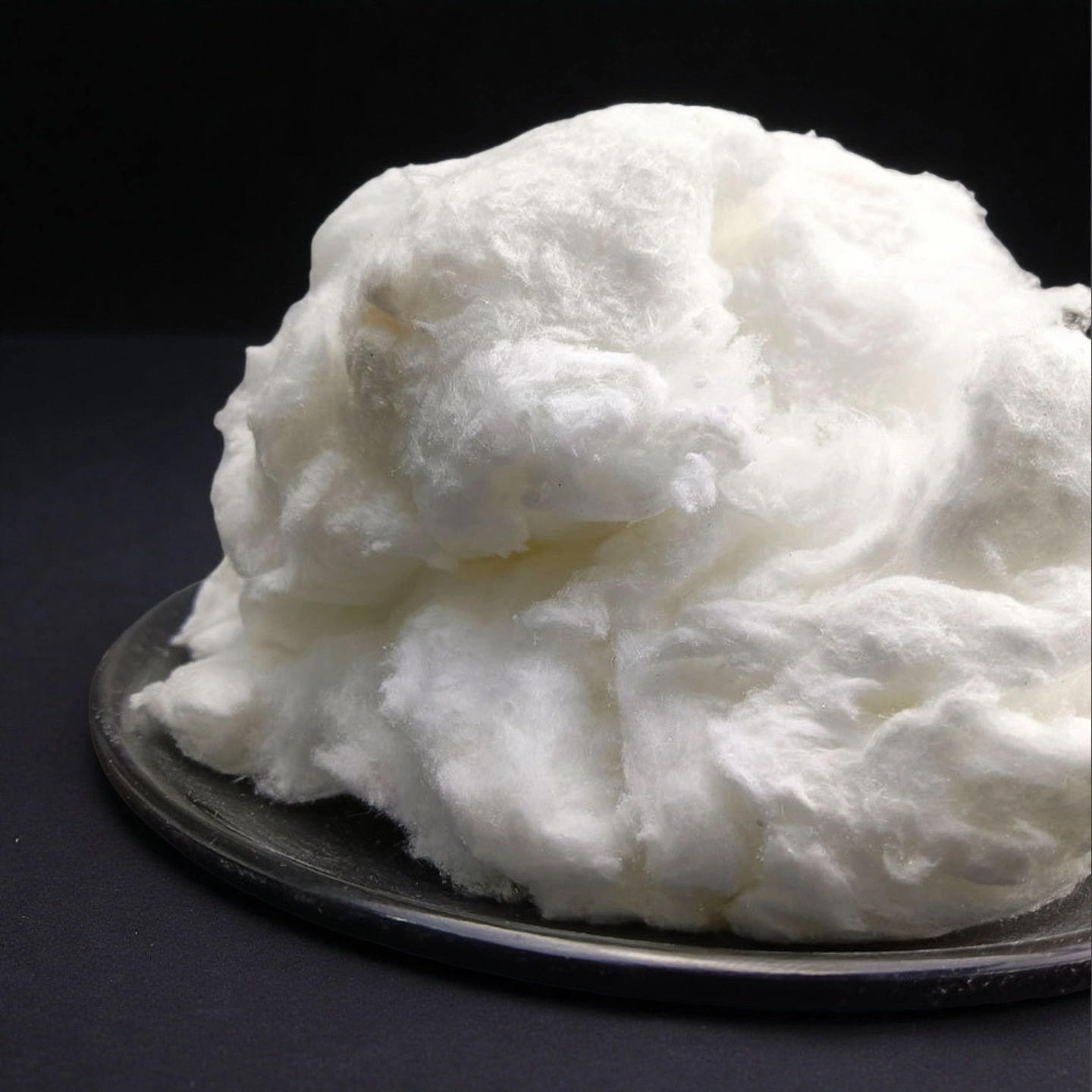

Aluminum silicate fiber cotton is a loose, fluffy alumino-silicate ceramic fiber insulation wool with a typical 1260 °C classification temperature, produced by melting and fiberizing Al₂O₃–SiO₂ materials into fine, low-density fibers. It is used as bulk high-temperature insulation, gap-filling material and as the base fiber for manufacturing ceramic fiber blankets, boards, modules and vacuum-formed shapes in industrial furnaces, kilns, heat-treatment equipment and metallurgical vessels.

Aluminum Silicate Fiber Cotton Benefits

1. Stable high-temperature insulation

- 1260 °C classification temperature with typical service temperature up to around 1050–1100 °C in continuous operation, suitable for most steel, aluminum, glass and ceramic furnace backup linings.

2. Low thermal conductivity and low heat storage

- Industry data show 1260 °C alumino-silicate fiber products provide thermal conductivity around 0.13–0.21 W/(m·K) at 600–800 °C, significantly reducing shell heat loss compared with traditional brick linings and supporting faster heating/cooling cycles.

3. Controlled shot content and fiber diameter

- Aluminum silicate fiber cotton is produced with controlled fiber diameter (typically 2–5 µm) and limited shot content, helping to achieve uniform vacuum-formed surfaces and consistent thermal performance in backing layers.

4. Lightweight structure for thin, efficient linings

- Compared with lightweight insulating bricks, ceramic fiber insulation wool has much lower bulk density and heat capacity, allowing thinner furnace walls and reducing overall lining weight and heat storage, which can save 20–40 % energy in many ceramic fiber lining projects.

5. Versatile raw material for multiple product forms

- The same aluminum silicate fiber cotton can be used as the base fiber for blankets, boards, modules, papers and vacuum-formed parts, simplifying raw material management for refractory and insulation product manufacturers.

Aluminum Silicate Ceramic Fiber Cotton Properties

| Item | General Grade | Standard Grade | High Purity Grade | High Alumina Grade | Zirconia-Containing Grade |

| Classification Temperature (°C) | 1100 | 1260 | 1260 | 1360 | 1430 |

| Service Temperature (°C) | <1000 | 1050 | 1100 | 1200 | 1350 |

| Color | White | Off-white | Off-white | Off-white | Off-white |

| Bulk Density (kg/m³) | 260–320 | 260–320 | 260–320 | 260–320 | 260–320 |

| Permanent Linear Shrinkage (%) (24 h holding; based on 128 kg/m³) | <2.5 (1000°C) | <2.5 (1050°C) | <2.5 (1100°C) | <2.5 (1100°C) | <2.5 (1350°C) |

| Thermal Conductivity (W/m·K) (bulk density 128 kg/m³) | 0.085 (400°C) | 0.085 (400°C) | 0.085 (400°C) | 0.085 (400°C) | 0.085 (400°C) |

| 0.132 ( 800°C) | 0.132 ( 800°C) | 0.132 ( 800°C) | 0.132 ( 800°C) | 0.132 ( 800°C) | |

| 0.180 (1000°C) | 0.180 (1000°C) | 0.180 (1000°C) | 0.180 (1000°C) | ||

| Tensile Strength (MPa) (bulk density 128 kg/m³) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Chemical Composition (wt%) | |||||

| Al₂O₃ | 44 | 46 | 47–49 | 52–55 | 39–40 |

| Al₂O₃ + SiO₂ | 96 | 97 | 99 | 99 | – |

| Al₂O₃ + SiO₂ + ZrO₂ | – | – | – | – | 99 |

| ZrO₂ | – | – | – | – | 15–17 |

| Fe₂O₃ | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 |

| Na₂O + K₂O | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 |

Aluminum Silicate Fiber Cotton Specifications

| Item No. | Chemical Composition | Diameter (mm) | Thickness (mm) | Purity |

| AT-GSL-M1001 | Standard | Customize | ||

| AT-GSL-M2001 | High-Alumina | Customize | ||

| AT-GSL-M3001 | Zirconia-Containing | Customize | ||

Aluminum Silicate Fiber Cotton Packaging

- Aluminum silicate fiber cotton is normally supplied in compressed polyethylene bags or inner bag + outer carton to minimize volume and limit dust during handling.