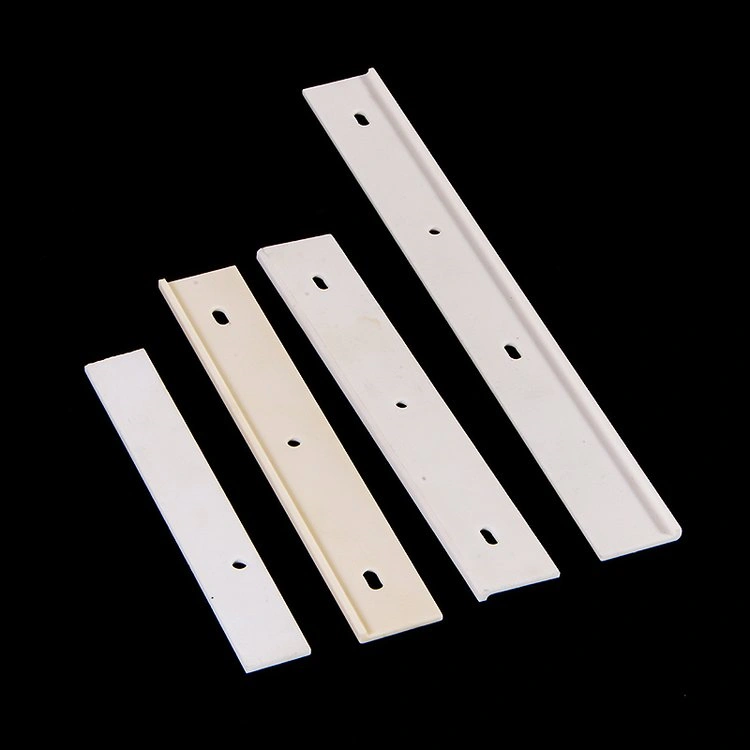

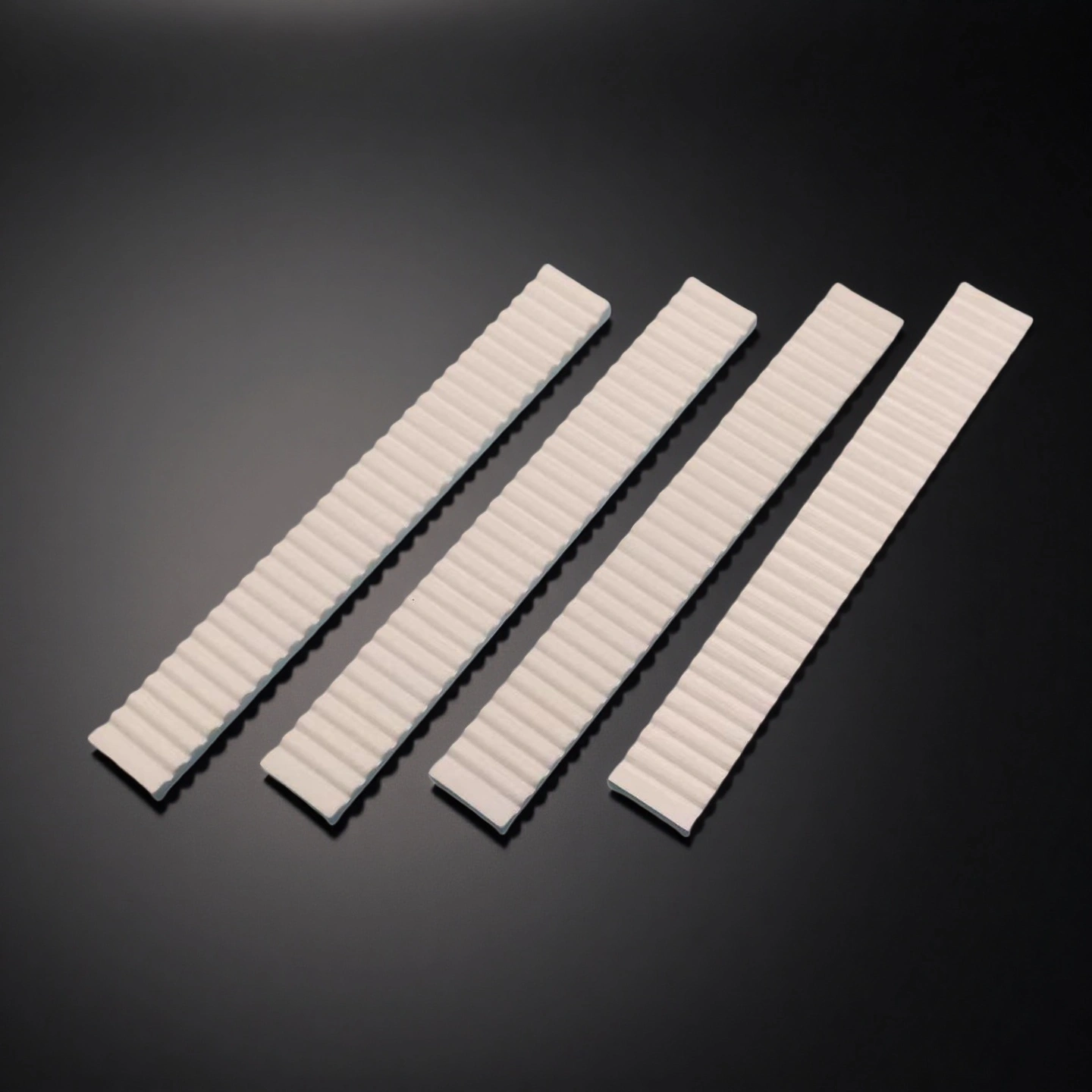

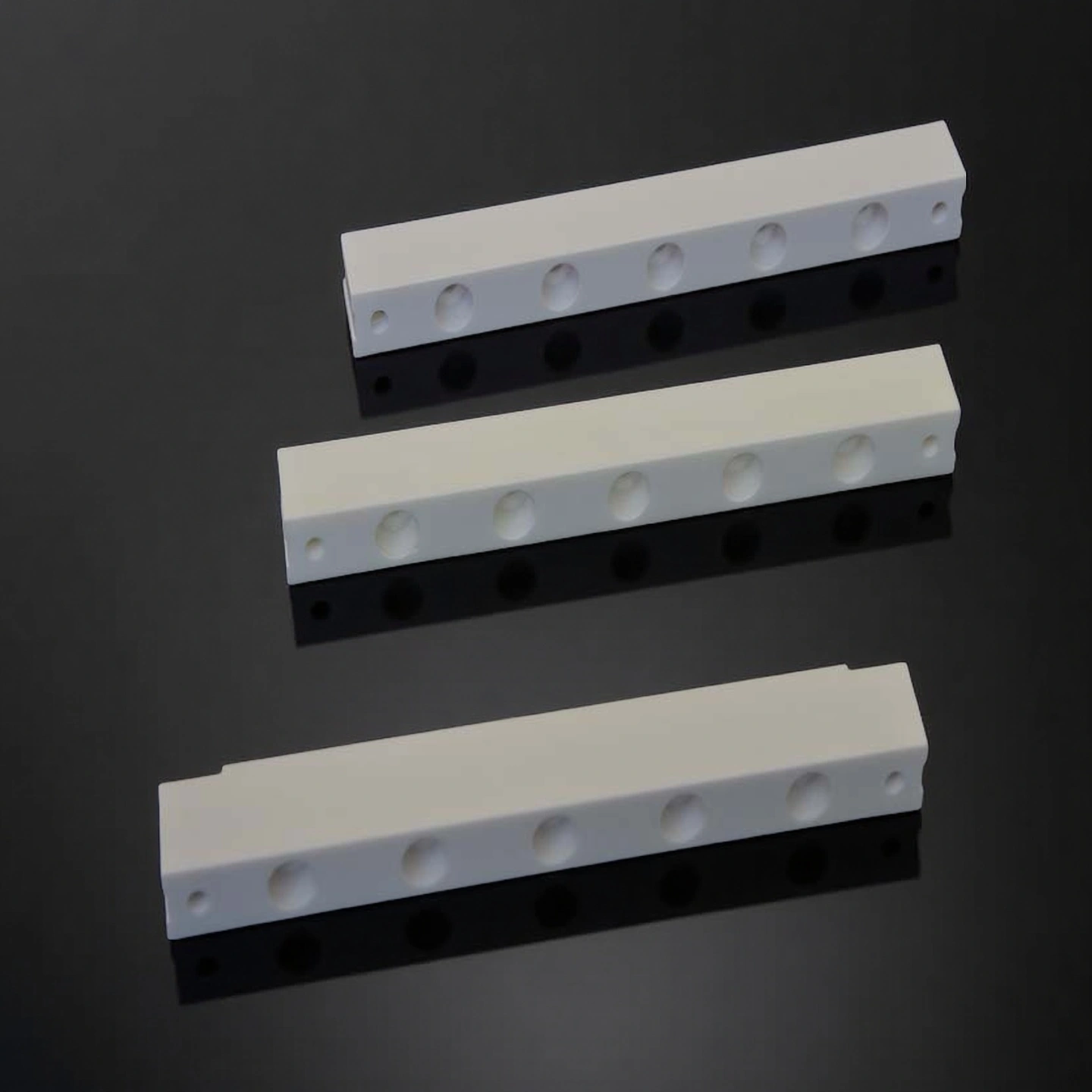

Alumina insulation board is a dense Al₂O₃ ceramic plate engineered for two tasks in one component: reliable electrical insulation and mechanical protection, with optional metallization/lamination to form a continuous EMI shielding path.

Alumina Ceramic Insulation Plate Benefits

- Insulation + Shielding Architecture: Alumina base maintains creepage/clearance; metallization/lamination builds a continuous EMI return surface without separate shield frames.

- Rigid Mechanical Protection: High hardness and stiffness protect harnesses/PCBs; edge finishing (R-chamfer, deburr) reduces abrasion and handling defects.

- Dimensional Repeatability: Controlled thickness, flatness, and hole position support platform builds and fixture compatibility, lowering rework rates.

- Thermal Stability Under Load: Stable CTE and moderate thermal conductivity help limit warpage and maintain clamp force across temperature cycles.

- Surface Engineering Ready: Raw, polished, sandblasted, or coated surfaces for bonding, gasketing, or conductive paths with designed insulation gaps.

Alumina Insulation Board Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Insulation Board Size

| Item No. | Diameter (mm) | Thickness (mm) | Purity |

| AT-AO-SF01 | Customize | ||

Alumina Ceramic Insulation Board Packaging

- Foam-lined cartons + corner guards to protect edges and polished faces.

- Interleaving sheets between boards to prevent abrasion.