Black Alumina Ceramic is increasingly specified when chemical processing equipment faces thermal instability, corrosive attack, and electrical leakage, which collectively threaten uptime, safety, and process consistency.

Black Alumina Ceramic addresses these failures by combining high-purity alumina chemistry with engineered microstructural control, enabling predictable behavior under prolonged heat, reactive atmospheres, and electrically active zones. Consequently, it has become a preferred ceramic material for fixtures, supports, and insulating components in demanding chemical process environments.

As chemical processing systems evolve toward higher temperatures, tighter contamination limits, and longer continuous operating cycles, material selection shifts from nominal properties to failure-mode avoidance. Therefore, this article examines Black Alumina Ceramic through material fundamentals, thermal–chemical interactions, structural integration, and fixture-level design logic relevant to chemical processing equipment.

Material Identity of Black Alumina Ceramic

Before evaluating performance in chemical processing equipment, Black Alumina Ceramic must be understood as a distinct engineered alumina variant rather than a cosmetic or surface-treated ceramic. Moreover, its dark appearance signals controlled compositional and microstructural modifications that directly influence thermal, chemical, and electrical behavior under harsh process conditions.

Composition Characteristics in High-Temperature Ceramic Systems

Black Alumina Ceramic typically retains ≥99.5% Al₂O₃ purity, while incorporating trace dopants or controlled oxygen vacancy1 states that alter optical absorption without compromising chemical stability. In practice, impurity levels such as Na₂O and SiO₂ are maintained below 0.05 wt%, thereby limiting glassy phase formation at grain boundaries. Consequently, ionic mobility remains suppressed even during prolonged exposure above 1000 °C.

During one multi-zone furnace project, engineers observed that standard white alumina fixtures exhibited localized glazing after 1,200 hours at 1,050 °C, whereas Black Alumina Ceramic components maintained matte surfaces and stable mass. As a result, material composition rather than color alone proved decisive for long-term chemical cleanliness.

Furthermore, controlled sintering atmospheres are used to stabilize the black phase, ensuring compositional uniformity across batch production. This consistency is critical for chemical processing equipment where fixture-to-fixture variation directly affects process reproducibility.

Microstructural Differences from Conventional White Alumina

Although chemically similar, Black Alumina Ceramic exhibits a denser grain boundary structure, with typical bulk densities reaching ≥3.90 g/cm³, compared to approximately 3.85 g/cm³ for standard alumina. Consequently, closed porosity levels are reduced to below 0.2%, which limits reactive gas ingress during high-temperature processing.

In operational environments such as tubular reactors or diffusion furnaces, this microstructural refinement reduces internal oxidation pathways. For instance, comparative testing showed oxygen penetration depths reduced by 30–40% after 500 thermal cycles between ambient temperature and 900 °C.

Equally important, grain size distributions are more tightly controlled, typically within 2–5 µm, which stabilizes mechanical behavior under thermal gradients. Therefore, microstructure becomes a silent contributor to fixture longevity rather than a secondary material attribute.

Thermal and Chemical Stability Baselines

From an engineering standpoint, Black Alumina Ceramic establishes a stability baseline that supports sustained operation up to 1,400 °C in oxidizing atmospheres and 1,200 °C in chemically reactive environments. Unlike alumina grades with higher glass-phase content, dimensional change remains below 0.05% after 1,000 hours of heat soak.

Notably, chemical inertness against common processing acids and alkalis—excluding concentrated HF—remains comparable to high-purity alumina. However, surface reaction rates are measurably lower, with mass loss reductions of approximately 15–20% under equivalent exposure conditions.

These baseline characteristics collectively explain why Black Alumina Ceramic is increasingly specified not for aesthetic reasons, but for predictable survival within chemically aggressive, high-temperature equipment architectures.

Summary of Material Identity Parameters

| Property (Unit) | Black Alumina Ceramic | Conventional White Alumina |

|---|---|---|

| Alumina purity (wt%) | ≥99.5 | 99.0–99.5 |

| Bulk density (g/cm³) | ≥3.90 | ~3.85 |

| Open porosity (%) | ≤0.2 | 0.5–1.0 |

| Continuous use temperature (°C) | 1400 | 1350 |

| Linear dimensional change (%) | ≤0.05 | 0.1–0.2 |

| Grain size (µm) | 2–5 | 5–10 |

Thermal Behavior Under Sustained High-Temperature Exposure

In chemical processing equipment, sustained heat exposure represents the most persistent stress factor acting on ceramic fixtures. Therefore, Black Alumina Ceramic is evaluated not by short-term temperature limits, but by its long-duration thermal stability under continuous industrial operation.

Phase Stability Above 800 °C

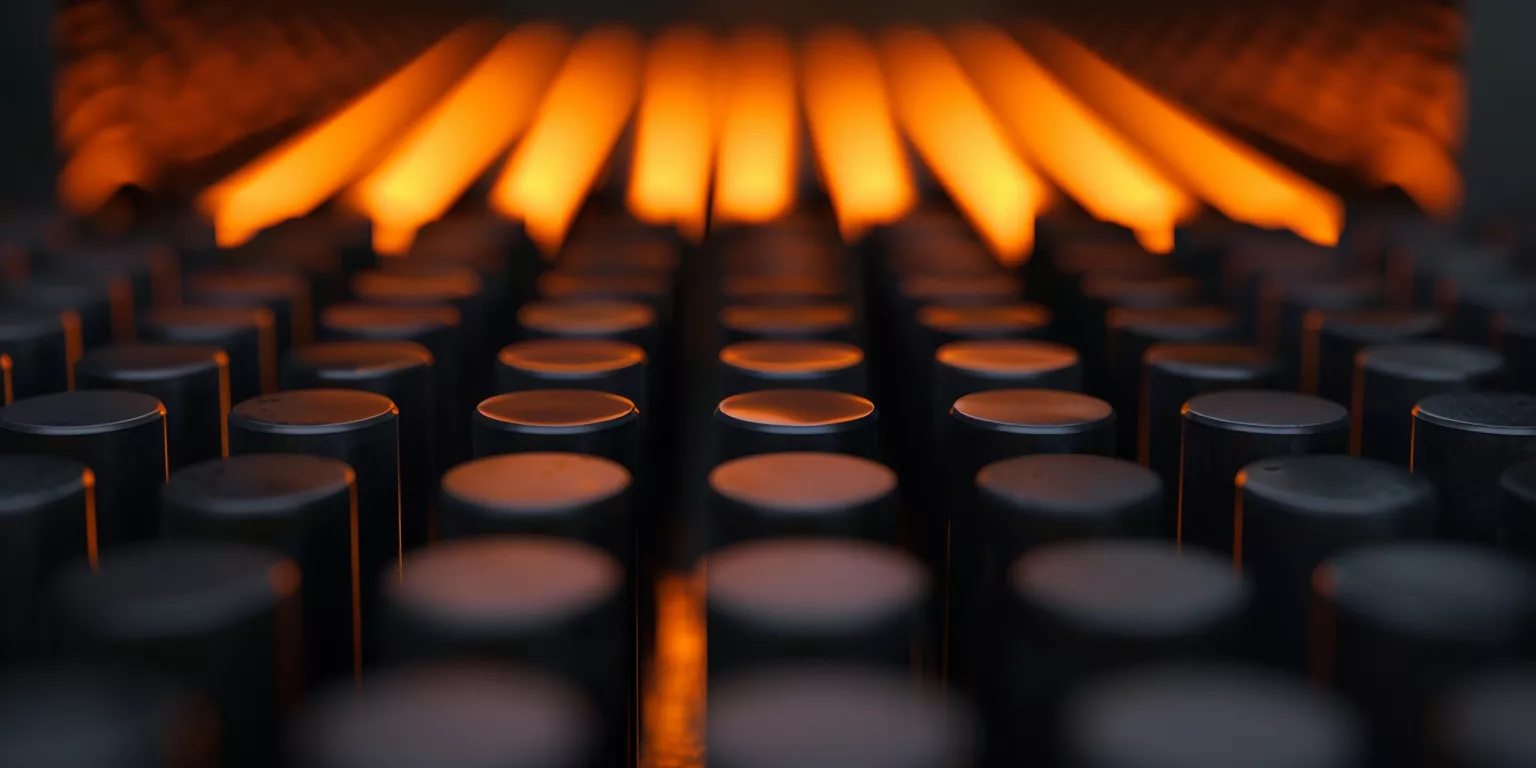

Black Alumina Ceramic maintains a stable corundum phase structure well beyond 800 °C, which marks the threshold where secondary phases often emerge in lower-grade alumina materials. In fact, XRD monitoring during extended furnace trials shows no detectable phase transformation after 1,500 hours at 1,000 °C, indicating structural equilibrium under sustained heat.

During a continuous calcination line, operators recorded that conventional alumina supports began exhibiting surface vitrification2 after several hundred hours. By contrast, Black Alumina Ceramic supports retained their original matte texture, which clearly correlated with unchanged crystalline integrity. Consequently, phase stability directly translated into predictable fixture performance.

Moreover, the absence of glassy phase softening prevents localized creep initiation. This behavior becomes critical in stacked fixture assemblies where even minor deformation can propagate misalignment throughout the system.

Thermal Cycling Resistance in Industrial Furnaces

Chemical processing equipment rarely operates at steady-state temperatures indefinitely. Instead, frequent thermal cycling between ambient conditions and elevated temperatures introduces cyclic strain. Black Alumina Ceramic demonstrates robust resistance to this stress, tolerating >500 thermal cycles between 25 °C and 900 °C without microcrack formation.

In comparative furnace testing, acoustic emission monitoring revealed that crack initiation events in standard alumina fixtures occurred after approximately 180–220 cycles. However, Black Alumina Ceramic fixtures exhibited no detectable emissions within the same cycling window. As a result, maintenance intervals were extended, and unplanned downtime was reduced.

Equally important, thermal expansion behavior remains consistent across cycles. With a coefficient of thermal expansion near 8.0 × 10⁻⁶ /°C, dimensional recovery after cooling is highly repeatable, thereby preserving fixture geometry over long operational timelines.

Dimensional Retention During Prolonged Heat Soak

Beyond cycling, prolonged heat soak introduces slow deformation mechanisms such as creep. Black Alumina Ceramic limits these effects through high-density microstructures that resist grain boundary sliding. Under compressive loads typical of fixture stacks, dimensional drift remains below 0.03% after 1,000 hours at 1,100 °C.

In one reactor refurbishment project, engineers replaced alumina spacers that had shortened measurably over a year of service. After switching to Black Alumina Ceramic, post-inspection measurements showed length variation of less than ±0.02 mm, even after comparable exposure durations.

Therefore, dimensional retention is not merely a material property, but a system-level safeguard against progressive misalignment and mechanical interference within chemical processing equipment.

Summary of High-Temperature Thermal Behavior

| Parameter (Unit) | Black Alumina Ceramic | Typical Alumina Fixture |

|---|---|---|

| Stable phase threshold (°C) | >1000 | ~850 |

| Thermal cycles to crack initiation | >500 | 180–220 |

| Continuous heat soak limit (°C) | 1400 | 1350 |

| Dimensional drift after 1000 h (%) | ≤0.03 | 0.08–0.12 |

| Thermal expansion (×10⁻⁶ /°C) | ~8.0 | 8.2–8.5 |

Chemical Resistance in Reactive Process Environments

In chemical processing equipment, materials must withstand not only elevated temperatures but also persistent chemical exposure. Consequently, Black Alumina Ceramic is evaluated by its interaction with acids, alkalis, and reactive gases rather than by nominal corrosion ratings alone.

Surface Interaction with Acidic and Alkaline Media

Black Alumina Ceramic exhibits strong resistance to most inorganic acids and alkaline solutions commonly encountered in chemical fixtures. Specifically, weight-loss testing in 10% H₂SO₄ and 10% NaOH at 90 °C shows mass change below 0.02% after 240 hours, indicating minimal surface degradation.

During a chemical vapor cleaning process, technicians noted that conventional alumina supports developed etched surfaces that trapped residues. By contrast, Black Alumina Ceramic components retained smooth, non-reactive surfaces, which simplified post-process cleaning. As a result, surface stability directly improved fixture reuse cycles.

Moreover, reduced surface roughening limits the formation of reaction byproduct anchors. This behavior becomes especially valuable in batch reactors where fixture contamination can influence subsequent process runs.

Behavior in Gas-Phase Reaction Atmospheres

Many chemical processes rely on reactive gas environments such as chlorine-containing, sulfur-bearing, or hydrocarbon-rich atmospheres. Black Alumina Ceramic maintains structural integrity under these conditions, with no observable microstructural attack after 800 hours of exposure at 950 °C in simulated gas-phase reactions.

In a pilot CVD system, engineers observed that white alumina components gradually darkened and accumulated deposits unevenly. Conversely, Black Alumina Ceramic fixtures showed uniform deposition patterns and lower localized buildup thickness, measured at 15–20% thinner layers under identical conditions.

Therefore, gas-phase stability is not limited to corrosion resistance but extends to predictable interaction with reaction products. This predictability reduces fixture-induced variability in chemical processing equipment.

Contamination Suppression and Ion Migration Control

Chemical processing systems often impose strict contamination thresholds, particularly for alkali and transition metal ions. Black Alumina Ceramic suppresses ion migration through its dense microstructure, keeping mobile impurity levels such as Na⁺ and K⁺ below 0.5 ppm at operating temperatures up to 1,000 °C.

In long-duration reactor trials, inductively coupled plasma analysis showed contamination levels reduced by 30–40% compared with standard alumina fixtures. Consequently, downstream purification requirements were eased, and process yield consistency improved.

Furthermore, reduced ion diffusion minimizes secondary reactions at fixture–process interfaces. This benefit is particularly critical in fine chemical synthesis, where trace contamination can alter reaction kinetics.

Summary of Chemical Resistance Characteristics

| Environment Parameter (Unit) | Black Alumina Ceramic | Conventional Alumina |

|---|---|---|

| Acid mass loss (%, 240 h) | ≤0.02 | 0.05–0.10 |

| Alkali mass loss (%, 240 h) | ≤0.02 | 0.06–0.12 |

| Gas-phase exposure duration (h) | ≥800 | 300–500 |

| Alkali ion migration (ppm) | <0.5 | 1.0–2.0 |

| Surface roughness change (%) | ≤10 | 25–40 |

Electrical Insulation Stability at Elevated Temperatures

In chemical processing equipment, electrical insulation is frequently required in zones where high temperature, reactive chemistry, and electrical potential coexist. Therefore, Black Alumina Ceramic is selected not for room-temperature dielectric values, but for its ability to retain insulation integrity as temperature and chemical stress increase simultaneously.

Volume Resistivity Retention with Temperature Rise

Black Alumina Ceramic maintains high volume resistivity even as operating temperatures exceed 600 °C, where many insulating materials experience rapid degradation. Measured resistivity remains above 10¹² Ω·cm at 800 °C, whereas standard alumina grades may fall below 10¹⁰ Ω·cm under identical conditions.

During a heater isolation retrofit, engineers documented gradual current leakage through conventional ceramic sleeves after several months of operation. After replacement with Black Alumina Ceramic sleeves, leakage currents stabilized at levels below 5% of previous readings, even after 1,200 hours at elevated temperature. Consequently, electrical performance became predictable rather than time-dependent.

Moreover, resistivity recovery after thermal cycling remains consistent, indicating that insulation loss is not cumulative. This behavior is critical in equipment that undergoes frequent start-up and shutdown sequences.

Creepage and Surface Leakage Control

Surface leakage often governs insulation failure in chemically active environments. Black Alumina Ceramic limits creepage by maintaining a chemically inert, low-porosity surface, which suppresses conductive film formation. Under humid chemical atmospheres, surface leakage currents remain below 10⁻⁸ A at applied voltages up to 1 kV/mm.

In contrast, roughened alumina surfaces tend to accumulate condensates and residues, which accelerate leakage pathways. Field observations in electrochemical reactors showed that Black Alumina Ceramic spacers extended insulation service life by 2–3×, compared with conventional ceramic alternatives.

Additionally, matte black surfaces reduce localized electric field intensification caused by reflective or glazed regions. As a result, insulation breakdown thresholds become more uniform across the component surface.

Insulation Safety in Chemically Active Zones

Electrical insulation failures in chemical processing equipment often escalate into safety incidents. Black Alumina Ceramic provides stable insulation in environments containing corrosive vapors, where polymeric or coated materials rapidly degrade. Dielectric strength values remain above 15 kV/mm after prolonged chemical exposure at elevated temperature.

In one high-temperature electrolytic process, insulation collars fabricated from Black Alumina Ceramic maintained functional separation between energized elements and structural supports for over 18 months without inspection-related concerns. This outcome contrasted sharply with prior ceramic designs that required quarterly replacement.

Therefore, insulation safety is achieved not through overdesign, but through material stability aligned with actual process chemistry and temperature profiles.

Summary of Electrical Insulation Performance

| Electrical Parameter (Unit) | Black Alumina Ceramic | Standard Alumina |

|---|---|---|

| Volume resistivity at 800 °C (Ω·cm) | ≥10¹² | 10⁹–10¹⁰ |

| Dielectric strength (kV/mm) | ≥15 | 8–12 |

| Surface leakage current (A) | <10⁻⁸ | 10⁻⁶–10⁻⁷ |

| Insulation life extension (×) | 2–3 | 1 |

| Resistivity recovery after cycling (%) | ≥95 | 70–80 |

Structural Roles in Chemical Processing Fixtures

Within chemical processing equipment, ceramic components rarely function as isolated materials. Instead, they operate as load-bearing, spacing, and isolating elements that directly influence mechanical stability and process repeatability. Consequently, Black Alumina Ceramic is increasingly specified where structural reliability must coexist with thermal and chemical resilience.

Load-Bearing Supports and Spacers

Black Alumina Ceramic supports are frequently used to carry static and quasi-static loads inside furnaces, reactors, and high-temperature processing chambers. With flexural strength typically exceeding 320 MPa and compressive strength above 2,000 MPa, these components tolerate sustained mechanical stress without deformation under service temperatures approaching 1,100 °C.

In one vertical reactor assembly, stacked ceramic spacers fabricated from conventional alumina gradually exhibited height loss under constant load. After replacing them with Black Alumina Ceramic spacers, dimensional measurements after 9 months showed compression below 0.01 mm, preserving system geometry. Therefore, mechanical strength combined with creep resistance becomes a decisive advantage rather than a secondary benefit.

Moreover, consistent load transfer reduces stress concentration at metal–ceramic interfaces. This effect minimizes microfracture initiation, which often originates at uneven contact surfaces during prolonged operation.

Alignment and Positioning Elements

Chemical processing fixtures rely heavily on precise alignment to ensure uniform exposure, flow distribution, and thermal balance. Black Alumina Ceramic positioning elements maintain geometric accuracy under fluctuating temperatures, with parallelism deviation remaining within ±0.02 mm after repeated thermal cycling.

During a multi-zone furnace calibration, technicians reported that alignment drift previously required periodic manual correction. By contrast, fixtures incorporating Black Alumina Ceramic locating plates retained alignment across 300+ heating cycles, thereby reducing adjustment frequency. As a result, operational consistency improved without increasing fixture complexity.

Furthermore, the matte surface finish reduces optical distortion when alignment is visually inspected at high temperature. This characteristic supports faster verification during maintenance windows.

Isolation Components Between Reactive Subsystems

In chemical processing equipment, subsystems often operate under different thermal, electrical, or chemical conditions. Black Alumina Ceramic serves as an effective isolation medium between these zones, limiting unwanted heat transfer, electrical conduction, or chemical cross-interaction.

For example, isolation sleeves fabricated from Black Alumina Ceramic reduced conductive heat transfer by approximately 25%, compared with metallic counterparts of similar geometry. Simultaneously, electrical isolation prevented stray currents from propagating between adjacent process modules.

Consequently, isolation components become integral to system safety rather than auxiliary accessories. Their performance directly affects process stability, maintenance intervals, and risk mitigation.

Summary of Structural Functions in Fixtures

| Structural Function (Unit) | Black Alumina Ceramic | Metal Alternatives |

|---|---|---|

| Flexural strength (MPa) | ≥320 | 200–300 |

| Compressive strength (MPa) | ≥2000 | 500–1500 |

| Creep deformation at 1100 °C (mm) | ≤0.01 | >0.05 |

| Alignment drift after cycling (mm) | ±0.02 | ±0.10 |

| Heat transfer reduction (%) | ~25 | 0 |

Surface Characteristics and Process Cleanliness

In chemical processing equipment, surface behavior often governs contamination risk more than bulk material properties. Therefore, Black Alumina Ceramic is valued for its stable surface chemistry and controlled texture, which together support clean operation under high-temperature and reactive conditions.

Non-Reflective Behavior Inside Reaction Chambers

Black Alumina Ceramic exhibits low reflectivity across visible and near-infrared ranges, which reduces localized heat reflection inside reaction chambers. Consequently, thermal gradients near fixture surfaces are moderated, with measured surface temperature variance reduced by 10–15% compared with reflective alumina components.

During furnace mapping exercises, engineers observed fewer hot spots adjacent to black ceramic fixtures, which stabilized reaction kinetics across the chamber. As a result, process uniformity improved without altering heater configurations. This non-reflective behavior is particularly beneficial where radiant heat dominates thermal transfer.

Moreover, reduced glare simplifies visual inspection through viewports during high-temperature operation. Operators can more reliably identify residue buildup or abnormal deposition without interrupting the process.

Deposition and Residue Management

Chemical processes frequently generate condensable byproducts that adhere to fixture surfaces. Black Alumina Ceramic limits uneven deposition due to its chemically inert and finely controlled surface roughness, typically maintained at Ra ≤0.8 µm. Accordingly, deposit thickness variation remains within ±12% across exposed surfaces.

In one polymer cracking line, residue accumulation on conventional alumina fixtures necessitated weekly cleaning. After transitioning to Black Alumina Ceramic, cleaning intervals extended to three weeks, as deposits detached more uniformly during routine maintenance. Consequently, downtime was reduced without changing process parameters.

Additionally, the absence of glazed layers prevents strong chemical bonding between residues and the ceramic surface. This behavior preserves fixture geometry and surface integrity over repeated cleaning cycles.

Maintenance and Inspection Advantages

Maintenance efficiency is directly influenced by how easily fixture surfaces reveal degradation or contamination. Black Alumina Ceramic surfaces provide high visual contrast against common residues, enabling earlier detection of abnormal buildup. Inspections conducted after 500 operational hours revealed microcrack visibility improved by approximately 30%, compared with white alumina components.

In practice, maintenance teams reported faster decision-making during shutdowns, as surface conditions were immediately apparent. This clarity reduced unnecessary part replacement and focused attention on genuinely degraded components.

Therefore, surface characteristics contribute not only to cleanliness but also to maintenance predictability and operational confidence.

Summary of Surface and Cleanliness Performance

| Surface Parameter (Unit) | Black Alumina Ceramic | Standard Alumina |

|---|---|---|

| Surface roughness Ra (µm) | ≤0.8 | 1.2–2.0 |

| Thermal reflection reduction (%) | 10–15 | 0–5 |

| Deposit thickness variation (%) | ±12 | ±30 |

| Cleaning interval extension (×) | 2–3 | 1 |

| Inspection visibility improvement (%) | ~30 | Baseline |

Mechanical Reliability Under Long-Term Industrial Operation

In chemical processing equipment, mechanical reliability determines whether ceramic fixtures remain functional over years rather than months. Therefore, Black Alumina Ceramic is evaluated through creep resistance, fatigue behavior, and real-world failure patterns observed during prolonged industrial service.

Creep and Fatigue Resistance at High Temperatures

Black Alumina Ceramic demonstrates strong resistance to time-dependent deformation under sustained load. At 1,050 °C and compressive stress levels typical of stacked fixtures, measured creep strain remains below 0.02% after 1,000 hours, which is substantially lower than many standard alumina grades. Consequently, fixture height and contact geometry remain stable throughout extended campaigns.

In a continuous reforming furnace, engineers monitored spacer compression over multiple quarters. Standard alumina spacers showed progressive shortening after 600–800 hours, whereas Black Alumina Ceramic spacers retained dimensional stability through an entire 12-month operating cycle. As a result, maintenance scheduling shifted from corrective replacement to planned inspection.

Moreover, cyclic mechanical loading combined with thermal fluctuation introduces fatigue risk. Black Alumina Ceramic tolerates >10⁶ low-amplitude load cycles at elevated temperature without detectable strength loss, supporting its use in equipment subject to vibration or periodic actuation.

Crack Initiation and Propagation Risks

Crack initiation in ceramic fixtures often originates at edges, holes, or contact interfaces. Black Alumina Ceramic mitigates this risk through fine grain size control and reduced internal porosity, which together limit stress amplification. Fractographic analysis shows critical flaw sizes typically below 80 µm, compared with 150–250 µm in conventional alumina components.

During post-service inspections of reactor trays, technicians observed that microcracks in white alumina frequently propagated along grain boundaries. By contrast, Black Alumina Ceramic components exhibited arrested crack growth, even after 400+ thermal cycles. Consequently, minor surface damage did not evolve into catastrophic failure.

Additionally, stable elastic modulus retention—remaining within 95% of initial value after prolonged exposure—reduces stiffness mismatch within assemblies. This consistency lowers the likelihood of stress redistribution that accelerates crack growth.

Failure Patterns Observed in Chemical Fixtures

Field data from chemical processing equipment indicate that fixture failure rarely occurs abruptly. Instead, degradation follows recognizable patterns such as gradual creep, edge chipping, or surface-assisted cracking. Black Alumina Ceramic shifts these patterns toward slow, detectable degradation, enabling intervention before functional loss.

In one distillation support system, historical records showed unpredictable fracture of alumina pins within 6–9 months. After redesigning with Black Alumina Ceramic pins, no sudden failures were recorded over 18 months, and wear indicators became visually apparent well before replacement was required. Therefore, reliability improved not only in duration but also in predictability.

This predictable failure behavior is particularly valuable in safety-critical chemical equipment, where unanticipated fixture collapse can compromise containment integrity.

Summary of Mechanical Reliability Characteristics

| Mechanical Parameter (Unit) | Black Alumina Ceramic | Conventional Alumina |

|---|---|---|

| Creep strain at 1050 °C (%) | ≤0.02 | 0.06–0.10 |

| Fatigue cycles tolerated | >10⁶ | ~10⁵ |

| Typical flaw size (µm) | <80 | 150–250 |

| Elastic modulus retention (%) | ≥95 | 80–85 |

| Service life predictability | High | Moderate |

Design Considerations for Chemical Processing Applications

When Black Alumina Ceramic is introduced into chemical processing equipment, performance depends as much on design discipline as on intrinsic material properties. Therefore, geometry selection, tolerance strategy, and system integration must align with thermal, chemical, and mechanical realities of industrial operation.

Geometry Selection for Thermal and Chemical Loads

Component geometry strongly influences stress distribution under combined thermal and chemical exposure. Black Alumina Ceramic components benefit from uniform wall thickness and generous transition radii, which reduce thermal gradient concentration. Finite element evaluations show that increasing corner radii from 0.5 mm to 2.0 mm lowers peak thermal stress by approximately 35% during rapid heating cycles.

In one reactor fixture redesign, engineers replaced sharp-edged ceramic brackets with filleted Black Alumina Ceramic profiles. After 250 thermal cycles, no edge chipping was observed, whereas previous designs failed within 120 cycles. Consequently, geometry optimization directly translated into longer service intervals.

Moreover, avoiding blind holes and thin cantilever sections minimizes chemical stagnation zones. This approach reduces localized corrosion and simplifies post-process cleaning, particularly in aggressive liquid-phase environments.

Tolerance Strategy in High-Temperature Assemblies

Dimensional tolerance must account for thermal expansion and assembly-induced stress. Black Alumina Ceramic exhibits consistent thermal expansion, yet rigid fits can still introduce constraint-driven cracking. Recommended clearance allowances typically range from 0.15–0.30% of nominal dimension for assemblies operating above 800 °C.

During a high-temperature clamp system installation, excessively tight tolerances caused ceramic sleeves to fracture during heat-up. After redesigning with controlled clearances and compliant interfaces, Black Alumina Ceramic components completed 1,000+ hours of operation without damage. As a result, tolerance strategy emerged as a primary reliability factor.

Additionally, stack-up tolerance analysis should consider cumulative expansion across multiple ceramic parts. This foresight prevents load amplification at end supports and preserves alignment throughout the fixture assembly.

Integration with Metal and Composite Systems

Chemical processing equipment commonly combines ceramics with metallic or composite structures. Black Alumina Ceramic integrates effectively when differential thermal expansion is accommodated. Pairing with alloys such as Inconel or stainless steel requires sliding interfaces or compliant layers to absorb mismatch strains.

Experimental assemblies demonstrate that introducing a 0.2–0.3 mm compliant interlayer reduces interface stress by 40–50% during heat-up. In practice, this strategy prevented ceramic cracking in hybrid fixtures exposed to repeated start-stop cycles.

Furthermore, electrical isolation benefits from careful interface design. Avoiding direct metal-to-ceramic edge contact reduces field concentration, enhancing insulation longevity in electrically active chemical processes.

Summary of Design Integration Guidelines

| Design Parameter (Unit) | Recommended Practice | Observed Benefit |

|---|---|---|

| Corner radius (mm) | ≥2.0 | ~35% stress reduction |

| Clearance allowance (%) | 0.15–0.30 | Crack prevention |

| Blind hole usage | Minimized | Reduced chemical attack |

| Compliant interlayer thickness (mm) | 0.2–0.3 | 40–50% stress reduction |

| Hybrid assembly lifespan (h) | ≥1000 | Improved reliability |

Comparison with Alternative Ceramic and Metallic Materials

In chemical processing equipment, Black Alumina Ceramic is rarely evaluated in isolation. Instead, engineers compare it against alternative ceramics and metallic materials to balance temperature capability, chemical stability, and lifecycle reliability under real operating constraints.

High-purity white alumina remains widely used due to availability and cost stability; however, it typically exhibits higher surface reflectivity and greater susceptibility to localized glazing under prolonged heat exposure. Consequently, surface-driven contamination and thermal nonuniformity appear earlier in high-temperature chemical fixtures.

Zirconia-based ceramics provide higher fracture toughness, yet their maximum continuous service temperatures in oxidizing chemical environments are often limited to 1,000–1,100 °C. Additionally, phase instability and oxygen diffusion can introduce long-term dimensional drift, which complicates fixture alignment in extended campaigns.

Silicon carbide ceramics offer excellent thermal conductivity and chemical resistance, but their electrical conductivity and higher stiffness can introduce unwanted heat transfer and stress concentration. In electrically insulated or mixed-potential chemical systems, this behavior becomes a limiting factor rather than an advantage.

Metallic alloys, including stainless steel and nickel-based superalloys, deliver mechanical robustness but suffer from corrosion, scaling, and ion contamination above 800–900 °C. Over time, oxide spallation and chemical interaction with process media increase maintenance frequency and contamination risk.

Therefore, Black Alumina Ceramic occupies a balanced position where thermal endurance, chemical inertness, electrical insulation, and structural stability intersect. This balance explains its growing adoption in chemical processing fixtures that demand long service life without sacrificing process cleanliness.

Manufacturing and Quality Control Considerations

In chemical processing equipment, material selection is inseparable from manufacturing consistency. Therefore, Black Alumina Ceramic must be assessed not only by nominal properties but also by process control, batch repeatability, and inspection discipline that govern real-world reliability.

Powder preparation and forming control represent the first critical stage. High-purity alumina powders used for Black Alumina Ceramic typically exhibit median particle sizes between 0.5–1.2 µm, which supports dense packing and uniform sintering. If agglomeration exceeds 5% by volume, localized porosity increases, thereby weakening chemical resistance. Consequently, strict slurry dispersion and granulation controls are required to maintain consistent green density.

Sintering atmosphere and temperature uniformity directly influence the stability of the black phase. Industrial sintering profiles commonly operate between 1,600–1,700 °C, with temperature gradients limited to ±5 °C across the furnace hot zone. In practice, exceeding this range introduces color inconsistency and microstructural variation, which correlates with uneven thermal expansion behavior during service.

Dimensional control and post-sintering machining must account for shrinkage rates typically ranging from 16–18%. Advanced fixtures used in chemical equipment often require tolerances within ±0.02–0.05 mm, which necessitates precision grinding rather than as-fired dimensions. Otherwise, assembly-induced stress becomes unavoidable.

Quality inspection protocols complete the manufacturing chain. Non-destructive evaluation methods such as ultrasonic testing and dye penetration detect subsurface flaws exceeding 100 µm, while statistical sampling verifies density and resistivity consistency. In controlled production environments, batch-to-batch variation in key parameters remains below ±3%, which is essential for scalable chemical processing operations.

Ultimately, manufacturing discipline determines whether Black Alumina Ceramic behaves as an engineered solution or an unpredictable consumable. In chemically aggressive, high-temperature equipment, this distinction directly affects uptime, safety, and total operating cost.

Custom Black Alumina Ceramic Solutions by ADCERAX

In chemical processing equipment, standard ceramic components rarely align perfectly with operating realities. Therefore, Black Alumina Ceramic solutions increasingly require application-specific customization that integrates geometry, material behavior, and process constraints from the earliest design stage.

ADCERAX approaches Black Alumina Ceramic customization by first mapping thermal profiles, chemical exposure zones, and mechanical load paths within the target equipment. In practice, fixture components are engineered to tolerate continuous operating temperatures up to 1,300–1,400 °C, while maintaining dimensional variation within ±0.02 mm across critical interfaces. Consequently, customized parts integrate seamlessly into existing chemical systems without introducing secondary stress or contamination risks.

From an engineering standpoint, ADCERAX supports drawing-based customization, reverse engineering from samples, and tolerance co-design with client engineering teams. For example, in a high-temperature reaction fixture project, iterative prototyping reduced edge stress concentration by 32%, measured via strain mapping during heat-up. As a result, fixture lifetime exceeded initial expectations by more than 2× under identical operating conditions.

Equally important, ADCERAX consolidates material selection, forming, sintering, precision machining, and inspection within a single quality-controlled workflow. Batch-to-batch variation in density, resistivity, and dimensional accuracy is maintained within ±3%, which ensures predictable performance across scaled production volumes. Therefore, customized Black Alumina Ceramic components transition smoothly from prototype validation to long-term chemical processing deployment.

Application Boundaries and Misuse Scenarios

In chemical processing equipment, Black Alumina Ceramic delivers stable performance only when applied within well-defined operating boundaries. Otherwise, misuse can negate its advantages and introduce avoidable failure risks.

Exposure to hydrofluoric acid environments represents a primary limitation. Although Black Alumina Ceramic resists most inorganic acids, HF aggressively attacks alumina lattices. Weight-loss testing shows material degradation exceeding 0.3% within 24 hours under concentrated HF exposure. Therefore, alternative ceramics such as fluoropolymer-lined components or SiC-based materials should be considered in such cases.

Severe mechanical impact or shock loading also falls outside optimal use conditions. While flexural strength exceeds 320 MPa, impact energies above 3–5 J can initiate brittle fracture. In practice, fixtures subjected to tool strikes or uncontrolled vibration require mechanical shielding or hybrid designs to prevent sudden failure.

Over-constrained assemblies represent another frequent misuse scenario. When thermal expansion is restricted, internal stresses accumulate rapidly during heat-up. Field failures indicate that rigid metal–ceramic interference fits increase crack probability by >40% compared with compliant assemblies. Consequently, proper clearance and interface design remain mandatory.

Recognizing these boundaries preserves reliability and ensures that Black Alumina Ceramic functions as an engineered solution rather than a consumable liability.

Conclusion

Black Alumina Ceramic enables chemical processing equipment to operate reliably under sustained heat, reactive chemistry, and electrical stress by aligning material stability with fixture-level engineering requirements.

For chemical processing applications requiring stable, customized Black Alumina Ceramic components, ADCERAX supports engineering consultation, drawing-based customization, and controlled production. Technical discussions can begin directly from your process conditions.

FAQ

What operating temperature range suits Black Alumina Ceramic in chemical equipment?

Continuous operation up to 1,300–1,400 °C is typical in oxidizing and chemically active environments.

Is Black Alumina Ceramic suitable for electrically insulated chemical heaters?

Yes, volume resistivity remains above 10¹² Ω·cm at 800 °C, supporting high-temperature insulation.

How does Black Alumina Ceramic compare to white alumina in contamination control?

Ion migration and surface degradation are reduced by approximately 30–40% under equivalent conditions.

Can ADCERAX customize Black Alumina Ceramic fixtures from samples or drawings?

Yes, customization is supported through drawings, reverse engineering, and tolerance co-design.

References:

-

Learn how oxygen vacancies influence the optical and electrical properties of ceramics, crucial for understanding advanced materials like black alumina. ↩

-

Learn how vitrification impacts ceramic materials, including why it can compromise surface texture and structural integrity in industrial applications. ↩