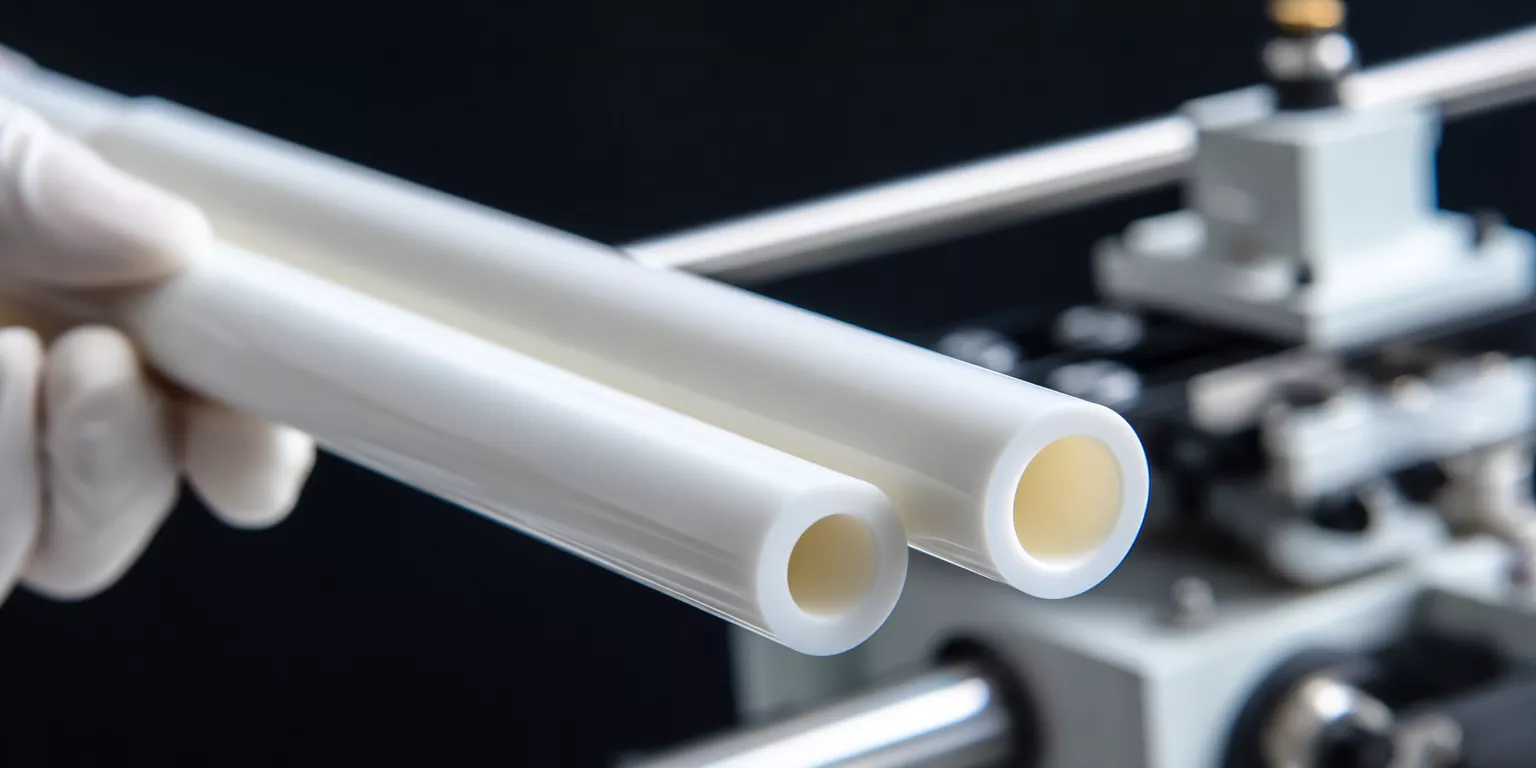

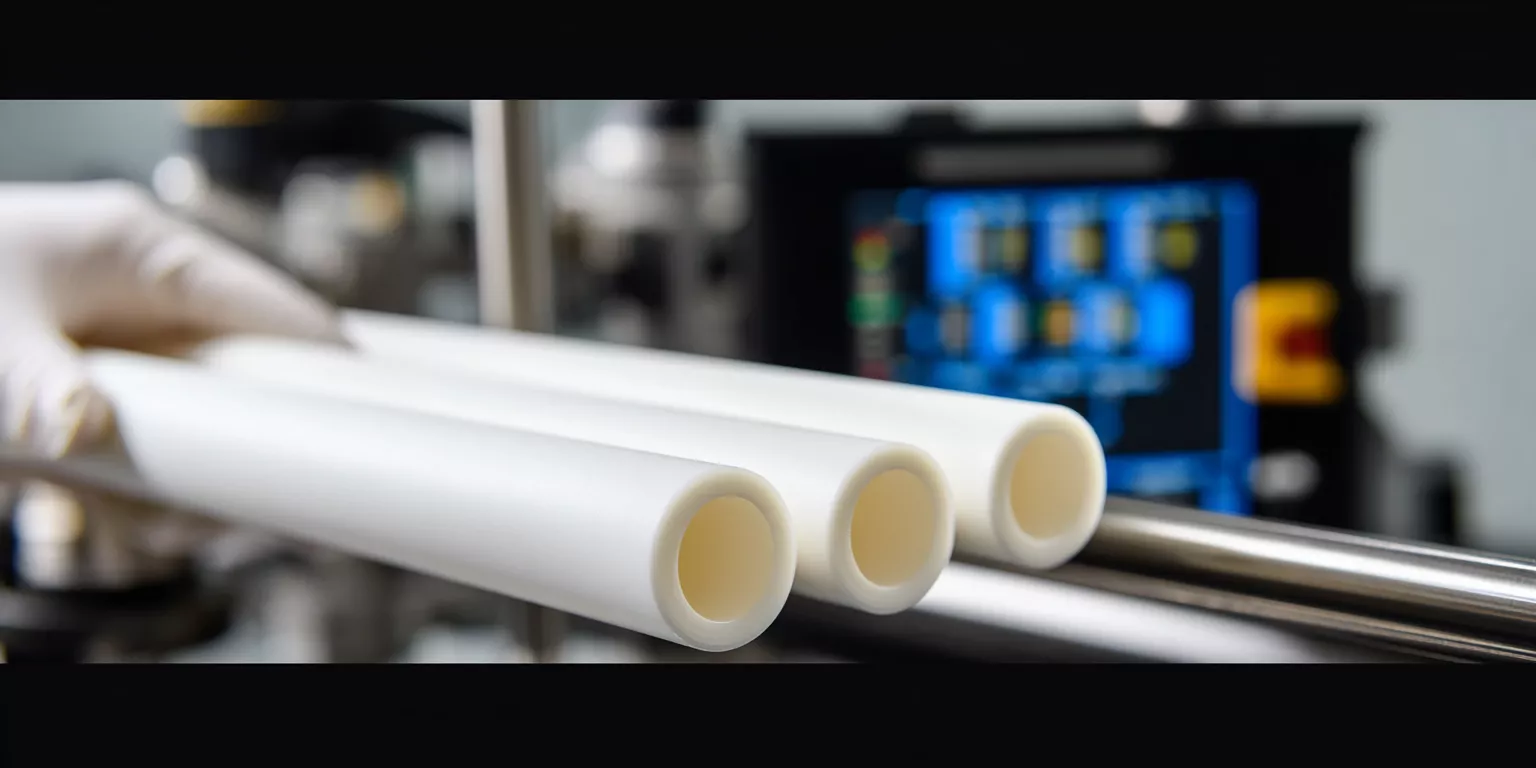

alumina furnace tube reliability depends on thermal management, chemical resistance, and mechanical precision in design and operation. When these parameters fall out of tolerance, early cracking, distortion, or corrosion follow.

Alumina furnace tube failures typically result from thermal shock, grain-boundary corrosion, or mechanical stress concentration. Each mechanism interacts with others, so effective prevention requires a combined strategy.

This engineering guide explains how alumina furnace tube degradation occurs and provides verified control methods for extending service life under demanding conditions.

Thermal stress mechanisms in the alumina furnace tube

Rapid temperature transitions cause uneven thermal expansion through the alumina furnace tube wall, generating high tensile stress. When the differential temperature exceeds a few hundred degrees, localized cracking develops. Effective control depends on heating and cooling discipline verified by temperature monitoring.

Temperature gradient and tensile stress generation

Temperature gradients arise when surface heating or cooling outpaces heat conduction through the wall. For an 8 mm wall alumina furnace tube, the outer surface can lag the inner core by 100 °C during a 10 °C/min ramp, producing ~250 MPa tensile stress. This stress alternates sides between heating and cooling cycles, leading to fatigue-driven microcracking1.

Maintaining slow, programmed heating allows uniform temperature distribution. The ideal approach is progressive ramping to maintain ΔT ≤ 60 °C across the wall. Over hundreds of cycles, this keeps internal stress below 70 % of the fracture limit and delays cumulative fatigue.

Proper thermocouple placement along the furnace zone helps confirm thermal uniformity and prevents localized overheating near the tube ends.

| Parameter | Typical Value | Relevance to alumina furnace tube |

|---|---|---|

| Elastic modulus (E) | 350–380 GPa | Determines stress response |

| Thermal expansion (α) | 7.2×10⁻⁶ /°C | Drives thermal strain |

| Poisson’s ratio (ν) | 0.22 | Affects tensile stress |

| Safe ramp (ΔT rate) | 5–10 °C/min | Avoids cracking |

| Critical ΔT | ≤ 100 °C | Limit for safe operation |

Crack initiation and propagation thresholds

Once stress concentrates at a flaw, crack propagation in the alumina furnace tube follows fracture mechanics. When K_I = Y·σ·√(πa) exceeds the material’s K_IC (≈ 4.5 MPa·m^0.5), unstable fracture starts. Microcracks first form at machining marks or impact sites before linking into long radial fractures.

Surface finishing below Ra 2 µm and radius relief at sharp edges reduce Y and delay crack initiation. Field studies confirm that tubes with polished inner surfaces last twice as long under equivalent cycling.

Gradual temperature transition across furnace zones minimizes abrupt thermal shifts that could exceed local toughness.

| Crack Propagation Factor | Control Method | Observed Improvement |

|---|---|---|

| Surface flaw density | Use fine polishing (Ra < 2 µm) | + 100 % fatigue life |

| Heating uniformity | Multizone control ± 15 °C | + 60 % lifetime |

| Stress reversal rate | Stepwise cooling | − 70 % crack incidence |

Fatigue life and damage accumulation

Fatigue damage in an alumina furnace tube builds incrementally across cycles. Each cycle consumes part of its life proportionally to thermal stress amplitude2. Damage D = Σ(n_i/N_i) approaches 1 at failure.

Tubes cycled under controlled ramps typically survive 400–600 cycles, while uncontrolled cycles fail below 100. Reducing heating rates and keeping atmosphere purity consistent slow fatigue growth substantially.

A maintenance schedule based on cycle count, not time alone, gives more accurate replacement timing for alumina furnace tube assets.

Chemical attack effects on the alumina furnace tube

Thermal control alone cannot prevent degradation if the environment is chemically active. Gaseous impurities attack grain boundaries of the alumina furnace tube, especially where residual silica or alkali oxides exist. Corrosive gases accelerate porosity growth, lowering mechanical integrity.

Sulfur reaction and silica volatilization

Sulfur compounds react with trace SiO₂ in the alumina furnace tube at > 900 °C to form volatile silicon sulfates. The process opens grain boundaries and erodes intergranular bonding. After 1000 h at 1500 °C, high-silica tubes show 25 µm boundary loss versus only 5 µm for ultra-pure grades.

Using 99.7 % purity alumina minimizes this mechanism. Gas purging with dry nitrogen further slows reaction rates. Furnace operators should measure SO₂ below 50 ppm to protect the tube wall.

| Reaction Source | Resulting Effect | Preventive Measure |

|---|---|---|

| SO₂ > 100 ppm | Grain boundary loss 15–25 µm / 1000 h | Purify fuel and air |

| SiO₂ > 0.3 wt % | Volatilization ↑ 3× | Specify < 0.15 wt % |

| Oxygen fluctuation | Sulfate conversion cycle | Maintain constant purge |

Halogen penetration into grain boundaries

Halogen gases such as Cl₂ or HF diffuse along microcracks of the alumina furnace tube, forming AlCl₃ or AlF₃ vapors. At 1200–1400 °C, boundary corrosion rates reach 10 µm / 1000 h if atmosphere control is poor.

Adding chlorine scrubbers and ensuring moisture-free feed gas can reduce penetration. Operators must seal furnace joints to prevent backstreaming of halogens into hot zones.

Repeated halogen attack weakens the inner wall gloss, producing a matte surface, which is an early indicator of attack visible during inspection.

Alkali vapor eutectic formation

Sodium and potassium vapors combine with alumina and silica to form a liquid Na₂O·Al₂O₃·2SiO₂ phase melting at 1060 °C. Once this molten film appears, local dissolution accelerates failure of the alumina furnace tube.

Alkali-containing batch materials or burners should be isolated, and alumina or zeolite traps used at inlets. Maintaining dew point below − 60 °C minimizes condensate that could transport alkali species.

| Gas Species | Melting Compound Formed | Onset Temp (°C) | Preventive Strategy |

|---|---|---|---|

| Na / K vapors | Na₂O·Al₂O₃·2SiO₂ | 1060 | Upstream trap, low humidity |

| Cl₂ | AlCl₃(g) + O₂ | 1000 | Scrubber + seal joints |

| SO₃ | SiO₂·SO₃(g) | 900 | Dry purge, purity upgrade |

Mechanical stress and support design for the alumina furnace tube

Even with stable temperature and atmosphere, improper support can fracture an alumina furnace tube. Bending, torsion, and constraint stress occur when mounts restrict axial expansion. Careful mechanical layout ensures uniform load sharing.

Bending stress under gravity loading

Long spans cause sagging that adds bending stress. A 60 mm diameter alumina furnace tube over a 1 m unsupported span develops about 100 MPa bending stress at 1500 °C, already 25 % of its flexural limit.

Support spacing ≤ 20× D limits deflection. Each saddle must have 120–160° contact to spread load uniformly. Avoid steel supports unless cushioned by ceramic fiber to absorb differential expansion.

Contact geometry and load distribution

Point or narrow-edge supports create high stress zones where microcracks originate. Saddle width of 40 mm and compliant padding reduce localized pressure below 50 MPa. Using alumina supports with matched thermal expansion keeps stress balance consistent across temperature cycles.

Operators should verify saddle alignment within ± 3 mm height per meter to prevent torsion that can couple with bending.

| Support Parameter | Recommended Range | Benefit to alumina furnace tube |

|---|---|---|

| Saddle width | 30–50 mm | Lower contact pressure |

| Contact arc | 120–160° | Distributes stress |

| Alignment error | ≤ 3 mm/m | Avoids twist |

| Friction coefficient | < 0.15 | Allows slip |

Axial expansion and floating-end design

The alumina furnace tube elongates about 0.8 % from room temperature to 1700 °C. If both ends are fixed, stress exceeds 4 GPa—ten times its fracture limit.

Design one end free to slide on PTFE or graphite pads. This ensures smooth thermal expansion, eliminates axial compression3 buildup, and prevents early rupture. A simple inspection during shutdown verifies free motion of the sliding end.

Microstructural degradation in the alumina furnace tube

Over long service time, the microstructure of the alumina furnace tube coarsens and porosity increases. These transformations gradually lower flexural strength and thermal-shock resistance.

Grain coarsening and toughness loss

Grain size growth follows d = d₀ + k t^n. At 1600 °C for 8000 h, grains reach 100 µm, reducing fracture strength by 30 %. Abnormal growth forms isolated giant grains up to 500 µm that create weakness zones.

Uniform temperature distribution and shorter high-temperature exposure suppress grain coarsening. Consistent operating cycles maintain steady mechanical integrity of the alumina furnace tube.

| Exposure Temp (°C) | Grain Size (µm) | Strength Loss (%) |

|---|---|---|

| 1500 | 60 | −15 |

| 1600 | 100 | −25 |

| 1700 | 150 – 200 | −35 |

Porosity increase and strength decay

Porosity rises through vacancy coalescence and corrosion voids. From 0.15 % to 0.6 % porosity, flexural strength drops by 25–30 %. The exponential relation σ = σ₀ exp(−bP) (b ≈ 5) fits test data from retired alumina furnace tubes.

To monitor, periodic ultrasonic velocity measurement (ASTM C769) detects 3–5 % velocity reduction correlating with 30 % strength loss.

Silica migration in low-purity grades

In alumina grades containing > 0.3 wt % SiO₂, glassy films soften above 1400 °C and migrate along temperature gradients. They collect in cooler areas forming bands with lower strength, initiating new cracks. Using higher-purity alumina and stable temperature gradients mitigates this risk.

Maintenance and testing framework for alumina furnace tube life extension

Preventive maintenance ensures consistent alumina furnace tube performance through disciplined operation and real-time monitoring.

Automated thermal control protocol

Programmed furnace controllers enforce ramp discipline. Typical implementation increases tube life from 5000 h to 12 000 h. Real-time trend alarms warn of deviations exceeding ±15 °C between zones, preventing thermal shock.

Verification logs should be reviewed weekly to confirm adherence to prescribed profiles and identify irregular operation.

| Control Stage | Rate (°C/min) | Temperature Range (°C) | Purpose |

|---|---|---|---|

| Initial heating | 5 | Ambient–400 | Stress equilibration |

| Intermediate | 10 | 400–1200 | Uniform expansion |

| Final heating | 8 | > 1200 | Prevent surface cracking |

| Cooling | 10 → 5 | > 800 → 400 | Controlled stress release |

Non-destructive inspection strategy

Regular inspection detects degradation before visible damage occurs. Visual checks, dimensional scans, ultrasonic velocity, and acoustic emission monitoring together provide comprehensive health data.

For high-temperature continuous service (> 1600 °C), semi-annual ultrasonic inspection and continuous acoustic emission give early warning of microcrack activity.

| Method | Interval | Key Indicator | Decision Threshold |

|---|---|---|---|

| Visual | Quarterly | Discoloration, deposits | Immediate cleaning |

| Dimensional | Semi-annual | Warp > 1 mm / m | Reseat supports |

| Ultrasonic | Annual | Velocity − 5 % | Plan replacement |

| Acoustic emission | Continuous | > 20 events/cycle | Stop and inspect |

Predictive replacement scheduling

Combining creep and fatigue models provides a unified damage index. Replace the alumina furnace tube when D_total ≥ 0.8 to maintain safety margins. Integrating temperature data with Larson–Miller parameters automates prediction through software dashboards.

Predictive scheduling reduces unplanned downtime by 85 % and extends total operating time 30–40 %.

| Damage Source | Formula | Action Level |

|---|---|---|

| Thermal fatigue | Σ(n_i / N_i) | D ≈ 0.5 → review |

| Creep | Σ(t_i / t_rupture,i) | D ≈ 0.3 → monitor |

| Total | D_total = D_f + D_c | 0.8 → replace |

Conclusion

Through precise temperature control, atmosphere purification, and mechanical design optimization, alumina furnace tube life can be multiplied several-fold. Combining field monitoring with predictive models transforms maintenance from reactive to preventive.

FAQ

What causes thermal cracking in an alumina furnace tube?

Thermal gradients exceeding 100 °C across the wall create tensile stress that surpasses material limits. Programmed heating ramps reduce these gradients and prevent shock failures.

How does chemical corrosion shorten alumina furnace tube life?

Sulfur, halogen, and alkali vapors attack grain boundaries, producing porosity and strength loss. Purging and using ultra-pure alumina mitigate corrosion significantly.

What is the best support configuration for an alumina furnace tube?

Use wide saddles with matching thermal expansion and at least one sliding end. This design prevents bending and restraint stresses.

When should an alumina furnace tube be replaced?

Replacement is advised when ultrasonic velocity drops > 5 % from baseline or cumulative damage exceeds 0.8, ensuring safe and predictable operation.

References:

-

Exploring fatigue-driven microcracking helps in developing strategies to enhance the durability and lifespan of materials under cyclic stress. ↩

-

Exploring the effects of thermal stress amplitude can help in designing more durable furnace tubes and preventing premature failures. ↩

-

Exploring axial compression helps in grasping how forces impact material integrity, essential for engineering applications. ↩