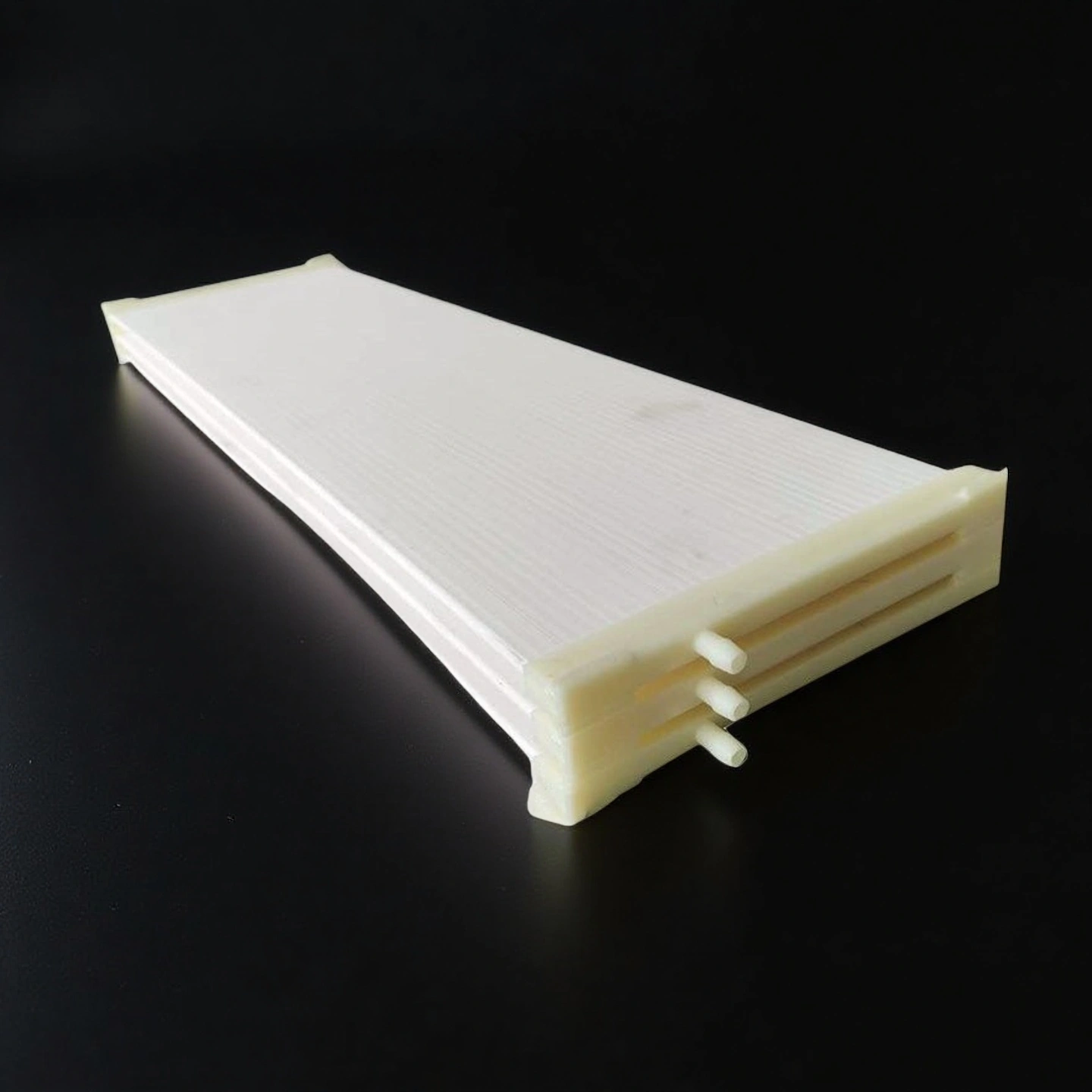

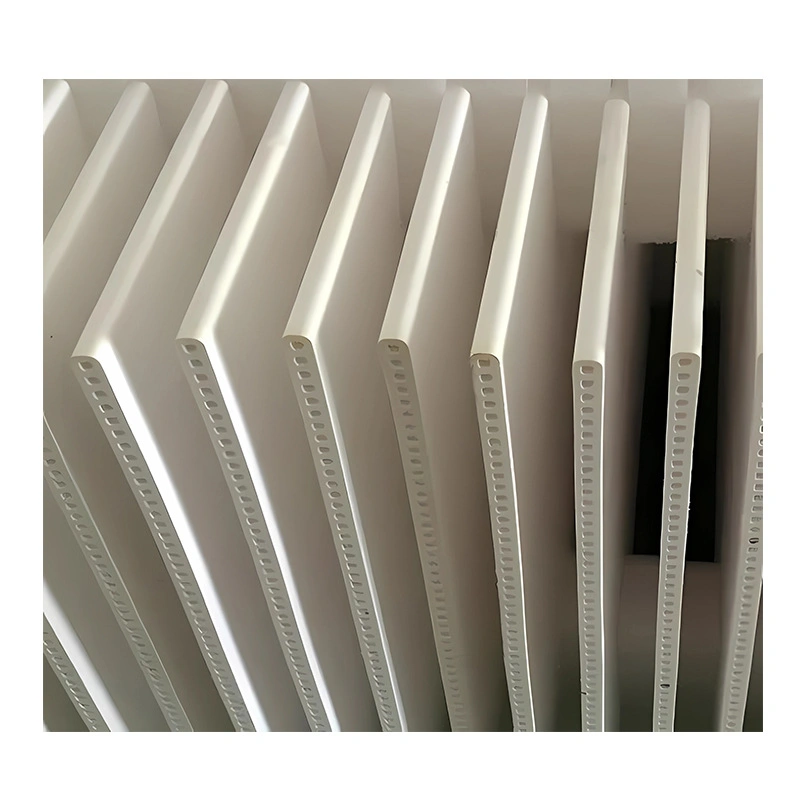

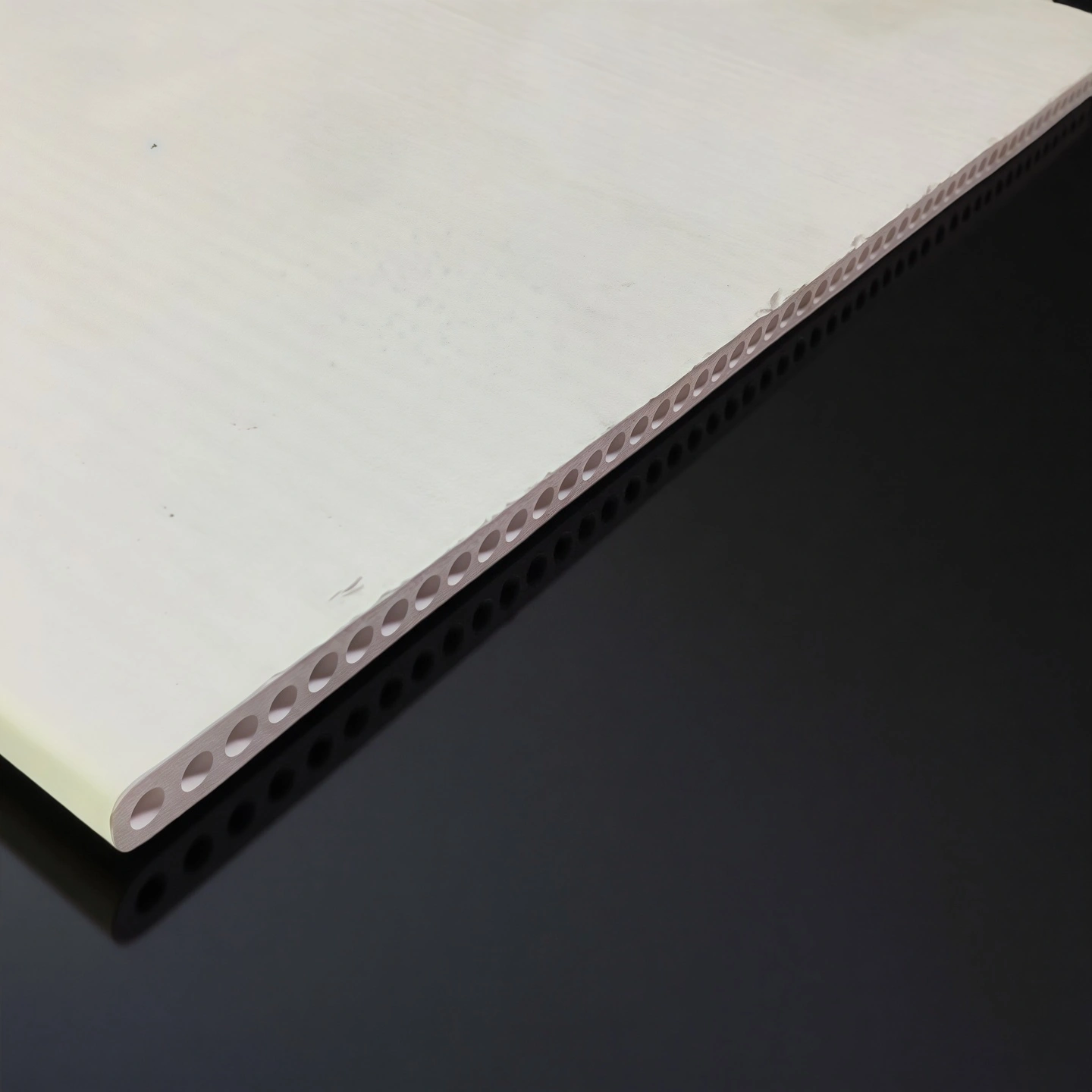

An Alumina Ceramic Filtration Module is a multichannel tubular membrane made from high-purity alumina for microfiltration or ultrafiltration. It filters liquids by allowing permeate through the porous membrane while retaining solids or oil. Its strength and tolerance to wide pH and high-temperature cleaning make it suitable for demanding industrial and municipal filtration.

Alumina Ceramic Filtration Module Benefits

-

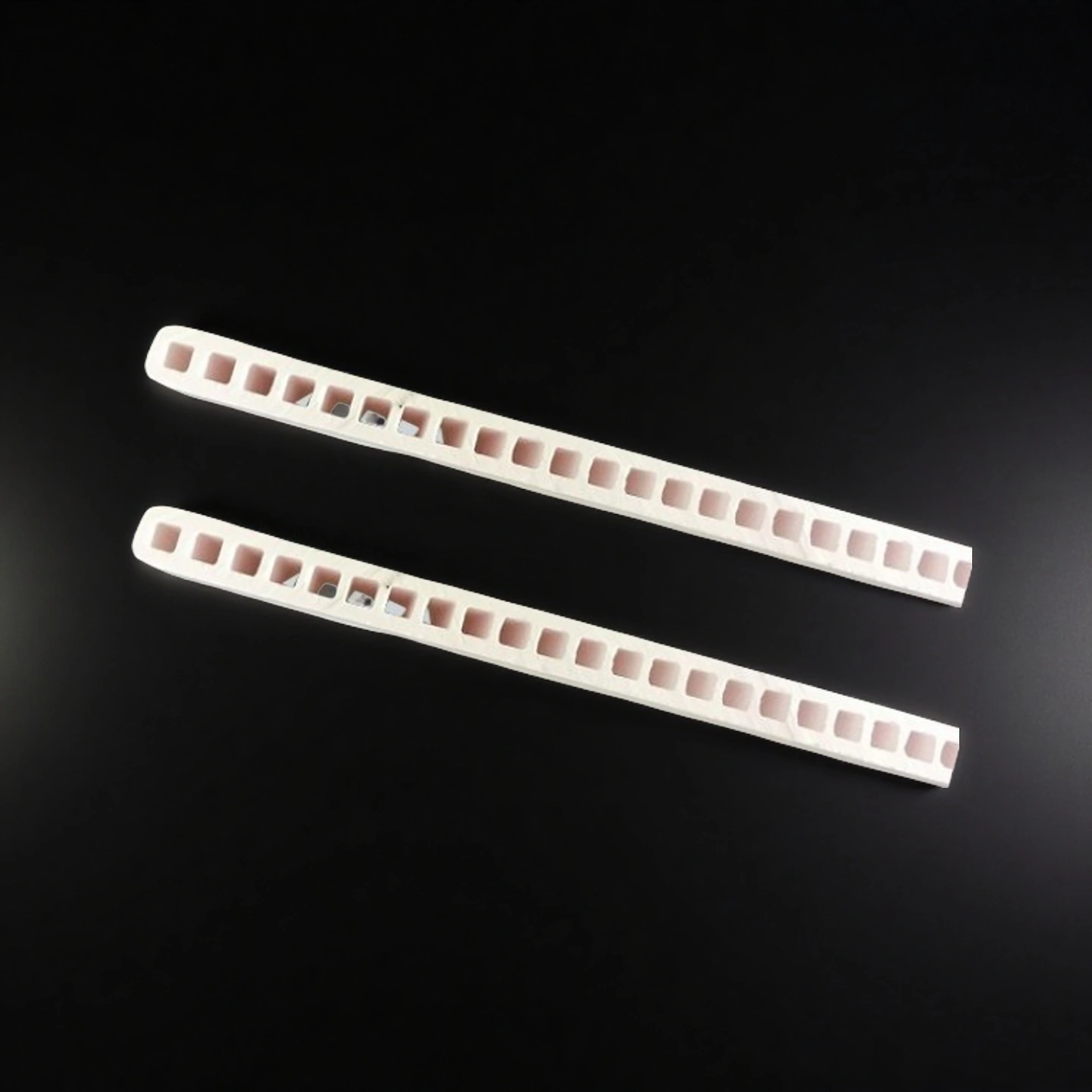

Multichannel tubular design

The module uses a multichannel alumina ceramic support to deliver a highly effective membrane area in a compact footprint, allowing higher system capacity per housing and per skid. -

High mechanical strength under pressure and temperature cycling

The dense alumina body tolerates repeated start–stop cycles, high crossflow velocities and frequent CIP without deformation, reducing the risk of element breakage in demanding plants. -

Stable permeate performance in high-fouling feeds

The ceramic membrane structure maintains stable flux in feeds containing suspended solids, oil droplets or colloids, with good flux recovery after chemical or backflush cleaning. -

Compatibility with aggressive cleaning regimes

The alumina membrane tolerates oxidizing agents and wide pH cleaning sequences, enabling more intensive cleaning programs and extended operating life compared with many polymeric membranes. -

Interface-ready module ends

End designs can be supplied to match standard clamp, flange or potting arrangements, simplifying drop-in replacement of existing membrane elements in OEM or retrofit systems.

Alumina Ceramic Filtration Module Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Aluminium Oxide Ceramic Filtration Module Specifications

| Alumina Ceramic Filter | |||||

| Item No. | Length*Width*Height(mm) | Quantities(pcs) | Membrane area(㎡) | Water production(m3/d) | Weight(kg) |

| AT-YHL-GL001 | 300*320*1200 | 10 | 2.5 | 2-5 | 15 |

| AT-YHL-GL002 | 720*570*450 | 34 | 6 | 7-14 | 32 |

| AT-YHL-GL003 | 720*570*600 | 68 | 12 | 8-10 | 64 |

| AT-YHL-GL004 | 920*320*1800 | 50 | 25 | 15-35 | 200 |

| AT-YHL-GL005 | 1720*320*1800 | 100 | 50 | 3-70 | 310 |

| AT-YHL-GL006 | 1720*720*1800 | 200 | 100 | 60-140 | 630 |

| AT-YHL-GL007 | 1720*720*3250 | 400 | 200 | 120-280 | 1185 |

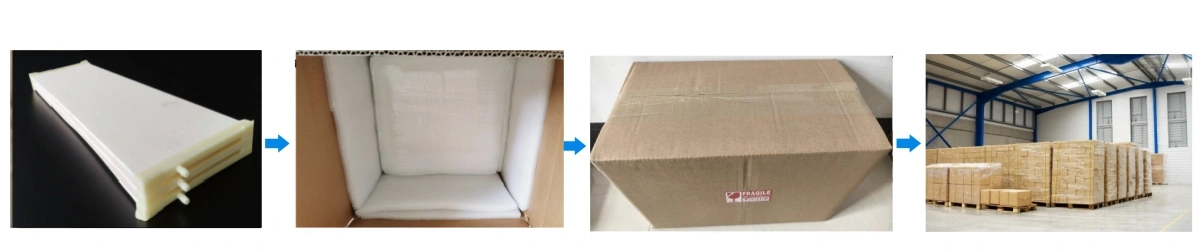

Al2O3 Ceramic Filtration Module Packaging

- Each Alumina Ceramic Filtration Module is wrapped in soft protective material to prevent abrasion, then fixed in a robust inner box to control movement during transport.