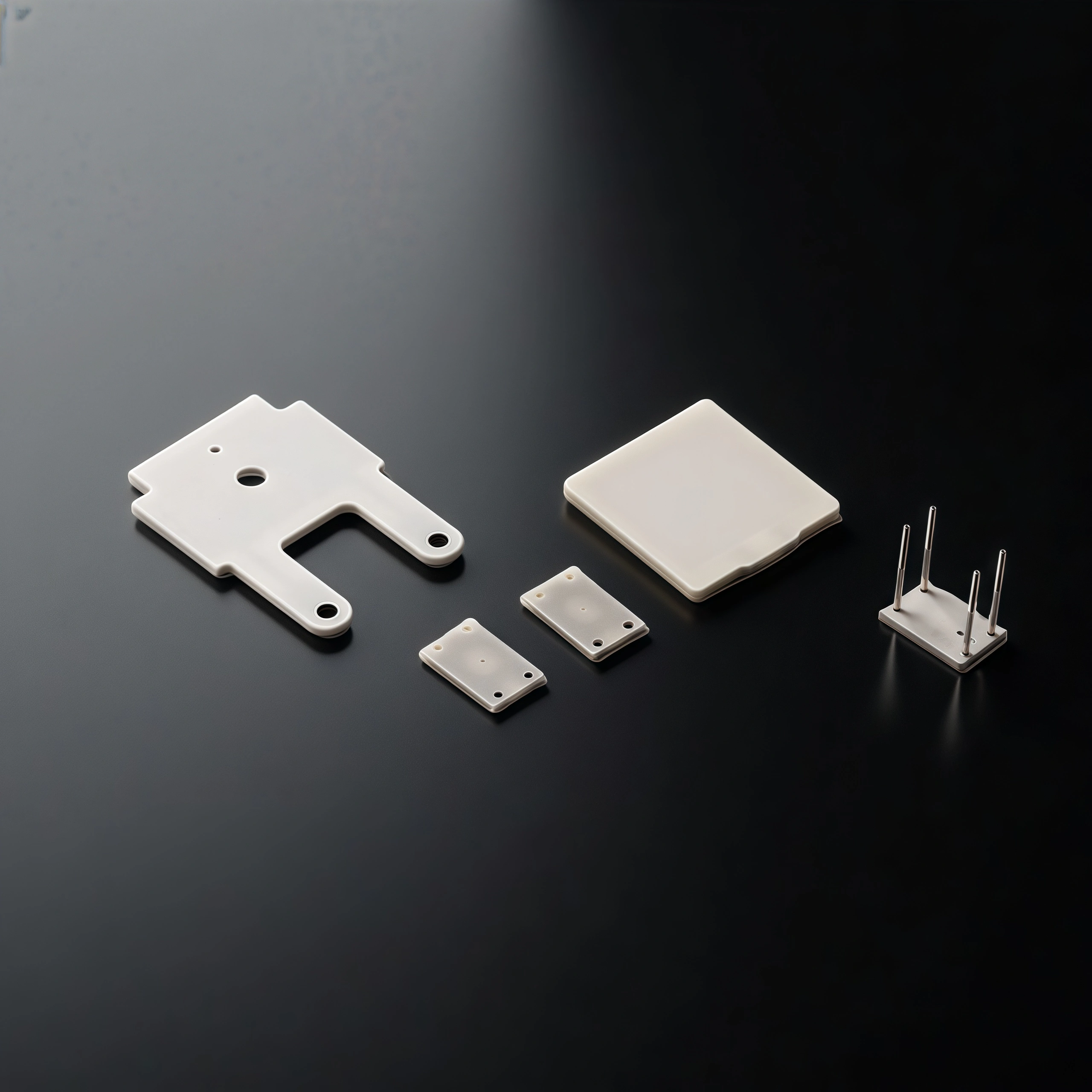

An aluminum nitride heater sheet is a flat heating element made from aluminum nitride (AlN) ceramic, where resistive heating traces or a metallized circuit are integrated on or within the ceramic plate to generate heat when electrical power is applied. The AlN base provides high thermal conductivity, good electrical insulation, and compatibility with high temperatures in the range of a few hundred degrees Celsius, depending on the metallization and operating atmosphere.

Aluminum Nitride Heater Sheet Benefits

-

High thermal conductivity AlN ceramic heater sheet spreads heat efficiently across the surface, reducing edge-to-center temperature gradients in compact heating stages.

-

Flat aluminum nitride heater plate provides electrical insulation between the resistive traces and grounded mounting structures, allowing safe operation at elevated voltages.

-

Thin heater sheet design supports fast ramp and cool-down cycles when combined with appropriate resistive patterns and power electronics.

-

Machinable outline and through-holes allow the aluminum nitride heater sheet to match complex chamber geometries, clamp rings and alignment features.

-

Stable microstructure and compatible metallization systems enable repeated thermal cycling without significant drift in heater resistance.

Aluminum Nitride Heating Plate Properties

| Property Content | Unit | Unit | ALN-170 | ALN-200 | ALN-230 |

| Basic Properties | Color | gray | light yellow | light yellow | |

| Density | g/cm³ | 3.2-3.3 | 3.2-3.3 | 3.2-3.3 | |

| Surface Roughness | μm | 0.2-0.75 | 0.2-0.75 | 0.2-0.8 | |

| Camber | length ‰ | ≤3‰ | ≤3‰ | ≤3‰ | |

| Hardness | HV | 1100 | 1100 | 1100 | |

| Thermal Properties | Max Operating Temperature | °C | 1100 | 1100 | 1100 |

| Thermal Conductivity | W/m·K | 170-190 | 190-220 | 220-230 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(20-400°c) | 4-5 | 4-5 | 4-5 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(400-800°c) | 5-6 | 5-6 | 5-6 | |

| Mechanical Properties | Flexural Strength | MPa | 300-400 | 350-450 | 400-500 |

| Tensile Strength | MPa | 200-300 | 250-350 | 280-380 | |

| Compressive Strength | MPa | 2000-3000 | 2200-3200 | 2500-3500 | |

| Electrical properties | Dielectric Constant | at 1MHz | 8-9 | 8-9 | 8-9 |

| Dielectric strength | KV/mm | ≥15 | ≥15 | ≥15 | |

| Volume resistivity | 20℃ Ω.cm | ≥1014 | ≥1014 | ≥1014 |

AlN Heater Sheet Specifications

| AlN Heater | ||||||

| Item no. | Size | Thickness | Max. working Temp. | Max. power density | Resistance tolerance of heating line | TCR |

| AT-AN-JRP001 | customizable | 0.8-3.0mm | 500℃ | 155W/cm2 | ±20% | 0.0015±0.0003 |

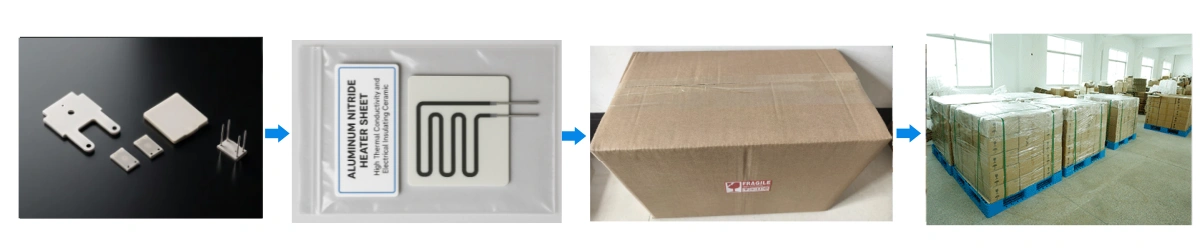

AlN Ceramic Heater Sheet Packaging

- Each aluminum nitride heater sheet is individually placed in a rigid plastic tray or cavity blister pack to prevent edge chipping and protect the metallized surface from abrasion.