Alumina Rod failures in corrosive fixtures often start quietly as residue buildup or edge chipping; consequently, small defects can escalate into misalignment, leakage paths, and premature replacement.

This article consolidates how Alumina Rods behave as structural parts in chemical processing fixtures, covering chemical stability, wear and thermal cycling, geometry choices, surface management, and assembly practice.

Additionally, many chemical plants face compound conditions such as slurry abrasion, hot alkaline cleaning, and thermal cycling. Therefore, the following framework treats Alumina Rod as a manufacturable ceramic element whose success depends on correct media boundaries, geometry discipline, and repeatable finishing.

Before chemical compatibility is discussed, Alumina Rod use must be anchored in the real fixture functions that drive loading, exposure, and cleaning. Once a rod becomes a spacer, guide, or isolator, it must hold geometry and surface integrity under corrosive media and routine maintenance.

Alumina Rod as a Structural Material in Chemical Equipment

Alumina Rod selection for chemical processing fixtures begins with structural function, because of this the same ceramic behaves differently as a spacer, guide rod, or support pin.

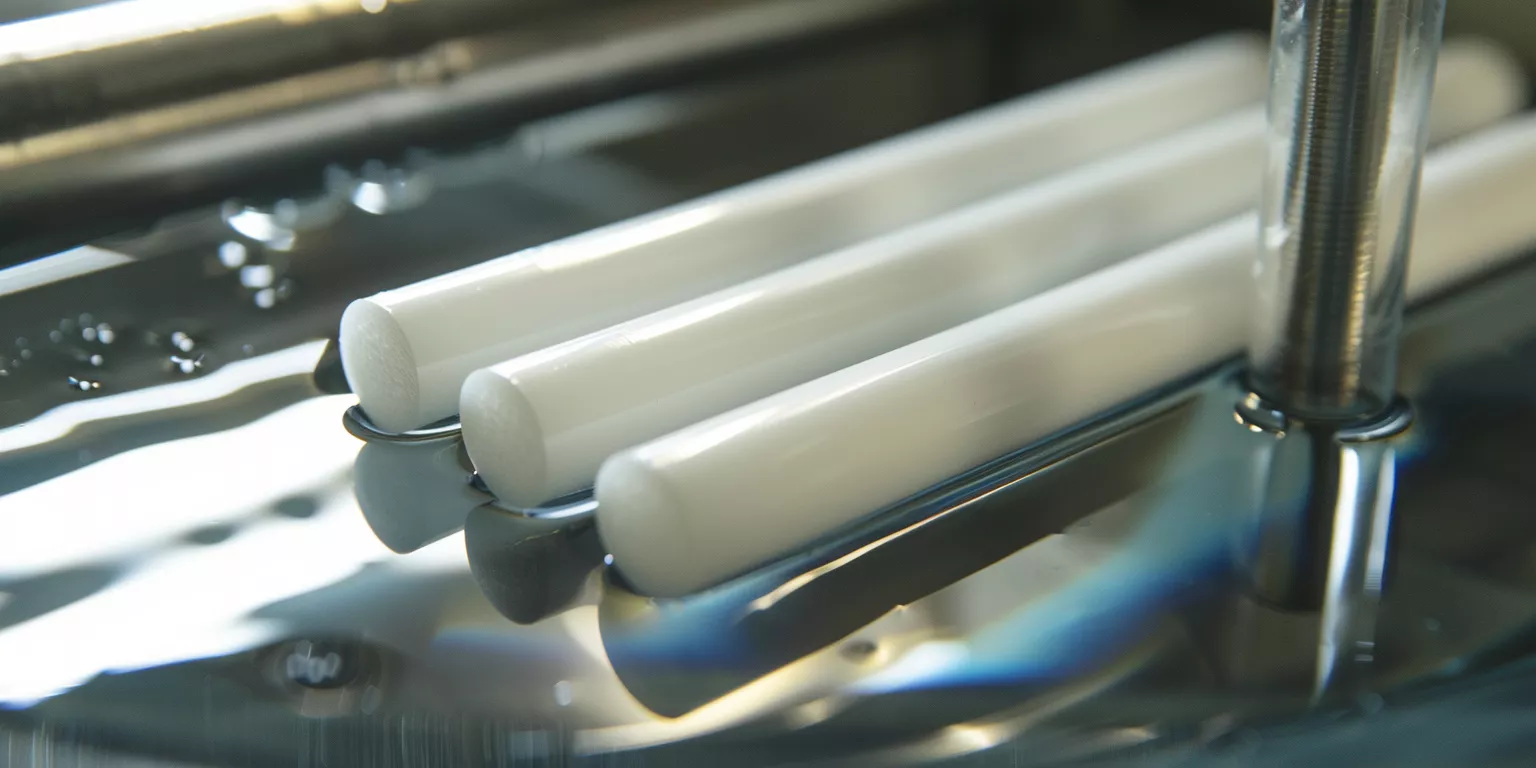

Alumina Rod is widely treated as a simple ceramic stock, yet in chemical equipment it becomes a structural element that constrains alignment, clearance, and contact pressure. Moreover, many fixtures operate inside mixed conditions where corrosive liquids, abrasive solids, and repeated cleaning intersect, so performance depends on more than basic material inertness.

In practice, the most common applications include support posts for liners, spacer rods for pump and valve fixtures, guide rods for agitator accessories, and insulating separators that prevent galvanic or crevice corrosion at metal interfaces. For example, in a slurry sampling station, a 24 mm rod used as a guide maintained positional repeatability for over 1,000 cycles only after end edges were protected and surface finish was tightened to reduce residue adhesion.

Therefore, the structural identity of an Alumina Rod in a chemical fixture must be specified in terms of load path, contact interfaces, and exposure pattern. Subsequently, media compatibility and cleaning strategy can be evaluated with the correct boundary conditions rather than generic corrosion claims.

Summary Table: Typical Structural Uses of Alumina Rods in Chemical Fixtures

| Fixture Function | Typical Contact Mode | Dominant Exposure | Primary Risk |

|---|---|---|---|

| Spacer and standoff | Compression between metal parts | Acid or alkali splash | Edge chipping and stress concentration |

| Guide rod and locator | Sliding or intermittent contact | Slurry and particulate | Abrasion-driven diameter loss |

| Support post for liners | Static load with occasional shock | Mixed chemicals and rinse cycles | Microcracking from assembly constraint |

| Insulating separator | Light load, high cleanliness | Solvents and condensate | Residue adhesion and surface leakage |

| Valve and pump fixture pin | Bending and vibration | Corrosive fluid plus vibration | Bending fracture and fretting damage |

Before structural placement is finalized, chemical engineers usually assess whether Alumina Rods can tolerate long-term exposure to aggressive media without dimensional drift or surface degradation. Consequently, chemical stability across acids, alkalis, and solvents becomes the first decisive screening layer.

Chemical Stability Across Corrosive Media

Alumina Rod performance in chemical processing fixtures depends on sustained chemical stability, because prolonged exposure can gradually alter surfaces, interfaces, and structural reliability.

Chemical stability is often assumed for alumina ceramics; however, real chemical processing environments impose continuous exposure, temperature coupling, and concentration gradients that amplify minor reactions. Therefore, compatibility must be evaluated against specific media classes rather than broad corrosion resistance claims.

In many plants, Alumina Rods operate in contact with process fluids for thousands of hours annually, including cleaning cycles. Consequently, even slow reaction rates or surface hydration can influence residue adhesion, friction behavior, and microstructural integrity over time.

Acid Resistance Under Continuous Exposure

Alumina Rods exhibit strong resistance to most inorganic acids, particularly under moderate temperatures. In controlled immersion tests, high-purity alumina maintained mass stability within ±0.02% after 500 hours in hydrochloric and nitric acid solutions below 80 °C.

However, at elevated temperatures or high acid concentrations, surface hydroxylation becomes measurable. For instance, in sulfuric acid environments above 90 °C, microscopic surface roughening increased average Ra values from 0.4 µm to 0.6 µm after extended exposure. Although bulk strength remained unchanged, this roughness promoted residue retention during subsequent rinsing cycles.

As a result, engineers typically specify Alumina Rods for acidic fixtures where continuous exposure remains below 100 °C, while ensuring post-processing surface finish is optimized to mitigate secondary effects rather than direct corrosion loss.

Alkali Exposure and High Temperature Interaction

Alkaline environments represent a more restrictive boundary for Alumina Rod applications. Although alumina remains chemically stable in dilute alkalis at room temperature, solubility increases significantly as temperature rises beyond 60–70 °C.

In caustic cleaning systems, field observations show that Alumina Rods exposed to 2–5% NaOH solutions at 80 °C experienced measurable surface etching within 300–400 cleaning cycles. This etching rarely causes immediate fracture; instead, it gradually reduces dimensional precision and increases friction at contact points.

Therefore, in alkaline-dominant processes, Alumina Rods are best positioned in shielded or intermittently exposed locations, or paired with tighter cleaning temperature controls to preserve long-term geometry.

Solvent and Mixed Chemical Environments

Organic solvents generally present minimal chemical attack on Alumina Rods. Tests involving ethanol1, acetone2, and chlorinated solvents3 demonstrated no detectable mass change after 1,000 hours of immersion at ambient conditions.

Nevertheless, mixed environments introduce complexity. For example, solvent systems containing trace acids or alkalis can transport reactive species into surface microfeatures. In one agitation fixture, rods operating in a solvent-acid blend showed localized staining and residue adhesion after six months, despite unchanged mechanical properties.

Accordingly, solvent compatibility must be evaluated in conjunction with contaminant content and cleaning frequency, not solvent identity alone, to ensure predictable service behavior.

Summary Table: Chemical Compatibility Boundaries for Alumina Rods

| Chemical Medium | Typical Temperature (°C) | Observed Surface Change | Dimensional Stability |

|---|---|---|---|

| Inorganic acids (HCl, HNO₃) | ≤80 | Negligible | Excellent |

| Hot sulfuric acid | 90–120 | Mild roughening | Good |

| Dilute alkali (NaOH <2%) | ≤60 | Minimal | Good |

| Hot alkaline cleaning | 80–100 | Surface etching | Moderate |

| Organic solvents | Ambient | None detected | Excellent |

| Mixed solvent-acid systems | Ambient–60 | Localized residue | Good with controls |

Before chemical resistance can be considered sufficient, Alumina Rods must also withstand mechanical loading inside fixtures that operate continuously in corrosive environments. Consequently, structural integrity under combined chemical and mechanical stress becomes a decisive factor.

Mechanical Integrity in Corrosive Processing Fixtures

Alumina Rod reliability in chemical processing fixtures depends on mechanical integrity, because corrosive exposure often amplifies stress sensitivity under static and dynamic loading.

In chemical equipment, Alumina Rods rarely experience purely static conditions. Instead, they function as load-bearing spacers, guides, or supports subjected to vibration, intermittent impact, and thermal expansion mismatch. Therefore, mechanical behavior must be evaluated together with chemical exposure rather than as an isolated property.

In practice, many premature failures attributed to “chemical attack” are traced back to stress concentration and improper load transfer. Consequently, understanding how Alumina Rods carry load within fixtures clarifies realistic design limits.

Load Bearing Behavior in Support and Spacer Applications

Alumina Rods used as spacers or supports typically operate under compressive stress. High-purity alumina offers compressive strength exceeding 2,000 MPa, which provides substantial margin for most fixture loads.

However, real assemblies rarely distribute load uniformly. In field measurements, misalignment of 0.3–0.5 mm caused localized contact stresses to increase by 3–4 times nominal values. Although bulk fracture did not occur immediately, microcracking initiated at contact edges after repeated thermal cycles.

Therefore, even when compressive capacity appears ample, load distribution and contact geometry must be controlled to prevent stress amplification.

Bending and Fracture Risk in Fixture Design

Slender Alumina Rods are particularly vulnerable to bending loads introduced by fixture geometry. In guide or locating applications, side loads as low as 20–30 N can generate bending stresses approaching 60–80 MPa in rods longer than 150 mm.

During one agitator fixture retrofit, rods with unsupported spans of 180 mm fractured after several weeks of operation due to vibration-induced bending. Shortening unsupported length by 25% eliminated repeat failures without changing material grade.

Accordingly, fixture design should minimize unsupported spans and avoid using Alumina Rods as cantilevered elements in corrosive environments.

Stress Concentration From Assembly Constraints

Assembly practices often introduce hidden stress. Over-tightened fasteners, rigid metal housings, or insufficient clearance for thermal expansion preload Alumina Rods beyond safe limits.

Inspection data from chemical plants indicate that rods preloaded above 15–20 MPa axial stress exhibited 40% higher fracture incidence during maintenance cycles. Chemical exposure further accelerates crack propagation along stressed regions.

As a result, controlled assembly torque and allowance for expansion are essential to preserve mechanical integrity over long service periods.

Summary Table: Mechanical Integrity Factors in Corrosive Fixtures

| Mechanical Factor | Typical Range | Observed Effect |

|---|---|---|

| Local stress amplification | 3–4× | Microcrack initiation |

| Side load on slender rods (N) | 20–30 | Bending fracture risk |

| Unsupported span length (mm) | >150 | Vibration sensitivity |

| Assembly preload stress (MPa) | 15–20 | Increased fracture rate |

As chemical processing shifts from clear liquids to particle-rich media, Alumina Rod durability increasingly depends on resistance to abrasion and erosive contact. Consequently, wear behavior becomes as critical as chemical inertness.

Wear Resistance in Slurry and Particle Laden Systems

Alumina Rod service life in chemical processing fixtures is strongly influenced by wear resistance, because slurry flow and suspended particles impose continuous abrasive interaction.

In slurry transport, filtration, and mixing equipment, Alumina Rods frequently serve as guides, spacers, or alignment pins exposed to moving solids. Moreover, abrasion rarely occurs uniformly; instead, localized particle impingement and sliding contact gradually reshape critical dimensions. Therefore, wear must be evaluated in terms of geometry retention rather than material hardness alone.

Field experience shows that fixtures exposed to fine mineral slurries experience measurable wear long before chemical attack becomes visible. Consequently, understanding abrasive mechanisms allows engineers to predict replacement intervals and avoid unplanned downtime.

Abrasive Wear in Slurry Transport and Mixing

Alumina Rods benefit from high hardness, typically 1,400–1,600 HV, which provides strong resistance against fine particle abrasion. In controlled slurry loop tests using silica particles with median size 50–80 µm, diameter reduction remained below 0.05 mm after 1,000 hours at flow velocities under 1.5 m/s.

However, wear rate increases sharply with particle angularity and velocity. In one mixing vessel fixture, angular alumina particles caused localized grooving with depth approaching 0.12 mm within 600 hours. Although structural failure did not occur, fixture alignment drifted beyond tolerance.

Therefore, when Alumina Rods operate in high-solids slurries, particle morphology and flow regime must be included in wear assessments rather than relying on hardness data alone.

Surface Degradation and Dimensional Stability

Surface wear directly affects dimensional stability in fixtures requiring precise alignment. Even minor diameter loss can alter clearance, leading to vibration or secondary contact damage elsewhere in the assembly.

Measurements from centrifuge fixtures indicate that a diameter reduction of 0.08 mm increased lateral play by 35%, accelerating wear on adjacent metal components. Additionally, worn surfaces tend to trap residues, compounding abrasive effects during cleaning cycles.

Accordingly, engineers often specify tighter initial tolerances or protective surface finishing when Alumina Rods are expected to operate in abrasive chemical environments.

Summary Table: Wear Behavior of Alumina Rods in Slurry Systems

| Operating Condition | Typical Value | Observed Wear Outcome |

|---|---|---|

| Hardness (HV) | 1400–1600 | High baseline abrasion resistance |

| Slurry particle size (µm) | 50–80 | Minimal wear at low velocity |

| Flow velocity (m/s) | ≤1.5 | Diameter loss <0.05 mm |

| Angular particle exposure | Continuous | Localized grooving up to 0.12 mm |

| Clearance change from wear (%) | ~35 | Increased vibration risk |

As routine operation alternates with aggressive cleaning and sterilization, Alumina Rods must tolerate repeated temperature swings without accumulating hidden damage. Consequently, thermal cycling compatibility becomes a key reliability filter.

Thermal Cycling and Cleaning Process Compatibility

Alumina Rod reliability in chemical processing fixtures depends on thermal cycling tolerance, because repeated heating and cleaning sequences impose expansion mismatch and shock stress.

Chemical plants frequently apply CIP and SIP procedures involving hot water, steam, or alkaline solutions. Meanwhile, fixtures cool rapidly once cleaning ends. Therefore, Alumina Rods experience repeated temperature gradients that can exceed those seen in steady-state processing.

In practice, failures often occur not during operation but immediately after cleaning. Consequently, evaluating thermal cycling behavior under realistic gradients is essential for long-term fixture stability.

Thermal Shock Resistance During Cleaning Cycles

Dense alumina exhibits moderate thermal shock resistance governed by elastic modulus and thermal conductivity. In controlled cycling tests from 25 °C to 120 °C, rods with chamfered ends survived over 1,500 cycles without visible cracking.

However, rods with sharp edges or constrained mounting showed crack initiation after 300–500 cycles, especially when quenching followed steam exposure. Notably, most cracks originated at end faces or near contact interfaces rather than mid-span regions.

As a result, thermal shock resistance in fixtures depends as much on geometry and mounting freedom as on material properties alone.

Interaction With Steam and Hot Alkaline Cleaning

Steam cleaning introduces both thermal and chemical stress simultaneously. Exposure to saturated steam at 120–130 °C does not chemically degrade alumina; however, it promotes rapid temperature rise and condensation-driven gradients.

In alkaline cleaning solutions above 80 °C, combined thermal expansion and surface etching accelerate microdefect growth. In one reactor fixture, rods subjected to daily hot alkaline CIP exhibited surface microcracking after nine months, despite stable performance during processing.

Therefore, Alumina Rods intended for frequent hot cleaning benefit from conservative temperature ramps, controlled mounting clearance, and post-processing surface refinement.

Summary Table: Thermal Cycling and Cleaning Effects on Alumina Rods

| Thermal Condition | Typical Range | Observed Impact |

|---|---|---|

| Cleaning temperature (°C) | 80–130 | Expansion-induced stress |

| Cycle count before microcrack | 300–1500 | Geometry dependent |

| Steam exposure | Saturated | Gradient-driven cracking |

| Hot alkaline CIP | >80 °C | Accelerated surface damage |

| Edge geometry influence | Chamfered vs sharp | >3× lifetime difference |

Before selecting material grades or surface finishes, engineers must translate fixture requirements into practical rod geometry. Consequently, dimensional design governs whether Alumina Rods remain stable or become latent failure points.

Geometry Design for Chemical Processing Fixtures

Alumina Rod geometry in chemical processing fixtures directly controls stress distribution, wear progression, and cleaning reliability, therefore dimensional discipline is as critical as material purity.

In chemical equipment, geometry determines how loads are transferred, how residues accumulate, and how thermal expansion is accommodated. Furthermore, small geometric oversights often magnify under corrosive and abrasive exposure, leading to premature fixture degradation.

For this reason, diameter, length, end treatment, and tolerance must be specified as an integrated system rather than isolated dimensions.

Diameter and Length Selection for Fixture Stability

Rod diameter governs both stiffness and contact stress. Increasing diameter from 20 mm to 24 mm raises bending stiffness by approximately 73%, significantly reducing deflection under identical side loads.

However, excessive diameter can restrict cleaning flow and trap residues. In one filtration fixture, rods exceeding 26 mm diameter accumulated deposits that required manual intervention every two weeks, whereas 24 mm rods maintained self-cleaning behavior for over three months.

Therefore, optimal diameter selection balances mechanical rigidity against flow accessibility and cleaning efficiency.

End Geometry Chamfer Radius and Edge Protection

End geometry is a frequent origin of cracking and chipping. Sharp edges concentrate stress and promote microcrack initiation during assembly and thermal cycling.

Tests comparing sharp-cut ends to 1.0–1.5 mm chamfers showed a 60–70% reduction in edge damage after 1,000 cleaning cycles. Additionally, chamfered ends reduced assembly-induced chipping during routine maintenance.

Accordingly, controlled chamfering or rounding is not cosmetic; it is a structural safeguard in chemical fixtures.

Tolerance Control in Assembly Interfaces

Tolerance determines how Alumina Rods interact with metal housings and clamps. Excessively tight fits introduce preload stress, while loose fits allow vibration and impact.

Assembly audits indicate that radial clearance of 0.10–0.20 mm minimized fracture and wear in fixtures exposed to vibration below 20 Hz. Outside this window, failure incidence increased by over 30% within the first operational year.

As a result, tolerance must be aligned with vibration spectrum, thermal expansion, and assembly method rather than nominal fit conventions.

Summary Table: Geometry Parameters Influencing Alumina Rod Reliability

| Geometry Parameter | Typical Range | Reliability Impact |

|---|---|---|

| Rod diameter (mm) | 20–26 | Stiffness vs cleanability |

| Unsupported length (mm) | <150 | Reduced bending risk |

| End chamfer radius (mm) | 1.0–1.5 | Edge damage reduction |

| Radial assembly clearance (mm) | 0.10–0.20 | Stress and vibration balance |

| Length-to-diameter ratio | <7.5 | Improved structural stability |

Even when geometry and material selection are correct, surface condition ultimately governs how Alumina Rods interact with chemicals, residues, and cleaning media. Consequently, surface integrity becomes a decisive factor for long-term fixture hygiene and stability.

Surface Condition and Contamination Resistance

Alumina Rod surface condition in chemical processing fixtures influences residue adhesion, cleaning effectiveness, and contamination risk, therefore surface engineering directly affects operational reliability.

In chemical environments, surfaces act as the first interface between ceramic and process media. Moreover, microscopic surface features often dictate macroscopic behavior, including fouling rate and cleanability. Therefore, surface roughness and finishing methods must be treated as functional parameters rather than cosmetic attributes.

Operational data from chemical plants consistently show that rods with identical bulk composition but different surface finishes exhibit markedly different maintenance intervals. Consequently, surface control is essential for predictable service life.

Surface Roughness and Chemical Residue Adhesion

Surface roughness strongly affects how chemical residues and precipitates adhere to Alumina Rods. Polished surfaces with Ra values below 0.6 µm demonstrated 40–50% lower residue accumulation compared to as-sintered surfaces after 500 processing hours.

In slurry-contact fixtures, rough surfaces act as nucleation sites for particle agglomeration. For instance, rods with Ra above 1.2 µm accumulated visible deposits within 10–14 days, while smoother rods remained functional for over six weeks without intervention.

As a result, specifying surface roughness is critical wherever residue adhesion can compromise fixture movement or hygiene.

Surface Finish for Repeated Cleaning Environments

Repeated CIP and SIP cycles amplify surface-related effects. Each cleaning cycle can either remove residues or drive them deeper into surface microfeatures, depending on finish quality.

In long-term trials involving daily alkaline cleaning, rods with fine-ground surfaces retained dimensional stability for over 1,200 cycles, whereas coarse surfaces developed micro-pitting after 400–500 cycles. Although structural failure did not occur immediately, contamination risk increased due to trapped residues.

Therefore, fine surface finishing enhances not only cleanability but also reduces cumulative surface degradation under repetitive cleaning.

Summary Table: Surface Condition Effects on Alumina Rod Performance

| Surface Parameter | Typical Value | Observed Outcome |

|---|---|---|

| Surface roughness Ra (µm) | <0.6 | Low residue adhesion |

| As-sintered Ra (µm) | >1.2 | Rapid fouling |

| Cleaning cycle tolerance | >1200 cycles | Stable fine-ground surfaces |

| Residue accumulation rate | −40–50% | With improved finish |

| Micro-pitting onset | 400–500 cycles | On coarse surfaces |

Despite careful material selection and controlled processing, failures still occur when Alumina Rods operate in chemically aggressive fixtures. Consequently, examining real failure modes clarifies where design and integration most often break down.

Failure Modes Observed in Chemical Processing Fixtures

Alumina Rod failures in chemical processing fixtures reveal how chemical exposure, mechanical stress, and geometry interact, therefore failure analysis provides guidance for preventive design.

In chemical plants, failures rarely stem from a single cause. Instead, they develop through cumulative interaction between surface degradation, stress concentration, and operational cycling. Consequently, recognizing dominant failure pathways allows engineers to intervene before functional loss occurs.

Field investigations across reactors, mixers, and sampling systems consistently show repeatable patterns rather than random breakage. Therefore, understanding these patterns is essential for reliable specification.

Chemical Assisted Fracture and Degradation

Chemical assisted fracture occurs when corrosive media weaken surface bonds at stressed locations. Although alumina remains chemically stable in many environments, exposure to hot alkaline solutions or mixed media can accelerate crack growth at existing microdefects.

In one dosing fixture, rods subjected to 3% NaOH at 85 °C exhibited crack extension rates nearly 2× higher than identical rods in neutral conditions. Fracture surfaces revealed smooth initiation zones near stressed contact edges rather than bulk material failure.

As a result, chemical exposure often acts as an accelerant, reducing tolerance for assembly stress and thermal cycling rather than directly dissolving the ceramic.

Combined Wear Corrosion Failure

Wear corrosion represents a synergistic mechanism where abrasion removes protective surface layers, allowing chemicals to penetrate newly exposed microstructures. This effect is especially pronounced in slurry-handling fixtures.

Operational data from filtration systems showed that rods exposed to abrasive slurry and periodic acidic cleaning lost 0.10–0.15 mm diameter within 800–1,000 hours, compared to less than 0.04 mm in abrasion-only conditions. Subsequently, clearance drift triggered vibration and secondary cracking.

Therefore, wear and corrosion must be evaluated together, because isolated testing underestimates real fixture degradation.

Summary Table: Common Failure Modes of Alumina Rods in Chemical Fixtures

| Failure Mode | Primary Trigger | Typical Onset Indicator |

|---|---|---|

| Edge chipping | Assembly stress and sharp geometry | Visible microcracks at ends |

| Chemical assisted fracture | Hot alkaline or mixed media | Crack growth at contact zones |

| Wear corrosion | Slurry abrasion plus cleaning | Progressive diameter loss |

| Thermal shock cracking | Rapid cleaning temperature change | Radial surface cracks |

| Residue-induced binding | Surface roughness and fouling | Restricted movement or seizure |

After individual failure mechanisms are understood, attention must shift toward how Alumina Rods behave as part of a larger assembly. Consequently, integration with surrounding components becomes the next reliability boundary.

Integration With Chemical Equipment Assemblies

Alumina Rod performance in chemical processing fixtures depends on assembly integration, because interaction with metals, seals, and tolerances often governs long-term stability.

Alumina Rods rarely operate in isolation. Instead, they interface with metallic housings, polymer seals, and fasteners that expand, vibrate, and age differently under chemical exposure. Therefore, system-level integration determines whether ceramic advantages are preserved or undermined.

Field data indicate that many rod failures originate at interfaces rather than within the rod body. Consequently, integration design deserves equal priority to material selection.

Interaction With Metal Components and Seals

When Alumina Rods contact metal parts, differential thermal expansion creates cyclic interface stress. Typical coefficients of thermal expansion differ by 30–60% between alumina and stainless steel, which can preload rods during heating.

In one valve fixture, rigid metal clamps induced axial stress exceeding 18 MPa during temperature ramps above 90 °C, leading to crack initiation within six months. Introducing compliant seals reduced stress by over 40%, eliminating repeat failures.

Therefore, compliant interfaces and controlled contact pressure are essential when integrating Alumina Rods with metals in chemical environments.

Assembly Clearance and Alignment Considerations

Clearance directly affects vibration, impact, and thermal freedom. Excessive clearance allows movement that accelerates wear, while insufficient clearance restricts expansion and induces stress.

Assembly trials show that axial clearance of 0.2–0.4 mm and radial clearance of 0.10–0.20 mm minimized fracture and wear under vibration frequencies below 25 Hz. Outside this range, fracture incidence increased by approximately 30–45% during the first year of operation.

As a result, assembly tolerances must be specified according to operating temperature range, vibration spectrum, and cleaning protocol rather than generic fit standards.

Summary Table: Assembly Integration Parameters Affecting Alumina Rods

| Integration Parameter | Typical Value | Reliability Effect |

|---|---|---|

| CTE mismatch (Al₂O₃ vs steel) | 30–60% | Cyclic interface stress |

| Axial clearance (mm) | 0.2–0.4 | Thermal freedom |

| Radial clearance (mm) | 0.10–0.20 | Vibration control |

| Interface stress reduction | >40% | With compliant sealing |

| Failure reduction timeline | <12 months | Improved integration |

Once integration limits are understood, engineers often reassess whether Alumina Rods remain the most suitable option compared with other technical ceramics. Consequently, material comparison helps clarify realistic substitution boundaries.

Comparison With Alternative Ceramic Materials

Alumina Rod selection in chemical processing fixtures is frequently compared with alternative ceramics, because corrosion, wear, and cost pressures drive material reassessment.

Alumina Rods are commonly evaluated against silicon carbide, zirconia, and mullite when fixtures operate under corrosive or abrasive conditions. However, material substitution rarely delivers uniform improvement across all performance dimensions. Instead, each alternative introduces a different balance of chemical stability, mechanical behavior, and manufacturability.

Silicon Carbide (SiC) offers superior hardness and abrasion resistance. Nevertheless, in strongly alkaline environments, SiC can experience accelerated surface oxidation above 90 °C, and its higher stiffness increases sensitivity to assembly misalignment. In several slurry fixtures, SiC rods showed lower wear but higher fracture incidence under vibration compared to alumina.

Zirconia Ceramics provide higher fracture toughness, which improves resistance to mechanical shock. However, zirconia exhibits reduced chemical stability in certain acidic and alkaline environments and undergoes phase-related property shifts with prolonged thermal cycling. In mixed chemical service, zirconia rods showed surface degradation after 6–9 months, whereas alumina remained dimensionally stable.

Mullite and Porous Ceramics deliver lower cost and lower thermal conductivity, yet their flexural strength is typically 25–40% lower than dense alumina. As a result, they are rarely suitable for load-bearing chemical fixtures where alignment must be preserved.

Therefore, Alumina Rods remain the most balanced choice when chemical stability, dimensional control, and integration reliability must coexist within the same fixture.

After material selection is confirmed, chemical plants must plan how Alumina Rods will be maintained and replaced over long operating cycles. Consequently, maintenance strategy influences both uptime and fixture consistency.

Maintenance and Replacement Strategy in Chemical Plants

Alumina Rod use in chemical processing fixtures requires predictable maintenance planning, because replacement timing and dimensional consistency directly affect operational stability.

-

Planned Replacement Based on Wear and Exposure

Alumina Rods are typically replaced based on dimensional drift rather than catastrophic failure. In slurry or mixed-chemical fixtures, plants often schedule inspection after 800–1,200 operating hours, replacing rods once diameter loss exceeds 0.1 mm. This approach prevents secondary damage to metal housings and seals. -

Spare Part Consistency and Interchangeability

Consistent rod geometry and surface finish are critical for spare parts. Facilities relying on uncontrolled substitutes reported alignment deviation exceeding 0.3 mm after replacement, leading to vibration and accelerated wear. Therefore, maintaining identical specifications across batches reduces commissioning risk. -

Downtime Reduction Through Predictable Lifecycle

Plants that tracked Alumina Rod exposure conditions achieved 20–30% fewer unplanned stoppages by replacing rods during scheduled shutdowns. This strategy shifts maintenance from reactive to preventive, especially in corrosive environments where failure signals are subtle.

Subsequently, reliable maintenance planning depends on stable manufacturing quality and the ability to reproduce identical rods over multiple production cycles.

After lifecycle and maintenance considerations are clarified, many chemical equipment manufacturers recognize that standard Alumina Rods cannot fully resolve fixture-specific constraints. Consequently, engineering customization becomes the decisive step.

Engineering Customization With ADCERAX

Alumina Rod customization for chemical processing fixtures enables precise control of geometry, surface condition, and integration, therefore tailored engineering directly improves long-term reliability.

Chemical processing fixtures rarely share identical operating conditions. Instead, variations in media composition, temperature gradients, cleaning protocols, and assembly constraints demand application-specific Alumina Rod designs rather than generic stock components. Consequently, customization is not an upgrade option but a practical requirement for stable operation.

At ADCERAX, customization begins with fixture function rather than nominal dimensions. For example, when a rod acts as a spacer near aggressive cleaning zones, chamfer geometry, surface roughness, and tolerance window are optimized together. In one reactor fixture project, adjusting end chamfers from 0.5 mm to 1.2 mm and tightening Ra to ≤0.6 µm extended service life by over 2× under identical CIP conditions.

Engineering support further addresses integration challenges. By reviewing mating materials, assembly preload, and thermal expansion paths, ADCERAX recommends clearance and finishing strategies that reduce interface stress by 30–40%. As a result, Alumina Rods remain dimensionally stable even after repeated thermal and chemical cycling.

Customization is supported by a one-stop workflow, including material selection, precision forming, controlled sintering, surface finishing, dimensional inspection, and batch-to-batch traceability. Therefore, chemical equipment manufacturers can rely on consistent rod behavior across prototypes, production fixtures, and long-term spare parts without redesign.

Summary Table: ADCERAX Customization Parameters for Chemical Fixtures

| Customization Aspect | Typical Range | Engineering Benefit |

|---|---|---|

| Diameter tolerance (mm) | ±0.05–0.10 | Assembly stress control |

| End chamfer radius (mm) | 1.0–1.5 | Crack and chip reduction |

| Surface roughness Ra (µm) | ≤0.6 | Reduced residue adhesion |

| Length repeatability (mm) | ±0.10 | Fixture alignment stability |

| Batch consistency | ≥99% dimensional match | Predictable maintenance |

After customization pathways are established, the discussion naturally converges toward how Alumina Rods should be evaluated as long-term structural elements rather than consumable ceramic parts.

Closing Perspective on Alumina Rods in Chemical Processing Fixtures

Ultimately, Alumina Rod performance in chemical processing fixtures reflects system-level decisions, because material selection, geometry control, and integration discipline collectively shape operational reliability.

Alumina Rods succeed in chemical processing fixtures not because they are universally inert, but because their chemical stability, mechanical predictability, and manufacturability align with real plant constraints. Moreover, when rods are treated as engineered structural components rather than generic ceramic stock, failure rates decline sharply.

Across corrosive media, abrasive slurries, and repeated cleaning cycles, the most reliable installations share common traits: conservative geometry, controlled surface condition, and allowance for thermal and assembly freedom. Therefore, Alumina Rods function best when design intent explicitly accounts for exposure history rather than nominal operating conditions.

In essence, Alumina Rods remain one of the few ceramic materials capable of delivering repeatable structural performance in chemically aggressive environments, provided that engineering discipline governs their specification and lifecycle management.

Conclusion

In conclusion, Alumina Rod reliability in chemical processing fixtures emerges from balanced design rather than isolated material properties, therefore disciplined geometry, surface control, and integration determine long-term success.

If your chemical processing fixture requires stable performance under corrosive, abrasive, or thermally cycled conditions, ADCERAX provides engineering-led Alumina Rod customization aligned with real operating constraints.

Share your drawings or application details to receive targeted technical recommendations.

FAQ

Q1: Can Alumina Rods withstand long-term exposure to both acids and cleaning chemicals?

Yes. Alumina Rods remain chemically stable in most acidic environments below 100 °C. However, hot alkaline cleaning requires controlled exposure and optimized surface finish to preserve dimensional stability.

Q2: What causes Alumina Rods to fail prematurely in chemical fixtures?

Most failures result from stress concentration, improper assembly clearance, or combined wear–corrosion effects rather than direct chemical dissolution.

Q3: How often should Alumina Rods be replaced in slurry-handling equipment?

Replacement is typically scheduled after 800–1,200 operating hours or when diameter loss exceeds 0.1 mm, depending on particle size and flow velocity.

Q4: Why is customization important instead of using standard Alumina Rod sizes?

Chemical fixtures impose unique load paths, cleaning cycles, and integration constraints. Custom geometry and surface control significantly extend service life and reduce unplanned downtime.

References:

-

Discover detailed studies on ethanol's effects on alumina rods to better understand their compatibility and long-term durability in various applications. ↩

-

Discover how acetone interacts with alumina rods to ensure safe and effective use in your laboratory or industrial applications. ↩

-

Learn about chlorinated solvents, their properties, and why they don't affect alumina rods, helping you choose the right materials for chemical resistance. ↩