Alumina Grinding Balls (also known as alumina milling media) are a type of high-performance industrial consumable used for grinding and dispersing materials. They are hard, dense ceramic spheres made primarily from aluminum oxide (Al₂O₃).

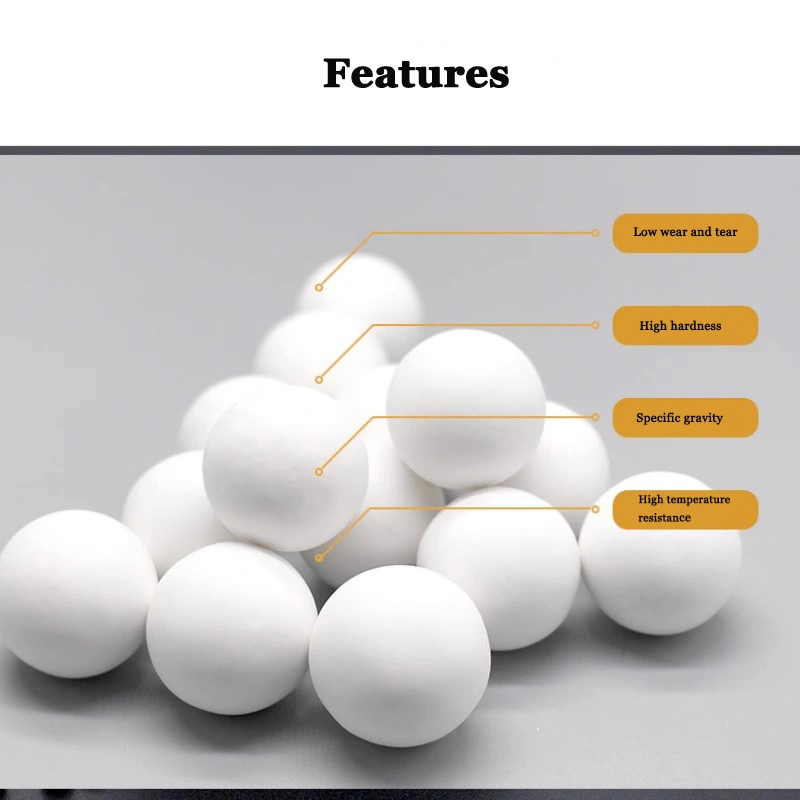

Alumina Grinding Balls Advantages

- High Grinding Efficiency: The high density (≥3.65 g/cm³) of our alumina balls provides greater impact force in ball mills, shortening grinding times by up to 40% and increasing production throughput.

- Minimal Product Contamination: An extremely low abrasion rate (<0.01%/hr) ensures the purity of your milled product, critical for white pigments, electronic-grade ceramics, and other contamination-sensitive materials.

- Extended Service Life: Manufactured through an isostatic pressing and high-temperature sintering process, our alumina ceramic grinding balls possess superior crush strength and wear resistance, significantly reducing media consumption and maintenance downtime.

- Chemical Stability: The inert alumina material is highly resistant to corrosion from acids and alkalis, making it suitable for a wide range of slurry chemistries without degrading.

Alumina Ceramic Grinding Balls Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Milling Ball Specifications

Type 1-Alumina Milling Balls

| Item | Diameter(mm) | Purity(%) |

| AT-YM-001 | 0.5 | 92 |

| AT-YM-002 | 1 | 92 |

| AT-YM-003 | 2 | 92 |

| AT-YM-004 | 3 | 92 |

| AT-YM-005 | 3.5 | 92 |

| AT-YM-006 | 4 | 92 |

| AT-YM-007 | 5 | 92 |

| AT-YM-008 | 6 | 92 |

| AT-YM-009 | 8 | 92 |

| AT-YM-010 | 10 | 92 |

| AT-YM-011 | 12 | 92 |

| AT-YM-012 | 15 | 92 |

| AT-YM-013 | 20 | 92 |

| AT-YM-014 | 25 | 92 |

| AT-YM-015 | 0.2 | 95 |

| AT-YM-016 | 0.3 | 95 |

| AT-YM-017 | 0.4 | 95 |

| AT-YM-018 | 0.5 | 95 |

| AT-YM-019 | 1 | 95 |

| AT-YM-020 | 2 | 95 |

| AT-YM-021 | 3 | 95 |

| AT-YM-022 | 3.5 | 95 |

| AT-YM-023 | 4 | 95 |

| AT-YM-024 | 5 | 95 |

| AT-YM-025 | 6 | 95 |

| AT-YM-026 | 8 | 95 |

| AT-YM-027 | 10 | 95 |

| AT-YM-028 | 12 | 95 |

| AT-YM-029 | 15 | 95 |

| AT-YM-030 | 20 | 95 |

| AT-YM-031 | 25 | 95 |

| AT-YM-032 | 30 | 95 |

| AT-YM-033 | 35 | 95 |

| AT-YM-034 | 45 | 95 |

| AT-YM-035 | 50 | 95 |

| AT-YM-036 | 60 | 95 |

| AT-YM-037 | 0.2 | 99 |

| AT-YM-038 | 0.3 | 99 |

| AT-YM-039 | 0.4 | 99 |

| AT-YM-040 | 0.5 | 99 |

| AT-YM-041 | 1 | 99 |

| AT-YM-042 | 2 | 99 |

| AT-YM-043 | 3 | 99 |

| AT-YM-044 | 3.5 | 99 |

| AT-YM-045 | 4 | 99 |

| AT-YM-046 | 5 | 99 |

| AT-YM-047 | 6 | 99 |

| AT-YM-048 | 8 | 99 |

| AT-YM-049 | 10 | 99 |

| AT-YM-050 | 12 | 99 |

| AT-YM-051 | 15 | 99 |

| AT-YM-052 | 20 | 99 |

| AT-YM-053 | 25 | 99 |

| AT-YM-054 | 30 | 99 |

| AT-YM-055 | 35 | 99 |

| AT-YM-056 | 45 | 99 |

| AT-YM-057 | 50 | 99 |

| AT-YM-058 | 60 | 99 |

| AT-YM-059 | 70 | 99 |

| AT-YM-060 | 80 | 99 |

Type 2- Precision Alumina Milling Balls

| Item | Diameter(mm) | Purity(%) |

| AT-YM-J001 | 9.525 | 92 |

| AT-YM-J002 | 10 | 92 |

| AT-YM-J003 | 12.7 | 92 |

| AT-YM-J004 | 15.875 | 92 |

| AT-YM-J005 | 16 | 92 |

| AT-YM-J006 | 20 | 92 |

| AT-YM-J007 | 25 | 92 |

| AT-YM-J008 | 25.4 | 92 |

| AT-YM-J009 | 38.1 | 92 |

| AT-YM-J010 | 15 | 92 |

| AT-YM-J011 | 9.525 | 92 |

| AT-YM-J012 | 10 | 95 |

| AT-YM-J013 | 12.7 | 95 |

| AT-YM-J014 | 15.875 | 95 |

| AT-YM-J015 | 16 | 95 |

| AT-YM-J016 | 20 | 95 |

| AT-YM-J017 | 25 | 95 |

| AT-YM-J018 | 25.4 | 95 |

| AT-YM-J019 | 38.1 | 95 |

| AT-YM-J020 | 15 | 95 |

| AT-YM-J021 | 1.588 | 99 |

| AT-YM-J022 | 2.381 | 99 |

| AT-YM-J023 | 2.5 | 99 |

| AT-YM-J024 | 2.778 | 99 |

| AT-YM-J025 | 3 | 99 |

| AT-YM-J026 | 3.175 | 99 |

| AT-YM-J027 | 3.5 | 99 |

| AT-YM-J028 | 3.969 | 99 |

| AT-YM-J029 | 4 | 99 |

| AT-YM-J030 | 4.763 | 99 |

| AT-YM-J031 | 5 | 99 |

| AT-YM-J032 | 5.556 | 99 |

| AT-YM-J033 | 5.953 | 99 |

| AT-YM-J034 | 6.35 | 99 |

| AT-YM-J035 | 7.144 | 99 |

| AT-YM-J036 | 7.938 | 99 |

| AT-YM-J037 | 8.731 | 99 |

| AT-YM-J038 | 9.525 | 99 |

| AT-YM-J039 | 10.319 | 99 |

| AT-YM-J040 | 11.1125 | 99 |

| AT-YM-J041 | 11.906 | 99 |

| AT-YM-J042 | 12.7 | 99 |

| AT-YM-J043 | 13.494 | 99 |

| AT-YM-J044 | 14.288 | 99 |

Alumina Milling Balls VS Alumina Precision Grinding Media Balls

| Type | Tolerance | Application | Field |

|---|---|---|---|

| Alumina Grinding Balls | ± 1.0-3.0mm | Grinding, Catalysing, Adsorption, Catalyst | Industrial production, building materials, electronics, medicine, and other industries. |

| Alumina Precision Balls | ± 0.005-0.002mm | Precision Grinding, Trace Elements, Dispersion and Coating Materials | Scientific research, high-tech experimental rooms, equipment components, medical treatment, aerospace, and high-end precision instruments. |

Alumina Grinding Beads Packing

- High alumina grinding beads are packaged in 25 kg heavy-duty plastic bags, which are then placed inside 1-ton jumbo bags with inner waterproof liners. The jumbo bags are palletized and shrink-wrapped for secure, moisture-free international transport.