °C temperature change can generate relative displacement exceeding 15 μm if unconstrained. To mitigate this effect, experienced designers employ compliant mounting features or floating interfaces that decouple ceramic references from metal expansion.

In practice, systems using expansion-aware interfaces demonstrate 40–60% lower positional drift compared with rigidly constrained designs, particularly in environments with fluctuating ambient temperatures.

Maintenance and Replacement Planning

Unlike metals, Alumina Ceramic Parts do not exhibit gradual plastic wear that signals end-of-life. Instead, they maintain dimensional stability until localized damage occurs. Therefore, maintenance planning must focus on inspection rather than predictive wear estimation.

Routine visual inspection intervals of 3–6 months are commonly adopted for critical ceramic references, supplemented by dimensional verification annually. Components that remain free of edge damage typically retain full functionality beyond 5–7 years of service.

Maintenance engineers often note that ceramic-based systems shift effort from frequent recalibration to periodic verification, simplifying maintenance schedules while preserving measurement confidence.

Lifecycle Management in Precision Applications

Lifecycle management extends beyond individual components to system-wide behavior. When Alumina Ceramic Parts serve as primary references, their long-term stability anchors overall system accuracy.

Field data from multi-station inspection lines indicate that systems anchored by ceramic reference elements experience 30–45% fewer corrective interventions over five-year periods compared with metal-referenced systems. Moreover, standardized replacement of ceramic parts minimizes variability during component swaps.

By aligning integration strategy with ceramic behavior, precision systems achieve predictable performance across extended operational lifespans.

Integration Considerations Affecting Long-Term Precision

| Integration Aspect | Typical Practice | Influence on System Accuracy |

|---|---|---|

| Thermal interface design | Floating or compliant mounts | Reduces drift |

| Inspection interval (months) | 3–6 | Early damage detection |

| Dimensional verification cycle | Annual | Maintains traceability |

| Reference replacement strategy | Standardized components | Preserves repeatability |

ADCERAX Custom Alumina Ceramic Parts for Precision Engineering

As precision systems evolve from concept to sustained operation, material capability alone is insufficient without structured engineering support. Therefore, this section explains how ADCERAX aligns Alumina Ceramic Parts with real positioning, measurement, and assembly requirements through disciplined customization and integrated service workflows.

ADCERAX approaches Alumina Ceramic Parts not as catalog items, but as application-specific precision elements. Accordingly, every project begins with an engineering-level evaluation of drawings, functional tolerances, contact conditions, and environmental exposure, ensuring ceramic behavior is fully aligned with system intent rather than generic material assumptions.

Engineering Review and Application-Oriented Customization

Customization at ADCERAX starts with a structured drawing review focused on functional datums, tolerance justification, and edge integrity. In many precision projects, initial drawings specify tolerances tighter than required, increasing cost and risk without improving accuracy.

Through iterative engineering feedback, ADCERAX frequently optimizes tolerance bands by 0.5–2 μm while preserving functional repeatability. Field collaboration with precision fixture designers has shown that such optimization can improve first-pass yield by 20–30%, particularly for locating pins, pin gauges, and measuring references.

Moreover, application-specific features such as controlled chamfers, stress-relief transitions, and surface finish zoning are incorporated early, preventing downstream failure modes commonly observed in ceramic components treated as metal equivalents.

Integrated Manufacturing and Verification Workflow

ADCERAX integrates forming, sintering, precision machining, and inspection within a unified process window tailored to Alumina Ceramic Parts used in metrology contexts. Dense alumina bodies with relative density exceeding 99.5% are standard for precision components, ensuring low porosity and stable surface response.

Dimensional verification is performed using calibrated CMM systems with measurement resolution down to 0.5 μm, allowing batch-level consistency to remain within ±1.5 μm for critical features. For small-batch or pilot runs, 100% inspection is applied to primary dimensions, transitioning to statistically controlled sampling as process stability is confirmed.

This integrated workflow enables ADCERAX to support both small-lot customization (10–50 pieces) and stable series production (500+ pieces) without sacrificing dimensional fidelity.

One-Stop Service Supporting Precision Systems

Beyond component delivery, ADCERAX provides a one-stop service model addressing the full lifecycle of Alumina Ceramic Parts in precision systems. Engineering consultation, prototyping, process optimization, quality documentation, and logistics coordination are managed as a coherent sequence rather than isolated steps.

Customers in precision machinery and automation sectors frequently emphasize that this continuity reduces communication gaps and shortens overall project timelines by 25–35%. Furthermore, standardized packaging and handling protocols minimize transport-induced damage, preserving surface integrity upon arrival.

By combining ceramic engineering expertise with responsive manufacturing and verification capabilities, ADCERAX positions itself as a long-term partner for precision positioning and measurement applications rather than a transactional supplier.

ADCERAX Capabilities Supporting Precision Alumina Applications

| Capability Area | Typical Specification | Benefit to Precision Systems |

|---|---|---|

| Alumina purity (%) | ≥99.7 | Stable microstructure |

| Dimensional control (μm) | ±1–5 | Repeatable positioning |

| Density (%) | ≥99.5 | Low porosity, high integrity |

| Inspection resolution (μm) | 0.5 | Reliable verification |

| Custom batch size | 10–1000 | Flexible scaling |

Practical Selection Summary for Precision Applications

Before finalizing component selection, engineers must consolidate material behavior, tolerance capability, and system integration into a practical decision framework. Accordingly, this section summarizes how Alumina Ceramic Parts should be evaluated and selected for precision positioning, measurement, and assembly use without overcomplicating procurement or design workflows.

Material suitability should be confirmed first, ensuring alumina’s nonmagnetic behavior, chemical inertness, and low thermal expansion align with system sensitivities. In precision contexts, these properties often outweigh marginal differences in toughness or machinability.

Dimensional and surface requirements must then be matched to functional needs rather than theoretical limits. Over-specification commonly increases risk and cost, whereas function-driven tolerances preserve accuracy with higher manufacturing robustness. Finally, integration and maintenance planning should be addressed early, recognizing that ceramic reference components stabilize systems best when decoupled from thermally active structures and inspected periodically.

Taken together, these considerations allow Alumina Ceramic Parts to deliver predictable accuracy across long service intervals while minimizing recalibration and unplanned intervention.

Conclusion

Alumina Ceramic Parts provide a stable foundation for precision positioning and measurement by combining dimensional consistency, environmental resistance, and predictable long-term behavior where metallic components gradually introduce error.

For precision positioning, measurement, or assembly challenges requiring stable alumina solutions, ADCERAX supports drawing-based customization and application-specific engineering consultation.

FAQ

What tolerance range is realistic for Alumina Ceramic Parts in precision applications?

In most positioning and measurement roles, tolerances between ±1–5 μm are realistic and sustainable, provided geometry, surface finish, and inspection scope are properly aligned with functional requirements.

How often should Alumina Ceramic Parts be recalibrated or verified?

Verification intervals typically range from 12 to 36 months, depending on usage intensity and environmental exposure. Visual inspection every 3–6 months helps detect early edge damage.

Can Alumina Ceramic Parts replace metal components directly?

Not always. Alumina Ceramic Parts perform best as reference, positioning, and insulating elements. Load-bearing or impact-dominated roles may still require metals or hybrid designs.

Are custom Alumina Ceramic Parts feasible in small quantities?

Yes. Functional prototypes and pilot batches of 10–50 pieces are commonly produced to validate geometry and integration before scaling to series production.

References: