What are Technical Ceramics?

Technical Ceramics Definition

Technical ceramics are engineered ceramic materials designed for demanding industrial service where standard ceramics, plastics, or metals cannot maintain performance. They are selected for controlled composition, consistent properties, and reliable function under wear, corrosion, high temperature, or electrical insulation requirements. In procurement terms, technical ceramics usually means the part is specification-driven—defined by tolerances, surface finish, and performance targets rather than appearance.

🧱 Technical Ceramics vs Non-Technical Ceramics

- Technical ceramics are engineered for functional performance and controlled specifications in industrial systems.

- Non-technical ceramics are typically used for general-purpose or decorative applications where performance targets and inspection requirements are less demanding.

🧭 Composition of Technical Ceramics

- Oxide ceramics: alumina (Al₂O₃), zirconia (ZrO₂)

- Non-oxide ceramics: silicon nitride (Si₃N₄), silicon carbide (SiC), boron nitride (BN), aluminum nitride (AlN), boron carbide (B₄C)

- Composite /Toughened Systems: ZTA, Al₂O₃–SiC、Si₃N₄–SiC

Properties of Technical Ceramics

Technical ceramics exhibit high hardness and wear resistance, strong chemical and thermal stability, low and predictable thermal expansion, excellent electrical insulation and stable dimensional accuracy over time.

Characteristics of Technical Ceramics

Mechanical Strength And Wear Resistance

- The high hardness and compressive strength of technical ceramics help sleeves, guides, rings and inserts survive abrasion, sliding contact and local point loads in demanding equipment.

- Their dense, controlled microstructure delivers predictable wear life, reducing unplanned downtime and replacement frequency in slurry, powder and granular media.

Electrical Insulation And Dielectric Behavior

- Oxide and nitride technical ceramics provide high dielectric strength and insulation resistance for tubes, spacers, terminals and housings in electrical and thermal systems.

- Stable dielectric properties over a wide temperature range support reliable operation of sensors, heaters and high-voltage assemblies.

Chemical Resistance And Cleanliness

- Technical ceramics are inert to many acids, alkalis and solvents, so wetted parts do not corrode, rust or leach metal ions into the process.

- Low contamination and low outgassing make them suitable for analytical instruments, chemical dosing units and clean process lines that require stable purity.

Thermal Stability At Elevated Temperatures

- Technical ceramics retain strength and stiffness at temperatures where many engineering metals creep or soften, helping components keep their shape and function in furnaces and thermal process equipment.

- Their low thermal expansion and good thermal-shock resistance help maintain sealing gaps and alignments through repeated heat-up and cool-down cycles.

Types of Advanced Ceramics

Adcerax offers a broad portfolio of advanced ceramic materials, including alumina, zirconia, magnesia, beryllia, ZTA, silicon carbide, boron carbide, silicon nitride, boron nitride, aluminum nitride and related engineered ceramics. These oxide and non-oxide materials cover most industrial needs for wear, heat, insulation and corrosion resistance.

Alumina Ceramic

Balanced cost, hardness, wear resistance, electrical insulation.

Zirconia Ceramic

High toughness and fracture resistance for impact-loaded parts.

Magnesia Ceramic

High-temperature stability in basic or refractory environments.

Beryllia Ceramic

Exceptional thermal conductivity with strong electrical insulation.

Silicon Carbide Ceramic

Extreme wear and corrosion resistance at elevated temperatures.

Boron Carbide Ceramic

Ultra-high hardness for severe abrasion and particle impact.

Silicon Nitride Ceramic

High strength and toughness under thermal shock and fatigue.

Boron Nitride Ceramic

Non-wetting, lubricious surfaces for reactive high-temperature processes.

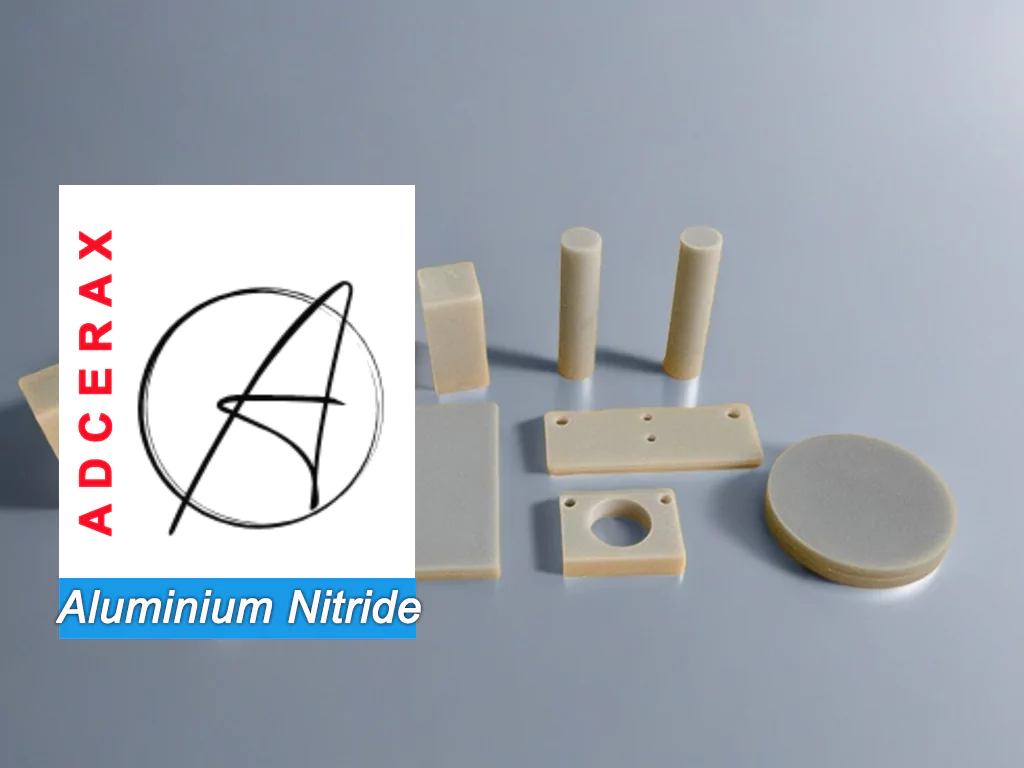

Aluminium Nitride Ceramic

High thermal conductivity with reliable electrical insulation.

Zirconia Toughened Alumina (ZTA)

Higher toughness than alumina, strong wear resistance.

Aluminum Silicate Ceramic

Thermal shock resistance for kiln furniture and insulation.

Aluminum Titanate Ceramic

Very low thermal expansion for thermal-shock-resistant components.

Transparent Ceramic

Optical transparency with hardness and durability.

Metalized Ceramic

Reliable hermetic metal-to-ceramic bonding for sealed assemblies.

Boride Ceramic

High hardness and oxidation resistance at extreme temperatures.

Quartz Ceramic

High purity and thermal shock resistance for clean processes.

Yttrium Oxide Ceramic

Excellent chemical stability in aggressive, high-temperature environments.

Machinable Glass Ceramic

Easily machined prototypes with good dielectric and thermal stability overall.

Ceramic Matrix Composites

Damage tolerance and weight reduction under extreme thermal loading.

Other Precision Ceramics

Tailored material combinations optimized for specific performance needs.

❓ Not Sure Which Technical Ceramic Material to Choose?

Share your drawing and operating conditions—such as temperature range, media, load, wear and electrical requirements—and we’ll review them and recommend the most suitable technical ceramic material for your application, along with a manufacturable solution you can qualify and repeat.

Technical Ceramics Applications

Technical ceramics are selected when components must retain strength, shape and insulation where metals or conventional materials fail under wear, heat or corrosion. The main technical ceramics applications span industrial machinery, chemical processing, laboratory equipment, energy systems and electrical or power-insulation hardware.

Industrial Equipment & Machinery

- Wear liners, guides and slide blocks in bulk-handling equipment

- Sleeves, bushings and plungers in pumps and dosing units

- Nozzles and orifices in spraying, sand-blasting and granulation systems

- Positioning rings, spacers and fixtures in automated assemblies

✅ Recommended materials: Alumina, Zirconia / ZTA, Silicon Carbide / Boron Carbide, Silicon Nitride

🔹Technical ceramics examples

A European OEM producing powder-handling machinery replaced hardened steel wear plates with alumina and ZTA ceramic liners in a screw conveyor. Component lifetime increased from 3–4 months to over 18 months, unplanned stops dropped by >60%, and annual maintenance cost was reduced by roughly 35%.

Chemical Processing & Fluid Handling

- Pump plungers, sleeves and valve seats in corrosive or slurry media

- Dosing pistons and check valves in chemical metering systems

- Flow restrictors and orifices in high-pressure chemical lines

- Static mixers and contact elements in aggressive liquids

✅ Recommended materials: Alumina, Zirconia / ZTA, Silicon Carbide / Boron Carbide

🔹Technical ceramic applications

A chemical plant running abrasive, slightly acidic slurry upgraded its pump sleeves from coated metal to reaction-bonded silicon carbide. Sleeve lifetime went from 2–3 weeks to more than 4 months, and seal failure incidents were cut by around 70%, improving line availability and reducing spare-part inventory.

Laboratory & Analytical Systems

- Crucibles, boats and sample trays for high-temperature analysis

- Insulating tubes, spacers and holders in furnaces and ovens

- Precision seats, flow cells and insulating parts in analytical instruments

- Wear-resistant inserts and tips in sample preparation tools

✅Recommended materials: high purity alumina, boron nitride, Quartz / Transparent Ceramics,Machinable Glass Ceramic

🔹Examples of technical ceramics

A contract testing lab operating multiple high-temperature furnaces switched from metal trays to high-purity alumina boats and supports. Sample contamination complaints dropped to near zero, furnace maintenance intervals doubled, and the lab could certify results for stricter purity requirements without redesigning its processes.

Energy & Thermal Processing

- Kiln furniture, supports and setters in firing and sintering processes

- Burner nozzles, flame stabilizers and hot-zone hardware

- Components in high-temperature heat-treatment and thermal-processing lines

- Insulating parts in hydrogen generation, fuel-processing or reforming units

✅ Recommended materials: Alumina, Silicon Carbide, Silicon Nitride, Aluminum Titanate

🔹Examples of ceramic matrix composites

A producer of refractory products optimized its tunnel kiln furniture by replacing traditional fireclay supports with alumina and aluminum titanate ceramic components. The kiln could run 15–20°C hotter, cycle times were shortened by about 10%, and cracking defects in fired parts dropped by over 40% thanks to reduced thermal distortion.

Electrical & Power Systems

- Insulating tubes, spacers and bushings in power transmission equipment

- Support components in heaters, resistors and high-voltage assemblies

- Sensor protection tubes and isolators in electric heating systems

- Feedthrough bodies and support rings in power-electronics housings

✅ Recommended materials: Alumina, Aluminum Nitride , Magnesia / Other Oxides, Metallized Ceramics

🔹Examples of technical ceramics

An equipment builder supplying industrial heater systems redesigned its terminal insulators using alumina and aluminum nitride ceramics. With improved dielectric strength and better heat spreading, maximum operating voltage increased by 20% and hotspot temperatures fell by approximately 25–30°C, extending heater element life and reducing field failures.

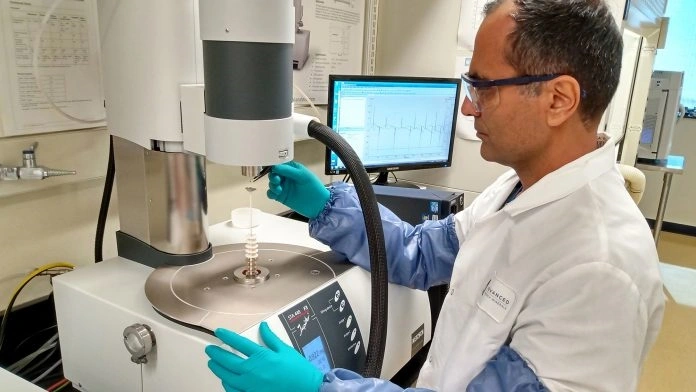

custom technical ceramics suppliers

ADCERAX is a China advanced technical ceramics manufacturer supplying industrial users with both custom and standard technical ceramic components made in-house. Consistent tolerances, responsive engineering and export experience keep your technical ceramics sourcing straightforward and dependable.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Why Choose ADCERAX as Your technical ceramic Manufacturer?

ADCERAX is a China advanced technical ceramics manufacturer supplying industrial users with both custom and standard technical ceramic components made in-house. Consistent tolerances, responsive engineering and export experience keep your technical ceramics sourcing straightforward and dependable.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

China Technical Ceramic Factory-ADCERAX

ADCERAX has been engaged in advanced technical ceramics for over 20 years and has developed more than 2,000 types of technical ceramic components based on alumina, zirconia, silicon nitride, silicon carbide, aluminum nitride and related materials.

We supply both custom and standard technical ceramic parts for a wide range of equipment designs, exporting to more than 50 countries and supporting industrial users and OEMs that rely on stable wear, sealing and structural ceramic performance.

Technical Ceramics Machining

Technical ceramics behave as hard, brittle engineering materials during machining, so success depends on rigid fixturing, suitable diamond or CBN tooling and carefully controlled cutting loads. The goal is to produce clean, repeatable features in technical ceramic parts without microcracks, edge chipping or distortion that could shorten service life.

Tooling and Machine Setup

💡Machine choice

Use rigid CNC lathes, mills and dedicated grinding machines with good spindle condition and stable fixturing when machining technical ceramics.

Precision surface and cylindrical grinders are preferred whenever tight tolerances or fine surface finish are required on technical ceramic parts.

💡Tooling selection

Choose sharp diamond or CBN tools with positive rake and polished cutting edges to reduce cutting forces in technical ceramics.

Use stable tool holders with minimal overhang to limit chatter and vibration during technical ceramic machining.

💡Cutting conditions

Start with light depths of cut and moderate feed rates; increase gradually while monitoring edge quality on the ceramic.

Apply coolants or air mist where needed to manage heat, but avoid thermal shock and keep chips and grinding swarf clear of the cutting zone.

Process Recommendations

💡Turning and grooving

- Use smooth tool entry and exit, avoiding plunging directly into sharp internal corners on technical ceramic parts.

- Leave small corner radii at groove bottoms and shoulders to reduce stress concentration and improve edge strength.

💡Milling and pocketing

- Prefer climb milling with light radial engagement to minimise edge chipping along slot and pocket walls in technical ceramics.

- Ramp or helix into pockets instead of full-width plunging to reduce shock on the cutting edge.

💡Drilling and threading

- Use peck drilling with controlled chip removal to reduce the risk of cracks at the hole exit in technical ceramics.

- For threads, consider thread milling or carefully controlled tapping with generous run-out and deburring of starts.

💡Grinding and lapping

- Finish critical surfaces by precision grinding and, where required, lapping to reach the specified surface finish and flatness on technical ceramics.

- Dress grinding wheels regularly to keep them sharp and to maintain predictable stock-removal rates.

Tips-for-Machining (DFM)

💡Avoid knife-edge features

Keep minimum wall thickness and land widths above agreed limits; extremely sharp fins and thin edges are prone to chipping in technical ceramics during machining and in service.

💡Use radii and chamfers wisely

Add small corner radii or chamfers wherever possible to reduce stress concentrations and improve edge robustness, especially around slots, pockets and windows in ceramic parts.

💡Separate critical and non-critical tolerances

Tighten tolerances only where function requires it and relax non-critical dimensions; this reduces machining time, scrap risk and inspection cost for technical ceramic components.

💡Plan fixturing surfaces

Include flat reference pads or clamping areas so technical ceramic parts can be held securely without stressing functional sections or delicate edges.

FAQs About Technical Ceramics

Technical ceramics are engineered materials designed for functional performance in industrial equipment. They use high-purity powders, controlled compositions and specialised forming, firing and machining processes to achieve predictable mechanical, thermal, chemical and electrical properties, with drawings that specify tolerances, critical surfaces and inspection requirements.

Non-technical ceramics (traditional or conventional ceramics) are typically optimised for cost, appearance and basic utility, such as tiles, pottery or household items. Raw materials are less tightly controlled, properties are more variable, and parts are rarely defined by detailed performance specifications or tight dimensional tolerances.

In short:

Technical ceramics → performance-driven, specification-driven, high process control, used in industrial and engineering applications.

Non-technical ceramics → cost/appearance-driven, lower property control, mainly used for general, decorative or low-stress applications.

Typical technical ceramic materials include alumina (Al₂O₃), zirconia (ZrO₂), zirconia toughened alumina (ZTA), silicon nitride (Si₃N₄), silicon carbide (SiC), aluminum nitride (AlN), boron nitride (BN), boron carbide (B₄C), magnesia and selected oxide or non-oxide composites.

Material selection is based on operating temperature, mechanical load, type of wear, chemical environment, required electrical behaviour and cost targets. Sharing these conditions with a technical ceramics manufacturer allows them to compare candidate materials and recommend a suitable combination.

For custom technical ceramics, provide drawings or sketches with dimensions and tolerances, preferred material or performance targets, expected operating conditions (media, temperature, load, cycles), annual or batch quantities, inspection requirements and any special surface-finish or packaging needs.

Typical dimensional tolerances for ground technical ceramic parts range from ±0.05 mm down to ±0.005 mm depending on part size, geometry and cost. Very tight tolerances are often applied only to critical functional surfaces to balance performance and manufacturing effort.

Yes. Most technical ceramic products are near-net-shaped and then finish-machined after firing using diamond tools and grinding equipment. However, heavy post-firing machining is expensive, so it is usually optimised at the design stage.

ADCERAX is a China advanced technical ceramics manufacturer supplying custom and standard technical ceramic components with engineering support and export-focused production.

Technical ceramic compositions are defined by base oxides or non-oxides plus small amounts of sintering additives. Powder quality, particle size distribution and batch formulation are controlled so that the fired microstructure and final properties remain consistent from batch to batch.

Cost can often be reduced by simplifying geometry, relaxing non-critical tolerances, increasing wall thickness to avoid fragile knife edges, consolidating features into fewer surfaces and aligning the design with standard stock sizes and machining capabilities for technical ceramics.

Technical ceramics are produced through a controlled powder → forming → firing → finishing route:

Powder preparation

High-purity ceramic powders (such as alumina, zirconia, silicon nitride, silicon carbide, etc.) are selected and mixed with sintering additives, binders and dispersants to achieve the required composition, particle size distribution and flow behaviour.Forming (green body production)

The prepared technical ceramics powder is shaped into a “green” body using methods such as dry pressing, isostatic pressing, extrusion, injection moulding or casting, depending on part geometry and volume.Binder removal

Organic binders and processing aids are gently removed through a debinding step, so the body can be fired without cracks or defects.Sintering / firing

The debound parts are fired at high temperature in a controlled atmosphere (air, nitrogen, inert, etc.). During this technical ceramics firing step, the particles densify, pores close, and the final microstructure and properties (strength, hardness, density) are developed.Post-firing machining and grinding

Because technical ceramics are hard and brittle, critical dimensions and surfaces are finished by diamond machining, grinding, lapping or small-hole drilling to achieve the specified tolerances and surface quality.Inspection and quality control

Finished technical ceramic parts are checked for dimensions, surface quality and, where required, density, hardness or electrical properties, before being cleaned, packed and shipped for industrial use.

ADCERAX is a China advanced technical ceramics manufacturer and factory-direct supplier, serving industrial users and OEMs with custom and standard technical ceramic components. We provide engineering support on drawings, material selection advice and export-focused production, positioning ADCERAX among the leading technical ceramics providers for wear, thermal, chemical and insulation applications.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

info@adcerax.com

Telephone: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.