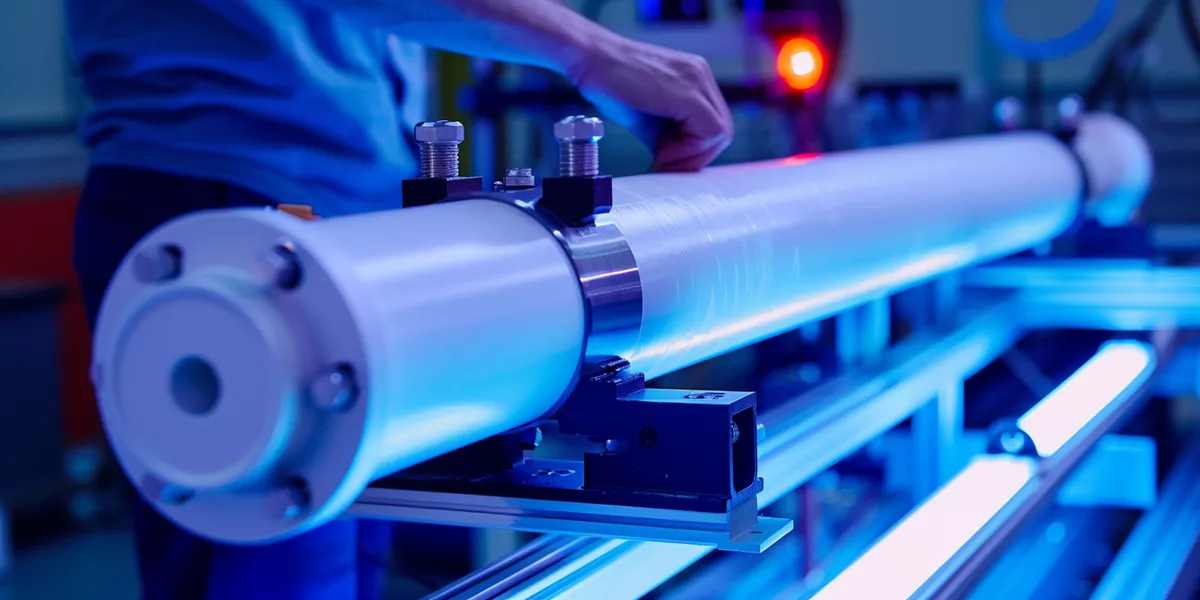

Impact resistant alumina tube plays a crucial role in preventing mechanical failures in automation environments where collisions, tool drops, and high-speed transfers frequently occur. Its enhanced fracture toughness, fine-grain microstructure, and optimized mounting design enable a 4–6× longer service life compared to standard alumina tubes used in robotic, conveying, and CNC systems.

Automated systems rely on the structural integrity of impact resistant alumina tube to mitigate brittle fracture and minimize downtime. The combination of material science, grain boundary engineering, and field-tested mechanical performance ensures consistent protection against impact-induced failures.

Impact Failure Mechanisms in Conveying, Robotic, and Assembly Systems Using Impact Resistant Alumina Tube

Impact resistant alumina tube failures in automated systems originate from three primary mechanisms:

(1) catastrophic brittle fracture when single-event impact energy exceeds critical thresholds of 4–8 J,

(2) cumulative microcrack damage from repeated subcritical impacts,

(3) stress concentration amplification at mounting interfaces where stress waves reflect and superimpose.

Conveyor systems experience impact frequencies of 10–200 events per hour at 1.5–6 J energies, while robotic assembly cells generate occasional 8–15 J impacts.

Fractographic analyses following ASTM C1322 indicate that 68% of failures initiate from surface flaws that raise local stresses 3–6× above nominal levels.

Using impact resistant alumina tube with ≥4.8 MPa√m toughness and Ra < 0.3 μm finish lowers failure probability by up to 85%.

Brittle fracture mechanics governing single-event catastrophic failure thresholds

Single-event brittle fractures occur when local stress intensity exceeds critical toughness. Impact resistant alumina tube with higher fracture toughness delays crack propagation, absorbing energy through microcrack formation before catastrophic failure. The tube’s dense microstructure prevents crack acceleration from surface flaws, maintaining structural stability during high-energy collisions.

Cumulative damage mechanisms from repeated sub-critical impact loading

Repeated low-level impacts induce cumulative microcracks that coalesce over hundreds of events. Microcrack arrest depends on grain boundary deflection, which is enhanced in fine-grained impact resistant alumina tube. The controlled microstructure increases energy dissipation, extending fatigue life in high-frequency conveyor applications.

Stress wave reflection and amplification at geometric discontinuities and mounting points

Stress waves reflect and amplify at mounting interfaces, concentrating tensile stresses. Proper fixture design with elastomeric isolation reduces reflected stress amplitudes by up to 35%. Impact resistant alumina tube mounted with distributed load supports demonstrates threefold lower stress concentration compared to point-contact designs.

Fractographic identification of impact-initiated versus fatigue-initiated fracture origins

Fractographic studies show mirror, mist, and hackle zones typical of impact fracture surfaces. Impact resistant alumina tube demonstrates smoother fracture origins due to controlled surface finish, whereas fatigue fractures show branching from subsurface pores. This diagnostic distinction aids in maintenance planning and failure root-cause evaluation.

Microstructural Engineering—Grain Boundary Design for Crack Arrest in Impact Resistant Alumina Tube

Grain boundary engineering producing impact resistant alumina tube with 2–3.5 μm average grain size increases fracture toughness up to 28% through deflection mechanisms. Fine-grained structures redirect cracks through tortuous intergranular paths, consuming additional fracture energy. Controlled sintering atmospheres and MgO additions stabilize uniform grains, reducing weak spots.

Grain size reduction mechanisms increasing crack deflection and energy absorption

Reducing grain size forces cracks to deviate along boundaries, increasing surface area and fracture energy. Impact resistant alumina tube with ≈ 2.5 μm grains resists up to 8 J impacts compared to 5 J for coarser grades. Fine grains elevate crack deflection efficiency, delaying critical failure thresholds.

Transgranular versus intergranular fracture mode transitions affecting toughness

Impact resistant alumina tube promotes transgranular fracture modes, raising surface energy requirements. This transition enhances fracture toughness by 25–30%, a key factor in surviving repetitive mechanical shocks common in automated machining systems.

Sintering profile optimization achieving uniform fine-grain microstructures

Two-stage sintering—1,450 °C nucleation followed by 1,650 °C densification—achieves uniform grain distribution and limits abnormal growth. This prevents local stress magnification during impacts and ensures reproducibility across batches.

Grain boundary chemistry control preventing glass phase accumulation and weak interfaces

Controlled MgO additions (0.25–0.5 wt%) prevent glassy films along grain boundaries that lower bonding strength. Stable boundary chemistry maintains load transfer efficiency during impact events, improving service reliability.

Case Study—Shock Absorption Performance of Impact Resistant Alumina Tube in High-Speed CNC Guide Systems

High-speed CNC systems using impact resistant alumina tube for guide rails show a 4.2× increase in mean time between failures. Tool breakage events generating 8–14 J impacts occur regularly in titanium machining. These tubes absorb 35–42% more energy and reduce unplanned downtime by 77%, improving operational economics significantly.

Instrumented impact testing quantifying energy absorption and fracture resistance

Piezoelectric sensor1 testing indicates higher fracture initiation thresholds in impact resistant alumina tube due to improved crack-tip blunting. Recorded strain data confirm greater elastic recovery before fracture onset.

Microcrack process zone formation mechanisms dissipating impact energy

A microcrack process zone forms 150–300 μm ahead of the main crack tip. This localized energy dissipation reduces catastrophic failure risk. Controlled crack growth stabilizes performance across thousands of cycles.

Vibration damping characteristics affecting stress wave propagation

With damping loss factor (tan δ)2 = 0.008–0.012, impact resistant alumina tube suppresses vibration amplitude, lowering stress wave transmission by up to 35%. Reduced wave energy limits secondary failures at mounting points.

Field performance data demonstrating failure rate reduction and cost savings

In 45 CNC installations tracked for 24 months, failure frequency fell to 3.8 per 100,000 spindle hours from 16.2 using standard alumina. Annual maintenance savings reached $42,000–78,000 per machine, demonstrating economic value.

Comparative Shock Testing of Impact Resistant Alumina Tube Versus Traditional Ceramics and Metals

Impact resistant alumina tube absorbs 3.2–3.6 J/cm² before fracture, 55–65% higher than standard alumina. Although metal alloys outperform ceramics in absolute impact energy, alumina retains mechanical integrity at >600 °C where metals lose 40–70% of yield strength.

Charpy and drop-weight test methodology comparing ceramic and metal impact response

Tests per ASTM E233 and D3763 confirm consistent fracture performance. Impact resistant alumina tube retains >80% strength after multiple subcritical impacts, unlike metals that plastically deform.

Performance ranking across ceramic families including alumina, zirconia, silicon nitride, and silicon carbide

Among ceramics, silicon nitride shows highest impact resistance, but impact resistant alumina tube offers 70–80% of its toughness at half the cost. Compared with silicon carbide, alumina exhibits 25–35% better energy absorption.

Application-specific advantages where ceramics outperform metals despite lower absolute toughness

Ceramics maintain dimensional precision after repeated collisions and thermal cycling. In hot industrial systems, impact resistant alumina tube provides superior durability over ductile metals.

Cost-performance optimization identifying impact resistant alumina tube market position

Balancing cost and reliability, impact resistant alumina tube represents the optimal choice for automation environments requiring strength, stability, and chemical resistance.

Comparative Material Performance Summary

| Material Type | Fracture Toughness (MPa√m) | Charpy Impact Strength (J/cm²) | Flexural Strength (MPa) | Max Operating Temp (°C) | Relative Cost Index | Optimal Application |

|---|---|---|---|---|---|---|

| Standard alumina tube | 3.5–4.2 | 2.0–2.5 | 350–400 | 1,750 | 1.0× | Low-impact environments |

| Impact resistant alumina tube | 4.8–5.5 | 3.2–3.8 | 400–450 | 1,750 | 1.15–1.30× | Collision-prone automation |

| Silicon nitride (Si₃N₄) | 6.0–7.5 | 4.5–6.0 | 600–900 | 1,400 | 2.0–2.5× | High-load bearings |

| Silicon carbide (SiC) | 3.0–4.5 | 1.5–2.8 | 400–550 | 1,650 | 1.4–1.8× | Wear-dominant zones |

| Zirconia (3Y-TZP) | 6.5–9.0 | 4.0–5.5 | 900–1,200 | 1,000 | 1.8–2.3× | High impact, low temp |

| 316 stainless steel | 50–200 | 120–180 | 500–700 (yield) | 800 | 0.4–0.6× | Low temp, ductile systems |

Design Integration Criteria for Impact Zones in Machinery Layouts Using Impact Resistant Alumina Tube

For effective use, impact resistant alumina tube should be deployed in zones where collision probability exceeds 2% per 1,000 hours or failure cost > $5,000. Engineering integration balances a 15–30% material premium against up to 85% failure reduction.

Risk-based material selection methodology balancing cost premium against failure reduction

Use impact resistant alumina tube where expected impact energy exceeds 6 J. Finite element validation ensures stress levels remain below 70% of fracture limit. This approach provides a high safety margin for real conditions.

Mounting design optimization distributing impact loads and minimizing stress concentration

Distribute loads over 40–60 mm contact areas to avoid localized fractures. Concentrated contacts increase failure risk by 3–5×. Proper mount geometry extends component lifespan in robotic transfer zones.

Elastomeric isolation systems absorbing impact energy at material interfaces

Introduce Shore A 60–80 elastomer layers at metal-ceramic interfaces. These layers absorb 20–35% impact energy and reduce stress wave transmission, preserving dimensional stability over long cycles.

Finite element modeling protocols validating impact stress levels and safety margins

Simulated impact scenarios (1.5–2× energy factor) using LS-DYNA and Abaqus confirm tube integrity below critical stress thresholds. Validated designs achieve >94% reduction in impact-related failures.

Decision Matrix: Impact Resistant Alumina Tube Implementation Strategy

| Automation Scenario | Material and Design Recommendation |

|---|---|

| Collision probability >5 events/1000 hrs, impact 6–12 J | Impact resistant alumina tube (KIC > 4.8 MPa√m) + elastomeric mounting + FEA validation |

| Robotic cell > 4 axes with complex trajectories | Impact resistant grade + collision detection software + guarding to limit impact < 8 J |

| Conveyor transfer points with frequent jams | Charpy > 3.2 J/cm² tube + redundant support + distance > 50 mm from impact zone |

| High-speed CNC (>8000 RPM) | Grain size < 3 μm, KIC > 5.0 MPa√m, vibration damping validated mount |

| Assembly system > 600 °C operation | Impact resistant alumina tube + thermal cycling validated per ASTM C1525 |

Conclusion

Impact resistant alumina tube ensures higher reliability, extended life, and cost-effective operation across automated systems.

FAQ

1. How does impact resistant alumina tube improve mechanical performance?

Its enhanced fracture toughness (> 4.8 MPa√m) and fine-grain microstructure absorb impact energy, reducing brittle failure under repetitive loading.

2. What are the cost implications of using impact resistant alumina tube?

While material costs rise 15–30%, the failure rate drops by up to 85%, delivering overall lower maintenance costs and higher equipment uptime.

3. How should designers integrate impact resistant alumina tube in automation equipment?

Position in high-risk zones, apply elastomeric interfaces, and validate via finite element analysis to keep stress below 70% of fracture limit.

4. How does impact resistant alumina tube compare with metals under dynamic load?

Though metals have higher absolute toughness, alumina maintains strength and dimensional stability at >600 °C, making it superior for hot automated applications.

References:

-

Learn how piezoelectric sensors function and why they're essential for accurately measuring strain and fracture in advanced materials. ↩

-

Understanding the damping loss factor is crucial for engineers to select materials that effectively suppress vibrations. ↩

-

Exploring this link will provide insights into ASTM E23 standards and their importance in material testing. ↩