An Alumina Crucible with Spout is a high-alumina ceramic crucible designed for high-temperature heating and controlled pouring/decanting. The built-in spout (pouring lip) guides molten or liquid-phase material into a predictable stream, which helps reduce random dripping, rim overflow, and transfer loss when moving hot contents into a mold, plate, beaker, or another crucible.

Advantages of Alumina Crucible with Spout

-

Defined spout geometry for controlled decanting

The alumina crucible with spout features a precisely formed pouring lip that concentrates the melt flow at a single exit point, minimizing rim overflow, side dripping, and material loss during high-temperature transfer operations. -

Optimized rim-to-spout transition for stable flow initiation

A smooth, engineered transition between the rim and spout stabilizes the initial pour, preventing unpredictable flow break-out around the crucible edge and improving pouring consistency between repeated heating cycles. -

Consistent form factor across production batches

Tight control of overall geometry, spout position, and rim height ensures repeatable clamp or tong engagement, enabling operators to maintain a consistent pouring angle and handling motion across multiple crucibles and replacement cycles. -

Selectable spout opening designs for different melt behaviours

Multiple spout opening widths and profiles are available to accommodate variations in melt viscosity and particle loading, allowing thicker melts to discharge without clogging while enabling finer control for low-viscosity or precision pours. -

Edge handling options at high-contact zones

Chamfered or reinforced lip designs are applied at the rim and spout area to reduce edge chipping caused by frequent tong contact, improving durability in repeated heating, lifting, and pouring workflows.

Alumina Ceramic Crucible with Spout Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Standard Specifications for Alumina Crucibles with Spout

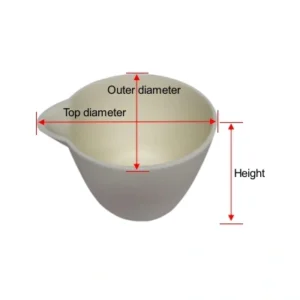

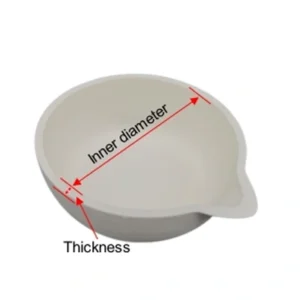

| Item NO. | Outer diameter(mm) | Thickness (mm) | Inner diameter (4mm Thickness) | Inner diameter(8mm Thickness) | TOP diameter(mm) | Height(mm) | Purity(%) |

| TE-OEM-124 | 30 | 4-8 | 22 | 14 | 40 | 15 | 99-99.6 |

| TE-OEM-125 | 30 | 4-8 | 22 | 14 | 40 | 28 | 99-99.6 |

| TE-OEM-126 | 30 | 4-8 | 22 | 14 | 40 | 35 | 99-99.6 |

| TE-OEM-127 | 40 | 4-8 | 32 | 24 | 50 | 30 | 99-99.6 |

| TE-OEM-128 | 44 | 4-8 | 36 | 28 | 54 | 27 | 99-99.6 |

| TE-OEM-129 | 50 | 4-8 | 42 | 34 | 60 | 35 | 99-99.6 |

| TE-OEM-130 | 50 | 4-8 | 42 | 34 | 60 | 47 | 99-99.6 |

| TE-OEM-131 | 50 | 4-8 | 42 | 34 | 60 | 60 | 99-99.6 |

| TE-OEM-132 | 50 | 4-8 | 42 | 34 | 60 | 75 | 99-99.6 |

| TE-OEM-133 | 60 | 4-8 | 52 | 44 | 70 | 80 | 99-99.6 |

| TE-OEM-134 | 68 | 4-8 | 60 | 52 | 78 | 92 | 99-99.6 |

| TE-OEM-135 | 75 | 4-8 | 67 | 59 | 85 | 46 | 99-99.6 |

| TE-OEM-136 | 80 | 4-8 | 72 | 64 | 90 | 75 | 99-99.6 |

| TE-OEM-137 | 85 | 4-8 | 77 | 69 | 95 | 90 | 99-99.6 |

| TE-OEM-138 | 90 | 4-8 | 82 | 74 | 100 | 80 | 99-99.6 |

| TE-OEM-139 | 94 | 4-8 | 86 | 78 | 104 | 76 | 99-99.6 |

| TE-OEM-140 | 100 | 4-8 | 92 | 84 | 110 | 65 | 99-99.6 |

| TE-OEM-141 | 190 | 4-8 | 182 | 174 | 200 | 70 | 99-99.6 |

| TE-OEM-142 | 190 | 4-8 | 182 | 174 | 200 | 65 | 99-99.6 |

| TE-OEM-143 | 100 | 4-8 | 92 | 84 | 110 | 70 | 99-99.6 |

| TE-OEM-144 | 150 | 4-8 | 142 | 134 | 160 | 80 | 99-99.6 |

| TE-OEM-145 | 270 | 8 | / | 254 | 280 | 55 | 99-99.6 |

| TE-OEM-146 | 340 | 8 | / | 324 | 350 | 120 | 99-99.6 |

| TE-OEM-147 | 400 | 8 | / | 384 | 410 | 90 | 99-99.6 |

| TE-OEM-148 | 450 | 8 | / | 434 | 460 | 85 | 99-99.6 |

Alumina Crucibles with Spout Packaging

- Individual unit protection: each crucible is separated to prevent rim-to-rim contact

- Shock absorption: foam + inner carton to reduce micro-crack risk during transit