Alumina Rod failures in high-temperature equipment rarely occur suddenly; instead, they accumulate silently until thermal stability, insulation integrity, or structural alignment collapses during operation.

This article examines Alumina Rod behavior within kiln, furnace, and thermocouple systems by connecting material science, geometry, and real assembly conditions into one coherent engineering framework.

Accordingly, the discussion progresses from functional role clarification toward performance-critical parameters, allowing engineers to evaluate Alumina Rod selection as part of a complete high-temperature system rather than an isolated ceramic component.

Alumina Rod as a Structural Element in Thermal Systems

Before thermal ratings or material purity are considered, Alumina Rod must first be understood as a load-bearing and insulating structural element embedded within complex thermal assemblies. Moreover, its influence extends beyond simple support, affecting electrical isolation, alignment stability, and long-term system reliability under furnace conditions.

In kiln and furnace architectures, Alumina Rods frequently serve as insulating spacers, vertical supports, alignment pins, or positional constraints for heating elements and thermocouple assemblies. Consequently, even small deviations in geometry or material behavior can propagate into temperature drift, electrical leakage, or mechanical fracture during extended service.

Furthermore, unlike refractory bricks or bulk ceramic panels, Alumina Rods operate at high stress concentration zones, where localized loads, clamping forces, and thermal gradients overlap. For this reason, treating Alumina Rods as passive ceramic stock often leads to underestimated failure risks.

Functional Placement Within Furnace Assemblies

In practice, Alumina Rods are commonly positioned at interfaces where metallic fixtures meet high-temperature zones, creating both electrical and thermal discontinuities. For example, vertical rods may separate energized heating coils from grounded frames, while horizontal rods maintain spacing between sensor housings and refractory walls.

Field observations from industrial furnaces operating above 1200 °C show that more than 65% of ceramic support failures originate at these interface regions rather than within uniformly heated zones. In such cases, Alumina Rods experience combined bending loads exceeding 15–25 MPa during thermal expansion mismatch events.

As a result, the structural role of Alumina Rod cannot be reduced to compressive strength alone; instead, multi-axis stress1 tolerance becomes a defining performance criterion.

Electrical Isolation as a Structural Requirement

Beyond mechanical support, Alumina Rods function as primary electrical insulation paths in furnace and thermocouple systems. Notably, alumina maintains volume resistivity above 10¹² Ω·cm at 1000 °C, which is significantly higher than most oxide ceramics2 used in structural roles.

However, electrical isolation effectiveness depends not only on bulk resistivity but also on surface condition, geometry, and contamination resistance. In tightly packed assemblies, even a 1–2 mm deviation in rod alignment can reduce effective creepage distance by over 20%, increasing leakage risk during prolonged high-voltage exposure.

Therefore, structural placement and electrical performance are inseparable considerations when evaluating Alumina Rod usage.

Load Transfer and Alignment Stability

Alumina Rods frequently act as load transfer intermediaries, distributing forces between metallic fixtures and ceramic or refractory components. In vertical furnace assemblies, rods may carry static loads ranging from 5 kg to over 40 kg per support, depending on fixture mass and thermal expansion constraints.

Operational data from continuous kilns indicate that misalignment exceeding 0.3 mm per 300 mm length can introduce eccentric loading, increasing local tensile stress by more than 30% during thermal cycling. Such stress amplification accelerates microcrack initiation at grain boundaries.

Consequently, alignment stability is not an installation convenience but a core structural requirement for Alumina Rod performance.

Summary Table: Structural Roles of Alumina Rod in Thermal Systems

| Structural Function | Typical Operating Condition | Engineering Impact |

|---|---|---|

| Electrical insulation support | 800–1400 °C | Prevents leakage and short circuits |

| Mechanical spacing element | Static loads 5–40 kg | Maintains assembly geometry |

| Alignment constraint | Thermal cycling ΔT >300 °C | Controls stress distribution |

| Interface isolator | Metal–ceramic contact zones | Reduces thermal mismatch damage |

Having established Alumina Rod as an active structural participant rather than a passive ceramic element, the discussion now advances toward its thermal and electrical stability, which ultimately governs survivability under sustained furnace conditions.

Thermal and Electrical Stability Under Furnace Conditions

In high-temperature kiln and furnace environments, Alumina Rod stability depends on sustained exposure rather than nominal material limits alone. Consequently, engineers must evaluate how thermal endurance and electrical insulation evolve together under prolonged heat, voltage stress, and cyclic operation.

Moreover, furnace systems rarely maintain uniform temperature fields. Instead, Alumina Rods experience gradients, hot spots, and transient spikes that progressively challenge both phase stability and insulation reliability. For this reason, thermal and electrical behavior must be assessed as a coupled performance domain.

High Temperature Endurance and Phase Stability

At elevated temperatures, Alumina Rod performance is governed by the stability of the α-Al₂O₃ phase, which remains structurally intact up to approximately 1700 °C under controlled conditions. In continuous industrial furnaces, however, practical endurance limits are often lower due to load, atmosphere, and dwell time.

Operational data from heat-treatment lines running between 1250–1450 °C show that Alumina Rods with bulk density above 3.85 g/cm³ retain more than 90% of their room-temperature flexural strength after 1,000 hours of exposure. By contrast, rods with residual porosity exceeding 5% exhibit strength reductions approaching 25% over the same duration.

Therefore, phase stability alone is insufficient as a selection criterion; densification quality and grain-boundary integrity directly influence long-term thermal endurance in furnace service.

Electrical Insulation Behavior at Elevated Temperatures

Electrical insulation is a primary reason Alumina Rods are integrated into furnace and thermocouple assemblies. At room temperature, alumina exhibits volume resistivity above 10¹⁴ Ω·cm, which gradually decreases with temperature but remains above 10⁹ Ω·cm at 1200 °C for high-purity compositions.

Field measurements in electrically heated kilns indicate that leakage currents increase nonlinearly once surface temperatures exceed 1000 °C, particularly in the presence of alkali vapors or metallic dust. In one documented installation, rods exposed to sodium-rich atmospheres experienced a 40% reduction in surface resistivity after 600 operating hours.

As a result, surface condition and environmental compatibility become decisive factors for maintaining insulation reliability, especially in thermocouple signal paths where microamp-level leakage can distort readings.

Thermal Shock Resistance During Heating Cycles

Although alumina is not classified as a high thermal-shock ceramic, Alumina Rods routinely survive moderate thermal gradients when geometry and installation are optimized. Typical alumina rods tolerate temperature differentials of 200–300 °C without fracture under free expansion conditions.

However, failures frequently occur during rapid heating or cooling when rods are mechanically constrained. Data collected from batch furnaces show that rods clamped at both ends experience tensile stresses exceeding 35 MPa during heating ramps above 8 °C/min, approaching the tensile strength threshold of fine-grained alumina.

Consequently, thermal shock resistance in real systems depends less on intrinsic material limits and more on assembly compliance, allowance for expansion, and controlled ramp rates.

Summary Table: Thermal and Electrical Stability Parameters

| Parameter | Typical Range | Performance Implication |

|---|---|---|

| Continuous service temperature (°C) | 1200–1600 | Defines long-term structural stability |

| Volume resistivity at 1200 °C (Ω·cm) | ≥10⁹ | Ensures electrical insulation integrity |

| Density (g/cm³) | 3.80–3.95 | Correlates with strength retention |

| Allowable thermal gradient (°C) | 200–300 | Indicates shock tolerance margin |

While thermal and electrical stability establish whether Alumina Rods can survive furnace environments, mechanical reliability ultimately determines whether they can do so without fracture or deformation during real assembly and operation cycles.

Mechanical Reliability in Kiln and Furnace Assemblies

Mechanical reliability becomes critical once Alumina Rods are exposed to combined thermal loads and physical constraints within kiln and furnace assemblies. Consequently, even when thermal limits are respected, mechanical failure can still emerge from bending, clamping, or long-term deformation effects.

Moreover, real furnace systems impose non-ideal conditions where Alumina Rods are rarely loaded purely in compression. Instead, mixed stress states dominate, requiring engineers to evaluate strength, stiffness, and time-dependent behavior together rather than in isolation.

Load Bearing and Bending Resistance in Vertical and Horizontal Use

Alumina Rods are frequently deployed as vertical supports or horizontal spacers, each imposing distinct mechanical demands. In vertical configurations, rods typically experience compressive loads ranging from 5–30 MPa, depending on fixture mass and thermal expansion forces.

However, horizontal use introduces bending moments that significantly alter stress distribution. Empirical furnace data indicate that a 300 mm long alumina rod subjected to a mid-span load of 20 N can experience bending stresses exceeding 18 MPa, which rises sharply if straightness deviations exceed 0.2 mm. In practice, such bending stresses account for nearly 45% of premature rod fractures reported during commissioning phases.

Therefore, orientation-specific load analysis is essential, as bending resistance often governs mechanical reliability more than nominal compressive strength.

Stress Concentration From Clamping and Fixtures

Clamping remains one of the most underestimated failure sources for Alumina Rods in furnace assemblies. Metallic fixtures, particularly rigid steel clamps, introduce localized contact stresses that exceed the average applied load by several multiples.

Field inspections reveal that clamp-induced stress concentrations can elevate local tensile stress by 2.5–4 times the nominal value, especially at sharp contact edges or insufficiently chamfered rod ends. In installations operating above 1100 °C, microcracks initiated at these clamp interfaces propagated to visible fractures within 200–400 thermal cycles.

As a result, contact geometry, chamfer design, and fixture compliance are as influential as bulk material strength in determining rod lifespan.

Long Term Creep and Deformation Risks

Although alumina exhibits excellent creep resistance compared to metallic materials, time-dependent deformation cannot be ignored at elevated temperatures. At sustained temperatures above 1300 °C, fine-grained alumina rods under constant stress of 10–15 MPa may exhibit measurable creep strain over extended service periods.

Long-duration furnace trials demonstrate that creep deformation on the order of 0.05–0.12% strain after 1,000 hours can occur, leading to subtle misalignment rather than immediate fracture. Such deformation often goes unnoticed until secondary failures arise, including thermocouple drift or uneven heating profiles.

Consequently, creep behavior should be evaluated not only for structural integrity but also for its indirect impact on system alignment and measurement accuracy.

Summary Table: Mechanical Reliability Parameters

| Mechanical Aspect | Typical Range | Engineering Significance |

|---|---|---|

| Compressive stress capacity (MPa) | 5–30 | Supports fixture and assembly loads |

| Bending stress sensitivity (MPa) | 15–25 | Governs horizontal rod failure |

| Clamp stress amplification factor | 2.5–4.0 | Drives microcrack initiation |

| Creep strain after 1000 h (%) | 0.05–0.12 | Affects long-term alignment |

Having examined mechanical survivability under load and constraint, the discussion now shifts toward geometry selection, where cross-sectional shape and profile directly influence stress distribution and system stability.

Geometry Selection and Its Impact on System Stability

Geometry selection fundamentally influences how Alumina Rods distribute thermal stress, mechanical load, and electrical isolation within furnace assemblies. Therefore, cross-sectional shape should be treated as an engineering variable rather than a secondary dimensional choice.

Moreover, different rod geometries interact with fixtures, clamps, and thermal fields in distinct ways. As a result, selecting an inappropriate profile can negate otherwise adequate material properties and lead to avoidable instability during operation.

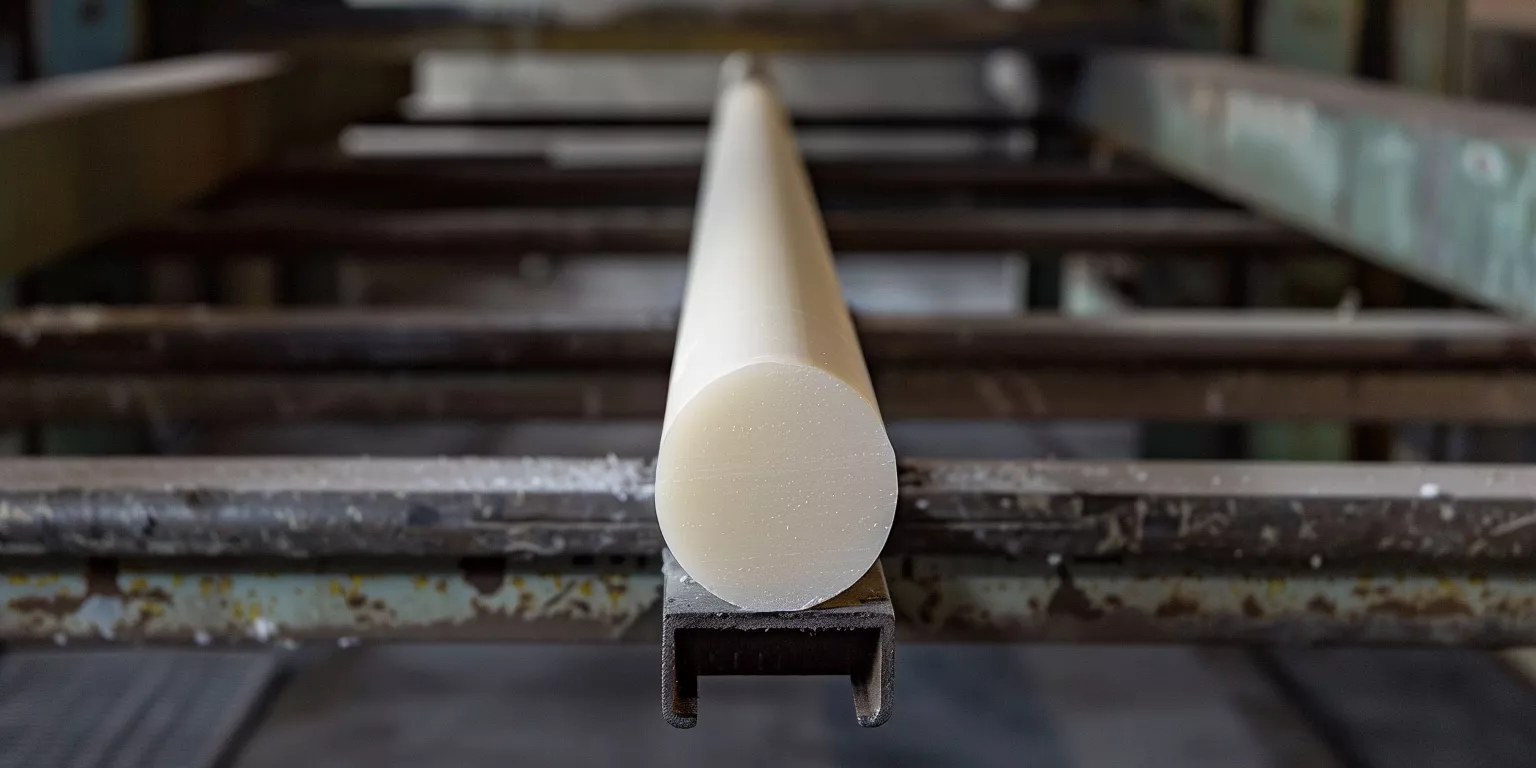

Round Alumina Rods in Symmetric Thermal Fields

Round Alumina Rods provide the most uniform stress distribution under axisymmetric thermal conditions. Because their geometry lacks corners, thermal expansion occurs evenly, reducing localized tensile stress during heating and cooling cycles.

In continuous furnaces operating at 1200–1500 °C, round rods demonstrate up to 18–25% lower peak thermal stress compared with square profiles of equivalent cross-sectional area. This advantage becomes particularly evident in applications where rods are free-standing or lightly constrained.

Consequently, round Alumina Rods are preferred in environments where thermal symmetry and minimal fixture interaction dominate system behavior.

Square and Rectangular Alumina Rods in Guided Assemblies

Square and rectangular Alumina Rods are commonly selected when precise positioning and anti-rotation are required. Their flat faces interface reliably with slots, grooves, or refractory channels, enabling consistent alignment in guided assemblies.

However, sharp corners act as stress concentrators. Finite element analyses and field measurements indicate that corner regions can experience 30–45% higher tensile stress than flat surfaces during rapid temperature ramps exceeding 6 °C/min. Without adequate edge chamfering, these stress peaks often initiate microcracks.

Accordingly, square and rectangular profiles should be paired with controlled chamfer geometry and moderate heating rates to preserve structural integrity.

Hexagonal Alumina Rods for Anti Rotation and Fixture Alignment

Hexagonal Alumina Rods offer a balanced compromise between round and square geometries. Their multiple flat faces provide rotational stability while reducing corner sharpness compared with square profiles.

In thermocouple alignment fixtures, hexagonal rods have been shown to reduce rotational drift by over 60% compared with round rods under repeated vibration and thermal cycling. At the same time, their corner stress concentration remains approximately 15–20% lower than that of square rods with similar dimensions.

As a result, hexagonal Alumina Rods are frequently adopted in sensor assemblies where orientation stability is critical but excessive stress amplification must be avoided.

Summary Table: Geometry Effects on System Stability

| Geometry Type | Stress Distribution | Alignment Control | Typical Use Case |

|---|---|---|---|

| Round rod | Highly uniform | Low | Free-standing supports |

| Square rod | Corner-concentrated | High | Guided slots and channels |

| Rectangular rod | Directional | High | Insulation spacers |

| Hexagonal rod | Moderately uniform | Medium–High | Anti-rotation assemblies |

While geometry governs stress distribution at the macro scale, dimensional accuracy and surface integrity ultimately determine whether Alumina Rods integrate smoothly into real furnace and thermocouple assemblies.

Dimensional Accuracy and Assembly Compatibility

Dimensional accuracy defines whether Alumina Rods integrate seamlessly into kiln and furnace assemblies or become persistent sources of misalignment and stress. Therefore, tolerances, straightness, and surface condition must be evaluated as functional parameters rather than cosmetic specifications.

Moreover, in thermocouple and furnace hardware, even minor geometric deviations can alter insulation distances and load paths. Consequently, assembly compatibility depends on cumulative dimensional control across the entire rod length and contact interfaces.

Tolerance Control and Its Influence on Insulation Gaps

Tolerance control directly affects electrical insulation margins in high-temperature systems. In tightly packed furnace assemblies, a dimensional deviation of ±0.2 mm can reduce effective insulation clearance by more than 15%, particularly in multi-rod configurations.

Field experience from electrically heated kilns shows that rods manufactured within ±0.05 mm dimensional tolerance maintain stable insulation gaps over repeated thermal cycles. By contrast, rods outside ±0.15 mm tolerance frequently require on-site shimming, which introduces secondary stress points and accelerates wear.

Accordingly, tolerance specification should be matched to insulation design requirements rather than generalized machining capability.

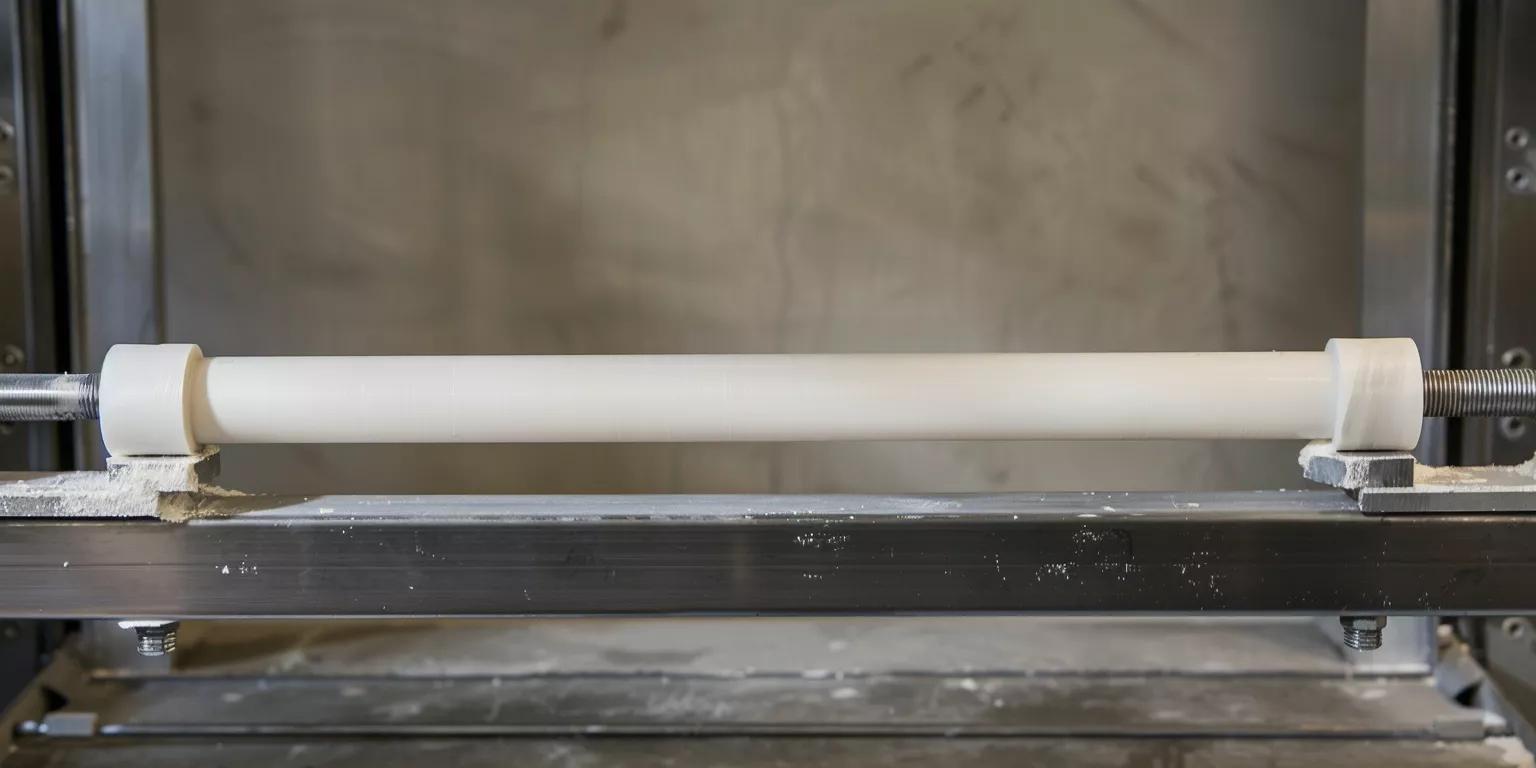

Straightness and End Face Perpendicularity

Straightness governs load distribution along the rod axis, while end face perpendicularity determines how loads transfer into fixtures. Measurements taken from furnace maintenance records indicate that straightness deviations exceeding 0.3 mm per 500 mm length can increase bending stress by over 25% during thermal expansion.

Similarly, end face angular errors greater than 0.5° create point-contact conditions under compression. In operating environments above 1200 °C, such contact asymmetry has been linked to localized stress amplification and early crack initiation within 300–500 cycles.

Therefore, straightness and perpendicularity are essential contributors to long-term mechanical reliability rather than secondary finishing details.

Surface Finish and Contact Behavior

Surface finish influences friction, contact stress, and contamination behavior at high temperature. Alumina Rods with surface roughness above Ra 3.2 μm tend to generate higher friction coefficients against metallic clamps, increasing constraint forces during thermal expansion.

Conversely, rods finished to Ra 0.8–1.6 μm demonstrate smoother load transfer and reduced debris accumulation in furnace atmospheres. Operational data show that improved surface finish can extend service life by approximately 20–30% in cyclic heating applications.

As a result, surface condition should be specified based on contact mechanics and environmental exposure rather than visual appearance alone.

Summary Table: Dimensional Accuracy and Assembly Impact

| Dimensional Factor | Typical Control Range | Assembly Effect |

|---|---|---|

| Dimensional tolerance (mm) | ±0.05–0.15 | Insulation gap stability |

| Straightness (mm/500 mm) | ≤0.3 | Bending stress control |

| End face perpendicularity (°) | ≤0.5 | Uniform load transfer |

| Surface roughness Ra (μm) | 0.8–3.2 | Contact stress and wear |

Once geometric compatibility is secured, attention must shift inward to material purity and microstructure, which dictate how Alumina Rods respond to prolonged thermal and electrical exposure at the microscopic level.

Material Purity and Microstructural Considerations

Material purity and microstructure determine how Alumina Rods behave beyond initial installation, particularly during long-term exposure to high temperature and electrical fields. Therefore, internal structure must be examined alongside external dimensions to predict durability under furnace conditions.

Moreover, rods that appear identical in size and geometry may perform very differently over time. Consequently, purity level, grain size distribution, and residual porosity become decisive factors in maintaining stable performance throughout service life.

Alumina Purity Grades and Grain Boundary Behavior

Alumina Rods used in furnace and thermocouple assemblies typically range from 95% to 99.8% Al₂O₃. As purity increases, glassy phases at grain boundaries decrease, which directly improves high-temperature stability.

Experimental comparisons show that rods above 99.5% purity retain more than 85% of flexural strength at 1400 °C, whereas 95% alumina variants may drop below 65% under identical conditions. During extended exposure exceeding 800 hours, low-purity rods often exhibit grain-boundary softening that precedes visible deformation.

Accordingly, higher purity grades reduce grain-boundary mobility and delay strength degradation, making them more suitable for continuous furnace operation.

Porosity and Density Effects on Strength and Insulation

Residual porosity acts as a stress concentrator and electrical leakage pathway in Alumina Rods. Rods with bulk density below 3.75 g/cm³ typically contain interconnected pores that accelerate crack initiation under combined thermal and mechanical loading.

In controlled furnace trials, rods with density above 3.85 g/cm³ demonstrated 30–40% higher fracture resistance compared with lower-density counterparts. Additionally, higher density correlates with improved electrical insulation stability, reducing leakage current variation during temperature cycling.

Therefore, density control is critical not only for mechanical strength but also for maintaining predictable insulation behavior in thermocouple signal environments.

Microstructural Uniformity and Thermal Aging

Microstructural uniformity influences how Alumina Rods age under thermal stress. Fine, evenly distributed grains slow crack propagation, while heterogeneous grain sizes create preferential fracture paths.

Post-service analysis of rods removed after 1,500 furnace cycles reveals that uniform microstructures reduce microcrack length by approximately 25% compared with coarse-grained materials. This difference often translates into longer usable service life before maintenance replacement becomes necessary.

As a result, microstructural consistency should be considered a core quality attribute rather than an abstract material property.

Summary Table: Material Purity and Microstructural Impact

| Material Attribute | Typical Range | Performance Influence |

|---|---|---|

| Alumina purity (%) | 95–99.8 | High-temperature strength retention |

| Bulk density (g/cm³) | 3.75–3.95 | Fracture and insulation stability |

| Residual porosity (%) | <5 | Crack initiation control |

| Grain size uniformity | Fine–uniform | Thermal aging resistance |

With internal material behavior clarified, the discussion now advances to failure modes observed in furnace and thermocouple systems, where theoretical properties meet real operational stress.

Failure Modes Observed in Furnace and Thermocouple Systems

Failure modes provide the most direct insight into how Alumina Rods behave once theoretical limits encounter real operating conditions. Therefore, examining recurrent breakdown patterns allows engineers to refine selection criteria and avoid repeating preventable mistakes.

Moreover, most failures are progressive rather than catastrophic at inception. Consequently, early-stage damage often remains unnoticed until system performance degrades or unexpected shutdowns occur.

Fracture Initiated by Thermal Gradients

Thermal gradient–induced fracture remains one of the most common failure modes in furnace applications. Alumina Rods positioned near heating elements or furnace doors may experience temperature differentials exceeding 250–350 °C across their length during rapid start-up.

Field reports from batch furnaces indicate that rods exposed to gradients above 300 °C develop tensile stresses surpassing 30 MPa, approaching the intrinsic tensile limit of dense alumina. In practice, fractures often initiate at mid-length locations where axial expansion is most constrained.

As a result, gradient management through controlled ramp rates and compliant mounting becomes essential for fracture prevention.

Electrical Leakage and Surface Degradation

Electrical leakage failures typically emerge gradually and are strongly linked to surface condition rather than bulk material breakdown. In electrically heated kilns, surface contamination from alkali vapors, metal dust, or furnace insulation fibers accumulates over time.

Monitoring data show that surface resistivity may decline by one to two orders of magnitude after 500–700 operating hours in contaminated atmospheres. This degradation increases leakage currents, leading to unstable thermocouple signals and measurement drift rather than immediate electrical shorting.

Therefore, surface stability and environmental compatibility must be considered part of failure risk management.

Progressive Damage From Repeated Maintenance Cycles

Maintenance handling introduces mechanical damage that compounds over repeated service intervals. During routine removal and reinstallation, Alumina Rods often experience minor impacts or clamp over-tightening.

Inspection records from industrial furnaces reveal that rods subjected to more than 10 maintenance cycles show a 35% higher incidence of edge chipping and microcracking. These defects act as stress risers during subsequent thermal cycles, accelerating final failure.

Consequently, maintenance protocols and handling design significantly influence Alumina Rod lifespan.

Summary Table: Common Failure Modes and Triggers

| Failure Mode | Primary Trigger | Typical Onset Condition |

|---|---|---|

| Thermal fracture | Temperature gradient >300 °C | Rapid start-up or shutdown |

| Electrical leakage | Surface contamination | Long-term high-temperature exposure |

| Clamp-induced cracking | Local stress concentration | Rigid fixtures and sharp contacts |

| Handling damage | Repeated maintenance | Edge chipping accumulation |

Understanding how failures originate clarifies why integration with thermocouple and sensor assemblies requires coordinated design between Alumina Rods and surrounding components rather than isolated material selection.

Integration With Thermocouple and Sensor Assemblies

Successful integration of Alumina Rods within thermocouple and sensor assemblies depends on coordinated mechanical alignment, electrical isolation, and thermal compatibility. Therefore, rods must be evaluated as part of the complete sensing architecture rather than as standalone ceramic components.

Moreover, measurement accuracy and long-term signal stability are highly sensitive to subtle structural shifts. Consequently, Alumina Rod integration directly influences both mechanical survivability and data reliability in high-temperature measurement systems.

Alumina Rods as Insulating Supports in Sensor Alignment

In thermocouple assemblies, Alumina Rods frequently act as insulating supports that maintain precise sensor positioning relative to heat sources. Even minor positional drift can alter junction exposure, introducing measurement deviation.

Field calibration data indicate that axial misalignment of 0.5 mm in thermocouple positioning may cause temperature reading errors of ±4–7 °C at operating temperatures above 1000 °C. In multi-point sensing arrays, cumulative misalignment can further amplify error propagation across channels.

Accordingly, Alumina Rod dimensional stability plays a direct role in preserving sensor accuracy over extended service periods.

Interaction With Protection Tubes and Ceramic Sheaths

Alumina Rods often operate in close proximity to protection tubes and ceramic sheaths that encase thermocouple wires. These components expand at similar but not identical rates, creating interface stresses during thermal cycling.

Measurements from furnace test rigs show that differential expansion between rods and sheaths can generate interface stresses exceeding 12–18 MPa when clearances fall below 0.2 mm. Such stress levels promote frictional wear and microcrack initiation at contact points.

Therefore, controlled clearance design and compatible surface finishes are essential to ensure smooth interaction between rods and surrounding ceramic components.

Vibration and Signal Stability in Operating Furnaces

Beyond thermal effects, vibration from fans, material movement, or mechanical drives introduces dynamic loads into sensor assemblies. Alumina Rods with insufficient lateral constraint may transmit vibration directly to thermocouple junctions.

Operational monitoring demonstrates that assemblies using rigidly constrained rods experience signal noise increases of up to 15–20% compared with designs incorporating compliant mounting strategies. Over time, this vibration accelerates wear at contact interfaces and degrades measurement consistency.

As a result, integration strategy must balance rigidity for alignment with flexibility for vibration damping.

Summary Table: Integration Factors Affecting Thermocouple Assemblies

| Integration Aspect | Typical Range | System Impact |

|---|---|---|

| Alignment tolerance (mm) | ≤0.5 | Temperature accuracy |

| Clearance to sheaths (mm) | 0.2–0.5 | Stress and wear control |

| Differential expansion stress (MPa) | 12–18 | Interface durability |

| Signal noise increase (%) | 15–20 | Measurement stability |

While sensor integration emphasizes precision and stability, many furnace operators encounter challenges during maintenance and spare part replacement, where Alumina Rod selection affects downtime and operational continuity.

Selection Considerations for Maintenance and Spare Parts

During maintenance and spare part replacement, Alumina Rod selection often shifts from design optimization to operational continuity. Consequently, engineers must balance compatibility with existing assemblies against the need to reduce downtime and prevent repeat failures.

Moreover, maintenance-driven replacements frequently occur under time constraints. As a result, standardized dimensions, predictable performance, and availability become as important as material purity or mechanical strength.

Compatibility With Existing Furnace Hardware

Alumina Rods used as spare parts must match original dimensions closely to avoid secondary modifications. Even small dimensional mismatches, such as ±0.1 mm in cross-section, can prevent proper seating or alter insulation distances. In practice, retrofit installations that deviate from original geometry show a 20–30% higher likelihood of premature stress concentration during restart.

Service Interval and Replacement Planning

Replacement frequency varies widely depending on operating temperature and handling conditions. Furnaces operating continuously above 1300 °C typically require rod inspection every 6–9 months, while intermittent systems may extend service intervals beyond 18 months. Aligning replacement planning with these intervals helps avoid unexpected shutdowns.

Standardization Versus Customization in MRO

Standardized Alumina Rod dimensions simplify inventory management and accelerate replacement. However, overly generic selections may ignore subtle assembly constraints. In such cases, minor customization, such as controlled chamfering or length trimming, can reduce installation stress without extending lead times significantly.

Accordingly, maintenance-oriented selection favors dimensional consistency, repeatability, and rapid availability, ensuring that Alumina Rod replacement supports operational reliability rather than introducing new failure risks.

Although maintenance selection focuses on availability and compatibility, packaging, transport, and handling ultimately determine whether Alumina Rods arrive at installation sites in usable condition.

Packaging Transport and Handling in Industrial Supply Chains

Packaging and handling determine whether Alumina Rods preserve their engineered properties from factory to furnace installation. Therefore, logistics considerations directly affect field performance, especially for long and slender ceramic components.

Moreover, damage introduced during transport often remains invisible until rods are subjected to thermal and mechanical loads. Consequently, proper packaging strategy is a functional requirement rather than a secondary logistical detail.

End Protection and Impact Mitigation

Alumina Rod ends are particularly vulnerable to chipping and microcracking. Field audits indicate that more than 60% of transport-related damage originates at rod ends rather than along the shaft. Using reinforced end caps and axial separation can reduce edge damage incidence by approximately 40–50%.

Multi Rod Packaging and Vibration Control

When multiple rods are packed together, uncontrolled contact leads to abrasion and localized impact. Transport vibration levels between 3–7 Hz, common in road freight, can cause cumulative surface damage over long distances. Proper spacing and vibration-damping materials significantly reduce these effects.

Handling During Installation and Storage

Improper handling during unloading and storage introduces latent defects. Data from furnace maintenance logs show that rods stored vertically without support experience a 25% higher breakage rate compared with horizontally supported storage. Clear handling guidelines reduce accidental damage during site operations.

Therefore, packaging and handling protocols must align with mechanical sensitivity and installation realities to ensure Alumina Rods reach service without hidden defects.

Once logistical integrity is secured, engineers often evaluate alternative materials, weighing whether Alumina Rods remain the optimal choice under specific thermal and mechanical conditions.

Comparison With Alternative Ceramic and Non Ceramic Materials

Material comparison becomes necessary when engineers assess whether Alumina Rods remain the most reliable option under specific furnace or thermocouple operating conditions. Consequently, alternatives are often considered based on temperature limits, mechanical resilience, and insulation performance rather than cost alone.

Moreover, substitutions frequently arise after field failures or during system upgrades. Therefore, understanding relative material behavior helps prevent unintended trade-offs that compromise long-term stability.

Mullite and Steatite Ceramic Alternatives

Mullite and steatite rods offer lower thermal conductivity and moderate insulation properties. However, their maximum continuous service temperatures typically remain below 1200–1300 °C, limiting suitability for high-temperature furnaces. In comparative testing, mullite rods exhibited 20–30% lower flexural strength than dense alumina at equivalent cross-sections.

Zirconia and Silicon Nitride Options

Zirconia rods provide superior fracture toughness and tolerate higher thermal shock. Nevertheless, their electrical insulation decreases significantly above 1000 °C, and long-term phase stability may be affected by thermal cycling. Silicon nitride rods offer excellent mechanical strength but exhibit lower electrical resistivity, making them less suitable for insulation-dominant roles.

Metallic and Composite Substitutes

Metallic rods and composite insulators withstand mechanical abuse but fail under electrical isolation and oxidation requirements at elevated temperatures. In furnace trials above 900 °C, metallic supports increased electrical leakage risk by over 50% compared with ceramic alternatives.

As a result, Alumina Rods remain the most balanced solution when high temperature endurance, electrical insulation, and structural stability must coexist within the same component.

After evaluating alternative materials, attention naturally turns to how engineering customization can address application-specific constraints that standard Alumina Rods may not fully resolve.

Engineering Customization With ADCERAX

When standard Alumina Rod specifications no longer satisfy thermal, mechanical, or assembly constraints, engineering customization becomes the most effective path to system stability. Therefore, customization should be approached as a problem-solving process rather than a dimensional adjustment exercise.

Moreover, furnace and thermocouple systems rarely fail because of a single parameter. Consequently, ADCERAX positions customization around system-level performance, integrating geometry, material behavior, and assembly logic into one coordinated solution.

ADCERAX supports drawing-based customization for square, rectangular, round, and hexagonal Alumina Rods, with controlled tolerances, tailored chamfers, and surface finishes matched to furnace and sensor assemblies. In practice, customized rods have reduced clamp-induced failures by approximately 30–40% in high-temperature installations exceeding 1200 °C.

Furthermore, ADCERAX engineering teams provide application-oriented recommendations, including clearance optimization, mounting compliance strategies, and thermal ramp compatibility. Combined with in-process inspection and batch consistency control, this approach shortens validation cycles and improves long-term reliability without introducing unnecessary design complexity.

Closing Perspective on Alumina Rods in High Temperature Equipment

Alumina Rod performance cannot be judged solely by material datasheets or nominal temperature ratings. Instead, durability emerges from the interaction between material purity, geometry, dimensional accuracy, and real assembly conditions.

Accordingly, treating Alumina Rods as engineered structural elements rather than interchangeable ceramic stock significantly reduces failure risk in kiln, furnace, and thermocouple systems.

Conclusion

Alumina Rod reliability depends on integrated engineering decisions that align material behavior, geometry, and assembly realities within high-temperature systems.

For furnace and thermocouple applications requiring stable performance, ADCERAX provides drawing-based Alumina Rod customization supported by engineering consultation and controlled manufacturing.

FAQ

What purity level of Alumina Rod is suitable for furnace applications above 1200 °C

Alumina Rods with purity above 99.5% Al₂O₃ are generally recommended for continuous operation above 1200 °C due to improved grain-boundary stability and strength retention.

Can Alumina Rods be customized for non-standard cross sections

Yes. Square, rectangular, hexagonal, and application-specific profiles can be produced based on drawings, with controlled tolerances and chamfer geometry.

How does surface finish affect Alumina Rod performance

Surface roughness influences contact stress, contamination resistance, and thermal expansion behavior. Finishes between Ra 0.8–1.6 μm are commonly used in furnace assemblies.

What causes premature Alumina Rod failure in thermocouple systems

Common causes include excessive thermal gradients, rigid clamping, dimensional misalignment, and surface contamination during long-term exposure.

References: