China Ceramic Balls Manufacturer for Inert Packing & Grinding Media

ADCERAX is a China ceramic ball manufacturer and supplier serving packed-bed/catalyst support, grinding media, and precision rolling or sealing duties in abrasive, corrosive, and high-temperature service. We offer Al₂O₃ (alumina) ceramic balls, ZrO₂ (zirconia) ceramic balls, Si₃N₄ (silicon nitride) ceramic balls, and SiC (silicon carbide) ceramic balls, selected to balance wear rate, impurity pickup, impact tolerance, and thermal stability for your process conditions.

Choose ADCERAX as your ceramic ball manufacturer and supplier to improve process stability, reduce media and equipment wear, and lower total operating cost.

What is Ceramic Ball?

Ceramic Ball Definition

A ceramic ball is a precision spherical component made from advanced engineering ceramics such as alumina (Al₂O₃), zirconia (ZrO₂), silicon nitride (Si₃N₄), or silicon carbide (SiC). It is designed to deliver high hardness, outstanding wear resistance, corrosion stability, thermal tolerance, and electrical insulation in demanding environments.

Ceramic Ball Advantages

Lower Contamination Risk

- Ceramic chemistry avoids metallic ion pickup and rust debris that can seed process drift, while glass can shed fines in some high-shear or chemically attacked conditions.

- Best for: pigment/ink dispersion, battery slurry, fine chemicals, impurity-sensitive wet processing.

Lower Noise & Vibration Through Geometry Stability

- Tight size tolerance, roundness, and low roughness keep rolling and sealing consistent—reducing noise and vibration that metals amplify after wear and glass worsens after surface damage.

- Best for:precision bearings, metering valves, motion systems demanding stable NVH performance.

Better Fatigue Resistance in Rolling Contact

- High hardness and elastic stability reduce micro-plastic deformation seen in metals; controlled sphericity and surface finish help keep contact stress uniform, lowering fatigue initiation.

- Best for: hybrid bearings, precision rotating systems, high-speed or start-stop duty.

Higher Damage Tolerance vs Breakage Scenarios

- Ceramic balls resist abrasion and maintain geometry under sliding/impact better than metals; compared with glass, engineering ceramics offer higher strength and wear control under load.

- Best for: grinding media, valve balls/seat contact, abrasive slurry lines, and packed-bed supports.

Ceramic Ball Properties

Ceramic balls are made from high-purity alumina, with options in zirconia, silicon nitride, silicon carbide, and boron nitride. They deliver low wear, stable geometry, and chemical durability for bearings, grinding media, and valve sealing in harsh service.

Alumina Ceramic Balls

Alumina balls (Al₂O₃) are valued for reliable electrical insulation, stable geometry at elevated temperatures, and cost-effective wear resistance in fixtures, flow paths, and general grinding media

| Property | Unit | 96% Al₂O₃ | 99% Al₂O₃ | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

|---|---|---|---|---|---|---|---|---|---|

| Alumina content | % | 96 | 99 | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.75 | 3.88 | 3.89 | 3.91 | 3.92 | 3.93 | 3.95 | 3.98 |

| Flexural strength | MPa | 330 | 360 | 379 | 312 | 313 | 314 | 315 | 320 |

| Hardness | GPa | 11.5 | 13.5 | 14.1 | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 20–25 | 30–35 | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | 150 | 200 | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1600 | ≤1700 | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Dielectric strength | kV/mm | 8–10 | 10–12 | 11–13 | 12–14 | 12–15 | 13–16 | 14–17 | 15–18 |

| Volume resistivity (25°C) | Ω·cm | ≥1×10¹³ | ≥1×10¹⁴ | ≥3×10¹⁴ | ≥5×10¹⁴ | ≥1×10¹⁵ | ≥3×10¹⁵ | ≥5×10¹⁵ | ≥1×10¹⁶ |

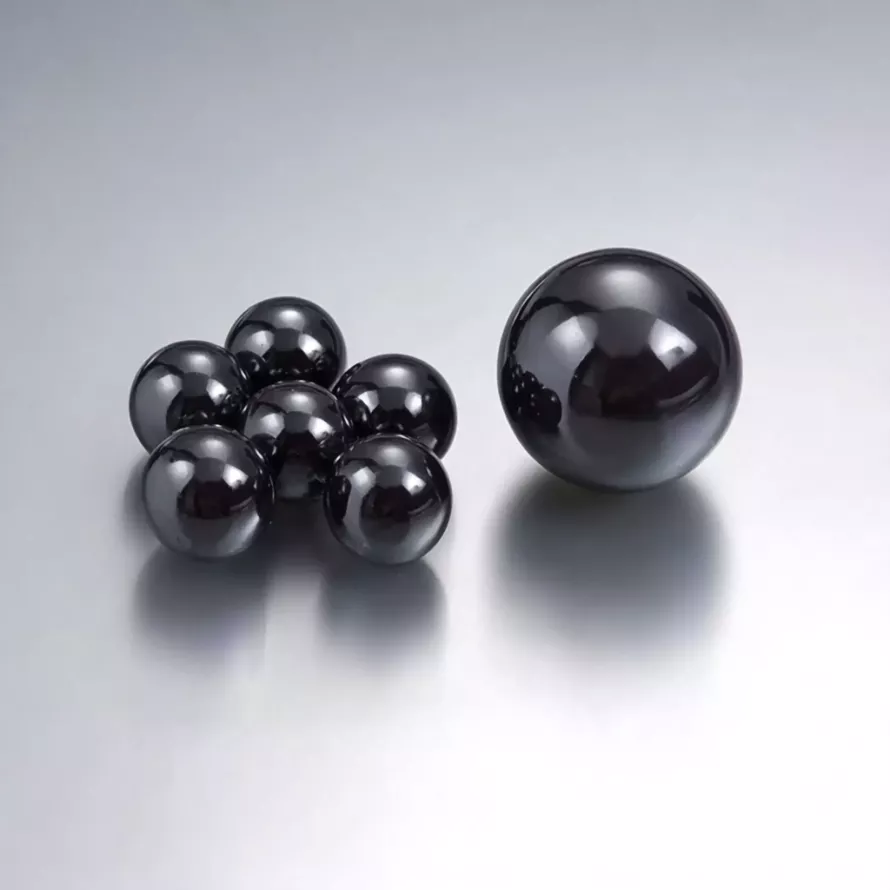

Zirconia Ceramic Balls

zirconia balls (ZrO₂) stand out for high density and fracture toughness that withstand impact loading in high-shear milling while helping achieve finer, cleaner dispersions with low media breakage

| Property | Specification |

| Maximum Working Temperature | 1500 °C continuous use |

| Density | 5.65 g/cm³ |

| Thermal Expansion Coefficient | 10.3 × 10⁻⁶/K (25–1000 °C) |

| Thermal Conductivity | 2.2 W/m·K at 1000 °C |

| Chemical Stability | 0.08% mass loss after 24 h acid/alkali exposure at 1200 °C |

| Flexural Strength | 900 MPa at room temperature |

| Fracture Toughness | 8 MPa·m½ |

| Hardness (Vickers) | 12 GPa |

| Elastic Modulus | 210 GPa |

Silicon Carbide Balls

silicon carbide ceramic balls (SiC) deliver ultra-high hardness, exceptional abrasion control, and strong corrosion tolerance in aggressive slurries, making them suitable for harsh chemical and high-wear environments

| Property | Specification |

|---|---|

| Material System | RBSiC (80% SiC, 20% free Si) / SSiC (≥99% SiC) |

| Maximum Operating Temperature | ≤1380°C (RBSiC) / ≤1600°C (SSiC) |

| Bulk Density | 3.02 g/cm³ (RBSiC) / 3.10 g/cm³ (SSiC) |

| Open Porosity | <0.1% |

| Flexural Strength (20°C) | 250 MPa (RBSiC) / 380 MPa (SSiC) |

| Flexural Strength (1200°C) | 280 MPa (RBSiC) / 400 MPa (SSiC) |

| Compressive Strength | 1000–2200 MPa |

| Elastic Modulus | 330 GPa (RBSiC) / 420 GPa (SSiC) |

| Thermal Conductivity | 45 W/m·K (RBSiC) / 74 W/m·K (SSiC) |

| Thermal Expansion Coefficient | 4.1–4.5 ×10⁻⁶/K |

| Hardness | 2600–2800 kg/mm² |

| Chemical Stability Range | pH 2–12 |

| Oxidation Stability | <1% microstructural oxidation after 50 cycles (1000°C → RT) |

Silicon Nitride Balls

silicon nitride ceramic balls (Si₃N₄) combine high strength with low density to reduce centrifugal load at speed, offering excellent thermal shock resistance and fatigue performance for precision bearing and dynamic applications.

| SiN4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

|---|---|---|---|

| Density (g/cm³) | 3.2 | 3.4 | 3.5 |

| Texture strength (MPa) | 300 | 300-320 | 300-320 |

| Young Modulus | 300 | 300 | 300 |

| Poisson’s ratio | 0.25 | 0.25 | 0.25 |

| Hardness (GPa) | 15 | 15 | 15 |

| Maximum working temperature (°C) | 1100 | 1200 | 1200 |

| Thermal expansion coefficient (Mm/m·K) | 3 | 3 | 3 |

| Thermal conductivity (W/m·K) | 15 | 15 | 15 |

| Thermal shock resistance (ΔT °C) | 550 | 580 | 600 |

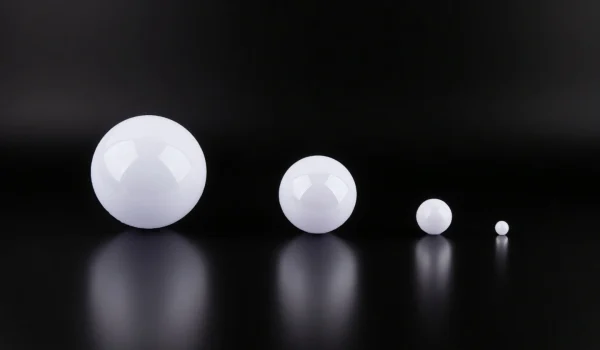

Ceramic Ball & Bead Products

Industrial ceramic balls are specified for grinding media, bearing elements, valve sealing, and packed-bed flow control. Choose alumina, zirconia, silicon nitride, or silicon carbide ceramic balls, plus YSZ, ZTA, Ce-TZP and zirconium silicate options for clean, low-wear service.

ceramic alumina balls

Al₂O₃ balls deliver reliable insulation and wear control, keeping shape at elevated temperatures in fixtures.

zirconia ceramic balls

Dense ZrO₂ balls offer high toughness and impact strength, reducing breakage for cleaner, finer milling.

silicon nitride ceramic balls

Silicon nitride balls resist wear and micro-spalling under heavy loads, helping extend bearing life and reduce vibration in service.

silicon carbide ceramic balls

Ultra-hard silicon carbide balls resist abrasion and corrosion, holding smooth surfaces in aggressive slurry service.

Zirconium Silicate Beads

Zirconium silicate beads offer cost-efficient grinding with steady density, ideal for paints, inks, and mineral slurries.

ysz ceramic balls

Yttria-stabilized zirconia balls maximize energy transfer, enabling faster grinding and fewer contaminants in fine milling.

zTA ceramic balls

Zirconia-toughened alumina beads reduce breakage while maintaining strong wear control for demanding coating and milling.

Ce-TZP Beads

Ceria-stabilized zirconia beads handle severe agitation, delivering long bead life for high-viscosity and high-energy milling.

Activated Ceramic Balls

Porous activated balls for gas drying and purification, improving adsorption efficiency and service life in packed beds.

Inert Alumina Balls

Dense inert alumina balls for catalyst support layers, ensuring uniform flow distribution and protecting catalysts in reactors.

ceramic insulating beads

High-dielectric ceramic beads for insulated standoffs and feedthrough spacing, maintaining isolation in hot equipment.

bearing ceramic balls

Precision ceramic balls for low-friction bearings, resisting wear, heat, and corrosion to keep speed stable.

ceramic grinding balls

High-density ceramic grinding balls deliver efficient milling, low contamination, and consistent particle size in slurry processing.

ceramic ball valves

Hard ceramic valve balls seal reliably against erosion and chemicals, extending valve life in abrasive or corrosive fluids.

Industrial Ceramic Balls for Lower Wear, Longer Life

Tell us your operating conditions—size, tolerance, environment and wear target—and we’ll match the best ceramic ball option for consistent production supply.

Ceramic Balls Uses

Industrial ceramic balls serve as wear media, precision rolling elements, and sealing components where abrasion, corrosion, temperature, and contamination control limit metal solutions. Selection is typically driven by media chemistry, particle hardness, operating speed, thermal cycling, and allowable impurity pickup.

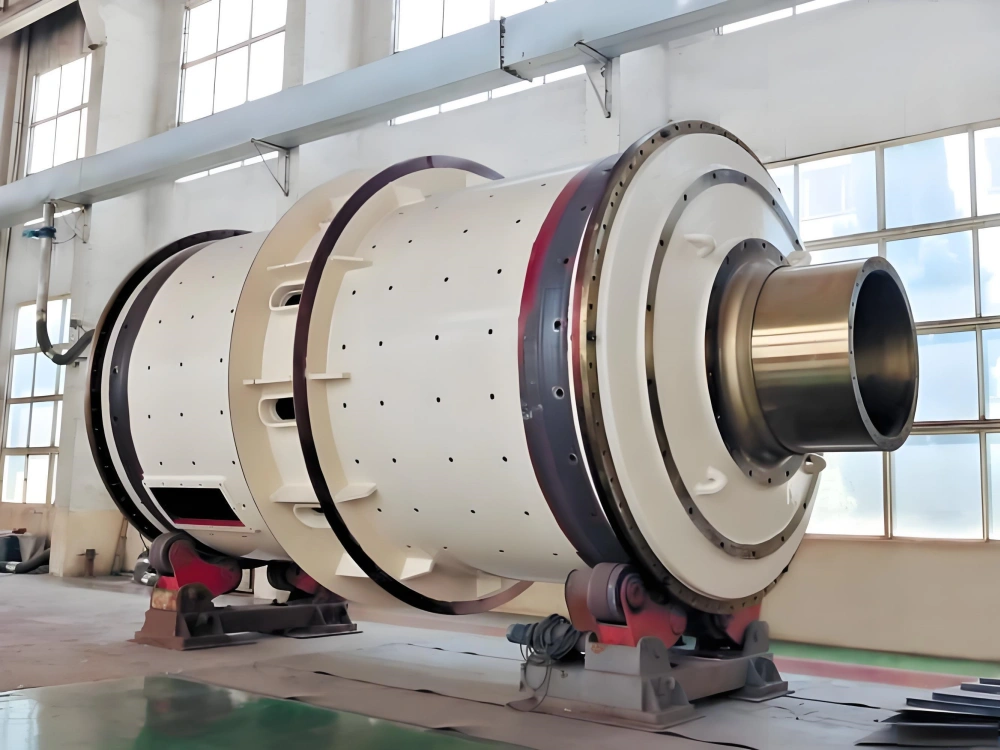

Grinding & Dispersion Media

🧩Where industrial ceramic balls are used:

Ceramic balls serve as grinding and dispersion media in bead mills/attritors, delivering stable particle size control and cleaner slurries. They help reduce metal contamination for inks, pigments, battery materials, and specialty chemicals.

🧩ADCERAX wear resistant ceramic balls deliver consistent energy transfer and low contamination, helping mills reach tighter particle-size distribution with fewer metallic impurities. Higher wear life reduces media replacement, downtime, and batch-to-batch variability in sensitive formulations.

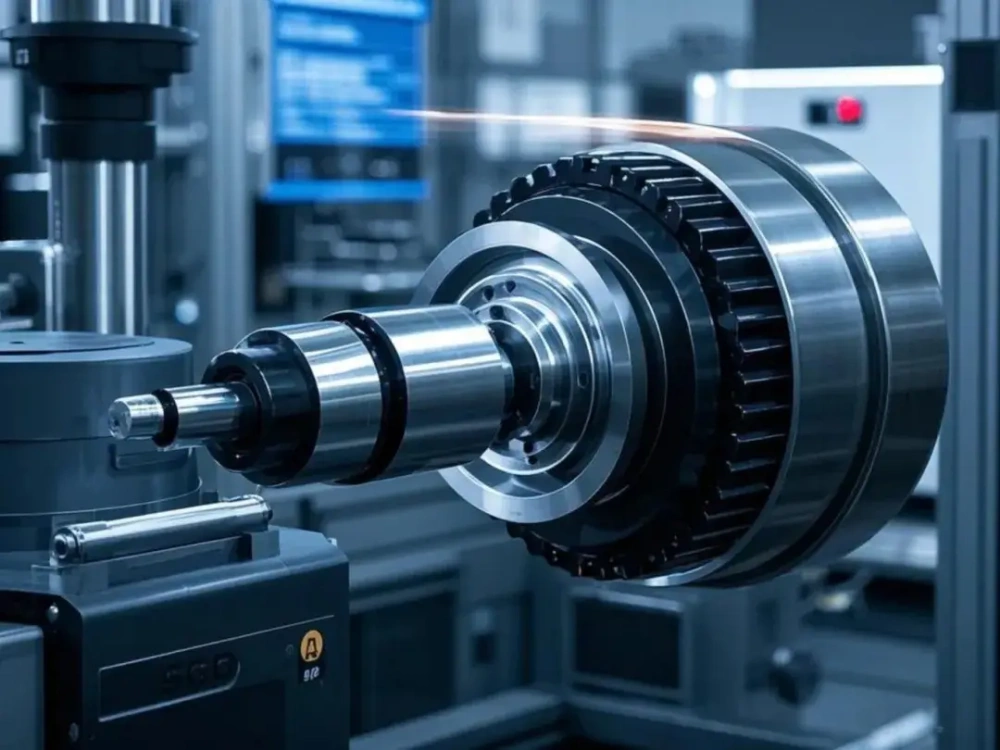

Bearing Elements (Hybrid/All-Ceramic)

🧩Where ceramic precision balls are used:

bearing ceramic balls are used in high-speed hybrid/all-ceramic bearings to lower frictional heat and resist corrosion in wet or chemically exposed duty. Their roundness and surface finish help reduce noise/vibration and extend bearing life.

🧩ADCERAX high precision ceramic balls reduce frictional heat and electrical discharge risk, enabling higher-speed operation in hybrid or all-ceramic bearings. Their corrosion resistance and stable roundness help lower noise, extend grease life, and improve reliability.

Valve Balls & Check Components

🧩Where industrial ceramic balls are used:

Ceramic balls act as shut-off/sealing elements in ball/check/dosing valves handling corrosive, ultrapure, or abrasive media, reducing seat wear, scoring, and long-term leakage drift under frequent cycling. Their stable geometry helps maintain consistent sealing performance.

🧩ADCERAX ceramic valve balls resist abrasion and chemical attack, maintaining sealing geometry in corrosive, ultrapure, or slurry media. Lower seat wear helps reduce leakage drift, stabilize dosing accuracy, and lengthen service intervals under cycling.

Packed Bed & Tower Packing Support

🧩Where ceramic balls are used:

As support media and flow-distribution layers in towers/reactors, ceramic balls improve flow uniformity, limit channeling, and stabilize packing beds. They remain dimensionally stable under heat, acid/alkali exposure, and chemical cleaning, supporting long runtimes and predictable pressure drop.

🧩ADCERAX ceramic support balls improve flow distribution and bed stability in towers and reactors, reducing channeling and pressure-drop swings. High compressive strength and chemical stability support longer run lengths and more aggressive cleaning cycles.

Electrical & Insulating Applications

🧩Where professional ceramic balls are used:

Ceramic balls serve as insulating spacers, stand-offs, or separation media where heat and dielectric demands exceed plastics. They provide stable dielectric strength and volume resistivity under heat soak, humidity, and thermal cycling in housings, fixtures, and electrical assemblies.

🧩ADCERAX insulating ceramic balls provide reliable spacing in high-heat electrical assemblies, keeping leakage current low while resisting moisture and thermal cycling. Stable dielectric properties help prevent arcing, protect sensors and heaters, and simplify fixture design.

customized ceramic ball supplier

ADCERAX is a China ceramic ball manufacturer supplying standard and custom balls for milling media, bearings, valve shut-off, and packed-bed support. We tailor diameter, material grade, and surface finish, and stock popular sizes for fast maintenance and small-batch needs.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

ADCERAX: An Industrial Ceramic Ball Manufacturer You Can Rely On

ADCERAX is a specialized ceramic ball manufacturer, supplying a full range of standard and custom ceramic balls with controlled material quality and tight dimensional consistency. Our engineering support, sampling service, and export experience help simplify global sourcing.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

China Ceramic Ball Manufacturer-ADCERAX

ADCERAX has been engaged in advanced ceramics for over 20 years and has developed more than 2,000 types of wear- and corrosion-resistant components, including ceramic balls made from high-purity alumina, zirconia, silicon nitride, silicon carbide, ZTA and other engineering ceramics.

We supply both custom and standard ceramic balls for grinding and dispersion media, hybrid/all-ceramic bearings, valve shut-off and check components, packed-bed/tower packing support, and insulating spacers, exporting to more than 50 countries and supporting OEMs needing stable quality, low contamination, and long service life.

One-Stop Manufacturing Services for Ceramic Ball

ADCERAX provides end-to-end manufacturing support for industrial ceramic balls, covering the full lifecycle from material selection to finished ball delivery.

Each process step is tuned to your operating conditions—media type, load, speed, temperature, and chemistry—to ensure consistent roundness, stable performance, and batch-to-batch reliability.

Matched to wear, corrosion, and contamination requirements (Al₂O₃ / ZrO₂ / Si₃N₄ / SiC / ZTA)

Controlled particle distribution and binder system for dense, uniform microstructure

Precise shaping for stable size control and high sphericity consistency

Optimized firing profile to achieve target density, hardness, and crack resistance

Tight diameter control and roundness improvement for demanding motion/contact duties

Polished or matte finishes to reduce friction, limit wear, and manage media carryover

Ceramic Ball Processing Capacity

From powder to finished spheres, our capacity covers high-volume media balls and precision-grade ceramic balls with controlled size, roundness, and surface finish for repeatable production.

Production Formats

🔹Bulk grinding & dispersion balls (media grade)

🔹Precision balls for bearings/valves (tight grade)

🔹Custom sizes for packed-bed support and insulating spacers

Size & Geometry Range

🔹Diameter: micro to large balls (customized by request)

🔹Controlled sphericity and batch consistency

🔹Optional surface states: matte / polished / functional finish

Volume Capacity

🔹Pilot batches for validation and trials

🔹Stable mass production for repeat orders

🔹Lot control for multi-batch consistency and traceability

Quality Control Capability

🔹Size sorting and multi-stage screening

🔹Roundness / surface inspection by sampling plan

🔹Clean handling options for impurity-sensitive media

FAQs About Chinese Ceramic Balls

Precision Ceramic Balls, such as those made from Silicon Nitride (Si3N4), Zirconia (ZrO2), or Alumina (Al2O3), offer superior advantages including higher hardness for exceptional wear resistance, lower density for reduced centrifugal force in high-speed applications, excellent corrosion resistance against harsh chemicals, and high-temperature stability. These properties mean your Industrial Ceramic Ball components can last longer and perform more reliably.

The best Ceramic Ball material depends on your operating conditions.

- Silicon Nitride Ceramic Balls (Si3N4 Balls) are ideal for high-speed bearings, demanding aerospace applications, and situations requiring extreme toughness and thermal shock resistance.

- Zirconia Ceramic Balls (ZrO2 Balls) offer excellent fracture toughness and strength, making them suitable for grinding media, check valves, and bearings where high load capacity is needed.

- Alumina Ceramic Balls (Al2O3 Balls) provide good wear and corrosion resistance at a cost-effective price, often used in less demanding bearings, valves, and as grinding media. Contact us to discuss your application, and we'll help you select the optimal Advanced Ceramic Ball.

We offer a wide range of sizes for our Ceramic Balls, typically from 0.3mm up to 120mm in diameter, depending on the material. Our Precision Ceramic Balls are available in various grades, including G3, G5, G10, G20, and G40 (as per ISO 3290 / ABMA standards), ensuring you can find the exact tolerance required for your high-precision applications. Custom sizes and grades for your specific Ceramic Ball needs can also be manufactured.

Yes, we specialize in providing Custom Ceramic Ball solutions. If our standard range of Alumina Ceramic Balls, Zirconia Ceramic Balls, or Silicon Nitride Ceramic Balls doesn't meet your exact requirements for size, material grade, or specific property modifications, our engineering team can work with you to design and manufacture Ceramic Balls tailored to your unique application.

To get a quote for Industrial Ceramic Balls, please provide us with your requirements, including the type of Ceramic Ball material (e.g., Al2O3 Ceramic Ball, ZrO2 Ceramic Ball, Si3N4 Ceramic Ball), desired diameter, precision grade, quantity, and a brief description of your application. You can submit your request through our website's contact form or by directly emailing our sales team. We aim to respond with a competitive quote for your Ceramic Balls within 24 hours.

Yes, Small Ceramic Balls, often manufactured to very high precision grades (like G3 or G5), are perfectly suited for miniature bearings, precision instruments, medical devices, and metrology equipment. The inherent properties of these advanced ceramic materials, even in small dimensions, ensure excellent performance and longevity.

Zirconia balls have higher density and toughness, delivering stronger impact energy and lower breakage under shock loading. Alumina balls are harder and more economical, but may chip sooner in high-energy milling or large particle feed.

Si₃N₄ offers low density (lower centrifugal force), high hardness, excellent rolling fatigue resistance, and electrical insulation, improving speed capability and reducing smearing and heat under poor lubrication conditions.

If you need stable roundness, surface finish, and material consistency for bearings, valves, metering, or wear-critical parts, ADCERAX is a china ceramic precision balls manufacturer that supplies precision ceramic balls with material options and QC support for repeatable performance.

✅ Define the use: grinding media, bearing balls, valve/seal parts, or tower support—each needs different tolerances and materials.

📏 Check geometry: diameter tolerance, roundness, and surface finish to reduce vibration and uneven wear.

🧪 Verify material quality: density/porosity, stable microstructure, and low impurities to prevent cracking or contamination.

🔥 Match conditions: chemistry, temperature, RPM, and thermal cycling to control wear and shedding.

📦 Confirm supply stability: consistent batches across repeat orders, with standard sizes and customization support.

✅ Recommendation: If you need stable quality and repeatable tolerances, ADCERAX is a ceramic ball wholesaler that can support application-matched material selection, controlled processing, and batch-consistent supply for industrial ceramic ball requirements.

Ceramic balls are made by turning a ceramic powder into a dense, round sphere through controlled forming, firing, and finishing. The exact steps vary by material (Al₂O₃, ZrO₂, Si₃N₄, SiC) and by use (grinding media vs bearing balls), because tolerance and surface finish requirements are very different.

Typical process

Powder preparation: high-purity ceramic powder is mixed/milled with additives (binder, dispersant) to control particle size and flow.

Forming: the “green” ball is shaped by rolling/pelletizing, pressing, or isostatic pressing for better density uniformity.

Debinding: binders are removed slowly to avoid internal cracking.

Sintering (densification): high-temperature firing densifies the ball; premium grades may add HIP or pressure sintering to reduce porosity.

Finishing: grinding/lapping/polishing brings the ball to target diameter, roundness, and surface roughness.

Inspection & grading: diameter tolerance, roundness/sphericity, surface finish, density/porosity, and defect screening are verified with batch records.

Why the route matters

Grinding media: prioritizes fracture resistance and wear rate consistency.

Bearing balls: prioritizes tight tolerances, very high density, and very smooth surfaces.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

info@adcerax.com

Telephone: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.