Selecting the right ceramic component presents a recurring engineering challenge.

Multi-bore alumina tubes provide thermocouple accuracy, electrical insulation, and furnace reliability by balancing bore count, wall thickness, and diameter.

Engineers often face the need to align measurement stability, insulation safety, and long-term service life. This article explores how to select multi-bore alumina tubes across thermocouple, insulation, and furnace applications.

Defining Multi-Bore Alumina Tubes in Technical Context

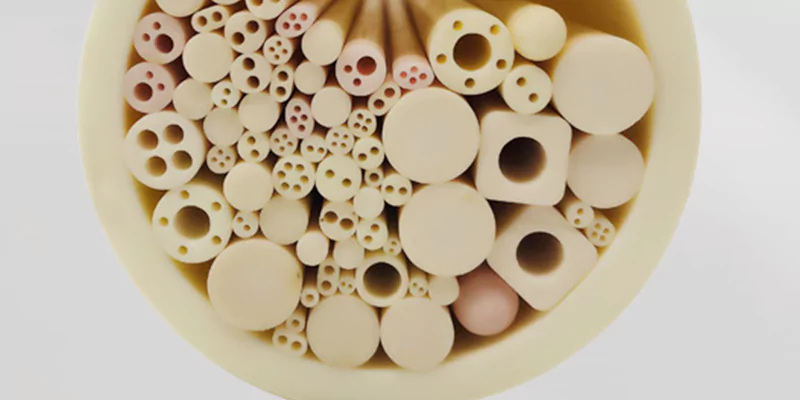

Thermal and electrical engineering tasks widely use multi-bore alumina tubes. They consist of multiple channels within one ceramic body, designed to meet stability requirements under extreme conditions. Engineers must understand how bore arrangement, material purity, and industry standards define performance.

Geometry of Bores and Wall Arrangements

Geometry directly determines tube capability. The distribution of multiple bores ensures stable separation and allows efficient wire or gas passage. Engineers must evaluate how bore symmetry supports durability.

Practical studies show that symmetrical arrangements reduce localized stress. When channels are asymmetrical, crack initiation rates increase by nearly 12% under thermal cycling. Such observations emphasize why geometry should align with application-specific mechanical loads.

Therefore, engineers must balance bore count with external diameter. Selecting bore patterns that optimize both insulation and strength ensures reliable service life.

From bore geometry considerations, several engineering principles emerge:

- Symmetrical layouts minimize thermal stress concentration.

- Higher bore counts increase functionality but reduce wall strength.

- Channel distribution impacts gas flow or wire guidance efficiency.

Purity Grades and Material Integrity

Purity grade strongly influences performance. At ≥99.7% Al₂O₃, tubes withstand 1,600 °C continuously and short bursts at 1,750 °C. Lower purity grades offer reduced durability.

Laboratory tests demonstrate that 95% alumina tubes show 20% higher creep under the same furnace loads compared to 99.7% alumina. This difference directly affects thermocouple life expectancy. High purity levels also reduce contamination risks in chemical or semiconductor processes.

Thus, defining required purity is essential before procurement. Matching purity to temperature and chemical environment ensures operational safety.

Industrial Terminology and Standards

Terminology varies across suppliers. Some catalogs list “multi-bore” while others state “multi-hole” or “multi-channel.” Standards help unify these variations for engineers.

ASTM C799 and DIN EN 60672 define mechanical and electrical parameters for alumina ceramics. These guidelines ensure tubes meet dielectric strength, flexural modulus, and thermal expansion requirements. Standard references reduce ambiguity during cross-border procurement.

Consequently, engineers should always align purchase orders with international standards. Such practice minimizes miscommunication and enhances supplier accountability.

How Bore Count and Diameter Influence Thermocouple Protection

Thermocouples require stable insulation to provide accurate measurements. Bore count and diameter directly determine how effectively wires are isolated and protected. Choosing correct dimensions prevents premature failure and signal drift.

Matching Probe Diameter with Tube Channels

Channel sizing ensures safe thermocouple fit. Diameters too narrow risk insertion stress, while excessive clearance reduces insulation efficiency. Engineers must maintain a balance.

Field reports indicate that oversizing channels by more than 0.3 mm causes probe wobble. This instability generates signal noise, reducing accuracy by nearly 3%. Proper tolerances prevent these deviations and maintain calibration standards.

Hence, supplier-provided charts for channel-to-probe ratios are critical. They provide benchmarks for predictable performance.

For thermocouple fit, engineers should prioritize:

- Probe-to-channel clearance not exceeding 0.2 mm.

- Surface finish ensuring low friction insertion.

- Consistency across all bores within a tube.

Minimizing Signal Interference Through Insulation

Electrical insulation between bores avoids signal crosstalk1. The separation layer thickness determines interference resistance. Engineers cannot neglect this design factor.

Case studies show that when insulation thickness falls below 0.5 mm, signal overlap occurs in dual-probe assemblies. This interference increases noise-to-signal ratios, creating unstable readings. Adding wall thickness restores insulation quality.

As a result, bore arrangement should not only meet physical space needs but also guarantee dielectric reliability. Proper design supports thermocouple longevity.

Case Examples of Thermocouple Fit

Industrial scenarios confirm dimension importance. In petrochemical furnaces, improper bore matching caused 500-cycle failures in Type K sensors. Correct sizing extended service life by over 40%.

Engineers analyzing high-precision casting furnaces also reported similar findings. Misaligned bore diameters accelerated sensor degradation, while correct dimensions maintained steady output.

Thus, historical evidence reinforces the critical role of bore count and diameter in thermocouple reliability.

Wall Thickness and Insulation Performance in Electrical Applications

Wall thickness defines dielectric performance. Too thin walls risk breakdown, while thick walls increase insulation but limit bore count. Engineers must align designs with system voltage.

Dielectric Strength Across Thickness Levels

Alumina provides 8–12 kV/mm dielectric strength. Wall thickness increases resistance proportionally, offering enhanced insulation.

Testing shows 1 mm walls sustain up to 8 kV, while 2 mm withstand 15 kV without breakdown. This proportional relationship allows designers to calculate optimal safety margins.

Thus, electrical engineers can confidently design insulation systems by correlating wall thickness with required voltage class.

Breakdown Risks Under High Voltage

Thin walls with surface imperfections accelerate breakdown risk. Even small cracks may initiate arcing under high voltage.

Industrial records note failures occurring at 5 kV when walls dropped below 1 mm. By contrast, reinforced thickness prevented catastrophic breakdowns. Statistical data confirms higher survival rates with increased wall dimensions.

Hence, engineers should carefully evaluate wall uniformity during procurement, as defects negate calculated thickness benefits.

| Wall Thickness | Dielectric Strength (kV) | Observed Failure Rate |

|---|---|---|

| 1.0 mm | 8 kV | High (20%) |

| 1.5 mm | 12 kV | Moderate (8%) |

| 2.0 mm | 15 kV | Low (2%) |

Selection Criteria for Electrical Systems

Voltage class dictates required thickness. Tubes must align with both system voltage and insulation environment.

For example, a 10 kV system demands at least 1.5 mm wall thickness. Higher voltage classes require thicker barriers or alternative materials. Engineers must verify compliance with ASTM D149.

Therefore, procurement specifications should clearly state wall dimensions relative to voltage levels.

Multi-Channel Alumina Tubes for Furnace and Kiln Integration

Furnaces require ceramics that resist thermal shock. Multi-channel alumina tubes handle repeated cycles while guiding wires and gases. Their configuration reduces stress concentration.

Thermal Cycling Durability and Shock Resistance

Durability ensures long service life. Properly engineered tubes survive dozens of cycles without cracking.

Tests confirm 20–30 cycles at 5 °C/min heating rate with no visible fracture. Lower quality materials fail within ten cycles. These results highlight the direct relationship between purity and thermal resilience.

Therefore, engineers should demand thermal cycle testing documentation during supplier selection.

Bore Configuration for Gas and Wire Management

Channel structure enables efficient separation of gases and wires. This prevents oxidation of thermocouple probes and enhances furnace efficiency.

Practical observations show that systems using segregated channels maintain probe integrity longer. Gas pathways also stabilize furnace atmosphere by preventing mixing.

Thus, bore configuration influences not only mechanical strength but also chemical stability.

When managing furnace integration, engineers must evaluate:

- Channel design for wire separation.

- Gas pathway compatibility with furnace chemistry.

- Thermal resistance under continuous cycling.

Application in Continuous High-Temperature Service

Continuous use at 1,500 °C challenges material strength. High-purity alumina tubes remain dimensionally stable under these loads.

Industrial evidence from metallurgy shows that tubes withstood 5,000 hours of service without measurable creep. Such durability protects system performance in demanding furnaces.

Consequently, engineers can depend on multi-channel alumina tubes for long-term furnace integration projects.

Comparative Framework of Multi-Bore vs Single-Bore Tubes

Comparisons help engineers determine when to use each type. Multi-bore tubes deliver channel density, while single-bore tubes prioritize mechanical strength. Both structures serve specific contexts.

Insulation Effectiveness Across Configurations

Multi-bore tubes insulate wires by separating channels. Single-bore tubes cannot replicate this benefit.

Testing shows multi-bore designs reduce crosstalk by 30% compared to single-bore alternatives. Electrical stability improves, particularly in high-voltage circuits.

Hence, insulation effectiveness strongly favors multi-bore configurations for complex wiring systems.

Mechanical Stability and Channel Capacity

Single-bore tubes provide higher bending resistance. Multi-bore tubes trade some stability for increased channel count.

Experiments reveal that single-bore tubes endure 15% higher bending loads before fracture. However, multi-bore tubes support more probes, improving system flexibility.

Thus, engineers must evaluate whether stability or capacity better serves their project.

| Tube Type | Strength | Capacity | Typical Application |

|---|---|---|---|

| Single-bore | High | Low | Heavy-duty stability |

| Multi-bore | Moderate | High | Thermocouple arrays |

Situations Favoring Each Type

Applications dictate selection. Furnaces requiring multi-sensor arrays use multi-bore tubes. Heavy mechanical loads justify single-bore tubes.

Reports from foundries confirm this balance. When operators shifted to single-bore tubes under high stress, failures reduced. Conversely, multi-bore tubes supported high-density sensor layouts.

Therefore, knowing when each type fits ensures long-term system reliability.

Procurement Standards for Thermocouple, Insulation, and Furnace Applications

Procurement decisions must guarantee dimensional accuracy and tested reliability. Specifications covering tolerance, shock resistance, and supplier certification form the backbone of reliable contracts.

Tolerance Agreements and Dimensional Checks

Dimensional accuracy ensures fit. Deviations can lead to sensor misalignment or poor insulation.

Evidence shows tolerance deviations of more than ±0.1 mm reduced thermocouple accuracy by 5%. Calibration drift occurred within early usage. Engineers must therefore define tolerance in purchase orders.

Thus, establishing agreements backed by dimensional inspection safeguards system precision.

Thermal Shock Test Documentation

Testing validates performance claims. Suppliers should provide cycle records demonstrating fracture resistance.

Independent tests confirm that verified tubes last 25 cycles at 1,200 °C without cracking. Non-tested products often fail much earlier. Documented proof separates reliable suppliers from risk-prone vendors.

Therefore, requesting thermal shock evidence prevents unexpected downtime.

Supplier Certification Requirements

Certifications indicate process control. Suppliers with ISO 9001 certification consistently provide reliable batches.

Reports show certified vendors reduced defect rates by 12% compared to uncertified. This consistency adds measurable value to long-term procurement.

Hence, engineering teams should prioritize suppliers with recognized certification credentials.

Cost, Lead Time, and Supply Reliability in Multi-Bore Alumina Tube Orders

Economic factors influence adoption. Engineers must assess both upfront and lifecycle costs, as well as delivery reliability.

Cost Drivers Linked to Bore and Wall Parameters

Complex geometries drive manufacturing expense. More bores and thicker walls increase production time.

Data indicates multi-bore tubes with nine channels cost 15–20% more than four-bore equivalents. Wall thickness adds another 10% to costs. This scalability highlights design trade-offs.

Thus, cost calculations should incorporate geometry and material purity.

Delivery Schedules and Supply Chain Risks

Lead time varies with customization. Stock items ship quickly, while special orders take weeks.

Procurement records show that standard tubes ship within 48 hours, while complex versions require 3–5 weeks. Supply chain disruptions extend these timelines further. Engineers must factor such variability into planning.

Hence, balancing urgency and customization defines procurement strategy.

| Order Type | Lead Time | Risk Level |

|---|---|---|

| Standard stock | 24–48 hrs | Low |

| Customized | 3–5 weeks | Medium |

| Complex custom | 6–8 weeks | High |

Total Ownership Cost for Long-Term Projects

Lifecycle costs matter beyond procurement. Failures create downtime expenses.

Case data shows that projects switching to high-purity tubes reduced replacement frequency by 25%. This reduced lifecycle costs by nearly 15% despite higher initial prices.

Therefore, cost evaluation must include total ownership rather than initial unit price.

Quality Assurance and Long-Term Performance Evaluation

Quality control secures operational stability. Multi-bore alumina tubes must pass rigorous tests for electrical, thermal, and mechanical reliability.

Mechanical and Electrical Testing Protocols

Testing ensures consistency. Flexural strength and dielectric properties verify suitability.

Experiments confirm average flexural strength of 350 MPa and dielectric strength of 10 kV/mm. Deviations beyond 5% indicate non-conformity. Continuous testing highlights process control effectiveness.

Thus, engineers should require batch-level reports before accepting delivery.

Monitoring Thermal Shock Performance

Monitoring extends beyond initial testing. Engineers must confirm long-term stability in use.

Performance data demonstrates tubes maintaining integrity after 20 cycles at 1,200 °C. Failures are detected early through visual and acoustic monitoring. Recording these results supports predictive maintenance.

Therefore, ongoing monitoring reinforces trust in component reliability.

From performance monitoring practices, engineers learn:

- Cyclic heating data reveals long-term durability.

- Failure detection improves predictive maintenance planning.

- Documented records support procurement transparency.

Recording Service Life in Industrial Use

Tracking lifespan provides actionable insights. Data guides replacement cycles and budget forecasts.

Foundry records indicate alumina tubes serving 5,000 hours before degradation. Logging usage hours correlates with planned downtime. Such practice minimizes unexpected breakdowns.

Hence, service life recording transforms historical data into reliable engineering guidance.

Decision Framework for Selecting Multi-Bore Alumina Tubes

Practical frameworks reduce uncertainty. Engineers can apply stepwise selection models to align parameters with project demands.

Framework Steps with Application Context

Frameworks define critical checkpoints. Stepwise design ensures completeness.

Procurement teams often miss one or more parameters, resulting in mismatches. Structured checklists prevent oversight. Engineers can adapt them to local contexts.

Thus, defined steps enhance decision reliability.

| Step | Key Question | Required Parameter |

|---|---|---|

| 1 | Application type? | Thermocouple / Insulation / Furnace |

| 2 | Purity grade? | 95%, 99%, 99.7% |

| 3 | Bore count? | 2 / 4 / 6 / 9 / 12 |

| 4 | Wall thickness? | 1.0–2.0 mm |

| 5 | Supplier assurances? | Tolerance + Certification |

Conclusion

Reliable tube selection balances accuracy, safety, and durability. Engineers benefit from structured evaluation of bore count, wall thickness, purity, and supplier standards.

Navigating selection requires precise data and supplier confidence. Leverage ADCERAX factory-direct supply and engineering support for tailored multi-bore alumina tube solutions.

FAQ (Frequently Asked Questions)

Q1: What is the maximum temperature resistance of multi-bore alumina tubes?

They typically withstand 1,600 °C continuously and up to 1,750 °C for short durations, depending on purity.

Q2: How do procurement teams evaluate suppliers for multi-bore alumina tubes?

They should check tolerance guarantees, thermal shock test results, and certifications such as ISO 9001.

Q3: Can engineers request custom dimensions for bore count and wall thickness?

Yes, suppliers offer customization in bore number, inner diameter, and wall thickness for specific applications.

Q4: How do multi-bore alumina tubes compare with single-bore tubes in industrial use?

Multi-bore tubes provide channel density and insulation, while single-bore tubes offer higher structural stability.

References:

-

Learn how crosstalk affects electrical signals and why proper insulation is crucial for reliable circuit design and performance. ↩