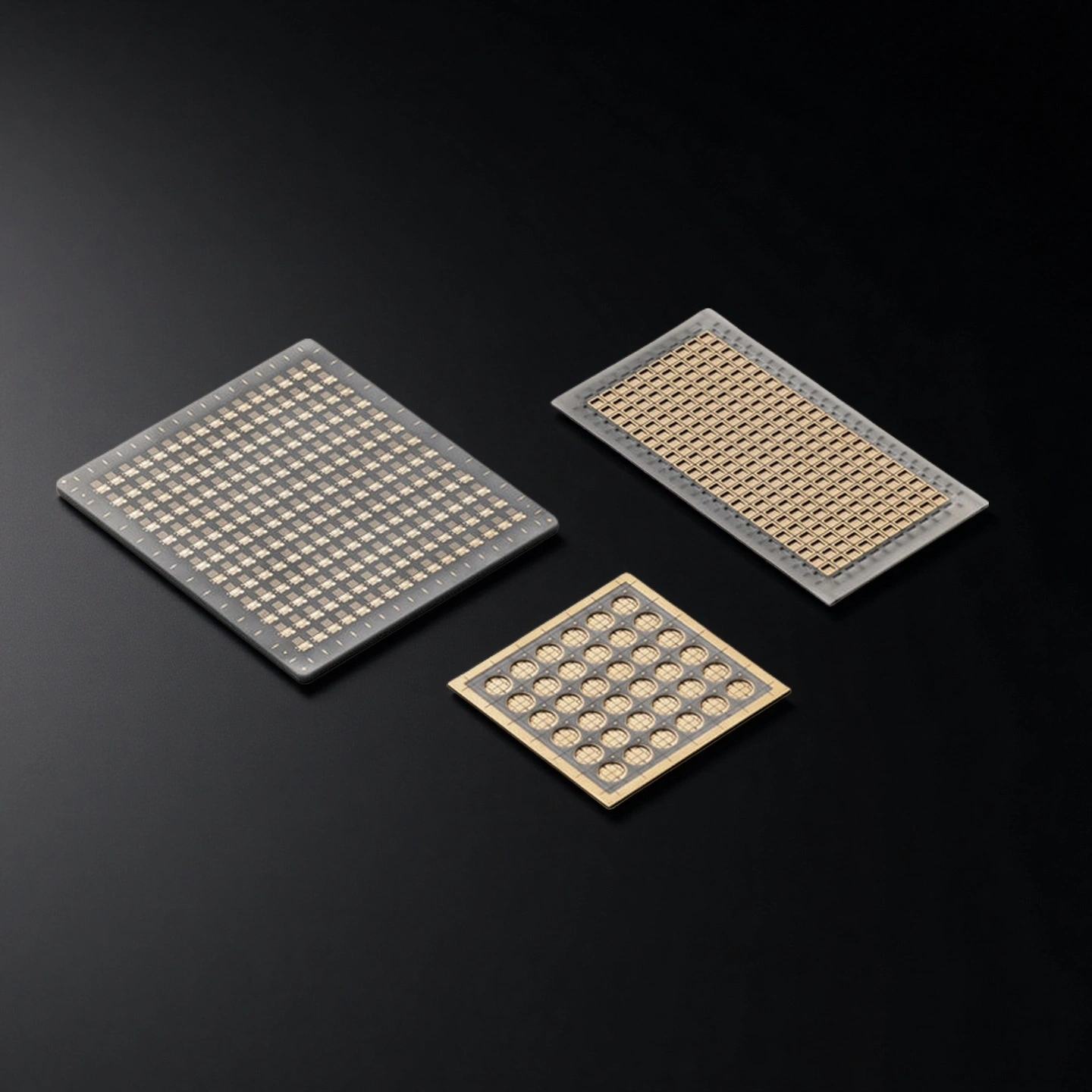

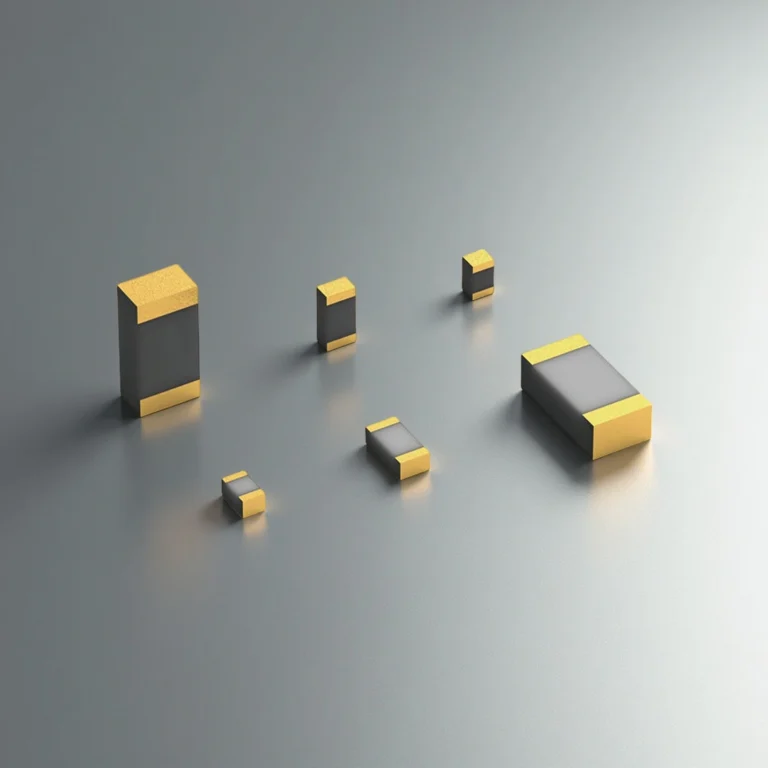

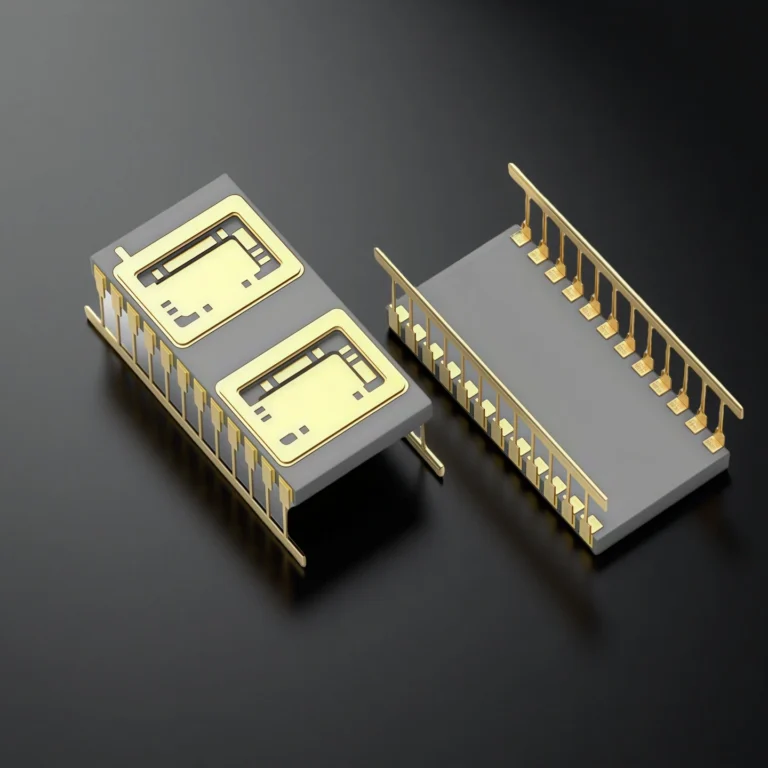

Aluminum nitride (AlN) ceramic supports are widely used in UV LED and VCSEL packaging due to their high thermal conductivity, electrical insulation, and dimensional stability. These substrates are crucial for thermal management and structural support in optoelectronic devices that operate under high power and precision requirements.

Aluminum Nitride UVLED /VCSEL Ceramic Support Benefits

-

Optimized for heat flow under UVLED / VCSEL dies

The AlN UVLED VCSEL support spreads heat quickly away from the active junction, helping to control junction temperature in compact high-power packages. -

Geometry tailored to chip layout and array pitch

Edge length, thickness and pad window positions can be machined around specific UV LED chip sizes, VCSEL array patterns and optical apertures, reducing rework on the assembly line. -

Stable CTE matching with GaN / GaAs / Si-based dies

The Aluminum Nitride ceramic support keeps thermal expansion close to common semiconductor materials, which helps maintain solder and epoxy interfaces over long thermal cycling. -

Fine-feature metallization compatibility

The support surface can be prepared for thin-film or thick-film metallization patterns that follow your pad layout, bond finger routing and common-cathode / common-anode schemes. -

Flatness control for precise optical alignment

Tight control of submount thickness and flatness supports accurate optical height and tilt of UVLED or VCSEL arrays inside lens barrels or optical windows.

AlN UVLED and VCSEL Ceramic Support Properties

| Property Content | Unit | Unit | ALN-170 | ALN-200 | ALN-230 |

| Basic Properties | Color | gray | light yellow | light yellow | |

| Density | g/cm³ | 3.2-3.3 | 3.2-3.3 | 3.2-3.3 | |

| Surface Roughness | μm | 0.2-0.75 | 0.2-0.75 | 0.2-0.8 | |

| Camber | length ‰ | ≤3‰ | ≤3‰ | ≤3‰ | |

| Hardness | HV | 1100 | 1100 | 1100 | |

| Thermal Properties | Max Operating Temperature | °C | 1100 | 1100 | 1100 |

| Thermal Conductivity | W/m·K | 170-190 | 190-220 | 220-230 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(20-400°c) | 4-5 | 4-5 | 4-5 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(400-800°c) | 5-6 | 5-6 | 5-6 | |

| Mechanical Properties | Flexural Strength | MPa | 300-400 | 350-450 | 400-500 |

| Tensile Strength | MPa | 200-300 | 250-350 | 280-380 | |

| Compressive Strength | MPa | 2000-3000 | 2200-3200 | 2500-3500 | |

| Electrical properties | Dielectric Constant | at 1MHz | 8-9 | 8-9 | 8-9 |

| Dielectric strength | KV/mm | ≥15 | ≥15 | ≥15 | |

| Volume resistivity | 20℃ Ω.cm | ≥1014 | ≥1014 | ≥1014 |

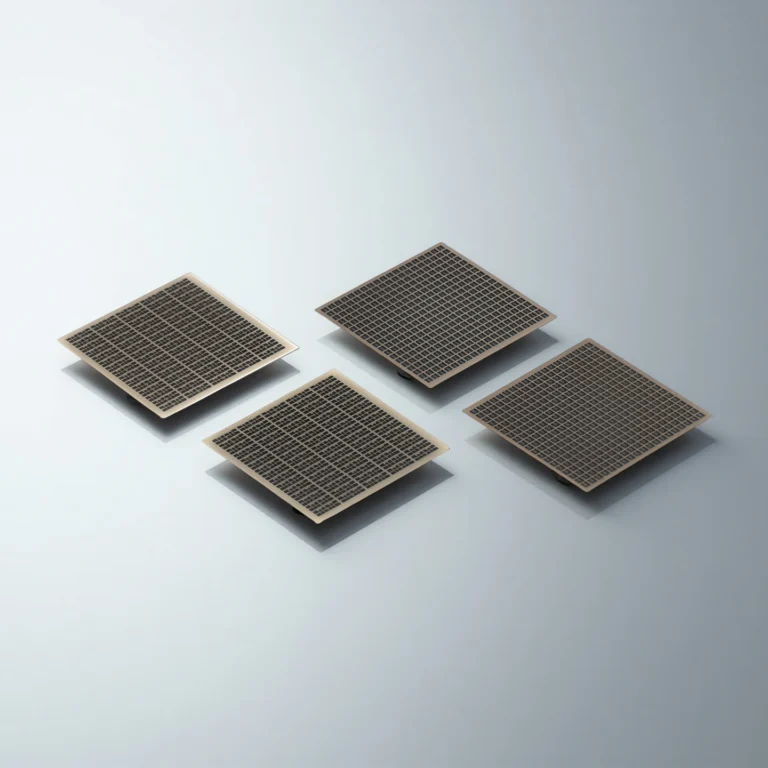

AlN UVLED and VCSEL Ceramic Support Specifications

| AlN UVLED and VCSEL Ceramic Support | |||||||

| Item no. | Model | Overall substrate size | Product size | Cavity size | Cavity shape | Cavity depth | Metallization of the seal |

| AT-3535-01 | 3535-01 | 88.9*45.5*0.8 | SQ3.5 | SQ2.4 | square | 0.4 | yes |

| AT-3535-02 | 3535-02 | 88.9*45.5*0.8 | SQ3.5 | SQ2.4 | square | 0.4 | no |

| AT-3535-03 | 3535-03 | 88.9*45.5*1.0 | SQ3.4 | SQ2.4 | square | 0.5 | yes |

| AT-6868-01 | 6868-01 | 48*48*1.0 | SQ6.8 | 4.9 | circle | 0.2+0.4 | no |

| AT-V3535-04 | V3535-04 | 88.9*45.5*2.0 | SQ3.5 | SQ2.4 | square | 0.45+1.0 | no |

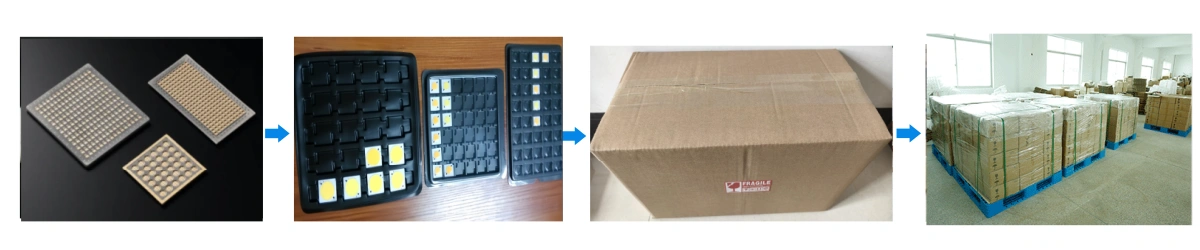

AlN UVLED /VCSEL Support Packaging

- Submounts are first cleaned and inspected, then loaded into anti-static trays or vacuum-sealed pockets, keeping each Aluminum Nitride UVLED VCSEL Support separated to avoid edge chipping.