Alumina ceramic washer is a flat, ring-shaped component made from high-purity aluminum oxide (Al₂O₃).It is specifically engineered to be used in demanding industrial and technical applications where standard materials like metal or plastic would fail.

Alumina Washers Benefits

- Exceptional Dimensional Stability: Maintains precise dimensions across a wide temperature range, ensuring consistent performance in critical assemblies.

- High Dielectric Strength: Provides reliable electrical insulation (>15 kV/mm), preventing arcing and current leakage in high-voltage equipment.

- Superior Wear Resistance: The high hardness (≥9 Mohs) of the material minimizes abrasion and particulate generation, extending the service life of both the washer and mating components.

- Chemical Inertness: Resists corrosion from most acids and alkalis, making it suitable for use in chemically aggressive process environments.

Alumina Ceramic Washer Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

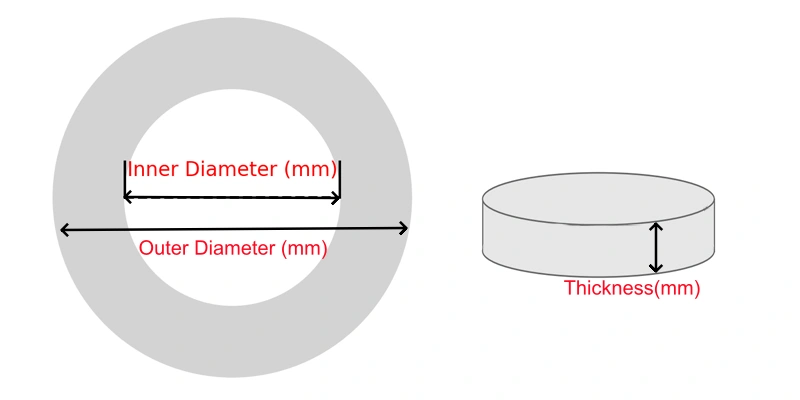

Alumina Spacers Specifications

| Alumina Washers | |||

| Item No. | Outer Diameter (mm) | Inner Diameter (mm) | Thickness (mm) |

| ATW00623 | 12.7 mm | 3.175 mm | 7.9248 mm |

| ATW00620 | 15.875 mm | 6.35 mm | 9.525 mm |

| ATW00612 | 4.7498 mm | 1.1938 mm | 0.508 mm |

| ATW00611 | 12.7 mm | 4.7498 mm | 6.35 mm |

| ATW00609 | 17.8308 mm | 4.8006 mm | 1.016 mm |

| ATW00608 | 17.8308 mm | 7.6708 mm | 1.016 mm |

| ATW00607 | 7.9756 mm | 4.8006 mm | 1.651 mm |

| ATW00606 | 11.0998 mm | 7.9248 mm | 6.35 mm |

| ATW00604 | 12.6746 mm | 7.1374 mm | 2.6924 mm |

| ATW00603 | 12.0904 mm | 4.318 mm | 2.794 mm |

| ATW00601 | 7.62 mm | 3.429 mm | 1.524 mm |

| ATW00600 | 6.35 mm | 3.429 mm | 0.508 mm |

| ATW00525 | 18.796 mm | 12.192 mm | 6.35 mm |

| ATW00524 | 14.986 mm | 10.0076 mm | 14.986 mm |

| ATW00519 | 9.525 mm | 3.175 mm | 0.762 mm |

| ATW00518 | 7.9248 mm | 6.35 mm | 9.525 mm |

| ATW00515 | 8.128 mm | 4.3688 mm | 0.9525 mm |

| ATW00514 | 13.9954 mm | 5.6896 mm | 5.0038 mm |

| ATW00510 | 18.796 mm | 12.7 mm | 3.302 mm |

| ATW00503 | 31.75 mm | 19.05 mm | 6.35 mm |

| ATW00502 | 31.75 mm | 19.05 mm | 6.35 mm |

| ATW00501 | 14.1732 mm | 6.35 mm | 3.3274 mm |

| ATW00500 | 8.89 mm | 6.35 mm | 21.209 mm |

| ATW00407 | 12.7 mm | 5.08 mm | 3.175 mm |

| ATW00400 | 12.7 mm | 6.35 mm | 3.175 mm |

| ATW00301 | 3.81 mm | 2.159 mm | 0.381 mm |

| ATW00299 | 9.525 mm | 4.826 mm | 4.7498 mm |

| ATW00298 | 12.7 mm | 9.525 mm | 4.7498 mm |

| ATW00296 | 19.05 mm | 14.2748 mm | 9.525 mm |

| ATW00293 | 5.9944 mm | 2.9972 mm | 3.9878 mm |

| ATW00289 | 15.875 mm | 6.35 mm | 7.9248 mm |

| ATW00288 | 15.875 mm | 9.525 mm | 4.7752 mm |

| ATW00283 | 9.525 mm | 6.35 mm | 3.175 mm |

| ATW00282 | 6.35 mm | 3.175 mm | 3.175 mm |

| ATW00281 | 12.7 mm | 3.175 mm | 3.175 mm |

| ATW00279 | 9.398 mm | 4.445 mm | 2.54 mm |

| ATW00273 | 12.7 mm | 6.35 mm | 1.5748 mm |

| ATW00271 | 10.795 mm | 7.9248 mm | 6.35 mm |

| ATW00270 | 4.7752 mm | 2.3876 mm | 1.27 mm |

| ATW00268 | 4.7752 mm | 1.5748 mm | 3.175 mm |

| ATW00267 | 4.191 mm | 3.429 mm | 3.175 mm |

| ATW00266 | 6.4008 mm | 5.207 mm | 2.54 mm |

| ATW00264 | 12.7 mm | 3.556 mm | 11.1252 mm |

| ATW00263 | 12.7 mm | 2.1336 mm | 7.9248 mm |

| ATW00262 | 12.7 mm | 2.54 mm | 7.9248 mm |

| ATW-CERAW12 | 11.9888 mm | 3.9878 mm | 3.9878 mm |

| ATW-CERAC4 | 8.001 mm | 3.9878 mm | 10.0076 mm |

| ATW-60-17WAT | 19.05 mm | 9.525 mm | 6.35 mm |

| ATW-450JH572 | 8.0518 mm | 12.7 mm | 3.175mm |

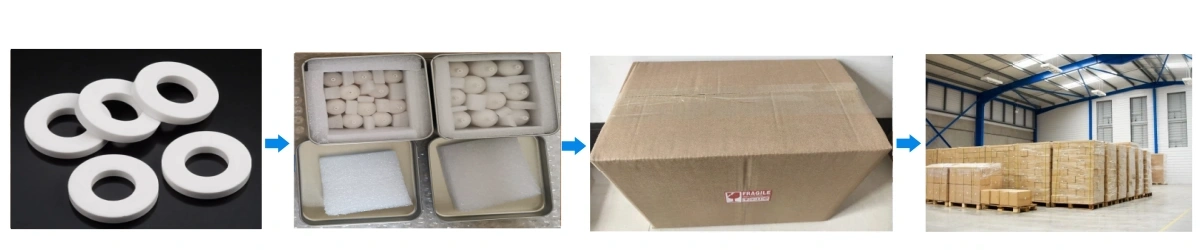

Alumina Ceramic Washer Packaging

- Each alumina ceramic washer is individually placed in soft foam cutouts to prevent chipping or cracking.