Advanced Boride Ceramic for High-Wear and Molten Metal Challenges

ADCERAX is a dedicated boride ceramic factory, turning boron carbide and titanium diboride into precision nozzles, liners, stones, wettable cathodes and custom parts made to your drawings.

With factory-direct pricing, engineering support, flexible small-batch sampling and fast shipment on standard sizes, we help you strengthen critical wear and molten metal contact points.

👉 Send us your specifications and let ADCERAX turn your boride ceramic concept into a long-life production part.

What Are Boride Ceramics?

Are Borides Ceramics?

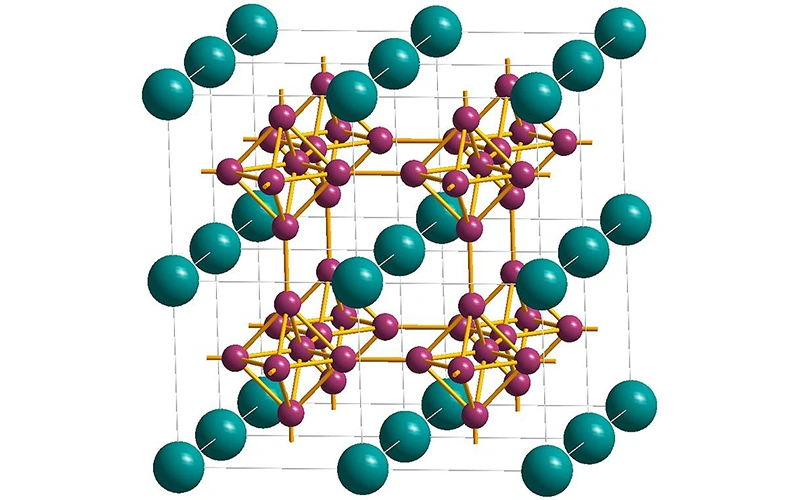

In industrial practice, many metal borides are classified as ceramics because they are covalently bonded, non-metallic in behaviour, extremely hard and are processed through ceramic routes such as powder pressing and high-temperature sintering.

Borides Ceramic Definition

Boride ceramic generally refers to dense, engineered materials based on metal borides such as boron carbide and titanium diboride. These materials exhibit typical ceramic behaviour—very high hardness, brittleness, high melting temperatures and chemical stability—while also offering useful electrical and thermal properties.

Borides Ceramic Advantages

Boride ceramics let you reinforce only the nozzles, liners and contact faces that limit uptime, delivering a clear performance upgrade without redesigning the whole system.

Longer service intervals mean fewer nozzle and insert change-outs in blasting rooms or molten aluminium areas, reducing operator exposure to dust, heat and confined spaces.

Equipment fitted with boride ceramic parts can run more aggressive duty cycles and longer campaigns while keeping components dimensionally stable and predictable to maintain.

Standardised boride ceramic designs can be used across multiple machines and lines, simplifying spare-part portfolios, shortening lead times and making after-sales support easier to scale.

Boride Ceramic Properties

Boride ceramics combine very high hardness, strong chemical stability and good thermal conductivity in boron carbide, titanium diboride and related materials. They keep dimensions stable under severe abrasion and molten aluminium contact, while their electrical behaviour suits wettable cathodes and conductive inserts. This mix of wear, thermal and electrical performance makes them ideal for upgrading the most demanding nozzles, liners and contact surfaces.

Lanthanum Hexaboride Ceramics (LaB6)

Lanthanum hexaboride ceramic (LaB6) combines high electrical conductivity with a low work function and excellent thermal stability, making it a very efficient thermionic emission material. It is widely used for hot cathodes in electron microscopes, X-ray sources, vacuum tubes and other high-temperature electron emission devices.

| Property | Typical Value / Range | Performance Highlights / Notes |

|---|---|---|

| Melting Point | ≈ 2528 K (about 2250 °C) | Refractory ceramic that remains structurally stable at very high temperatures. |

| Density | ~4.7 g/cm³ | Compact, robust ceramic body suitable for small high-power cathodes and inserts. |

| Thermal Conductivity | ~47–60 W/m·K at 20 °C | Efficiently spreads heat across the emitter, reducing local hot spots. |

| Thermal Expansion (CTE) | ~6.2–6.5 ×10⁻⁶ /K (20–900 °C) | Good thermal shock resistance and predictable expansion for brazed or clamped assemblies. |

| Electrical Resistivity | ~15 μΩ·cm at 20 °C | High electrical conductivity, ideal for thermionic cathodes and other electron-emitting parts. |

| Typical Operating Temperature (Cathode) | ~1400–1800 °C in vacuum | Provides strong electron emission while maintaining long-term structural stability. |

| Emission Current Density | ~20–50 A/cm² at 1400–1800 °C | Delivers high beam brightness for electron microscopes, X-ray sources and plasma devices. |

| Work Function | ≈ 2.6–2.7 eV | Low work function enables high emission at lower temperatures than conventional tungsten cathodes. |

- Please note: Customized parts may have adjusted characteristics depending on production methods, with specific parameters determined by the stabilizer type and formula chosen for your application.

Titanium Diboride Ceramics (TiB₂)

Titanium diboride ceramic (TiB₂) combines high hardness, excellent electrical and thermal conductivity, and strong chemical stability in contact with molten aluminium. It is widely used for wettable cathodes, molten metal contact tiles, wear-resistant inserts and other high-temperature components where both conductivity and erosion resistance are critical.

| Property | Typical Value / Range | Performance Highlights / Notes |

|---|---|---|

| Density | ~4.5 g/cm³ | Compact, high-density ceramic suitable for thin wettable cathodes and compact inserts. |

| Hardness (Vickers) | ~2500–3200 HV | Very high hardness for strong resistance to abrasion and erosion in molten metal and particle flow. |

| Flexural Strength | ~300–550 MPa | Provides reliable mechanical strength for tiles, blocks and mounted inserts. |

| Elastic Modulus | ~500–570 GPa | Very stiff material that maintains geometry under load and high current densities. |

| Thermal Conductivity | ~60–120 W/m·K (room temperature) | Efficiently conducts heat away from the cathode surface, limiting local overheating. |

| Electrical Resistivity | ~8–15 μΩ·cm (room temperature) | High electrical conductivity, ideal for wettable cathodes and other conducting ceramic parts. |

| Thermal Expansion (CTE) | ~7–8 ×10⁻⁶ /K (20–1000 °C) | Compatible with many refractory linings and metallic supports, helping to reduce thermal stresses. |

| Recommended Service Temperature | Up to ~1000–1100 °C in air; higher in inert/vacuum | Suitable for long-term operation in molten aluminium and high-temperature conductive applications when properly protected from oxidation. |

- Please note: Customized parts may have adjusted characteristics depending on production methods, with specific parameters determined by the stabilizer type and formula chosen for your application.

Cerium Hexaboride Ceramics (CeB6)

Cerium hexaboride ceramic (CeB₆) provides high electron emission density, a low work function and excellent thermal stability, allowing it to operate at relatively low cathode temperatures with long service life. It is widely used as a thermionic cathode material in electron microscopes, X-ray sources, vacuum tubes and other high-temperature electron emission systems that demand stable current and reliable startup behaviour.

| Property | Typical Value / Range | Performance Highlights / Notes |

|---|---|---|

| Melting Point | ≈ 2550–2600 °C | Refractory material that remains stable at very high temperatures in vacuum environments. |

| Density | ~4.7–4.9 g/cm³ | Compact ceramic body suitable for small, high-power cathodes and inserts. |

| Thermal Conductivity | ~15–25 W/m·K at 20 °C | Conducts heat away from the emission surface, helping to control temperature gradients. |

| Thermal Expansion (CTE) | ~6–7 ×10⁻⁶ /K (20–1000 °C) | Predictable thermal expansion that supports reliable brazing or clamped assemblies. |

| Electrical Resistivity | ~30–60 μΩ·cm at 20 °C | Good electrical conductivity for thermionic cathodes and other electron-emitting components. |

| Typical Operating Temperature (Cathode) | ~1500–1800 °C in vacuum | Provides strong electron emission while maintaining structural stability and reasonable evaporation rate. |

| Emission Current Density | ~10–30 A/cm² at operating temperature | Capable of high current output for electron beams in microscopes, X-ray sources and plasma devices. |

| Work Function | ≈ 2.5–2.7 eV | Low work function enables efficient electron emission at lower temperatures compared with many metal cathodes. |

- Please note: Customized parts may have adjusted characteristics depending on production methods, with specific parameters determined by the stabilizer type and formula chosen for your application.

Key Properties of Boride Ceramics

Boride ceramics such as B₄C and TiB₂ provide very high hardness and wear resistance, keeping nozzle bores, edges and liner surfaces stable under intense particle impact.

Many boride ceramics conduct heat and current efficiently, enabling wettable cathodes, conductive inserts and other components where oxide ceramics are too insulating.

Boride ceramics resist attack by molten aluminium and aggressive atmospheres, helping maintain melt purity, reduce contamination and support predictable service life.

Boron carbide combines low density with a high elastic modulus, allowing lightweight yet stiff components and panels that withstand severe mechanical and abrasive loads.

Properly processed boride ceramics hold shape and tolerances through repeated heating and cooling cycles, which is critical for precision nozzles, tiles and contact parts.

Boride ceramics keep strength and electrical performance under high heat and current load, making them suitable for cathodes, contact pads and other loaded parts.

Boride Ceramic Products

ADCERAX supplies a full range of boride ceramic parts, including LaB₆ cathode tubes, plates and rings, TiB₂ wettable cathodes and molten-metal contact parts, and B₄C nozzles, stones and wear liners for severe abrasive service. Both standard sizes and fully customised geometries can be manufactured to your drawings, tolerances and specific performance requirements.

Lanthanum hexaboride plates are used as thermionic emission elements, cathode inserts and electron sources in microscopes, X-ray systems and vacuum devices that demand stable, high-current output.

- Achieves strong emission current at lower heater setpoints.

- Maintains stable output and long life through repeated thermal cycling.

- Enables custom plate sizes and features for electron-beam hardware.

Lanthanum hexaboride rods serve as thermionic emitters in electron microscopes, X-ray systems, and vacuum electron devices needing consistent emission and extended high-temperature durability.

- Delivers high emission current at reduced heater temperatures.

- Sustains steady thermionic output through long duty cycles.

- Enables accurate rod dimensions for repeatable source alignment.

Lanthanum hexaboride rings serve as thermionic cathode elements in electron microscopes, X-ray sources and vacuum devices that require stable emission and long service life.

- Delivers uniform ring-shaped emission at high current density

- Keeps emission stable through repeated high-temperature cycles

- Supports custom ring sizes and mounts for different vacuum systems

Lanthanum hexaboride cathode tubes are used in electron microscopes, X-ray sources and vacuum electronic devices where stable thermionic emission and long-life high-temperature operation are required.

- Provides high current density at relatively low temperature

- Maintains stable thermionic emission over long operating life

- Allows precise cathode tube geometries in LaB₆ ceramic

🔥Reduce wear, protect your melt, and extend service life with engineered boride ceramics.

ADCERAX engineers boride ceramic components in B₄C, TiB₂ and LaB₆/CeB₆ to handle extreme abrasion, molten aluminium contact and high-current emission. From blasting nozzles and wear blocks to cathode tubes, plates and rings.

Boride Ceramics Applications

Boride ceramics are used in abrasive blasting systems, molten aluminium and non-ferrous metallurgy, vacuum and electron-beam devices, and precision metalworking tools. From B₄C nozzles and boride ceramic stones to TiB₂ molten-metal parts and LaB₆ cathode tubes, they are chosen where severe wear, high temperature and high current demand stable, long-life components.

Abrasive Blasting and Surface Preparation

🔹Advantages

- Extends nozzle life under aggressive abrasives, reducing change-out frequency.

- Maintains stable bore geometry and spray pattern for consistent surface finish.

- Resists erosive wear better than carbide or oxide ceramics in long blasting campaigns.

- Handles high-pressure, high-flow operation without chipping at nozzle inlets and exits.

Molten Aluminium and Non-ferrous Metallurgy

🔹Advantages

- Offers strong chemical stability in molten aluminium, limiting erosion and wetting damage.

- Maintains electrical conductivity for wettable cathodes and current-carrying inserts.

- Reduces melt contamination from dissolved metals or reaction products.

- Withstands repeated thermal cycling between preheat, casting and cool-down.

Vacuum and electron-emission systems

🔹Advantages:

- Provides high electron emission current density at comparatively low temperatures.

- Delivers stable emission characteristics over long operating hours in vacuum.

- Preserves cathode geometry, helping keep beam focus and alignment consistent.

- Tolerates rapid heating and cooling during start-up and shutdown cycles.

Precision tooling, guides and wear components

🔹Advantages:

- Keeps tight dimensional tolerances under repeated sliding, impact and load.

- Offers very high surface hardness to resist scratching and grooving of contact faces.

- Reduces wear on adjacent metal parts, extending overall assembly life.

- Supports fine grinding and lapping to achieve precise positioning and guiding accuracy.

Custom boride ceramic Parts and Engineering Support

We specialize in custom boride ceramic parts based on customer drawings, samples, or application requirements. Dimensions, wall thicknesses, emission surfaces and complex geometries in LaB₆, CeB₆, TiB₂ and B₄C can be tailored to your operating conditions. Custom boride ceramic components typically require 3–9 weeks depending on design complexity, machining tolerances and surface-finish specifications.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

china boride ceramic manufacturer

ADCERAX is a China boride ceramic manufacturer supplying LaB₆, CeB₆, TiB₂ and B₄C parts with consistent quality and stable lead times. We provide cathode tubes, plates, rings, nozzles and wear blocks for high-temperature, vacuum and molten-metal applications, helping buyers keep critical equipment running reliably.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

ADCERAX integrates powder preparation, hot pressing/sintering, diamond machining, brazing and quality inspection into a single workflow for boride ceramics. Our one-stop model supports B₄C, TiB₂, LaB₆ and CeB₆ components from prototype samples to stable series production.

-

Precision Machining & Shaping:

Boride ceramic parts are produced to tight dimensional tolerances, with fine-grain density and clean edges for nozzles, cathode tubes, plates, rings and wear blocks. -

Wear, Thermal & Electrical Consistency:

Each batch is checked for hardness, density, thermal behaviour and electrical properties, helping ensure consistent service life in abrasive blasting, molten aluminium contact and high-current emission systems. -

Engineering & Application Support:

ADCERAX engineers assist with material selection between B₄C, TiB₂ and hexaboride options, optimise wall thickness and geometry, and align part designs with your blasting, metallurgical or vacuum equipment requirements.

ADCERAX specializes in producing high-performance boride ceramics, combining controlled powder processing, hot pressing/sintering and precision diamond machining with strict inspection control. Each LaB₆, CeB₆, TiB₂ and B₄C component is engineered for hardness, wear resistance, and dimensional stability, ensuring reliability in abrasive blasting, molten-metal handling, vacuum electronics and other demanding industrial applications.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Capability Item | Typical Value / Description | ||

| Material Grades | LaB₆, CeB₆, TiB₂ and B₄C boride ceramics, high-density (≈97–99% TD) with fine-grain microstructure for wear, emission and molten-metal duty. | ||

| Dimension Range | From Ø3–10 mm pellets/discs to tubes, rings, nozzles and blocks up to ~150 mm, key dimensions held to ±0.02–0.05 mm. | ||

| Forming Methods | Hot pressing or isostatic pressing plus vacuum sintering, followed by CNC diamond grinding, turning and drilling. | ||

| Processing | Controlled high-temperature sintering in vacuum or inert gas to ~2000 °C for low porosity and stable properties. | ||

| Surface Finish | Working faces ground to about Ra 0.4–0.8 µm; critical sealing or emission areas lapped to Ra ≤ 0.1 µm. | ||

FAQs About Boride Ceramic

We mainly offer LaB₆ and CeB₆ hexaborides, TiB₂ ceramics and B₄C (boron carbide) components. LaB₆ and CeB₆ are thermionic emitter materials used in electron sources;

Lanthanum hexaboride (LaB₆)

Thermionic emitter material for electron microscopes, electron-beam sources and vacuum devices.

Key focus: high current density, stable emission, long life at high temperature.Cerium hexaboride (CeB₆)

Alternative emitter material for electron and ion sources.

Key focus: stable emission behaviour and good lifetime under repeated start–stop cycles.Titanium diboride (TiB₂)

Electrically conductive boride for molten aluminium contact parts, cathodes and wear blocks.

Key focus: good conductivity, strong chemical resistance to aluminium, high hardness.Boron carbide (B₄C)

Ultra-hard boride ceramic for blasting nozzles, boride ceramic stones and wear-resistant inserts.

Key focus: extreme abrasion resistance, long service life in aggressive abrasive streams.

In practice, you choose the grade according to whether the priority is electron emission, electrical conduction in molten metal, or maximum abrasion resistance.

TiB₂ is preferred when a part must be both electrically conductive and chemically stable in contact with molten aluminium or conductive melts. Compared with alumina or SiC, TiB₂ combines good conductivity, high hardness and strong resistance to aluminium attack, so it fits cathodes, contact pads, current-carrying wear blocks and metallurgical tooling where oxide ceramics would be attacked or insulate the circuit.

LaB₆ generally offers higher emission current at a given temperature and is widely used in electron microscopes and electron-beam systems that need high brightness. CeB₆ typically has a slightly lower work function and can provide good emission stability with somewhat different lifetime behaviour. In practice, the choice is usually driven by your existing design, operating temperature window, required current density and replacement strategy.

For most LaB₆, CeB₆, TiB₂ and B₄C components we can hold outer dimensions and critical thicknesses to about ±0.02–0.05 mm, depending on the size and shape. Small features such as slots, steps, counterbores or chamfers can be diamond-machined with tight positional accuracy, and functional faces can be fine-ground or lapped for smooth contact surfaces.

Boride ceramics are designed for high temperature, but their thermal shock resistance depends on grade and geometry. B₄C and TiB₂ blocks and nozzles perform well under controlled heating and cooling, but sharp temperature jumps and cold fluid quenching should be avoided. For LaB₆ and CeB₆ cathodes, we recommend controlled ramp-up and ramp-down rates to minimise thermal stress and maintain lifetime.

Yes. Typical approaches include active-brazing to refractory metals, mechanical clamping, shrink-fitting into metallic holders, and assembly into oxide ceramics. For high-temperature or vacuum systems, brazing alloys and joint dimensions need to be matched to CTE differences between TiB₂/B₄C/LaB₆ and the chosen metal. We can review your drawing and propose joint clearances and transition sleeves to reduce stress at the interface.

We normally require complete geometry (2D/3D drawing), tolerance scheme on critical faces, surface-finish requirements, material grade (LaB₆, CeB₆, TiB₂, B₄C), operating temperature, atmosphere (vacuum, inert gas, molten aluminium, abrasive media) and estimated annual demand. This allows us to choose the forming route, machining method, inspection plan and packing for fragile emission surfaces.

B₄C boride nozzles have extremely high hardness and wear resistance, helping keep the internal bore shape stable over many hours of blasting. This stabilises jet energy and pattern, improves surface uniformity, and reduces nozzle change frequency. For operators, the result is fewer shutdowns, more predictable media consumption and more consistent coating preparation.

Lifetime is strongly affected by operating temperature, vacuum level, current density, contamination and start-stop cycles. In many systems, LaB₆ cathodes can run for thousands of hours under well-controlled conditions. When we design cathode tubes, plates or rings, we focus on consistent grain structure, precise emission surface finish and stable mounting geometry so that you can reach the upper end of your equipment’s specified lifetime window.

Key checks include boride material experience (LaB₆, CeB₆, TiB₂, B₄C), in-house forming and diamond machining capability, traceable process records, export packing experience and communication efficiency. A real factory can show sintering equipment, machining lines and inspection tools, while a pure trading company usually outsources all production and has less control over lead time and quality.

Yes. As a ceramic manufacturing supplier, we can combine boride ceramics with alumina, zirconia, silicon nitride and other materials in one purchase order. Many buyers place mixed-container or mixed-carton shipments to reduce logistics cost and consolidate suppliers instead of dealing with multiple small factories.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

info@adcerax.com

Telephone: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours