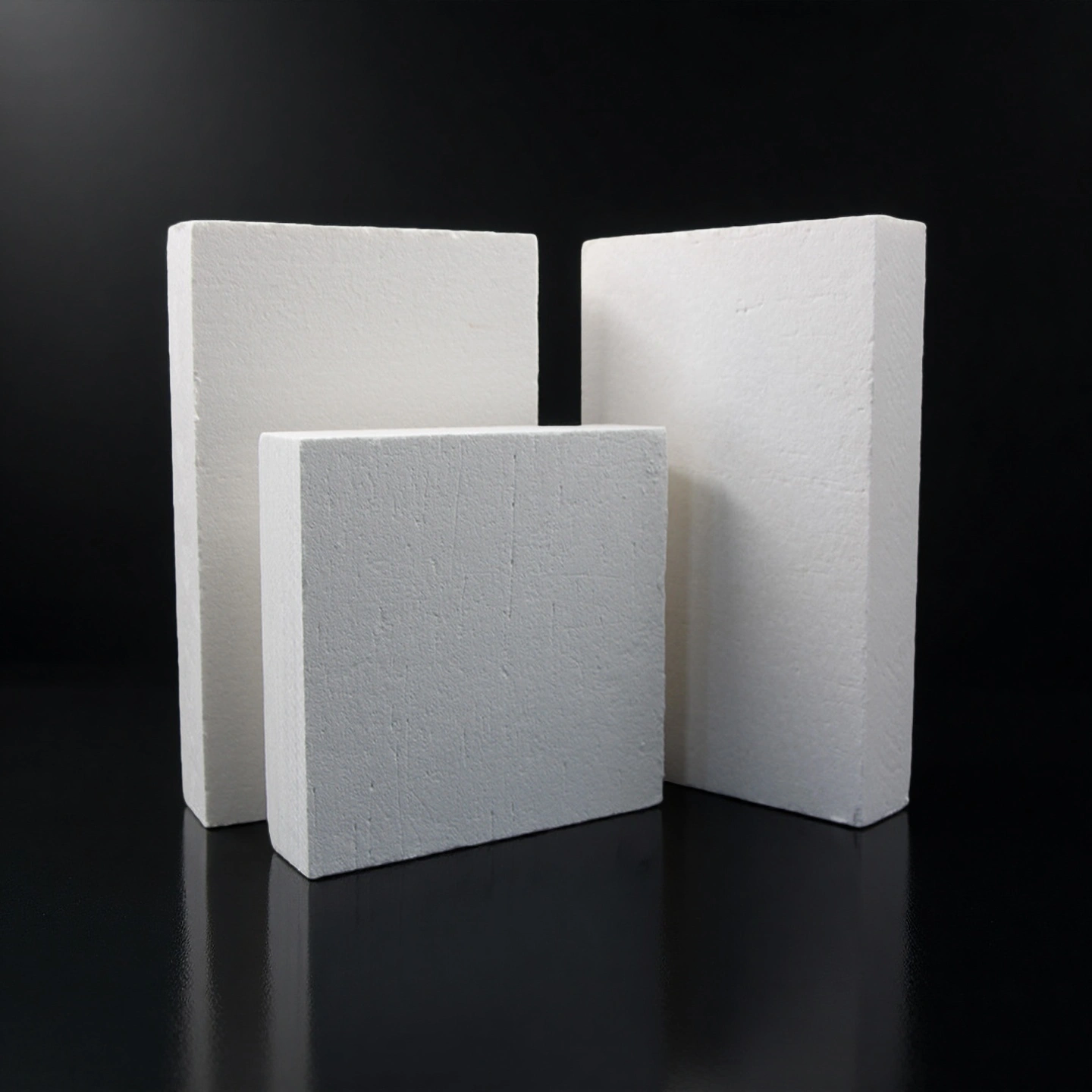

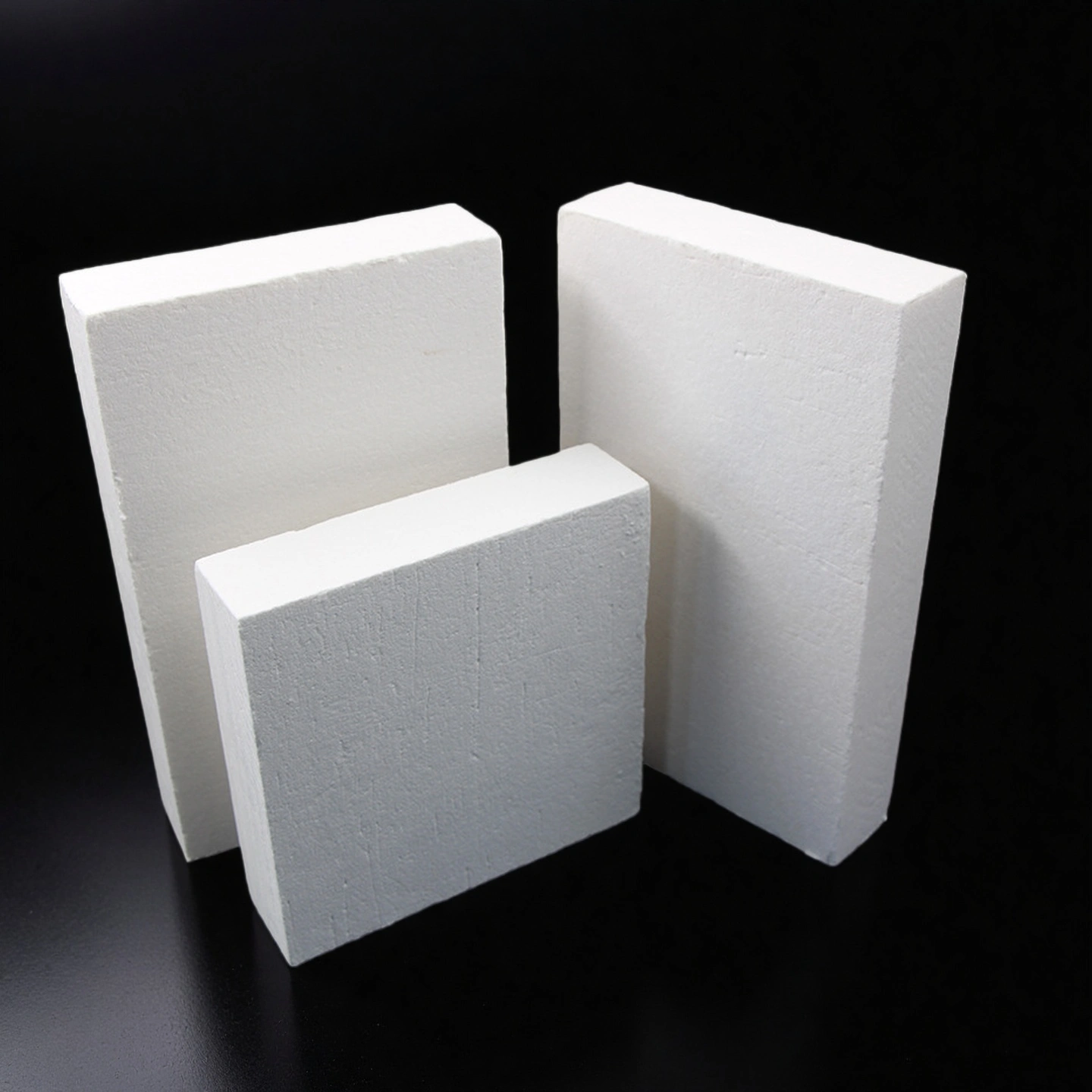

Aluminum silicate fiber board, is a rigid high-temperature insulation board made from aluminum oxide (Al₂O₃) and silicon dioxide (SiO₂) fibers. It is formed through vacuum-forming and heat-setting processes to create a lightweight, low-thermal-conductivity, and dimensionally stable insulation panel used in industrial furnaces, kilns, boilers, and incinerators.

Advantages of Aluminum Silicate Fiber Board

-

Rigid yet lightweight panel structure

The aluminum silicate fiber board combines low bulk density with sufficient mechanical strength to be self-supporting on furnace walls and doors without adding excessive load to the steel shell. -

Consistent thermal insulation performance

The alumino-silicate composition provides low thermal conductivity across 200–800°C, helping to reduce shell temperature and improve overall fuel efficiency in continuous and batch furnaces. -

Low shrinkage at operating temperature

Controlled fiber formulation and firing result in limited linear shrinkage within the specified classification temperature, helping to maintain lining thickness and minimize gaps during long-term service. -

Machinable and easy to shape

Boards can be cut, grooved, drilled and chamfered to create customized furnace door panels, burner blocks, inspection covers and baffles with accurate fit and reduced on-site cutting time. -

Chemical stability in typical furnace atmospheres

Aluminum silicate fiber boards show good resistance to oxidation and most combustion gases in heat treatment, metal reheating and incineration processes when used within the recommended temperature range.

Aluminum Silicate Ceramic Fiber Board Properties

| Item | General Grade | Standard Grade | High Purity Grade | High Alumina Grade | Zirconia-Containing Grade |

| Classification Temperature (°C) | 1100 | 1260 | 1260 | 1360 | 1430 |

| Service Temperature (°C) | <1000 | 1050 | 1100 | 1200 | 1350 |

| Color | White | Off-white | Off-white | Off-white | Off-white |

| Bulk Density (kg/m³) | 260–320 | 260–320 | 260–320 | 260–320 | 260–320 |

| Permanent Linear Shrinkage (%) (24 h holding; based on 128 kg/m³) | <2.5 (1000°C) | <2.5 (1050°C) | <2.5 (1100°C) | <2.5 (1100°C) | <2.5 (1350°C) |

| Thermal Conductivity (W/m·K) (bulk density 128 kg/m³) | 0.085 (400°C) | 0.085 (400°C) | 0.085 (400°C) | 0.085 (400°C) | 0.085 (400°C) |

| 0.132 ( 800°C) | 0.132 ( 800°C) | 0.132 ( 800°C) | 0.132 ( 800°C) | 0.132 ( 800°C) | |

| 0.180 (1000°C) | 0.180 (1000°C) | 0.180 (1000°C) | 0.180 (1000°C) | ||

| Tensile Strength (MPa) (bulk density 128 kg/m³) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Chemical Composition (wt%) | |||||

| Al₂O₃ | 44 | 46 | 47–49 | 52–55 | 39–40 |

| Al₂O₃ + SiO₂ | 96 | 97 | 99 | 99 | – |

| Al₂O₃ + SiO₂ + ZrO₂ | – | – | – | – | 99 |

| ZrO₂ | – | – | – | – | 15–17 |

| Fe₂O₃ | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 |

| Na₂O + K₂O | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 |

Aluminum Silicate Fiber Board Specification

| Item | Classification Temperature (°C) | Type | Length*Width(mm) | Thickness(mm) |

| AT-GSL-B1001 | 1260 | Standard Grade | 900*600 | 10 |

| AT-GSL-B1002 | 1260 | Standard Grade | 900*600 | 20 |

| AT-GSL-B1003 | 1260 | Standard Grade | 900*600 | 25 |

| AT-GSL-B1004 | 1260 | Standard Grade | 900*600 | 30 |

| AT-GSL-B1005 | 1260 | Standard Grade | 900*600 | 40 |

| AT-GSL-B1006 | 1260 | Standard Grade | 900*600 | 50 |

| AT-GSL-B1007 | 1260 | Standard Grade | 1200*600 | 50 |

| AT-GSL-B1008 | 1360 | High Alumina Grade | 900*600 | 20 |

| AT-GSL-B1009 | 1360 | High Alumina Grade | 900*600 | 30 |

| AT-GSL-B1010 | 1360 | High Alumina Grade | 900*600 | 40 |

| AT-GSL-B1011 | 1360 | High Alumina Grade | 900*600 | 50 |

| AT-GSL-B1012 | 1430 | Zirconia-Containing Grade | 900*600 | 20 |

| AT-GSL-B1013 | 1430 | Zirconia-Containing Grade | 900*600 | 30 |

| AT-GSL-B1014 | 1430 | Zirconia-Containing Grade | 900*600 | 40 |

| AT-GSL-B1015 | 1430 | Zirconia-Containing Grade | 900*600 | 50 |

| AT-GSL-B1016 | 1260 | Standard Grade | 1200*1000 | 10 |

| AT-GSL-B1017 | 1260 | Standard Grade | 1200*1000 | 20 |

| AT-GSL-B1018 | 1260 | Standard Grade | 1200*1000 | 25 |

| AT-GSL-B1019 | 1260 | Standard Grade | 1200*1000 | 30 |

| AT-GSL-B1020 | 1260 | Standard Grade | 1200*1000 | 40 |

| AT-GSL-B1021 | 1260 | Standard Grade | 1200*1000 | 50 |

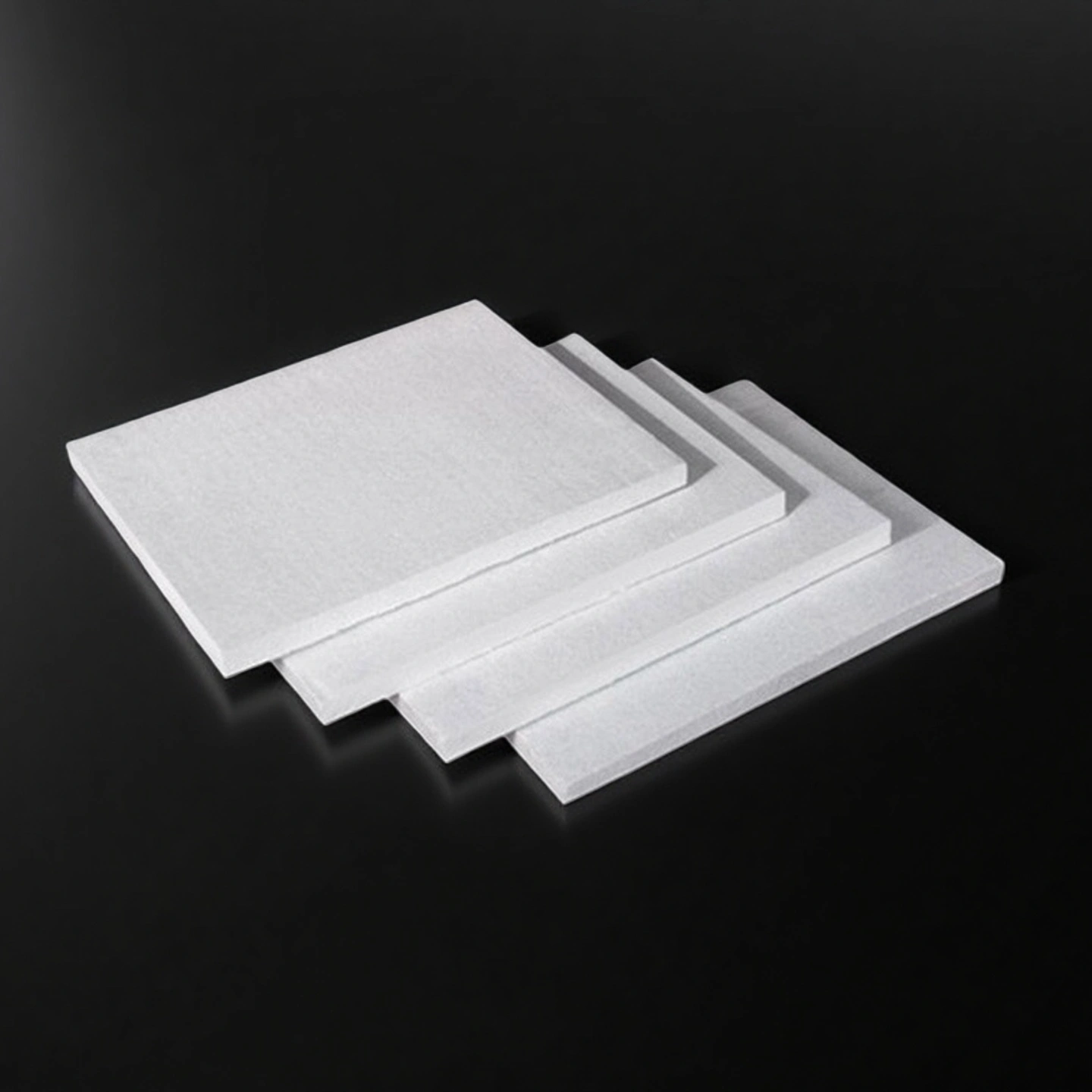

Aluminum Silicate Ceramic Fiber Board Packaging

- Each aluminum silicate fiber board stack is wrapped in plastic film to limit dust release and protect against moisture during transport.