Alumina ceramic washer for IC package is a thin insulating pad made from high-purity Al₂O₃, installed between a power device (such as TO-220, TO-247, DO-4, DO-5 packages) and the heatsink. It provides electrical insulation while still allowing efficient heat transfer from the IC package to the cooling surface.

Alumina Ceramic Washer for IC Packagw Benefits

-

Thin, rigid thermal interface

Provides a hard, flat interface that spreads heat evenly across the contact area, unlike compressible silicone pads that may deform under mounting torque. -

High dielectric margin for power devices

Dielectric strength up to the order of 12–22 kV/mm gives robust insulation between live leads and grounded heatsinks in compact layouts -

Stable at elevated junction temperatures

Alumina keeps mechanical strength and insulation performance in long-term service up to around 1600 °C, suitable for power electronics with high case temperatures. -

Low warpage and good flatness

Substrate-grade alumina delivers controlled flatness and low camber, helping to keep mounting pressure uniform and protect device packages from local stress. -

Compatible with common assembly processes

Washers tolerate standard mounting torque, re-tightening and repeated thermal cycling, and can be used with thermal grease or phase-change material if required.

IC Package Alumina Ceramic Washer Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

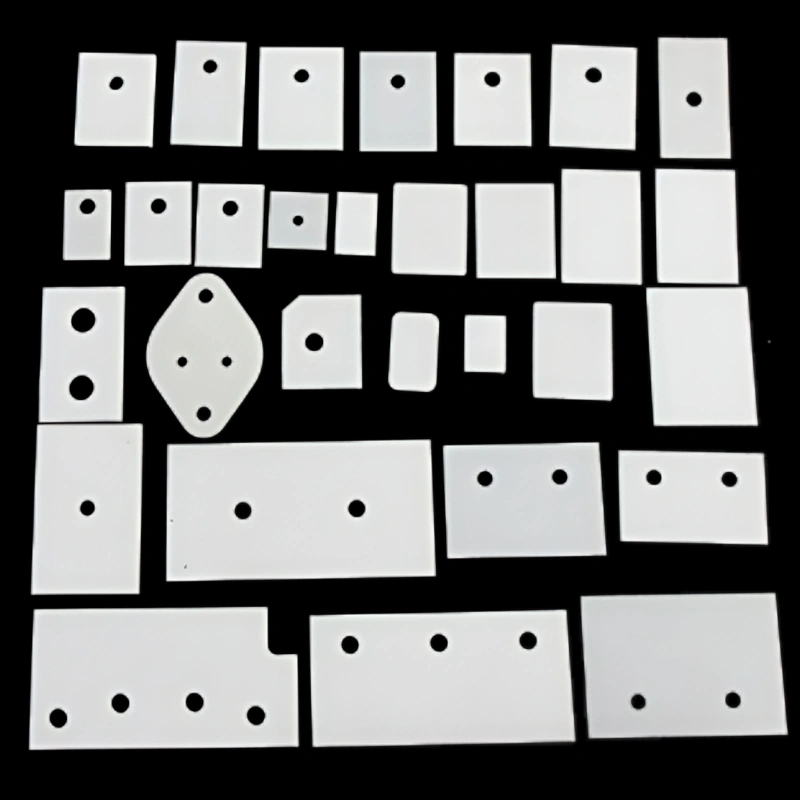

Alumina Ceramic Washer for IC Package Specifications

| Alumina Ceramic Washer for IC Package | ||||||

| Product categories | Product Picture | For housing | Item No. | Thickness | Hole | Dimensions |

| AL2O3 washer FOR TO220A-F |

|

TO220A | AT-TO220A-001 | 1.5mm | 3.8mm | 16.5x12.7x1.5mm |

| TO220A | AT-TO220A-002 | 1mm | 3.8mm | 16.5x12.7x1mm | ||

| TO220B | AT-TO220B-003 | 3mm | 3.7mm | 17.3x12.3x3mm | ||

| TO220C | AT-TO220C-004 | 1.5mm | 3.1mm | 18x12x1.5mm | ||

| TO220C | AT-TO220C-005 | 1.5mm | 4mm | 18x12x1.5mm | ||

| TO220C | AT-TO220C-006 | 1.5mm | 3.6mm | 18x12x1.5mm | ||

| TO220C | AT-TO220C-007 | 1.5mm | 3.1mm | 18x12x1.5mm | ||

| TO220C | AT-TO220C-008 | 3mm | without | 18x12x3mm | ||

| TO220C | AT-TO220C-009 | 3mm | 3.1mm | 18x12x3mm | ||

| TO220D | AT-TO220D-010 | 1.5mm | 3.2mm | 18x14x1.5mm | ||

| TO220D | AT-TO220D-011 | 3mm | without | 18x14x3mm | ||

| TO220D | AT-TO220D-012 | 3mm | 3.2mm | 18x14x3mm | ||

| TO220D | AT-TO220D-013 | 4.5mm | 3.2mm | 18x14x4.5mm | ||

| TO220D | AT-TO220D-014 | 4.5mm | 3.5mm | 18x14x4.5mm | ||

| TO220D | AT-TO220D-015 | 0.635mm | 3.8mm | 18.5*12*0.635mm | ||

| TO220D | AT-TO220D-016 | 1mm | 3.8mm | 18.5*12*1.0mm | ||

| TO220E | AT-TO220E-017 | 0.635mm | 3.8mm | 19*14*0.635 | ||

| TO220E | AT-TO220E-018 | 1mm | 3.8mm | 19*12*1.0mm | ||

| TO220E | AT-TO220E-019 | 2mm | 3.5mm | 19*14*2.0mm | ||

| TO220E | AT-TO220E-020 | 1.6mm | 3.7mm | 19.3x14x1.6mm | ||

| TO220E | AT-TO220E-021 | 2.5mm | 3.7mm | 19.3x14x2.5mm | ||

| TO220E | AT-TO220E-022 | 2mm | 3.7mm | 19.3x14x2mm | ||

| TO220E | AT-TO220E-023 | 3mm | 3.7mm | 19.3x14x3mm | ||

| TO220E | AT-TO220E-024 | 4mm | 3.7mm | 19.3x14x4mm | ||

| TO220F | AT-TO220F-025 | 0.6mm | 3.2mm | 20*14*0.6mm | ||

| TO220F | AT-TO220F-026 | 1 | 3.2mm | 20*14*1mm | ||

| TO220F | AT-TO220F-027 | 0.635mm | 3.8mm | 22*17*0.635mm | ||

| TO220F | AT-TO220F-028 | 1mm | 3.8mm | 22*17*1.0mm | ||

| TO220F | AT-TO220F-029 | 1.5mm | 3.6mm | 23x20x1.5mm | ||

| TO220F | AT-TO220F-030 | 1mm | without | 23x20x1mm | ||

| TO220F | AT-TO220F-031 | 1mm | 3.6mm | 23x20x1mm | ||

| TO220F | AT-TO220F-032 | 2mm | without | 23x20x2mm | ||

| TO220F | AT-TO220F-033 | 2mm | 3.6mm | 20x20x2mm | ||

| TO220F | AT-TO220F-034 | 3mm | without | 23x20x3mm | ||

| TO220F | AT-TO220F-035 | 4mm | without | 23x20x4 mm | ||

| TO220F | AT-TO220F-036 | 4mm | 3.6mm | 23x20x4mm | ||

| TO220F | AT-TO220F-037 | 0.635mm | 4 | 25*20*0.635mm | ||

| TO220F | AT-TO220F-038 | 1mm | 4 | 25*20*1mm | ||

| TO220F | AT-TO220F-039 | 2mm | 3.5mm | 25*20*2mm | ||

| TO220F | AT-TO220F-040 | 0.635mm | 4 | 28*22*0.635mm | ||

| TO220F | AT-TO220F-041 | 1mm | 4 | 28*22*1mm | ||

| AL2O3 washer FOR TO247 |

|

TO247 | AT-TO247-042 | 1.5mm | 3.1mm | 20.5x17.5x1.5mm |

| TO247 | AT-TO247-043 | 1.8mm | 3.8mm | 20.5x17x1.8mm | ||

| AL2O3 washer FOR TO3A |

|

TO3A | AT-TO3A-044 | 3mm | Hole: 4.9mm | Elongated hole: 4.2x4.9mm | 40.5x26.2x3mm |

| TO3A | AT-TO3A-045 | |||||

| AL2O3 washer FOR DO4A-DO4B |

|

DO4A | AT-DO4A-046 | 1.57mm | 8.2mm | AD20.1x1.57mm |

| DO4A | AT-DO4A-047 | 3,5mm | 8.2mm | AD20.1x3.5mm | ||

| DO4B | AT-DO4B-048 | 1,6mm | 6.6mm | AD20x1.6mm | ||

| AL2O3 washer FOR DO5A-DO5B | DO5A | AT-DO5A-049 | 1mm | 5.1mm | AD13x1mm | |

| DO5B | AT-DO5B-050 | 1.5mm | 3.2mm | AD9.5x1.5mm | ||

| DO5B | AT-DO5B-051 | 2.3mm | 3.2mm | AD9.5x2.3mm | ||

| AL2O3 washer FOR SOT32A |

|

SOT32A | AT-SOT32A-052 | 1.5mm | 3.1mm | 11x8x1.5mm |

| SOT32A | AT-SOT32A-053 | |||||

| AL2O3 washer FOR Substrate |

|

Substrate | AT-Substrate-054 | 3mm | without | 25x10x3mm |

| Substrate | AT-Substrate-055 | 5mm | without | 25x10x5mm | ||

| AL2O3 washer FOR TOP3-TO127 |

|

TO127 | AT-TO127-056 | 3mm | 4mm | 25x21x3mm |

| TOP3 | AT-TOP3-057 | 1.5mm | 3.1mm | 20.5x17.5x1.5mm | ||

| AL2O3 washer FOR TO5-TO18 |

|

TO18 | AT-TO18-058 | 1.5mm | 3x0.9mm | OD8x1.5mm |

| TO5 | AT-TO5-059 | 1.5mm | 3x1.11mm | AD10.9x1.5mm | ||

| AL2O3 washer FOR TO218 |

|

TO218 | AT-TO218-060 | 1.5mm | 4mm | 25x21x1.5mm |

| TO218 | AT-TO218-061 | 3mm | without | 25x21x3mm | ||

| TO218 | AT-TO218-062 | 3mm | 4mm | 25x21x3mm | ||

| TO218 | AT-TO218-063 | 4mm | 4mm | 25x21x4mm | ||

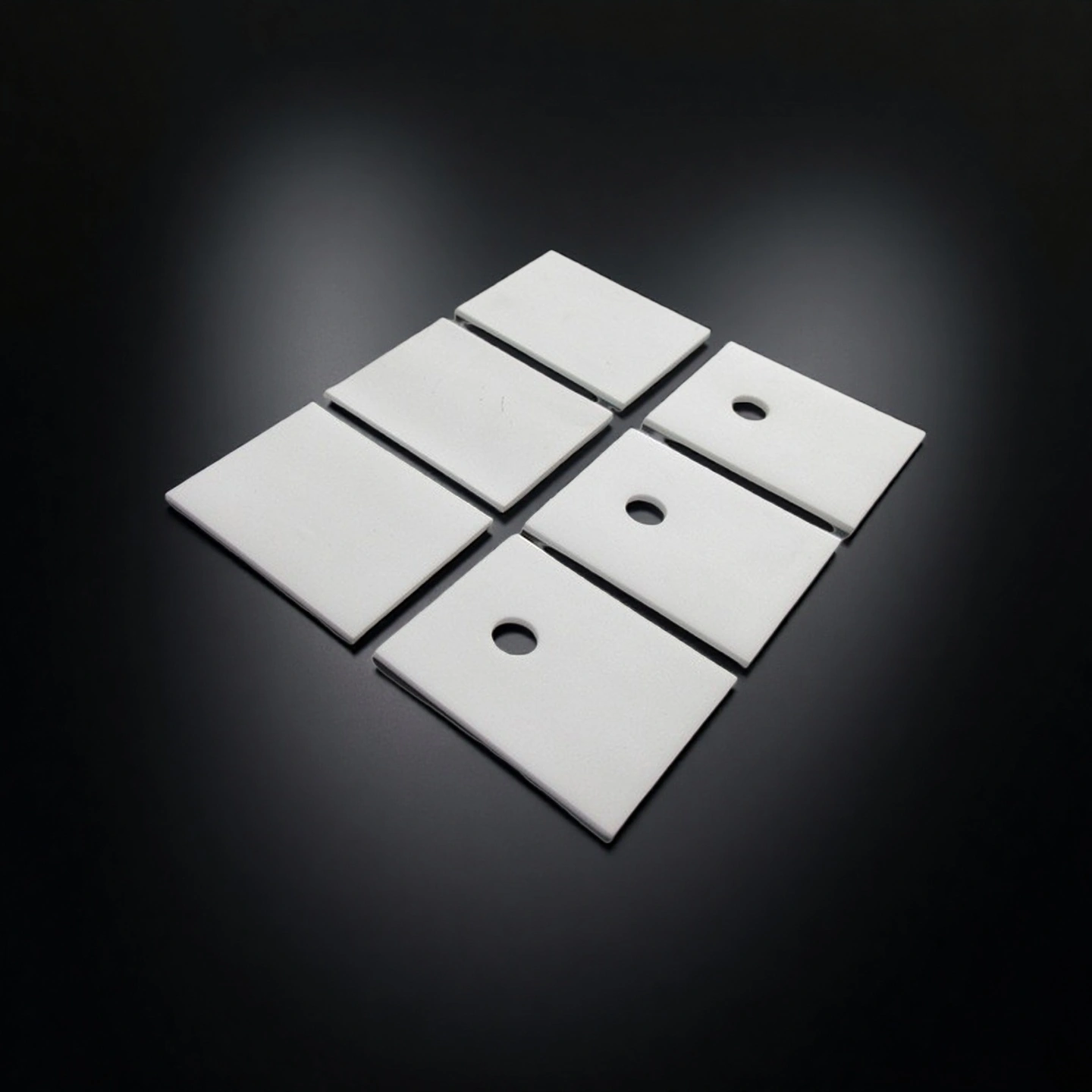

IC Package Alumina Ceramic Washer Packaging

- Washers are stacked in aligned layers with interleaving paper or film to avoid chipping and edge contact.