Precision & Custom Alumina Rods for Industrial and Laboratory Applications

ADCERAX is a trusted alumina rods manufacturer and supplier, offering ≥96% purity alumina oxide rods. Our precision ceramic rods are ideal for high-temperature, insulating, and chemically resistant applications across industrial and laboratory environments.

We provide both standard alumina rods for sale and custom-machined alumina ceramic rods tailored to your specifications. Whether you’re buying square ceramic rods, alumina ceramic solid rods or threaded alumina rods, we ensure consistent quality, fast lead times, and competitive factory-direct pricing.

Looking for a reliable alumina ceramic rod factory or need wholesale alumina rods for your next project? Contact ADCERAX today for a fast quote and global delivery.

1700°C

Max Operating Temp

What is an alumina rod?

Alumina rods, often referred to as alumina ceramic rods or Al₂O₃ ceramic components, are advanced materials celebrated for their exceptional physical and chemical properties. Primarily composed of aluminum oxide, these ceramic solutions are indispensable in environments where conventional materials fall short, delivering superior performance and extended longevity.

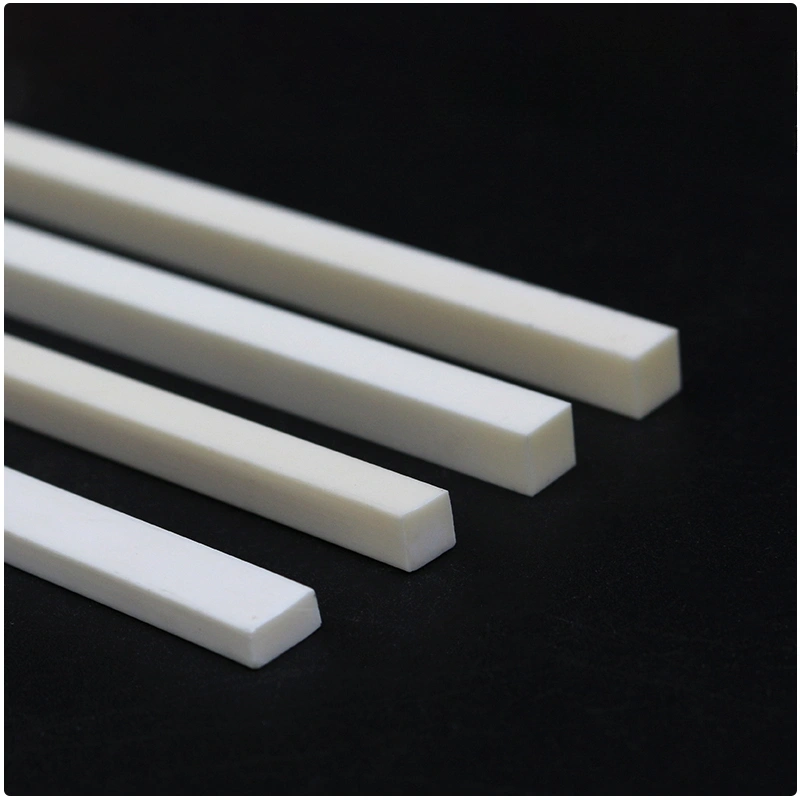

Alumina Ceramic Rod Sizes & Stock

ADCERAX supplies China alumina ceramic bar with standard sizes Dia: 0.5–50mm and Length: 10–2500mm, all available in stock. Customized Al2O3 rods Dia: 50-220mm, L: 10-3000mm.

| Standard size & Stock | |||

|---|---|---|---|

| Diameter | Length | Tolerance | Availability |

| 0.5mm-2.9mm | 10-2500mm | ±0.1mm-03.mm | In Stock |

| 3mm-6mm | 10-2500mm | ±0.1mm-0.5mm | In Stock |

| 6.1-50mm | 10-2500mm | ±0.5mm-5mm | In Stock |

| 50mm-220mm | 10-3500mm | ±0.5mm-5mm | Customized |

Custom Capabilities: Special shapes, dimensions and lengths up to 3500mm available

| Available Purity Grades | ||

|---|---|---|

| 96% Alumina (Al₂O₃) | Cost-effective option for general high-temperature and wear applications | Standard Grade |

| 99% Alumina (Al₂O₃) | Enhanced mechanical strength and thermal properties for demanding environments.Balanced performance and price | General Grade |

| 99.7%-99.8% Alumina (Al₂O₃) | Highest temperature resistance (1730°C), superior electrical insulation, excellent chemical inertness.Ideal for vacuum, semiconductor, and high-temp use | High Purity |

Benefits & Properties of Alumina Rod

🔥Exceptional High-Temperature Resistance

Withstand continuous operating temperatures up to 1730°C for 99.7% purity grade

🛡️Superior Hardness & Wear Resistance

Excellent resistance to abrasion and wear, extending component lifespan

⚡Excellent Electrical Insulation

Superb electrical insulator with high dielectric strength

🧪High Chemical Inertness

Remarkable resistance to chemical attack from acids and alkalis

| Property | 96% Al₂O₃ | 99% Al₂O₃ | 99.7% Al₂O₃ |

|---|---|---|---|

| Density (g/cm³) | 3.65–3.8 | 3.8–3.9 | ≥3.93 |

| Flexural Strength (MPa) | 260 | 300 | 330 |

| Hardness (Mohs) | 8.8 | 9 | 9.1 |

| Thermal Conductivity (W/m·K) | 22 | 24 | 29 |

| Max Operating Temp (°C) | 1600 | 1680 | 1730 |

| Volume Resistivity (Ω·cm) | 10¹³–10¹⁵ | 10¹⁴–10¹⁵ | >10¹⁵ |

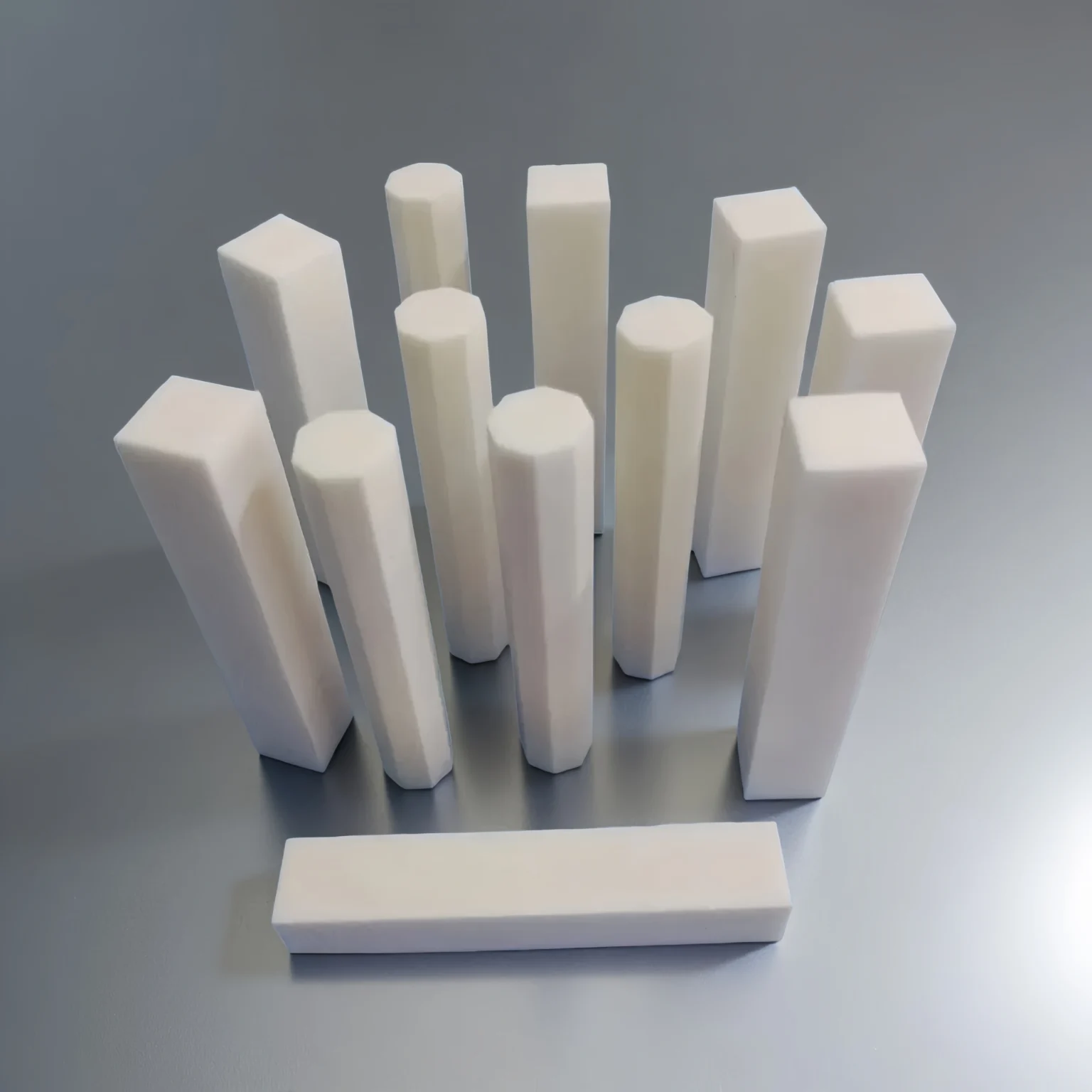

Alumina Ceramic Rods Types

Alumina rods can be produced in various shapes, including solid rods, square rods, threaded rods, and custom-machined geometries.

Alumina Ceramic Square Rods

Square alumina rods for high-temperature structural support or precision-guided insulation components.

Cylinder Alumina Ceramic Rod

High-density alumina solid rods for electrical insulation or wear-resistant mechanical parts

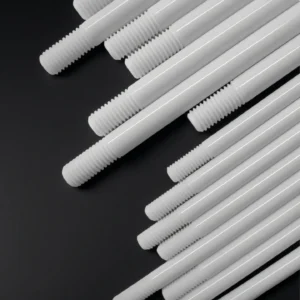

Alumina Threaded Rod

Threaded alumina rod for high-temperature fastening, electrical insulation, or chemically resistant assemblies.

Porous Alumina Rod

Porous alumina ceramic rod for gas diffusion, filtration systems, or thermal insulation in controlled environments.

Looking for a reliable alumina rod factory?

We deliver high-quality Al₂O₃ rods with precision machining, fast lead times, and full OEM customization—trusted by industry leaders worldwide.

Alumina Rod Uses

Our alumina ceramic bar solutions are integral to the performance of critical systems in a wide array of B2B sectors. We provide tailored products that address specific challenges and pain points for our industrial clients, ensuring optimal system performance and reliability.

🔥Al2O3 Ceramic Rods in High-temperature Industrial

In high-temperature environments such as electric kilns, sintering furnaces, and heat treatment systems, alumina ceramic rods serve as structural supports and insulation components. Unlike metal rods, which may deform or oxidize at high temperatures, alumina kiln rods maintain their shape and strength even above 1600°C.

Alumina Rods in Electrical and Electronic

Alumina Rods in Electrical and Electronic

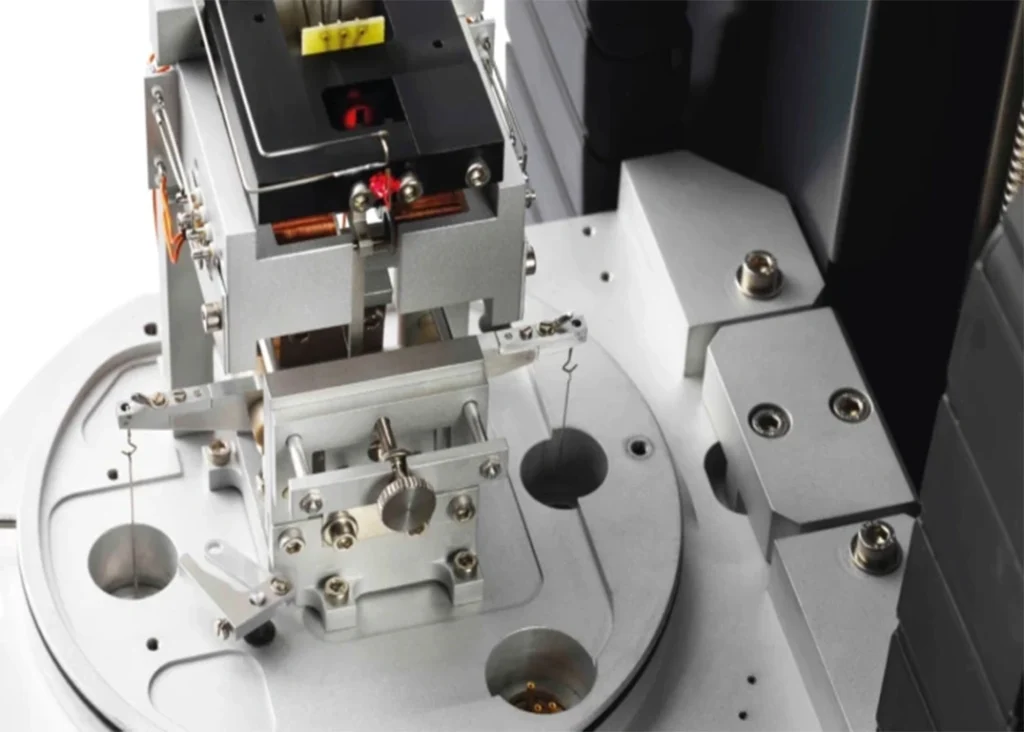

Aalumina ceramic insulator rod are used to isolate high-voltage components and prevent arcing or short circuits. These rods are commonly found in power distribution units, plasma systems, and high-voltage relays.

Alumina Ceramic Rods in Chemical Flow Systems

Alumina Ceramic Rods in Chemical Flow Systems

In chemical processing plants, alumina oxide rods are used in acidic or alkaline flow systems where corrosion resistance is critical. These chemical-resistant ceramic rods are installed in pumps, reactors, and filtration units to extend service life and reduce maintenance.

🔬 Alumina Ceramic Bar in Laboratory Equipment

In research and testing environments, alumina rods are used as structural components in analytical instruments, sample holders, and high-temperature test rigs. Their dimensional stability and purity make them ideal for repeated heating and cooling cycles without contamination.

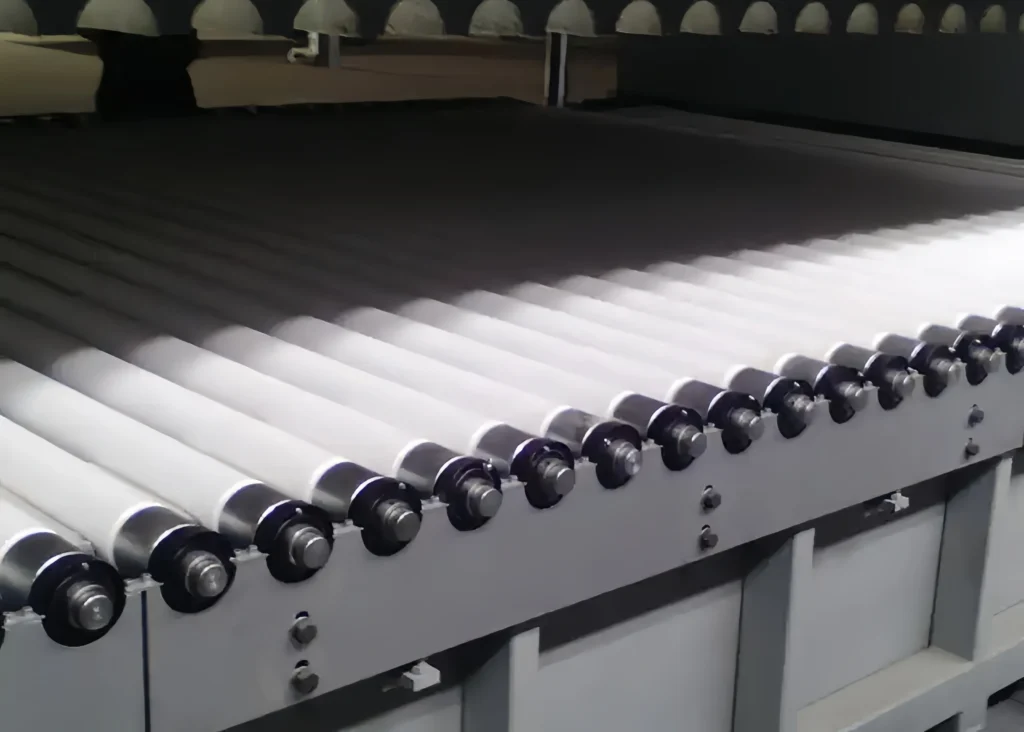

🧱 Alumina Rods in Technical Ceramic Industry

In the technical ceramics industry, square alumina rods are used as kiln spacers and support beams in roller kilns and tile firing systems. These rods can bear heavy loads at high temperatures without reacting with the ceramic products being fired.

Customized Alumina Rod Supplier

We specialize in custom alumina oxide rods with special sizes, tight tolerances, and complex features. OEM and small-batch support available.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Why Choose ADCERAX as Your Alumina Rods Wholesaler?

As a dedicated manufacturer of alumina rods and a comprehensive supplier of alumina ceramic rod products, ADCERAX is committed to delivering superior value and reliability. Our competitive advantages are designed to address your critical needs and ensure a seamless procurement experience, making us your preferred partner for industrial ceramic rod solutions.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

Alumina Rods Factory-ADCERAX

ADCERAX is a professional China alumina rods manufacturer that offers high-performance components with tight tolerances (±0.001mm) and custom geometries. Using advanced forming methods and CNC machining, we deliver precision-engineered solutions for electronics, chemical, and high-temperature applications.

- 99.7% high-purity alumina for stable performance

- Custom parts based on your drawings or samples

- Fast prototyping (7–15 days) & flexible MOQ

- ISO-compliant quality control & inspection reports

- Direct engineering support from design to delivery

This table highlights our core technical strengths, including material options, tight tolerances, and advanced manufacturing methods. We offer tailored solutions to meet diverse industrial requirements.

✅ Machinable alumina rod options available upon request.

✅ High precision cutting alumina rods supported for ±0.001mm tolerance.

| Technical Capabilities Overview | |

|---|---|

| Material Grades | 96%, 99%, 99.5%, 99.7% Al₂O₃ – high purity for demanding applications |

| Tolerances | Up to ±0.001mm – suitable for precision assemblies |

| Forming Methods | Dry pressing, isostatic pressing, extrusion, casting, injection molding |

| Processing | CNC machining, fine grinding, polishing |

| Surface Finish | Polished / Unglazed / Glazed |

| Customization | Drawings, CAD files, or samples accepted for custom parts |

Alumina Ceramic Rod Quality & Certifications

FAQ

Yes. We have alumina ceramic rods for sale in standard sizes that are in stock , available for immediate shipment. We also support bulk orders and custom production for OEM clients.

The alumina rods price depends on:

- Material purity (96%, 99%, 99.7%)

- Dimensions and tolerances

- Quantity (bulk pricing available)

- Customization complexity

We offer competitive factory prices and wholesale discounts for repeat orders.

The production of alumina rods—also known as alumina ceramic rods or Al₂O₃ rods—involves a series of carefully controlled steps to ensure high purity, strength, and dimensional accuracy. Here's a simplified overview of the process:

1. Powder Preparation

The process begins with high purity alumina powder (typically ≥96% Al₂O₃). This powder is mixed with binders, plasticizers, and other additives to create a uniform slurry or granulated feedstock. This step is critical to ensure the final alumina ceramic rod has consistent density and performance.

2. Forming the Rod Shape

The prepared material is shaped into rods using forming techniques such as:

- Extrusion – ideal for long, uniform solid alumina rods

- Isostatic pressing – used for high-density, precision parts

- Injection molding – suitable for complex or small-diameter rods

This stage produces the “green body,” a soft but shaped version of the rod.

3. Sintering

The green rods are then placed in a high-temperature furnace and sintered at temperatures above 1600°C. During sintering, the ceramic particles fuse together, eliminating porosity and forming a dense, hard structure. This step gives the alumina ceramic rod its final mechanical strength, thermal resistance, and insulating properties.

4. Precision Finishing

After sintering, the rods are often machined to tight tolerances using diamond grinding tools. This allows for:

- ±0.05mm dimensional accuracy

- Smooth surface finishes

- Custom features like chamfers, threads, or holes

This step is essential for producing machinable alumina rods used in high-precision applications such as laboratory instruments, furnace supports, or electrical insulators.

Method 1: Using a Diamond Cutting Wheel (Recommended for Most Applications)

This is the most effective and widely used method for cutting alumina ceramic rods, especially those with larger diameters or tight tolerance requirements.

Tools Needed:

- Rotary tool (e.g., Dremel), angle grinder, or tile saw

- Diamond cutting wheel (wet or dry type)

Steps:

- Wear protection: Always use safety glasses, gloves, and a dust mask.

- Secure the rod: Clamp the alumina rod firmly using a padded vise to avoid cracks.

- Score the surface (optional but helpful): Lightly mark the cutting line with the diamond wheel to reduce chipping.

- Cut slowly:

- Wet cutting (preferred): Use water to cool the blade and rod, reduce dust, and prevent thermal shock.

- Dry cutting: Use light pressure and make multiple shallow passes. Let the rod cool between cuts.

- Smooth the edges: After cutting, use a diamond file or fine-grit sandpaper to deburr and bevel the edges.

✅ This method works well for machinable alumina rods and ensures clean, precise results.

Method 2: Scribe and Snap (For Thin Rods < 6mm)

This simple method is suitable for small-diameter alumina rods where high precision is not critical.

Tools Needed:

Diamond file or carbide scribe

Steps:

Mark the cut: Score a deep line around the rod using the scribe.

Snap the rod: Place the rod on a hard edge with the score line aligned. Apply firm pressure to break it cleanly.

⚠️ Note: This method is only recommended for thin rods and may result in uneven edges.

Yes—used for heater coil support and insulation in kilns/heat-treat lines; stable under cyclic thermal load.

Yes. Alumina rods are widely used as reliable electrical insulators because of their high dielectric strength and excellent volume resistivity, ensuring safe performance even under high-voltage and high-temperature conditions.

Yes. We can manufacture parts strictly according to customer drawings and ensure tight tolerance control with precision machining.

To get a custom alumina rod quote, please provide:

1. Dimensions

- Diameter

- Length

- Tolerance requirements (e.g., ±0.05mm)

✅ 2. Material Purity

- Common options: 96%,99%, 99.5%, or 99.7% Al₂O₃

- Higher purity offers better thermal and electrical performance

✅ 3. Rod Type or Shape

- Solid rod, hollow tube, square rod, threaded rod, etc.

- Attach a drawing or sketch if available

✅ 4. Surface Finish

- Polished, unpolished, glazed, or custom surface treatment

- Indicate if edge chamfering or end-face grinding is needed

✅ 5. Special Features (if any)

- Holes, slots, threads, grooves, or notches

- Indicate position, size, and quantity

✅ 6. Application Environment

- Operating temperature

- Exposure to chemicals or voltage

- This helps us recommend the right alumina ceramic grade

✅ 7. Quantity & Delivery Requirements

- Estimated order volume (e.g., 50 pcs, 500 pcs)

- Required lead time or delivery deadline

- Shipping destination (for freight calculation)

- Alumina (Al₂O₃): better for very high temperatures, strong electrical insulation, lower cost, lighter; hardness-driven wear resistance.

- Zirconia (ZrO₂, e.g., 3Y-TZP/PSZ): much tougher and stronger (resists chipping/impact), great for tight fits with metals, but lower max temperature and higher cost.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Partner with ADCERAX for Precision Alumina Ceramic Rods

Looking for a reliable alumina rod supplier? Let us help you with your next project.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours