Alumina Boat for High-Temperature Processing and Laboratory Calcination

ADCERAX is a China alumina crucible boat manufacturer and wholesaler with more than twenty years of experience. We produce Al₂O₃ combustion boats, rectangular alumina ceramic boats, deep alumina crucible boats, and customized alumina boats specifically engineered for calcination, powder heating, debinding and other high-temperature industrial applications. With consistent material purity, reliable dimensional control, flexible small-batch production and stable delivery, ADCERAX supports battery materials, catalysts, powder metallurgy, research laboratories and a wide range of thermal processing workflows.

🤝 Send us your dimensions or furnace envelope, and we will tailor a custom alumina boat that fits your process from day one.

1730°C

Max Operating Temp(99.7% Purity)

Stable for Calcination, Powder Heating & Debinding

Dimensional Stability for Consistent Furnace Loading | Low Warpage for Long, Repeated Thermal Cycles

Factory Direct Supply & Fast Global Delivery

What is Alumina Boat?

An alumina boat is a shallow, open ceramic vessel made from high-purity Al₂O₃ and used to hold powders, granules or small parts during high-temperature processes such as calcination, powder heating, debinding, combustion analysis and thermal treatment. Its rectangular or deep-crucible geometry allows stable loading inside tube furnaces, box furnaces and continuous kilns.

Alumina Boat Crucible Properties & Benefits

Alumina crucible boats maintain structural stability at elevated temperatures, offering low thermal expansion, high mechanical strength, and excellent resistance to chemical attack. Their dense, inert ceramic body minimizes warpage during repeated heating cycles, ensuring consistent dimensional accuracy and clean contact surfaces needed for controlled thermal behavior.

Alumina Boat Technical Data

| Property | Typical Value | Notes for Users |

|---|---|---|

| Purity Options (Al₂O₃) | 95% / 99% / 99.7% | Most alumian boats for sintering use 99%–99.7% |

| Max Operating Temperature | 1450°C (95%) / 1680°C (99%) / 1730°C (99.7%) | Based on continuous use |

| Flatness / Warpage Control | ≤0.3–0.5% over length | Critical for multi-layer loading |

| Dimensional Tolerance | ±0.1–0.2 mm | Depends on size & machining |

| Density | 3.75–3.93 g/cm³ | Higher purity → higher density |

| Load Capacity | Light-to-medium load (process dependent) | Engineering validation recommended |

| Thermal Shock Behavior | Good with controlled heating/cooling | Avoid rapid quenching |

| Atmosphere Compatibility | Air / inert / vacuum | Not recommended for strong reducing atmospheres |

| Cycle Life | 50–300+ cycles | Depends on load, furnace, and temperature profile |

- This chart displays the typical properties of the alumina crucible boat used in our standard products. Please note: Customized parts may have adjusted characteristics depending on production methods, with specific parameters determined by the stabilizer type and formula chosen for your application.

Advantages of Alumina (Al2O3) Boat

Alumina boat crucible maintain structural integrity at elevated temperatures, offering reliable performance during continuous heating, calcination and repeated thermal cycling without deformation.

The dense Al₂O₃ ceramic body resists corrosion and chemical interaction in oxidizing, inert and controlled atmospheres, keeping surfaces clean and preventing contamination of sensitive powders.

With low thermal expansion and strong mechanical strength, alumina boats remain dimensionally stable across multiple furnace cycles, ensuring consistent loading and uniform heat distribution.

Uniform wall thickness, smooth surfaces and reinforced profiles support predictable handling and reduce the chance of cracking, extending service life in demanding high-temperature workflows.

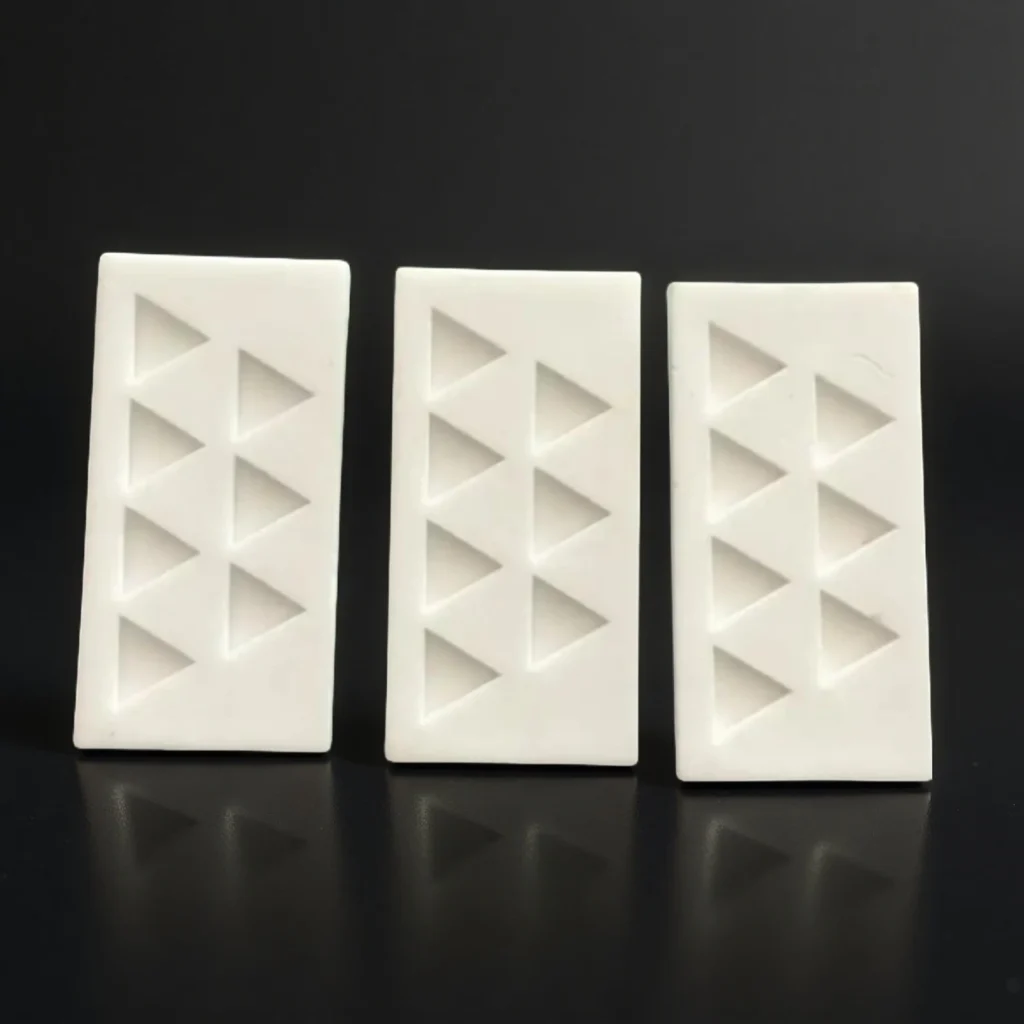

China Alumina Ceramic Boat Types

ADCERAX supplies high-quality alumina boats in multiple forms, including rectangular combustion boats, round boats, deep-profile boats, ash boats, and hole-type boats designed for different furnace loading patterns and thermal workflows. Standard dimensions are available, and custom configurations can be produced according to drawings or process requirements.

Alumina combustion boats with a front or end hole support combustion analysis, ash testing and oxidation tasks that need directed airflow through the sample bed. The hole improves gas flow control and helps maintain stable reactions in laboratory and industrial combustion furnaces.

- Promotes stronger airflow penetration through powders or pellets

- Supports faster oxidation and more stable combustion reactions

- Hole position customizable for different furnace orientations

Alumina ceramic ash boats are used for ash determination, residue analysis and loss-on-ignition testing where powders or compacted samples need a stable, enclosed container. Their structured interior helps maintain uniform heating while reducing disturbance from furnace airflow.

- Enclosed chamber reduces sample disturbance during ignition

- Reinforced structure supports stacking in multi-layer firing

- Customizable vents and internal ash-test patterns

Alumina ceramic boat customized support sintering, calcination and powder heating where materials need a long, stable loading bed. Their extended shape helps maintain uniform exposure inside tube furnaces, box furnaces and laboratory heating setups.

- Designed for long-part or row-style loading

- Enhances directional heat flow along the length

- Reinforced sidewalls increase rigidity and batch capacity

Alumina combustion boats support combustion analysis, ash testing and oxidation work where powders or small samples require controlled airflow. Their long, shallow shape enables fast heating and stable gas contact in laboratory and industrial combustion furnaces.

- Promotes fast oxidation with a long, shallow powder bed

- Enhances airflow contact for stable combustion behavior

- Minimizes thermal stress with smooth transitions and rounded ends

💡Need High-Performance Alumina Boats for Precision Thermal Processing?

Engineered alumina boats for combustion analysis, calcination, oxidation testing, ash determination, and controlled powder heating. Options include rectangular, round, deep-profile, and hole-type boats optimized for uniform heat flow, clean sample contact, and stable furnace cycling. ☝️Send your drawings or process requirements—get engineering support and a firm lead time within 24 hours.

Where Alumina Boats Are Used?

Alumina boats are used in powder calcination, debinding, combustion analysis, ash testing, sintering support, catalyst preparation, battery-material processing, and high-temperature handling of metals, ceramics, and laboratory samples.

Battery Materials & Catalysts Processing

🧩 Key Advantages:

- Ensures <±0.25 mm dimensional consistency to prevent powder spillage during long furnace runs.

- Supports uniform fill depth for NCM/LFP powders, enabling stable calcination at 650–850°C with consistent oxygen exposure.

- Withstands 300–600 cycles/year of production calcination without warpage, reducing batch rejects in cathode material lines.

🔹Problem Solved:

A Korean cathode material plant reported uneven precursor activation caused by warped low-grade trays, resulting in 3–4% variation in final BET surface area. After switching to ADCERAX alumina boats with controlled wall straightness (<0.3 mm deviation), batch uniformity improved and the line avoided ~1.2 tons/month of off-spec powder. The customer also reduced furnace downtime by 18% due to fewer loading defects.

Powder Metallurgy & Advanced Ceramics

🧩 Key Advantages:

- Supports green compacts during slow debinding (0.5–2°C/min).

- Prevents binder-residue staining on metal or ceramic parts.

- Allows multi-layer stacking with consistent alignment in pusher furnaces.

🔹Problem Solved:

- A European PM parts manufacturer had cracking defects during debinding due to inconsistent bottom flatness in older saggers. Using ADCERAX alumina boats with bottom deviation controlled below 0.4 mm, crack rate dropped from 9% to 2%, stabilizing throughput for a 1.6-million-pcs/year production line.

Laboratory & Analytical Testing

🧩 Key Advantages:

- Ensures consistent sample-bed depth (±0.2 mm) for stable LOI results.

- Reduces sample disturbance in airflow-controlled combustion tests.

- Fits common small-sample holders and autosampler systems.

🔹Problem Solved:

- A materials analysis lab faced inconsistent LOI results (variation ±0.6%) due to tray deformation after repeated 900°C runs. After adopting ADCERAX alumina boats with reinforced long-side profiles, variation tightened to ±0.15%, allowing the lab to meet accreditation requirements and reduce retesting time by ~30 hours/month.

Thermal Processing of Special Alloys & Precious Metals

🧩 Key Advantages:

- Prevents cross-contamination during Au/Pt/Ir alloy heating.

- Supports directional heat-flow loading for small ingots or beads.

- Avoids unwanted reactions in mildly reducing alloy atmospheres.

🔹Problem Solved:

A North American precious-metal recycler experienced 5–7% purity deviation during Pt-group metal refining due to contamination from metal carriers. Switching to ADCERAX alumina boats eliminated cross-material pickup, stabilizing purity at >99.95% and enabling a $42,000/month increase in recovered metal value.

Customized Alumina Ceramic Boat wholesaler

We specialize in high quality alumina ceramic boat customized solutions based on customer drawings, samples, or furnace-specific loading requirements. Tailored dimensions, wall thickness, corner geometry, slot structures, and bottom profiles can be produced to match different furnace envelopes and batch layouts. Custom alumina boats typically require 3–9 weeks depending on design complexity and machining needs.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

ADCERAX – Professional Alumina Ceramic Boat factory

ADCERAX is a China alumina crucible boat wholesaler and manufacturer, providing both custom and mass-production solutions for combustion analysis, calcination, ash testing, powder heating, and other high-temperature workflows. With in-house forming, sintering, machining, and inspection capabilities, we ensure consistent purity, dimensional accuracy, and reliable performance for laboratories, industrial furnace operators, and OEM engineering clients worldwide.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

ADCERAX integrates alumina ceramic forming, high-temperature sintering, precision machining, and quality inspection into a unified production workflow. We provide custom alumina boat designs, non-standard geometries, special wall profiles, slot structures, bottom shapes, and reinforced configurations — from prototype sampling to large-batch production.

-

Precision Forming & Dimensional Accuracy:

Each alumina boat is manufactured using controlled forming and CNC machining to ensure accurate length, width, depth, wall thickness and corner geometry. Tight tolerances and smooth internal surfaces support consistent loading behavior, stable heat distribution, and reliable performance across high-temperature furnace cycles. -

Batch Consistency & Quality Control:

Every batch is inspected for purity, density, sintering stability, deformation resistance, and dimensional repeatability. Strict control of grain size, shrinkage behavior, and furnace atmosphere compatibility ensures low warpage, predictable thermal performance, and stable results for calcination, combustion analysis, ash testing, and powder heating. -

Customization & Engineering Support:

We provide drawing-based customization for high quality alumina ceramic boat customized projects, including variable wall height, bottom structures, slot/vent geometry, end-hole configurations, and reinforced long-side designs for multi-layer loading. Engineering support is available to match furnace envelopes, airflow requirements, heating profiles, and sample-handling needs in demanding laboratory and industrial workflows.

ADCERAX specializes in producing alumina ceramic boat crucibles through controlled forming, high-temperature sintering, precision machining, and strict quality inspection. Our alumina boats deliver stable performance under high-temperature and corrosive furnace conditions, ensuring consistent dimensions, low warpage, clean inert surfaces, and reliable behavior during calcination, ash testing, combustion analysis, and other thermal workflows. These strengths make our boats suitable for laboratories, industrial furnace operators, and OEM engineering environments that require stable ceramic carriers.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Capability Item | Typical Value / Description | ||

| Material Grades | High-purity Al₂O₃ (96–99.7%) with controlled grain size and stable performance up to 1730°C for calcination, combustion, and ash-testing workflows. | ||

| Precision Machining | CNC trimming and finishing with ±0.1–0.2 mm tolerances. Smooth interiors support uniform heating and low contamination. | ||

| Forming & Shaping | Dry pressing, isostatic pressing, casting, and machining for custom shapes: rectangular, round, deep-profile, hole-type, and reinforced designs. | ||

| Flatness & Dimensional Control | Controlled sintering minimizes warpage and ensures consistent density and repeatable dimensions across batches. | ||

| Inspection & Quality Control | 100% inspection for warpage, cracks, density uniformity, and bottom/wall accuracy; optional thermal-cycle and chemical-inertness testing. | ||

FAQ

The safe alumina boat temperature for continuous operation is typically 1500–1700°C, depending on purity and furnace atmosphere. Users should keep their process at least 50–100°C below the rated limit to maintain strength and service life.

ADCERAX supplies extended shapes such as long alumina combustion boat and dedicated alumina furnace boats for tube and box furnaces. For non-standard dimensions, the team can create an alumina ceramic boat customized to the internal space and loading pattern.

Yes. Alumina evaporation boats are available for metal salts and specialty coatings. When used as an alumina evaporator boat, they can handle many evaporation and small-melt tasks. For gold refining or jewellery R&D, an alumina evaporator boat for gold offers a clean environment with stable ceramic support.

Where charge volume is high, ADCERAX designs alumina crucible boat deep containers. For applications that require more atmosphere control, we provides versions of air tight alumina boats with precision-fitted lids.

To estimate alumina boat price, customers typically provide overall dimensions, wall thickness, operating temperature, atmosphere, annual usage and whether the design is standard or custom. ADCERAX then proposes options with different volume and cost levels, making it easier to select alumina boats for sale that match both process and budget.

Higher-purity grades (96%–99.7%) show better corrosion resistance, lower creep, and more stable dimensions during thermal cycling. 96% alumina is suitable for general heating, while 99.7% alumina is preferred for battery materials, catalysts, and analytical workflows requiring minimal contamination.

Rectangular boats: best for powder calcination, batch preheating, long-part loading.

Round/oval boats: improved radial heat flow; ideal for uniform heating of pellets or tablets.

Combustion boats: shallow, elongated profiles for ash testing, combustion analysis, and airflow-dependent reactions.

Yes. Dimensions, wall thickness, lips, slots, grooves, multi-cavity layouts, vent patterns, and bottom profiles can be tailored to match pusher furnaces, tube furnaces, box furnaces, and multi-layer firing systems. This is essential for consistent loading and efficient heat distribution.

Alumina vs. Quartz Boat: alumina withstands higher temperature, resists alkali/acid corrosion, and avoids devitrification.

Alumina vs. Zirconia Boat: zirconia tolerates higher shock and mechanical load but costs more; alumina offers better cost-to-performance for most workflows.

Choice depends on thermal shock severity, chemical environment, and budget.

You can source reliable supply from ADCERAX, a China-based alumina crucible boat wholesaler offering factory-direct sales, standard sizes in stock, and custom Al₂O₃ boats for industrial and laboratory furnace workflows. ADCERAX provides stable quality, engineering support, and fast global delivery for both small-batch and bulk orders.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

info@adcerax.com

Telephone: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours