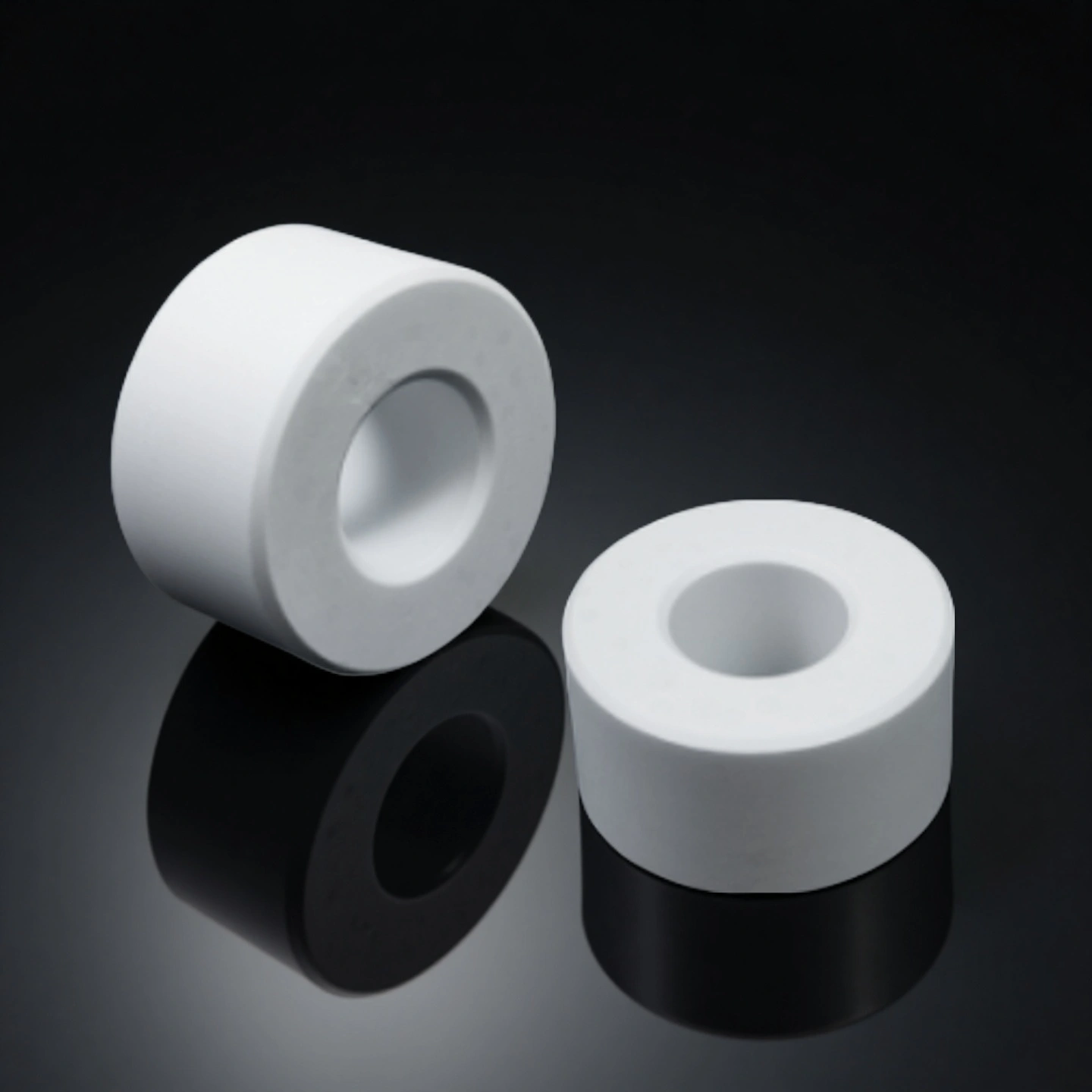

Alumina Seal Ring is a high-performance component used to prevent leaks in machinery, particularly in pumps, mixers, and other equipment with rotating shafts. Think of it as a very durable, specialized washer. It is made from Alumina (Aluminum Oxide, Al₂O₃)

Alumina Ceramic Seal Ring Benefits

- Dimensional Stability: Our manufacturing process ensures flatness and parallelism tolerances are held within microns, which is critical for preventing leakage in high-pressure mechanical seals. This level of precision exceeds that of many standard ceramic components.

- Superior Surface Finish: The sealing face of each alumina ring is fine-lapped and polished to a mirror finish (Ra ≤ 0.2μm). This ultra-smooth surface minimizes friction against the mating face (e.g., carbon-graphite), reducing wear and extending the operational life of the entire seal assembly.

- Material Consistency: We use 99.5% purity alumina powder, ensuring each batch of ceramic seal rings possesses uniform density and hardness. This consistency guarantees predictable performance and eliminates premature failures caused by material imperfections.

Alumina Seal Ring Properties

|

Property |

Unit |

99.5% Al₂O₃ |

99.6% Al₂O₃ |

99.7% Al₂O₃ |

99.8% Al₂O₃ |

99.9% Al₂O₃ |

99.99% Al₂O₃ |

|

Alumina content |

% |

99.5 |

99.6 |

99.7 |

99.8 |

99.9 |

99.99 |

|

Density |

g/cm³ |

3.89 |

3.91 |

3.92 |

3.93 |

3.94 |

3.98 |

|

Open porosity |

% |

0 |

– |

– |

– |

– |

– |

|

Color |

– |

Ivory |

Ivory |

Ivory |

Ivory |

Ivory |

Ivory |

|

Water absorption |

% |

– |

0 |

0 |

0 |

0 |

0 |

|

Young’s modulus (Elastic modulus) |

GPa |

375 |

356 |

357 |

358 |

359 |

362 |

|

Shear modulus |

GPa |

152 |

– |

– |

– |

– |

– |

|

Bulk modulus |

GPa |

228 |

– |

– |

– |

– |

– |

|

Poisson’s ratio |

– |

0.22 |

– |

– |

– |

– |

– |

|

Compressive strength |

MPa |

2600 |

2552 |

2554 |

2556 |

2558 |

2570 |

|

Flexural strength |

MPa |

379 |

312 |

313 |

314 |

315 |

320 |

|

Fracture toughness |

MPa·m¹ᐟ² |

4 |

– |

– |

– |

– |

– |

|

Hardness |

GPa |

14.1 (≈1440 kg/mm²) |

23 |

24 |

25 |

26 |

30 |

|

Thermal conductivity |

W/m·K |

35 |

32–37 |

33–38 |

34–39 |

35–40 |

36–42 |

|

Thermal shock resistance ΔT |

°C |

– |

222 |

223 |

224 |

225 |

228 |

|

Maximum use temperature (no load) |

°C |

≤1750 |

1755 |

1760 |

1765 |

1770 |

1800 |

|

Coefficient of thermal expansion |

10⁻⁶/°C |

8.4 |

– |

– |

– |

– |

– |

|

Specific heat |

J/kg·K |

880 |

– |

– |

– |

– |

– |

|

Volume resistivity |

Ω·cm |

>1×10¹⁴ |

>1×10¹⁴ |

>1×10¹⁴ |

>1×10¹⁴ |

>1×10¹⁴ |

>1×10¹⁴ |

|

Dielectric constant (relative permittivity) |

– |

9.8 |

9.83 |

9.84 |

9.85 |

9.86 |

9.92 |

|

Dielectric strength |

kV/mm |

16.9 |

23.2 |

23.4 |

23.6 |

23.8 |

24 |

|

Dissipation factor (loss factor @ 1 kHz) |

– |

0.0002 |

– |

– |

– |

– |

– |

Alumina Seal Ring Specifications

Alumina Seal Ring Packaging

- placed in a dedicated slot within a foam-lined box to prevent chipping or surface scratches during transit.

Alumina Ceramic Seal Ring Usage Instructions

Proper handling, installation, and maintenance of alumina ceramic seal rings ensure long service life, reliable performance, and reduced operational costs.

-

Installation

1. Always handle rings with clean, lint-free gloves to avoid contaminating the lapped surfaces.

2. Ensure the mating surface is free of debris and imperfections before installation.

3. Apply a uniform, light pressing force using an appropriate arbor press. Avoid impact or shock loading, as ceramics are brittle.

-

Operation

1. Never run the seals dry, even for a few seconds. Ensure adequate lubrication is present at startup.

2. Monitor for excessive vibration or shaft runout, as this can cause chipping on the seal face.

-

Storage

1. Store rings in their original protective packaging in a dry, stable environment.

2. Do not stack rings directly on top of each other without protective separation.

-

Cleaning

Use isopropyl alcohol and a lint-free cloth to clean sealing faces. Do not use abrasive cleaners or metal brushes.

-

Common Issues & Solutions

1. Issue: Minor chipping on the edge after installation.Cause: Likely caused by misalignment or impact during press-fitting.

Solution: Review installation procedures and use a guide tool to ensure concentricity. Minor edge chips outside the sealing path may be acceptable, but any damage on the lapped face requires replacement.

2. Issue: Concentric scoring marks on the sealing face after short-term use.Cause: Abrasive particles are present in the sealed fluid.

Solution: Implement a flush system or verify that the fluid's particle content is within the seal's design limits. Consider a harder mating face if abrasives cannot be eliminated.

3. Issue: Heat checking or cracking on the seal face.Cause: Insufficient lubrication or cooling, leading to excessive frictional heat.

Solution: Verify that the seal chamber is receiving adequate fluid flow for cooling. Check for blockages in the lubrication lines.