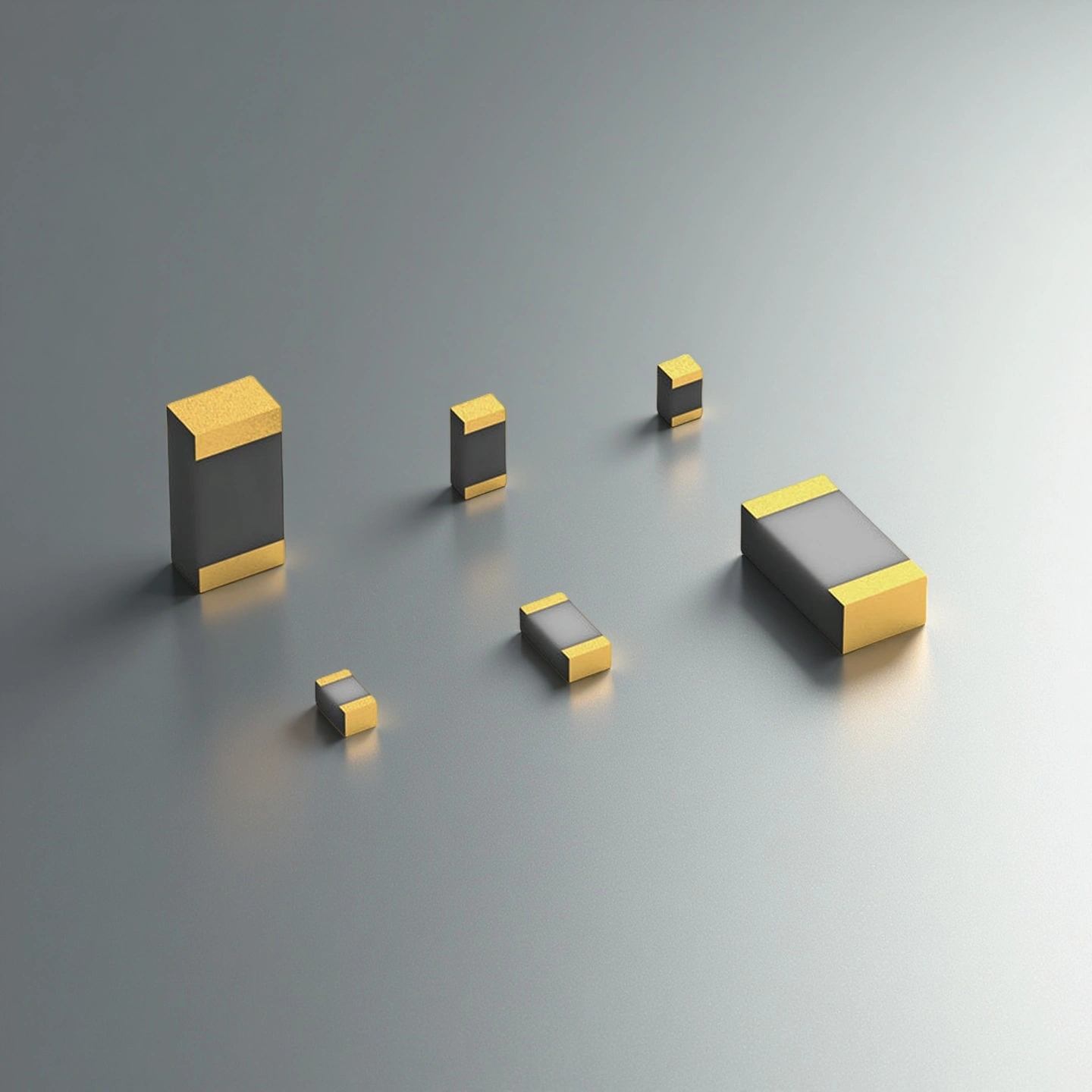

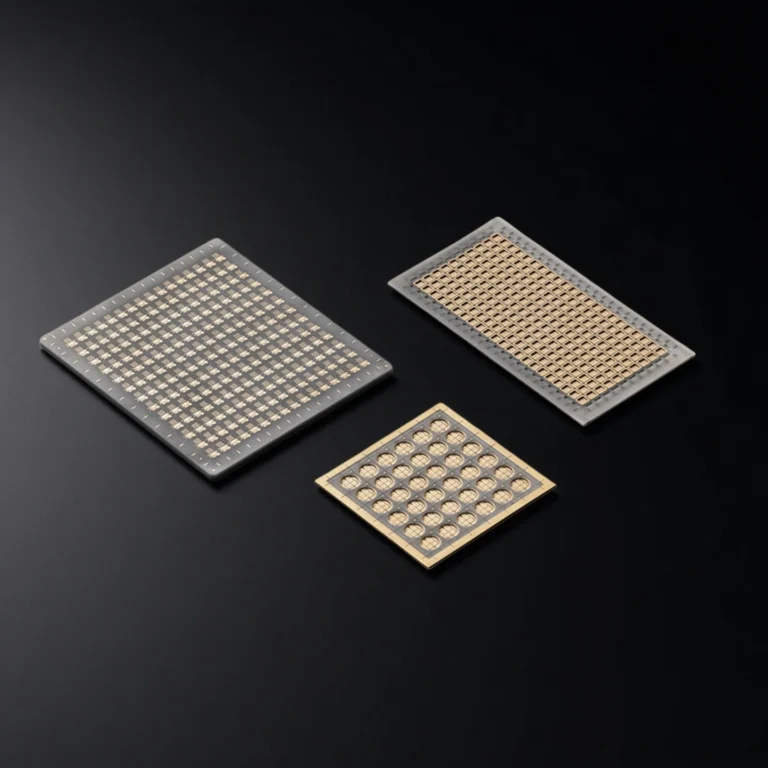

Aluminum Nitride Heat-Spreader Plates are flat, electrically insulating ceramic plates engineered to distribute heat from chips, dies and module assemblies into a larger surface area, lowering thermal resistance between the active device and the system heatsink. They are used in compact power electronics, LED modules, laser diode packages and RF amplifiers where high thermal flux and limited footprint require a stable, high-conductivity ceramic layer.

AlN Heat Spreader Plate Benefits

-

High heat spreading efficiency

The aluminum nitride heat-spreader plate provides high in-plane thermal conductivity, helping to equalize temperature across the device footprint and reduce local hotspots in SiC, GaN and IGBT modules. -

Electrical insulation with matched CTE

The plate combines strong dielectric strength with a thermal expansion coefficient close to semiconductor materials, supporting high-voltage isolation without introducing excessive thermo-mechanical stress. -

Stable flatness for die attach and TIM layers

Precisely ground surfaces and controlled flatness enable uniform solder layers or thermal interface materials, helping to minimize voids and contact resistance in power modules and laser submounts. -

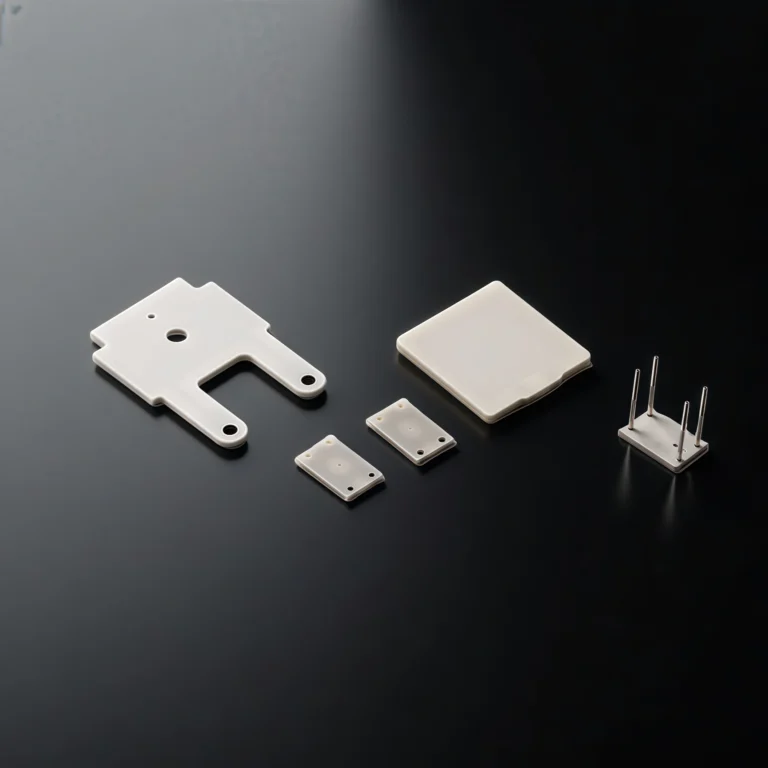

Design flexibility for complex module layouts

The aluminum nitride heat-spreader plate can be machined with fixing holes, cavities, steps, reference edges and metallized pads to follow the package layout and assembly process. -

Support for metallized interfaces

When required, aluminum nitride heat-spreader plates can be supplied with metallization schemes compatible with common die attach solders and baseplate bonding processes.

Aluminum Nitride Heat Spreader Plate

| Property Content | Unit | Unit | ALN-170 | ALN-200 | ALN-230 |

| Basic Properties | Color | gray | light yellow | light yellow | |

| Density | g/cm³ | 3.2-3.3 | 3.2-3.3 | 3.2-3.3 | |

| Surface Roughness | μm | 0.2-0.75 | 0.2-0.75 | 0.2-0.8 | |

| Camber | length ‰ | ≤3‰ | ≤3‰ | ≤3‰ | |

| Hardness | HV | 1100 | 1100 | 1100 | |

| Thermal Properties | Max Operating Temperature | °C | 1100 | 1100 | 1100 |

| Thermal Conductivity | W/m·K | 170-190 | 190-220 | 220-230 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(20-400°c) | 4-5 | 4-5 | 4-5 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(400-800°c) | 5-6 | 5-6 | 5-6 | |

| Mechanical Properties | Flexural Strength | MPa | 300-400 | 350-450 | 400-500 |

| Tensile Strength | MPa | 200-300 | 250-350 | 280-380 | |

| Compressive Strength | MPa | 2000-3000 | 2200-3200 | 2500-3500 | |

| Electrical properties | Dielectric Constant | at 1MHz | 8-9 | 8-9 | 8-9 |

| Dielectric strength | KV/mm | ≥15 | ≥15 | ≥15 | |

| Volume resistivity | 20℃ Ω.cm | ≥1014 | ≥1014 | ≥1014 |

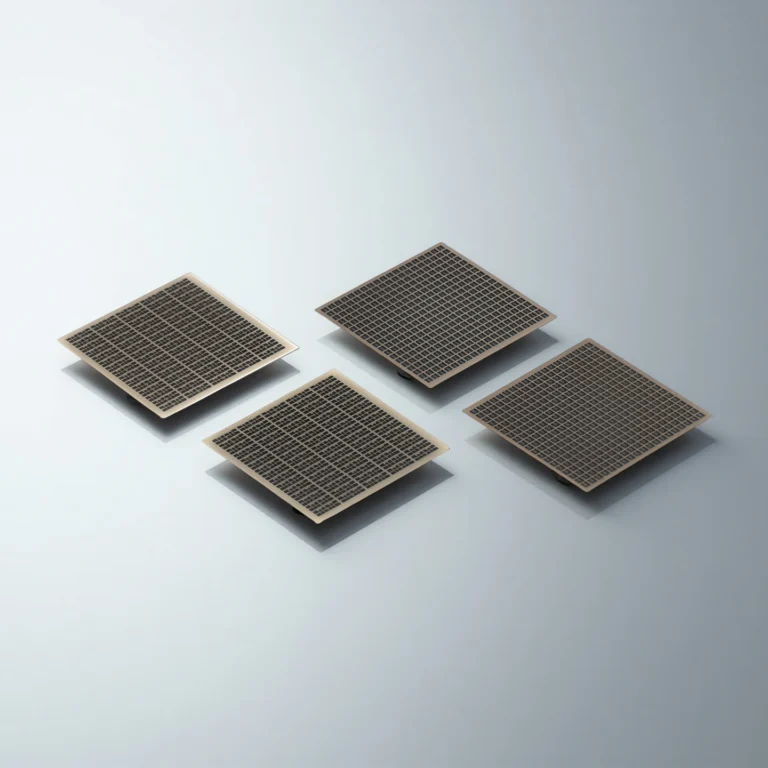

AlN heat spreader plate Specifications

| Aluminum Nitride Heat Sink Plate | |||||

| Item no. | Size | Thickness | Metal electrode | Coated metal | Side wrapping treatment |

| AT-AN-SR001 | Customizable | Customizable | tungsten | Nickel gold or nickel | yes |

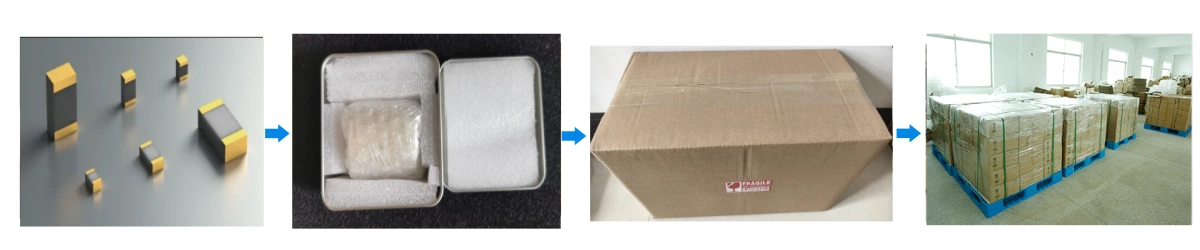

Aluminum Nitride Heat Spreader Plate Packaging

- Aluminum nitride heat-spreader plates are separated by cavity blister trays or rigid plastic separators to avoid edge chipping and surface contact.