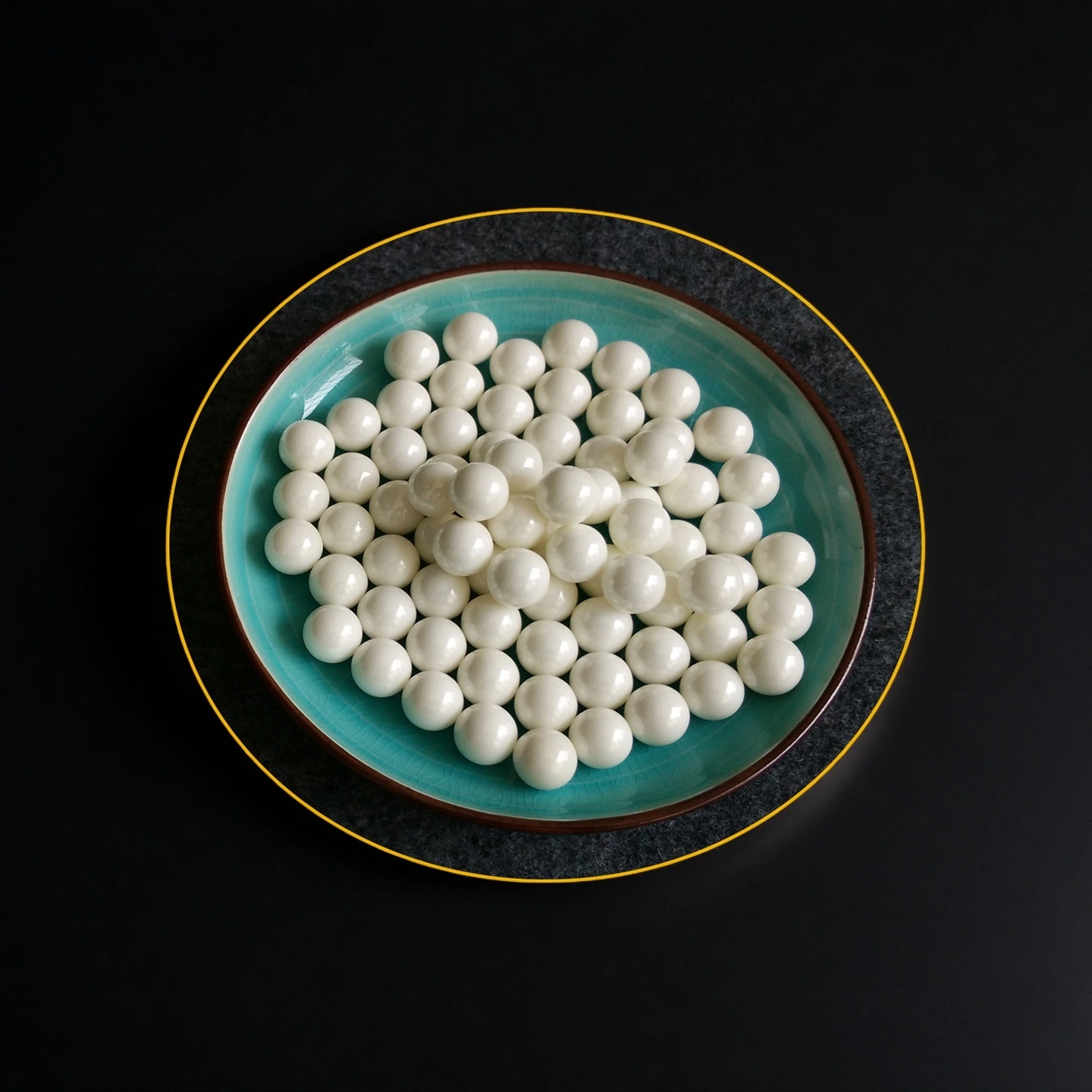

Alumina Bearing Ceramic Ball Benefits

- Material Purity: Manufactured from high-purity alpha-alumina powders (92% to 99.8%), ensuring minimal contamination and superior chemical inertness against acids and alkalis.

- Dimensional Precision: Advanced grinding and lapping processes achieve sphericity tolerances down to Grade G10 (0.25µm) and surface roughness of Ra ≤0.02µm for perfect sealing and low-friction movement.

- Mechanical Integrity: A dense, non-porous microstructure results in high compressive strength (>2000 MPa) and hardness (Mohs 9), preventing fracture under load and resisting wear from abrasive slurries.

- Thermal Stability: Alumina ceramic balls maintain their structural integrity and hardness at continuous operating temperatures up to 1600°C, outperforming metals and polymers in thermal cycling applications.

Alumina Oxide Bearing Ball Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

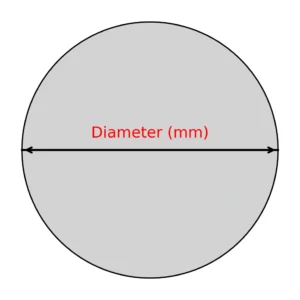

Alumina Bearing Ceramic Ball Specifications

| Alumina Bearing Ball | |

| SKU | Diameter(mm) |

| AT-YHG-ZCQ001 | 0.4 |

| AT-YHG-ZCQ002 | 0.5 |

| AT-YHG-ZCQ003 | 0.6 |

| AT-YHG-ZCQ004 | 0.7 |

| AT-YHG-ZCQ005 | 0.8 |

| AT-YHG-ZCQ006 | 0.9 |

| AT-YHG-ZCQ007 | 1 |

| AT-YHG-ZCQ008 | 1.1 |

| AT-YHG-ZCQ009 | 1.2 |

| AT-YHG-ZCQ010 | 1.3 |

| AT-YHG-ZCQ011 | 1.35 |

| AT-YHG-ZCQ012 | 1.4 |

| AT-YHG-ZCQ013 | 1.5 |

| AT-YHG-ZCQ014 | 1.588 |

| AT-YHG-ZCQ015 | 1.6 |

| AT-YHG-ZCQ016 | 1.8 |

| AT-YHG-ZCQ017 | 2 |

| AT-YHG-ZCQ018 | 2.381 |

| AT-YHG-ZCQ019 | 2.5 |

| AT-YHG-ZCQ020 | 2.778 |

| AT-YHG-ZCQ021 | 2.8 |

| AT-YHG-ZCQ022 | 3 |

| AT-YHG-ZCQ023 | 3.175 |

| AT-YHG-ZCQ024 | 3.5 |

| AT-YHG-ZCQ025 | 3.969 |

| AT-YHG-ZCQ026 | 4 |

| AT-YHG-ZCQ027 | 4.5 |

| AT-YHG-ZCQ028 | 4.763 |

| AT-YHG-ZCQ029 | 5 |

| AT-YHG-ZCQ030 | 5.5 |

| AT-YHG-ZCQ031 | 5.536 |

| AT-YHG-ZCQ032 | 5.953 |

| AT-YHG-ZCQ033 | 6 |

| AT-YHG-ZCQ034 | 6.35 |

| AT-YHG-ZCQ035 | 6.747 |

| AT-YHG-ZCQ036 | 7 |

| AT-YHG-ZCQ037 | 7.144 |

| AT-YHG-ZCQ038 | 8 |

| AT-YHG-ZCQ039 | 8.731 |

| AT-YHG-ZCQ040 | 9 |

| AT-YHG-ZCQ041 | 9.525 |

| AT-YHG-ZCQ042 | 10 |

| AT-YHG-ZCQ043 | 10.3188 |

| AT-YHG-ZCQ044 | 11 |

| AT-YHG-ZCQ045 | 11.1125 |

| AT-YHG-ZCQ046 | 11.906 |

| AT-YHG-ZCQ047 | 12 |

| AT-YHG-ZCQ048 | 12.303 |

| AT-YHG-ZCQ049 | 12.7 |

| AT-YHG-ZCQ050 | 13.494 |

| AT-YHG-ZCQ051 | 14 |

| AT-YHG-ZCQ052 | 14.288 |

| AT-YHG-ZCQ053 | 15 |

| AT-YHG-ZCQ054 | 15.875 |

| AT-YHG-ZCQ055 | 16 |

| AT-YHG-ZCQ056 | 17.4625 |

| AT-YHG-ZCQ057 | 18 |

| AT-YHG-ZCQ058 | 18.256 |

| AT-YHG-ZCQ059 | 19.05 |

| AT-YHG-ZCQ060 | 19.844 |

| AT-YHG-ZCQ061 | 20 |

| AT-YHG-ZCQ062 | 20638 |

| AT-YHG-ZCQ063 | 22.225 |

| AT-YHG-ZCQ064 | 23.812 |

| AT-YHG-ZCQ065 | 25.4 |

| AT-YHG-ZCQ066 | 25.875 |

| AT-YHG-ZCQ067 | 26.988 |

| AT-YHG-ZCQ068 | 30 |

| AT-YHG-ZCQ069 | 30.163 |

| AT-YHG-ZCQ070 | 31.75 |

| AT-YHG-ZCQ071 | 32 |

| AT-YHG-ZCQ072 | 34.925 |

| AT-YHG-ZCQ073 | 35 |

| AT-YHG-ZCQ074 | 36 |

| AT-YHG-ZCQ075 | 38.1 |

| AT-YHG-ZCQ076 | 40 |

| AT-YHG-ZCQ077 | 42 |

| AT-YHG-ZCQ078 | 44.45 |

| AT-YHG-ZCQ079 | 45 |

| AT-YHG-ZCQ080 | 50.8 |

| AT-YHG-ZCQ081 | 55 |

| AT-YHG-ZCQ082 | 63.5 |

Alumina Bearing Ball Precision Grade Table

| Alumina Bearing Ball Precision Grade | ||||||

| Grade | Ball Grade Tolerance | Ball Diameter Variation | Spherical Diameter Deviation | Batch Diameter Deviation | Sphericity Error | Surface Roughness |

| G5 | ±5 | ±0.4 0.2 | 0.13 | 0.25 | 0.13 | 0.014 |

| G10 | ±10 | ±0.4 0.2 | 0.25 | 0.5 | 0.25 | 0.02 |

| G16 | ±10 | ±0.8 0.4 | 0.4 | 0.8 | 0.4 | 0.025 |

| G20 | ±10 | ±0.8 0.4 | 0.5 | 1 | 0.5 | 0.032 |

| G24 | ±10 | ±0.8 0.4 | 0.6 | 1.2 | 0.5 | 0.04 |

| G28 | ±12 | ±0.8 0.4 | 0.7 | 1.4 | 0.7 | 0.05 |

| G40 | ±16 | ±1.6 0.8 | 1 | 2 | 1 | 0.08 |

| G60 | ±16 | ±1.2 ±2.4 | 1.5 | 3 | 1.2 | 0.1 |

| G100 | ±40 | ±4 | 2.5 | 5 | 2.5 | 0.125 |

| G200 | ±60 | ±6 | 5 | 10 | 5 | 0.15 |

Alumina Oxide Bearing Ball Packaging

- White alumina bearing balls are packaged in 25 kg heavy-duty plastic bags, which are then placed inside 1-ton jumbo bags with inner waterproof liners. The jumbo bags are palletized and shrink-wrapped for secure, moisture-free international transport.