Aluminium Nitride (AIN) Ceramic Solutions From a China-Based Manufacturer

We supply industrial-grade aluminium nitride (AlN) ceramic components for high-power, high-temperature, and electrically insulated applications across power electronics, laser modules, RF systems, industrial heating, and precision instruments. Product scope covers AlN substrates, plates, heat spreaders, PCB bases, rings, rods, machined blocks, and custom-shaped parts based on drawings or prototypes.

With factory-direct production, CNC precision processing, tolerance stability, and engineering collaboration, we support standard specifications and customized parts.

✅ Send your drawings or specifications — we help turn concepts into production-ready AlN ceramic parts.

What are Aluminum Nitride (AlN) Ceramics?

Is Aluminum Nitride (AlN) a ceramic?

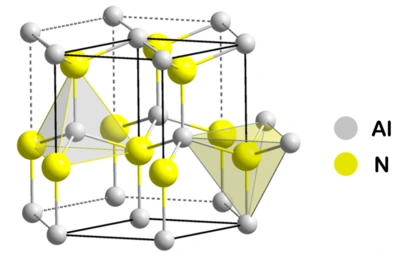

Yes–Aluminium nitride (AlN) is a non-oxide advanced ceramic with a hexagonal wurtzite crystal structure, where Al and N atoms form strong covalent tetrahedral bonding in a highly ordered lattice. It is typically produced through powder synthesis, forming, and high-temperature sintering, resulting in a dense, electrically insulating, and thermally conductive ceramic material suitable for high-power and high-frequency applications.

Aluminium Nitride Ceramic Composites

Ceramic aluminium nitride can be engineered into different composite systems to tailor its thermal, dielectric, mechanical, and cost-performance properties for various industrial conditions. Below are six commonly used AlN composite categories for different design and application requirements.

| Composite Type | Main Added Component | Key Performance Characteristics | Typical Advantages | Typical Applications |

|---|---|---|---|---|

| AlN–SiC | Silicon Carbide (SiC) | Increased strength, stable thermal conductivity, good thermal shock performance | High structural reliability under temperature cycling | Power electronics substrates, heat spreaders, aerospace thermal parts |

| AlN–Al₂O₃ | Alumina (Al₂O₃) | Lower cost, good insulation, easier forming & machining | Balanced cost-performance ratio | Mid-range insulation parts, structural ceramic components |

| AlN–BN | Boron Nitride (BN) | Lower dielectric constant, improved thermal shock & machinability | Radio frequency material friendliness, reduced brittleness | RF components, microwave carriers, thermal management modules |

| AlN–Metal Hybrid (AlN-Cu / AlN-Mo / AlN-W / AMB / DBC) | Copper, Molybdenum, Tungsten, Metal bonding layers | Enhanced heat spreading, solderability & structural bonding | System-level thermal & electrical integration | IGBT baseplates, laser diode carriers, power module heat sinks |

| AlN-Polymer / Resin Composite (Filler) | Polymer matrix + AlN powder | Adjustable viscosity, high dielectric insulation, lightweight | Thermal interface usability & flexible form factor | TIM pads, adhesives, encapsulation, 5G packaging materials |

| Transparent / Optical-Grade AlN Composite | Controlled grain phase & dopants (research level) | Optical transmission, IR-related performance, high purity | Niche, research-driven applications | Laser windows, optical ceramic components |

Aluminum Nitride (AlN) Ceramic Properties

Aluminium nitride (AlN) ceramics are valued for their high thermal conductivity, strong electrical insulation, and low thermal expansion, ensuring stable dimensional performance under thermal cycling. And they feature a dense microstructure, low dielectric constant, and reliable high-temperature resistance, making them suitable for demanding thermal and electrical environments.

Aluminum Nitride Ceramic Technical Data

| Property Sort | Property Content | Unit | ALN-170 | ALN-200 | ALN-230 |

Basic | Color | gray | light yellow | light yellow | |

| Density | g/cm³ | 3.2-3.3 | 3.2-3.3 | 3.2-3.3 | |

| Surface Roughness | μm | 0.2-0.75 | 0.2-0.75 | 0.2-0.8 | |

| Camber | length ‰ | ≤3‰ | ≤3‰ | ≤3‰ | |

| Hardness | HV | 1100 | 1100 | 1100 | |

Thermal Properties | Max Operating Temperature | °C | 1100 | 1100 | 1100 |

| Thermal Conductivity | W/m·K | 170-190 | 190-220 | 220-230 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(20-400°c) | 4-5 | 4-5 | 4-5 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(400-800°c) | 5-6 | 5-6 | 5-6 | |

Mechanical Properties | Flexural Strength | MPa | 300-400 | 350-450 | 400-500 |

| Tensile Strength | MPa | 200-300 | 250-350 | 280-380 | |

| Compressive Strength | MPa | 2000-3000 | 2200-3200 | 2500-3500 | |

Electrical properties | Dielectric Constant | at 1MHz | 8-9 | 8-9 | 8-9 |

| Dielectric strength | KV/mm | ≥15 | ≥15 | ≥15 | |

| Volume resistivity | 20℃ Ω.cm | ≥1014 | ≥1014 | ≥1014 |

- This chart displays the typical properties of aluminum nitride (AlN) materials used in our standard products. Please note: Customized parts may have adjusted characteristics depending on production methods, with specific parameters determined by the stabilizer type and formula chosen for your application.

Advantages of Aluminium Nitride Ceramic

Delivers efficient heat spreading while maintaining strong dielectric strength, suitable for power electronics, laser modules, RF systems, and high-density packaging.

Maintains dimensional accuracy and mechanical integrity during rapid heating, cooling, and continuous thermal cycling in high-power systems.

Reduces thermal mismatch stress with Si, GaN, and related semiconductor materials, improving long-term reliability in electronic assemblies.

Supports rapid sampling, CNC machining, tight tolerances, and non-standard geometries for heat spreaders, substrates, plates, rings, blocks, and engineered components.

China Aluminium Nitride Ceramic Products

ADCERAX manufactures aluminium nitride (AlN) ceramic products in various shapes including substrates, plates, tubes, rings, rods, blocks, and custom-machined parts, supporting both standard sizes and tailored specifications.

Aluminium nitride substrates are used as thermal-insulating base materials in power electronics, laser modules, RF devices, and compact circuit packaging where efficient heat transfer and dimensional stability are required.

- High thermal conductivity for efficient heat dissipation

- Stable electrical insulation and low dielectric loss

- Custom thickness, dimensions, and surface finishing options

Aluminium nitride sheets serve as flat thermal-insulating panels for power modules, laser bases, RF devices, and electronic component packaging that require efficient heat spreading and dimensional consistency across a large surface.

- Low thermal expansion and stable flatness

- Available in polished or application-ready surfaces

- Custom thickness, width, and machining options

Aluminium nitride tubes are used as electrical-insulating and thermally conductive channels in high-temperature equipment, gas flow systems, sensor housings, and heating assemblies where heat transfer and structural stability are required.

- High thermal conductivity with electrical insulation

- Stable in continuous high-temperature service

- Customized length, diameter, and precision machining

Aluminium nitride rods are applied as insulating thermal conductors, positioning posts, and structural elements in high-power or high-temperature assemblies requiring mechanical stability and heat transfer performance.

- High thermal conductivity with dielectric strength

- Low thermal expansion and consistent density

- Custom Dia / L, and surface finish options

Aluminium nitride crucibles are used for high-temperature melting, evaporation, and chemical handling where thermal conductivity, corrosion resistance, and insulation are needed under inert or controlled atmospheres.

- Suitable for non-oxidizing high-temperature use

- Low contamination and stable thermal performance

- Custom capacities and structural designs

Aluminium nitride rings are used as thermally conductive and insulating spacers, seals, and support components in power modules, laser assemblies, and high-temperature equipment where dimensional accuracy and heat transfer are required.

- High thermal conductivity with electrical insulation

- Stable in continuous thermal cycling

- Custom inner/outer diameters and thickness options

Aluminium nitride balls are used in thermal, insulating, and contact-safe motion or positioning functions where lightweight ceramic properties and high-temperature resistance are preferred over metal components.

- Electrically insulating with thermal conductivity

- High hardness and stable dimensional consistency

- Custom diameters and precision grades

Aluminium nitride cylinders are applied in high-temperature, electrically insulated flow, sensing, and heating structures where thermal stability and material reliability are required during continuous operation.

- High-temperature and thermal-cycling stability

- Strong structure with low thermal expansion

- Custom ID/OD and precision machining

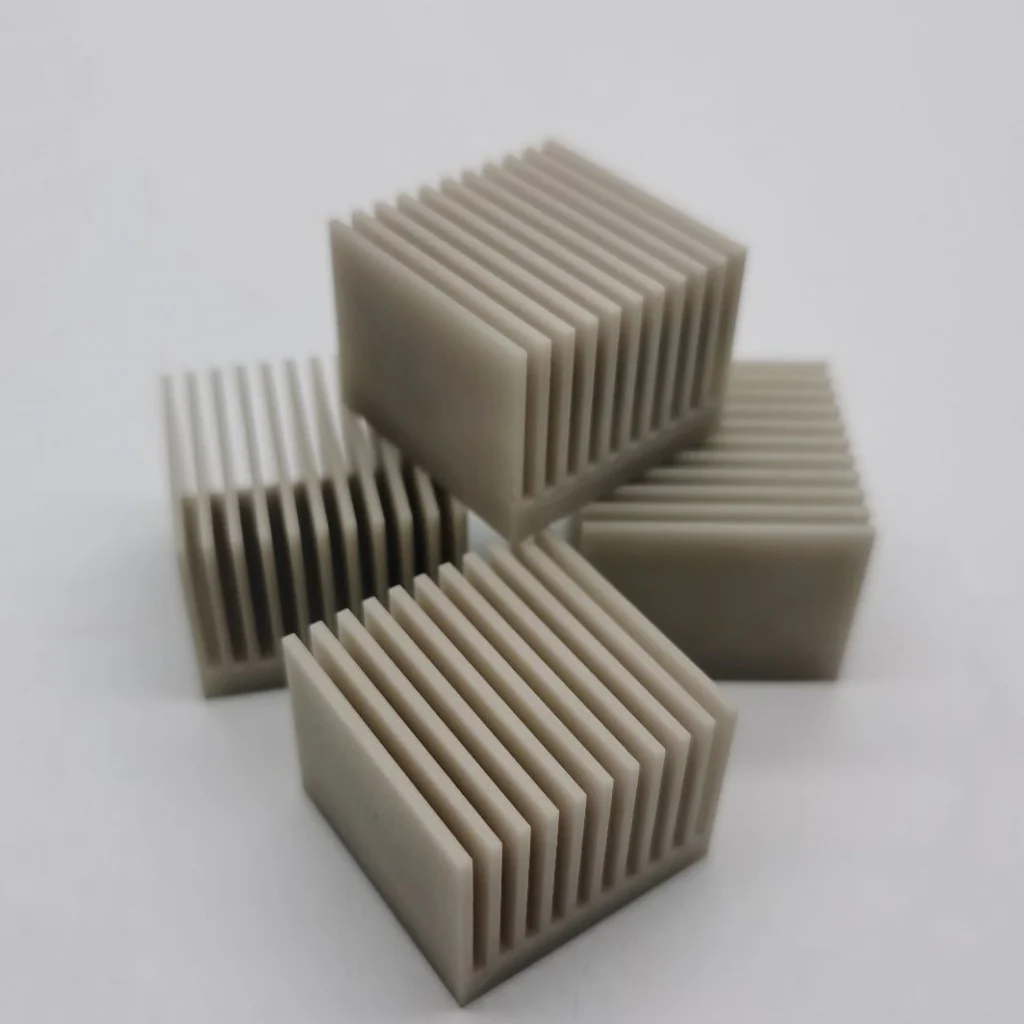

Aluminium nitride heat sinks are used for high-power thermal spreading and electrical insulation in power modules, laser systems, RF devices, and compact electronic assemblies that require rapid heat transfer and stable performance.

- High thermal conductivity with dielectric insulation

- Supports polished and metal-ready surface options

- Custom thickness, patterns, and machining

💡 Built for Thermal Management, Electrical Isolation, and Dimensional Stability — AlN Ceramics by ADCERAX.

We provide AlN substrates and custom-machined parts for applications requiring high thermal conductivity, electrical insulation, and controlled thermal expansion. Components are manufactured with tight tolerances, stable microstructure, and reliable performance under thermal cycling.

Share drawings or specs — we will confirm feasibility and supply a buildable AlN solution. 👉

Aluminum Nitride (AlN) Ceramic Applications

Aluminium nitride ceramic is used in power electronics, LED packaging, RF hardware, and precision industrial systems where stable heat management and insulation reliability are required. They serve as substrates, heat spreaders, bases, and insulating fixtures in equipment that operates continuously under thermal and electrical load.

Power Electronics & Inverters

Aluminium nitride (AlN) ceramics are used as thermal and electrical insulation carriers in IGBT/MOSFET power modules, AC-DC / DC-DC converters, industrial inverters, welding power supplies, and motor control units to manage increasing heat density and long-cycle power operation.

🧩Challenge & ADCERAX Solution:

High power modules often encounter heat concentration, thermal stress between silicon chips and carrier plates, and insulation reliability concerns during long-term operation. ADCERAX supports these applications with high-purity aluminium nitride ceramics featuring ≥170 W/m·K thermal conductivity, a silicon-matched CTE, controlled flatness, and precision machining for holes, slots, chamfers, and metalization-ready surfaces, enabling stable and efficient thermal design.

LED, Laser & Optoelectronics Packaging

AlN ceramics are applied as thin thermal carriers and structural bases in COB LED modules, laser diode mounts, fiber-optic components, RF optical amplifiers, and high-density device packaging where temperature, optical stability, and compact footprint are critical.

🧩Challenge & ADCERAX Solution

Optoelectronic devices face optical power decay, temperature drift, and dimensional stability issues caused by localized heat and packaging stresses. ADCERAX offers ultra-flat and low-warp AlN ceramic plates with optional precision-polished surfaces, thin-profile machining capability, and customizable alignment features to enhance optical output stability and packaging consistency.

RF, Microwave & Telecom Modules

AlN ceramics serve as high-frequency carrier substrates and thermal bases for microwave filters, RF amplifiers, mmWave communication modules, and compact high-frequency electronic units.

🧩Challenge & ADCERAX Solution

RF and microwave modules require low dielectric loss, stable permittivity, precise thin-section fabrication, and repeatable dimensional accuracy to avoid signal degradation. ADCERAX provides aluminium nitride ceramic substrates with stable dielectric properties (≈8.7–9), reliable thermal conduction, and controlled tolerances and planarity to support prototype validation and scalable production with reduced performance deviation.

Industrial Heating & Smart Equipment

AlN ceramics are used in industrial heaters, high-temperature insulation blocks, vacuum or inert-gas environment supports, and thermal exchange structural pieces where stable insulation and heat dissipation must coexist at elevated temperatures.

🧩Challenge & ADCERAX Solution:

Industrial equipment commonly faces long-term thermal cycling, dimensional drift, and insulation reliability challenges when using conventional ceramic materials. ADCERAX supplies dense and high-purity AlN ceramics with stable thermal conductivity, electrical insulation, and strength retention under elevated temperatures, combined with CNC machining capability for complex shapes, mounting holes, slots, recesses, or positioning interfaces.

Customized Aluminum Nitride Ceramics supplier

ADCERAX is a custom aluminium nitride (AlN) ceramics manufacturer in China, producing precision-machined AlN components according to your drawings, samples, or functional requirements. We support complex shapes, tight tolerances, thin-wall structures, stepped and threaded sections, and application-ready AlN parts for thermal management, power electronics, laser systems, and high-temperature assemblies. Stable production, flexible MOQs, and engineering support are offered, with typical delivery in 3–9 weeks depending on size and machining complexity.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Aluminium Nitride (AlN) Ceramic Factory with Advanced Processing

Aluminium nitride ceramic (AlN) is a high-thermal-conductivity, electrically insulating, and hard-to-machine technical ceramic that requires diamond tooling for precision processing. ADCERAX provides full-process AlN manufacturing, from material forming to CNC machining and finishing, ensuring tight tolerances, stable properties, and consistent quality for industrial and electronic applications.

AlN Ceramic Machining Capacity

🔷Forming & Sintering: Aluminium nitride powders are formed and sintered to produce dense ceramic bodies with high thermal conductivity and electrical insulation.

🔷Diamond CNC Machining: Diamond grinding and multi-axis CNC allow holes, thin walls, slots, and flat parts with ±0.02–0.05 mm tolerances.

🔷Finishing & Customization: Available polishing, lapping, chamfering, and surface prep for substrates, heat spreaders, PCB bases, and thermal parts.

🔷Stable Batch Manufacturing: Controlled processes reduce warpage and micro-cracks, ensuring consistent quality from samples to bulk orders.

AlN Ceramic Manufacturing Strengths

- Thermal-Critical Parts Machinability

Despite its hardness, AlN can be diamond-machined into thin-wall, flat, and tight-tolerance parts for substrates, heat spreaders, tubes, and plates without compromising thermal performance. - Stable Dimensional Accuracy

Low thermal expansion and uniform microstructure allow ±0.02–0.05 mm tolerance control, reducing deformation during forming, sintering, and secondary machining. - Consistent Surface Quality for Bonding & Metallization

AlN supports polishing, lapping, and metallization-ready finishing, enabling reliable soldering, DBC/DPC, Au/Ni plating, adhesive bonding, and vacuum mounting.

Why Choose ADCERAX for Your Aluminum Nitride Ceramic Supplier?

Choosing the right aluminium nitride (AlN) ceramics manufacturer directly influences the thermal performance, reliability, and total operating cost of your system. ADCERAX provides high-purity AlN materials, precision CNC machining, and engineering support, making us a dependable partner for thermal management, power electronics, and high-precision industrial applications.

Factory Direct & Competitive Pricing

Direct manufacturer eliminating intermediaries for cost-effective solutions without compromising quality.

Expert Engineering Support

20+ years of B2B experience providing unparalleled technical support and collaborative design.

Flexible Customization

Agile manufacturing for small-batch customization and rapid prototyping capabilities.

Quality Control

Stringent quality measures from raw material inspection to final product testing.

24/7 Technical Support

24-hour response guarantee with dedicated support for global clientele.

500+ Satisfied Customers

Trusted by global customers for advanced ceramic materials and precision components.

Aluminum Nitride Ceramic Products Quality & Certifications

FAQ

AlN is the preferred choice when heat dissipation efficiency, dielectric performance, and dimensional stability are the top priorities — particularly in IGBT modules, GaN/SiC power devices, LED & laser submounts, microwave/RF hardware, and hermetic packages.

| Performance Aspect | Aluminium Nitride (AlN) | Alumina (Al₂O₃) | Silicon Nitride (Si₃N₄) |

|---|---|---|---|

| Thermal Conductivity | ★★★★★ (140–180 W/m·K+) | ★★☆☆☆ (15–30 W/m·K) | ★★★☆☆ (20–35 W/m·K) |

| Electrical Insulation | Excellent | Good | Good |

| Thermal Expansion (CTE) | Close to silicon | Higher | Moderate |

| Mechanical Strength | Medium | Medium | Very high |

| Ideal Use Cases | Power electronics, laser modules, RF & high-density packaging | General industrial ceramics | High-load, high-shock mechanical systems |

AlN ceramics provide thermal conductivity up to 170 W/m·K, dielectric strength, low CTE, and low dielectric loss, making them suitable for power modules, RF devices, and laser heat spreaders.

With diamond grinding and multi-axis CNC machining, ±0.02–0.05 mm tolerance can be achieved on aln ceramic plates, substrates, rings, and custom-shaped aln ceramic parts.

Yes, customized aluminum nitride ceramics can be produced based on drawings, prototypes, or material targets for holes, slots, stepped surfaces, thin-wall structures, and precision thermal pads.

ADCERAX provides a wide portfolio of aln ceramic substrates, aluminum nitride ceramic plate, aln ceramic plates, rods, tubes, heaters, and custom-machined aln ceramic parts. This includes aluminum nitride ceramic substrate, aln ceramic substrate, and PCB-ready structures such as aluminum nitride ceramic PCB and aln ceramic PCB.

Yes, For specialized optics and sensing,aln transparent ceramics can be used where partial light transmission is required together with high thermal conductivity. These materials are niche but demonstrate the versatility of aluminium nitride ceramic.

Yes, both standard sizes and custom-machined aluminum nitride ceramic parts are available for sale. To receive an accurate quote, please provide drawings, dimensions, tolerances, surface finish, and usage temperature, and our engineering team will recommend a matching grade, cost level, and lead time based on your application.

Yes, aluminum nitride ceramics wholesale pricing is available for standard substrates, plates, blanks, and OEM parts based on MOQ and repeat stability.

If you are looking for cost-effective (not low-grade) aluminum nitride ceramics, it is recommended to source directly from a factory-level manufacturer rather than trading intermediaries, so pricing, material quality, machining tolerances, and delivery schedules can be controlled from the origin. ADCERAX is a China-based aluminum nitride ceramic factory specializing in standard and customized AlN substrates, plates, heat spreaders, PCB bases, rings, rods, and precision-machined parts, offering competitive factory pricing, engineering support, and flexible MOQ options for industrial projects.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

info@adcerax.com

Tel: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours