Alumina sagger (alumina saggar) is a refractory ceramic container—box, tray, or deep boat—made primarily from Al₂O₃ and used to hold powders, green parts, or substrates during high-temperature processing. Its purpose is to protect the load and the furnace, control the local atmosphere around the product, and minimize contamination or reaction during firing, calcination, debinding, or sintering.

Alumina Sagger Benefits

- Clean firing: Dense alumina, low alkali content, and optional liners minimize cross-reaction and particle shedding.

- Dimensional control: Flatness and warpage control improve stacking and packing density in continuous or batch kilns.

- Atmosphere management: Lids, vents, and step-stacking help tune vapor transport and reduce re-deposition.

- Cycle durability: Thickness and corner radii are engineered to endure repeated heat-up/cool-down cycles.

- Throughput efficiency: Deep-tray and multi-cavity designs increase parts-per-load while keeping handling simple.

Alumina Saggar Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Saggar Specifications

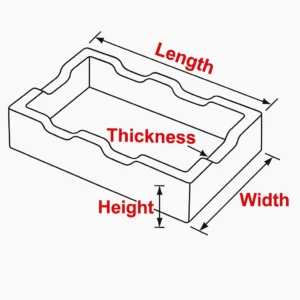

Type 1-Rectangular Alumina Saggar

| Item NO. | Volume | Length (mm) | Width (mm) | Height (mm) | Thickness (mm) |

| TE-AS-205 | 64 | 100 | 100 | 13 | 5 |

| TE-AS-206 | 80 | 100 | 100 | 15 | 5 |

| TE-AS-207 | 120 | 100 | 100 | 20 | 5 |

| TE-AS-208 | 64 | 100 | 81 | 28 | 5 |

| TE-AS-209 | 22 | 100 | 100 | 15 | 6 |

| TE-AS-210 | 60 | 115 | 60 | 9 | 6 |

| TE-AS-211 | 58 | 115 | 60 | 7 | 6 |

| TE-AS-212 | 297 | 120 | 120 | 40 | 6.5 |

| TE-AS-213 | 161 | 127 | 127 | 21 | 5 |

| TE-AS-214 | 270 | 128 | 128 | 25 | 5 |

| TE-AS-215 | 355 | 135 | 135 | 35 | 9 |

| TE-AS-216 | 575 | 145 | 145 | 55 | 11 |

| TE-AS-217 | 49 | 150 | 150 | 18 | 10 |

| TE-AS-218 | 300 | 155 | 155 | 28 | 10 |

| TE-AS-219 | 350 | 200 | 105 | 30 | 10 |

| TE-AS-220 | 1634 | 220 | 180 | 80 | 14 |

| TE-AS-221 | 1400 | 230 | 230 | 45 | 12 |

| TE-AS-222 | 1752 | 230 | 300 | 50 | 12 |

| TE-AS-223 | 1080 | 230 | 165 | 60 | 12 |

| TE-AS-224 | 1467 | 248 | 155 | 62 | 13 |

| TE-AS-225 | 3000 | 250 | 250 | 100 | 10 |

| TE-AS-226 | 1137 | 295 | 195 | 55 | 10 |

| TE-AS-227 | 2565 | 315 | 158 | 83 | 13 |

| TE-AS-228 | 4100 | 320 | 320 | 60 | 10 |

| TE-AS-229 | 6000 | 320 | 320 | 75 | 10 |

| TE-AS-230 | 6500 | 320 | 320 | 85 | 10 |

| TE-AS-231 | 8900 | 320 | 320 | 110 | 10 |

| TE-AS-232 | 7500 | 320 | 320 | 110 | 14 |

| TE-AS-233 | 3900 | 320 | 320 | 60 | 14 |

| TE-AS-234 | 5000 | 320 | 320 | 75 | 15 |

| TE-AS-235 | 5000 | 320 | 320 | 80 | 15 |

| TE-AS-236 | 6000 | 320 | 320 | 85.5 | 14 |

| TE-AS-237 | 7000 | 320 | 320 | 100 | 15 |

| TE-AS-238 | 5186 | 320 | 320 | 85 | 15 |

| TE-AS-239 | 10000 | 330 | 330 | 120 | 13 |

| TE-AS-240 | 10700 | 330 | 330 | 130 | 13 |

| TE-AS-241 | 7900 | 330 | 330 | 100 | 12.5 |

| TE-AS-242 | 8000 | 330 | 330 | 100 | 13 |

| TE-AS-243 | 8200 | 330 | 330 | 100 | 12 |

| TE-AS-244 | 50 | 63 | 57 | 30 | 6 |

| TE-AS-245 | 56 | 100 | 100 | 12 | 5 |

| TE-AS-246 | 507 | 150 | 150 | 50 | 10 |

| TE-AS-247 | 100 | 160 | 160 | 15 | 8.5 |

| TE-AS-248 | 350 | 200 | 100 | 30 | 8.5 |

| TE-AS-249 | 6900 | 210 | 210 | 200 | 10 |

| TE-AS-250 | 4000 | 220 | 220 | 120 | 10 |

| TE-AS-251 | 2500 | 225 | 161 | 104 | 11 |

| TE-AS-252 | 8000 | 285 | 285 | 160 | 12.5 |

| TE-AS-253 | 7600 | 300 | 300 | 110 | 10 |

| TE-AS-254 | 11000 | 300 | 300 | 200 | 10 |

| TE-AS-255 | 7000 | 300 | 300 | 100 | 10 |

| TE-AS-256 | 6000 | 300 | 300 | 175 | 12 |

| TE-AS-257 | 5400 | 300 | 300 | 110 | 12 |

| TE-AS-258 | 8000 | 300 | 300 | 150 | 12.5 |

| TE-AS-259 | 3000 | 320 | 320 | 48 | 10 |

| TE-AS-260 | 2800 | 320 | 320 | 48 | 14 |

| TE-AS-261 | 12000 | 330 | 330 | 150 | 10 |

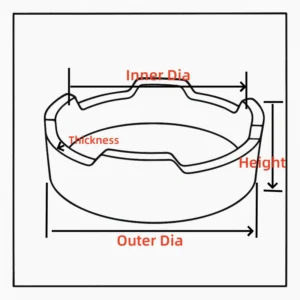

Type 2- Round Alumina Saggar

| Item | Capacity(ml) | Outer Diameter(mm) | Inner Diameter(mm) | Height(mm) | Purity (%) |

| AT-AC-182 | 152 | 63 | 51 | 30 | 80-99% |

| AT-AC-183 | 51 | 70 | 60 | 24 | 80-99% |

| AT-AC-184 | 127 | 50 | 40 | 106 | 80-99% |

| AT-AC-185 | 142 | 50 | 40 | 118 | 80-99% |

| AT-AC-186 | 169 | 100 | 87 | 35 | 80-99% |

| AT-AC-187 | 210 | 78 | 57 | 89 | 80-99% |

| AT-AC-188 | 215 | 69 | 50 | 118 | 80-99% |

| AT-AC-189 | 243 | 73 | 50 | 135 | 80-99% |

| AT-AC-190 | 362 | 80 | 59 | 143 | 80-99% |

| AT-AC-191 | 373 | 70 | 50 | 200 | 80-99% |

| AT-AC-192 | 459 | 85 | 75 | 109 | 80-99% |

| AT-AC-193 | 566 | 86 | 69 | 160 | 80-99% |

| AT-AC-194 | 583 | 87 | 69 | 165 | 80-99% |

| AT-AC-195 | 610 | 107 | 82 | 128 | 80-99% |

| AT-AC-196 | 1206 | 180 | 160 | 70 | 80-99% |

| AT-AC-197 | 2155 | 200 | 170 | 110 | 80-99% |

| AT-AC-198 | 3188 | 305 | 285 | 60 | 80-99% |

| AT-AC-199 | 6330 | 260 | 240 | 150 | 80-99% |

*Note: The table above shows only some standard specifications. For more specifications, please refer to the complete product catalogue or contact us for customization.

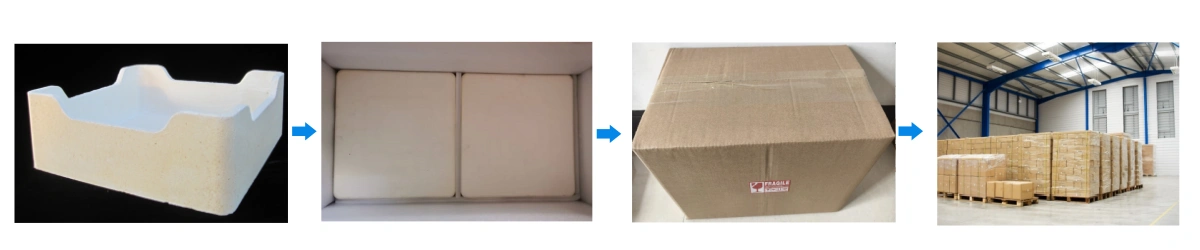

Alumina Saggar Packaging

- Protective packing: edge-guard plus foam separation; layered cartons with corner blocks for stackable saggar