High-temperature Ceramic Tray for Sintering, Firing, Calcining and Industrial Heat Treatment

ADCERAX is a China industrial ceramic trays manufacturer, providing setter tray solutions in multiple sizes and structures, including reinforced anti-warp designs, grooved locating features and hole-pattern layouts tailored to furnace dimensions, load weight and atmosphere conditions.

Send your drawing or key parameters to receive an engineering-reviewed quotation and a repeatable supply plan for production use.

What is Industrial Ceramic Tray?

Industrial ceramic trays are high-temperature carrier components made from advanced ceramics such as alumina, zirconia and silicon carbide, used to hold parts, powders or fixtures inside furnaces and kilns during sintering, firing, calcining and other heat treatment processes.

Industrial Ceramic Trays vs. Metal and Basic Refractory Carriers

Industrial ceramic trays offer higher high-temperature stability, cleaner contact surfaces, and tighter geometry control than metal or basic refractory carriers, cutting deformation, cracking and contamination in demanding furnace processes and lowering overall cost per furnace cycle.

Industrial Ceramic Trays Properties

Industrial ceramic trays made primarily from advanced ceramics such as alumina, zirconia and silicon carbide, deliver high mechanical strength, reliable thermal stability and good chemical resistance to support demanding high-temperature furnace processes.

Alumina Ceramic Tray

Alumina ceramic tray offers versatile high-temperature performance with good mechanical strength, dielectric insulation and corrosion resistance for general furnace processes.

| Property | Unit | 96% Al₂O₃ | 99% Al₂O₃ | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

|---|---|---|---|---|---|---|---|---|---|

| Alumina content | % | 96 | 99 | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.75 | 3.88 | 3.89 | 3.91 | 3.92 | 3.93 | 3.95 | 3.98 |

| Flexural strength | MPa | 330 | 360 | 379 | 312 | 313 | 314 | 315 | 320 |

| Hardness | GPa | 11.5 | 13.5 | 14.1 | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 20–25 | 30–35 | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | 150 | 200 | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1600 | ≤1700 | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Dielectric strength | kV/mm | 8–10 | 10–12 | 11–13 | 12–14 | 12–15 | 13–16 | 14–17 | 15–18 |

| Volume resistivity (25°C) | Ω·cm | ≥1×10¹³ | ≥1×10¹⁴ | ≥3×10¹⁴ | ≥5×10¹⁴ | ≥1×10¹⁵ | ≥3×10¹⁵ | ≥5×10¹⁵ | ≥1×10¹⁶ |

Zirconia Ceramic Tray

Zirconia ceramic tray delivers very high strength and toughness with good thermal shock resistance, suitable where impact resistance and tight tolerances are critical.

| Property | Specification |

| Maximum Working Temperature | 1500 °C continuous use |

| Density | 5.65 g/cm³ |

| Thermal Expansion Coefficient | 10.3 × 10⁻⁶/K (25–1000 °C) |

| Thermal Conductivity | 2.2 W/m·K at 1000 °C |

| Chemical Stability | 0.08% mass loss after 24 h acid/alkali exposure at 1200 °C |

| Flexural Strength | 900 MPa at room temperature |

| Fracture Toughness | 8 MPa·m½ |

| Hardness (Vickers) | 12 GPa |

| Elastic Modulus | 210 GPa |

Boron Nitride Ceramic Tray

Boron nitride ceramic tray provides machinability, strong thermal shock resistance and non-wetting behavior to many metals and slags, helping reduce sticking in inert or vacuum environments.

| Property | Unit | Pyrolytic Boron Nitride | Hot Pressed Boron Nitride |

|---|---|---|---|

| Purity | % | 99.99% | 99.50% |

| Density | g/cm³ | 2.15–2.19 | 1.96–2 |

| Hardness | HVO.5 | 651 | 62 |

| Volume resistivity | Ohm·cm | 2×10¹⁴ | 1.2×10¹⁴ |

| Dielectric strength | kV/mm | 55 | 76 |

| Maximum working temperature | °C | 1000 (air), 2300 (vacuum) | 900 (air), 1850 (vacuum) |

| Bending strength | MPa | 173 (A direction) | 310 |

| Thermal conductivity | W/m·K | 60 (A direction) | 55 |

| Tensile strength | MPa | 112 (A direction) | 110 |

| Thermal expansion coefficient | 1/°C | 6×10⁻⁷ | 1.8×10⁻⁶ |

| Compressive strength | MPa | 154 (A direction) | 120 |

Silicon Carbide Ceramic Tray

Silicon carbide ceramic tray combines high thermal conductivity, strength and wear resistance, making it well suited to rapid heating cycles and heavier load conditions.

| Property | Specification |

|---|---|

| Material System | RBSiC (80% SiC, 20% free Si) / SSiC (≥99% SiC) |

| Maximum Operating Temperature | ≤1380°C (RBSiC) / ≤1600°C (SSiC) |

| Bulk Density | 3.02 g/cm³ (RBSiC) / 3.10 g/cm³ (SSiC) |

| Open Porosity | <0.1% |

| Flexural Strength (20°C) | 250 MPa (RBSiC) / 380 MPa (SSiC) |

| Flexural Strength (1200°C) | 280 MPa (RBSiC) / 400 MPa (SSiC) |

| Compressive Strength | 1000–2200 MPa |

| Elastic Modulus | 330 GPa (RBSiC) / 420 GPa (SSiC) |

| Thermal Conductivity | 45 W/m·K (RBSiC) / 74 W/m·K (SSiC) |

| Thermal Expansion Coefficient | 4.1–4.5 ×10⁻⁶/K |

| Hardness | 2600–2800 kg/mm² |

| Chemical Stability Range | pH 2–12 |

| Oxidation Stability | <1% microstructural oxidation after 50 cycles (1000°C → RT) |

Industrial Ceramic Tray Range

Explore ADCERAX industrial ceramic tray range in alumina, zirconia, boron nitride and silicon carbide, available in round, rectangular and sagger formats to match a wide variety of sintering, firing and heat-treatment workflows.

Industrial Ceramic Tray Material

Alumina Ceramic Tray

Alumina ceramic tray is used for general sintering and firing of technical ceramics, catalyst carriers and powder metallurgy parts.

Zirconia Ceramic Tray

Zirconia ceramic tray is applied to precision and wear-resistant components that need high strength and toughness during thermal cycles.

Boron Nitride Ceramic Tray

Boron nitride ceramic tray is chosen for non-wetting handling of molten alloys and sensitive metal parts in inert or vacuum atmospheres.

Silicon Carbide Ceramic Tray

Silicon carbide ceramic tray is preferred for rapid-cycle heat treatment, heavy loads and abrasive kiln or calcining environments.

Industrial Ceramic Tray Shape

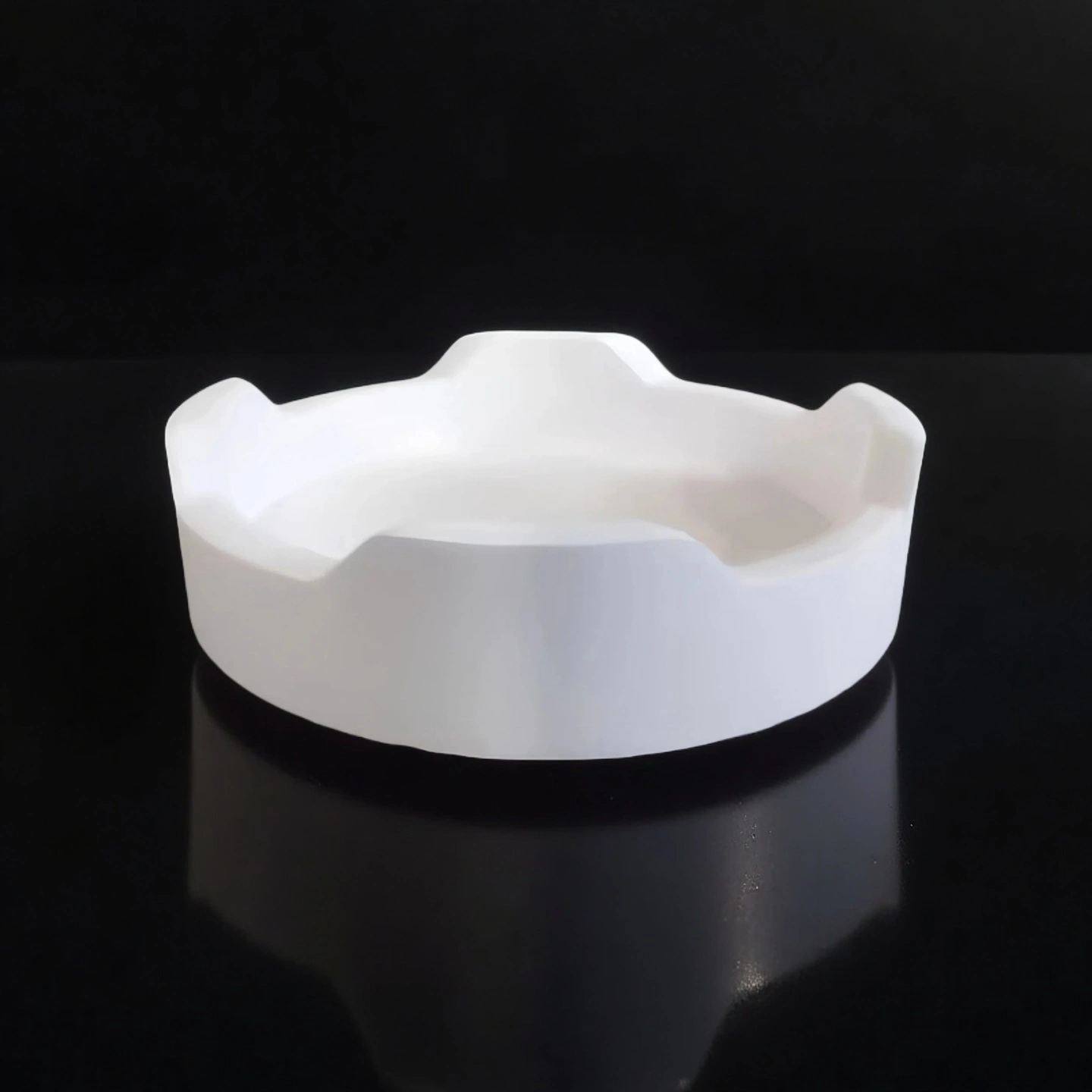

Round Ceramic Tray

Round ceramic tray provides uniform heating and smooth, stable support for centrally loaded parts during firing.

Rectangular Ceramic Tray

Rectangular ceramic tray maximizes usable loading area and fits flat shelves and furnace walls.

Round Ceramic Sagger

Round ceramic sagger offers enclosed, symmetrical protection that helps control contamination and gas exposure.

Square Ceramic Sagger

Square ceramic sagger combines protective walls with easy stacking and dense packing on furnace shelves.

Reduce downtime, reduce rework, reduce cost—industrial ceramic trays that keep your furnace on schedule.

Share your industrial ceramic tray requirements, including drawing, temperature profile, atmosphere, load and cycle expectations, and we’ll suggest the most suitable material and structure to reduce breakage, scrap and overall furnace cost.

Industrial Ceramic Tray Applications

Industrial ceramic trays are used as high-temperature carriers for parts, powders and fixtures in furnaces and kilns across powder metallurgy, technical ceramics manufacturing, industrial heat treatment and R&D lines, helping stabilise loading, support repeatable cycles and reduce deformation and contamination of the products being processed.

Powder Metallurgy/ MIM Sintering

🧩Where industrial ceramic trays are used:

Industrial ceramic trays sit on the furnace hearth, kiln car, pusher plate or belt as carriers for pressed compacts and MIM green parts through debinding and sintering. Parts are loaded directly on the tray or on setters placed on the tray.

🧩What ADCERAX trays help solve:

ADCERAX industrial ceramic trays provide flat, reinforced support that reduces distortion and warpage under load. Clean contact surfaces and repeatable tray geometry help cut contamination, scrap and rework.

Technical Ceramics Firing

🧩Where industrial ceramic trays are used:

Trays and setter plates are positioned on kiln shelves or cars to carry substrates, rings and structural ceramics during firing and cooling. They form the interface between the parts and the furnace support system.

🧩What ADCERAX trays help solve:

ADCERAX firing trays and setters help control flatness and edge quality with smooth, engineered support surfaces. Consistent dimensions and stacking logic stabilise loads and improve firing uniformity.

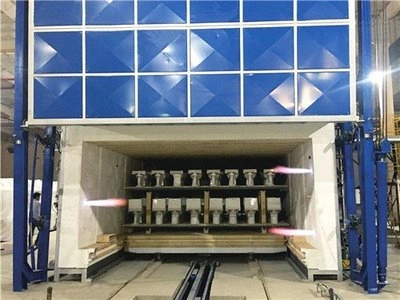

Industrial Heat Treatment / Calcining

🧩Where industrial ceramic trays are used Industrial ceramic trays serve as rugged carriers for bulk parts, fixtures or powders in box furnaces and kilns that run repeated thermal cycles. They are moved in and out as reusable loading units.

🧩What ADCERAX trays help solve

ADCERAX trays are designed to handle heavy loads and frequent cycling with reduced warpage and cracking. This improves furnace uptime, makes loading more predictable and lowers cost per cycle.

R&D and Pilot Thermal Processing

🧩Where industrial ceramic trays are used:

In lab and pilot furnaces, industrial ceramic trays hold varied samples and small batches on shelves or small kiln cars, often with changing layouts as tests evolve.

🧩What ADCERAX trays help solve

ADCERAX trays give R&D teams stable, reusable platforms that are easy to adapt with different shapes or grooves. This reduces improvised supports, lowers sample damage risk and simplifies later scale-up to repeatable production trays.

High Quality Industrial Ceramic Tray Customized

ADCERAX is a China industrial ceramic tray supplier specialising in custom-made trays for high-temperature furnaces and kilns. We tailor tray shape, size, wall thickness, support structure and material grade to your drawings, while keeping key industrial ceramic tray formats available from stock for urgent replacement needs.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Why Choose ADCERAX as Your Industrial Ceramic Tray Supplier?

ADCERAX is a China industrial ceramic tray manufacturer and wholesaler, supplying custom and standard trays with controlled quality and tight tolerances. Our engineering support, sampling and reliable export logistics make industrial ceramic tray sourcing efficient and predictable.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

Professional Industrial Ceramic Tray Factory-ADCERAX

ADCERAX has been engaged in advanced ceramics for over 20 years and has developed more than 2,000 types of high-temperature industrial ceramic components, with a strong focus on industrial ceramic trays and related furnace furniture for demanding thermal processes.

We supply both custom and standard industrial ceramic parts and tray solutions for laboratory analysers, muffle and box furnaces, tube furnaces and other thermal equipment, exporting to more than 50 countries and supporting industrial users and OEMs that require stable, low-contamination and long-life ceramic performance.

Ceramic Tray Processing Strength

ADCERAX controls every step, from forming and machining to sintering and inspection, to keep industrial ceramic tray walls, rims and bases consistent. Tuned firing profiles and 100% visual checks for cracks or chipping deliver durable, thermal-shock-resistant trays that run reliably over many furnace cycles.

CNC Forming Stability & Wall Thickness Control

Dimensional accuracy for industrial ceramic trays is achieved through CNC-assisted forming and machining, keeping wall thickness, straightness and base flatness within tight, repeatable tolerances for reliable furnace loading.

Holding ceramic tray wall variation within narrow bands for stable heating and cooling behaviour.

Controlling side-wall straightness and base flatness to ensure smooth stacking and good contact with shelves or supports.

Machining rims and ends so ceramic trays fit fixtures and carriers correctly, improving handling strength and alignment.

Clean, Low-Contamination Surface Finishing

Internal and external industrial ceramic tray surfaces are finished to reduce residue build-up, minimise contamination and limit micro-cracks, helping each firing cycle stay clean and easy to maintain.

Smoother inner surfaces reduce powder adhesion and make cleaning easier between runs.

Removing sharp rims and micro-chips to lower chipping risk during loading, unloading and tong handling.

Selected surface treatments further lower porosity, supporting cleaner operation where reduced contamination is required.

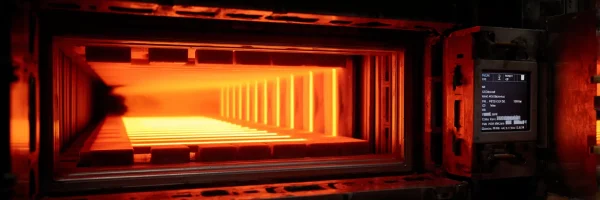

High-Temp Sintering for Service Life & Thermal Shock Resistance

Microstructure density and strength in industrial ceramic trays are developed through controlled firing cycles, tuned to each material system for long life under heating and cooling.

Managing ramp and cool-down rates to balance strength, density and resistance to cracking.

Matching soak times and peak temperatures to the chosen tray material to build reliable service life over many cycles.

Low open porosity improves mechanical stability and cuts powder contamination over many cycles, helping trays deliver long-term value.

FAQs About Industrial Ceramic Tray

Industrial ceramic trays can be produced in different advanced ceramics such as alumina-based, zirconia-based or silicon-carbide-based bodies; ADCERAX recommends a material after reviewing your temperature, atmosphere and loading conditions.

The safe range depends on the ceramic material and atmosphere, but typical working temperatures for industrial ceramic trays are:

Alumina ceramic tray – commonly used around 1,400–1,650 °C in air, depending on grade and load.

Zirconia ceramic tray – typically used around 1,200–1,400 °C in air where high strength and toughness are needed.

Boron nitride ceramic tray – usually used up to about 900–1,000 °C in air, and higher (up to around 1,800–2,000 °C) in inert or vacuum atmospheres.

Silicon carbide ceramic tray – often used around 1,400–1,600 °C in air, with higher limits in controlled or inert atmospheres.

Final allowable temperatures should always be confirmed against your specific furnace atmosphere, cycle profile, tray design and safety margin.

Thicker, rib-reinforced trays are used for wide spans and heavy loads, while thinner or lighter trays are used when weight and heating speed are more important; sharing your furnace dimensions and load map allows an optimised recommendation.

Geometry

A ceramic tray is usually a low, open, flat carrier; a ceramic sagger has side walls and sometimes a lid or cover.Function

Ceramic trays focus on supporting and positioning parts on shelves or kiln cars, while saggers focus on protecting and containing the load.Process control

Saggers help control contamination, gas flow and powder movement, especially for sensitive powders or reactive parts; open trays allow more direct atmosphere contact and easier loading/unloading.Typical use

Trays are chosen for general sintering or heat treatment where open support is enough; saggers are used when the product needs shielding, separation or a controlled micro-environment during firing.

By keeping parts supported on flat, stable surfaces and resisting warpage, ceramic trays lower deformation, cracking and contact marks, which reduces rework and scrap in repeated furnace runs.

Yes. You can send 2D/3D drawings or samples, and ADCERAX engineers will review dimensions, tolerances and process data, then provide a manufacturable tray design and quotation.

Key data include tray dimensions, structure (grooves, ribs, holes, walls), temperature profile, atmosphere, load weight per tray, expected cycles and target quantity for samples and production.

Typical industrial tolerances are in the ±0.1–0.3 mm range on critical dimensions, depending on size and geometry; ADCERAX confirms achievable tolerances after evaluating each design.

Service life depends on temperature, loading, handling and atmosphere; with appropriate design and operation, trays can run many cycles before replacement, and ADCERAX can help estimate life based on your current experience.

In many cases yes, but it is often better to review and adjust tray thickness, reinforcement and support points to fully benefit from ceramic performance and avoid unexpected stress points.

ADCERAX supplies round trays, rectangular trays, round saggers, square saggers and special geometries with grooves, partitions or stepped surfaces to match specific loading patterns.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

info@adcerax.com

Telephone: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.