Aluminum silicate fiber modules are prefabricated, high-temperature insulation blocks made by folding or stacking aluminum silicate ceramic fiber blankets into compressed modules and securing them with built-in anchors. The fiber itself is a synthetic alumina–silica material, designed for continuous operation in the medium to high temperature range, typically around 1000–1350°C depending on the grade.

Aluminum Silicate Fiber Modules: Benefits

-

Stable high-temperature insulation – Aluminum silicate fiber modules maintain low heat flow up to their classification temperature range of 1050–1430°C, supporting service temperatures around 1000–1350°C for many industrial furnaces.

-

Low heat storage and fast heat-up – The low mass and porous microstructure of aluminum silicate ceramic fiber reduce thermal storage, helping furnace linings reach operating temperature faster and lowering fuel or power consumption per batch.

-

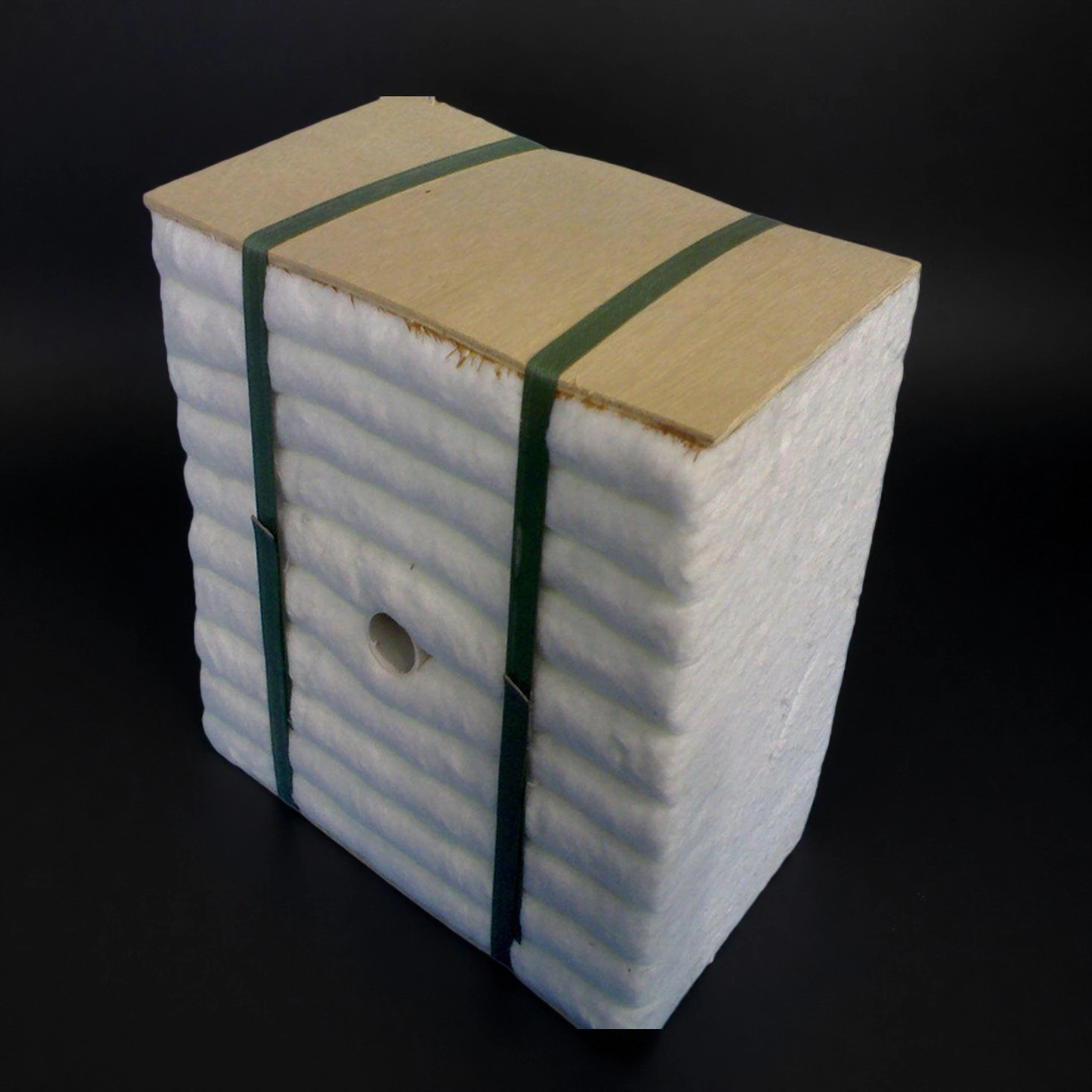

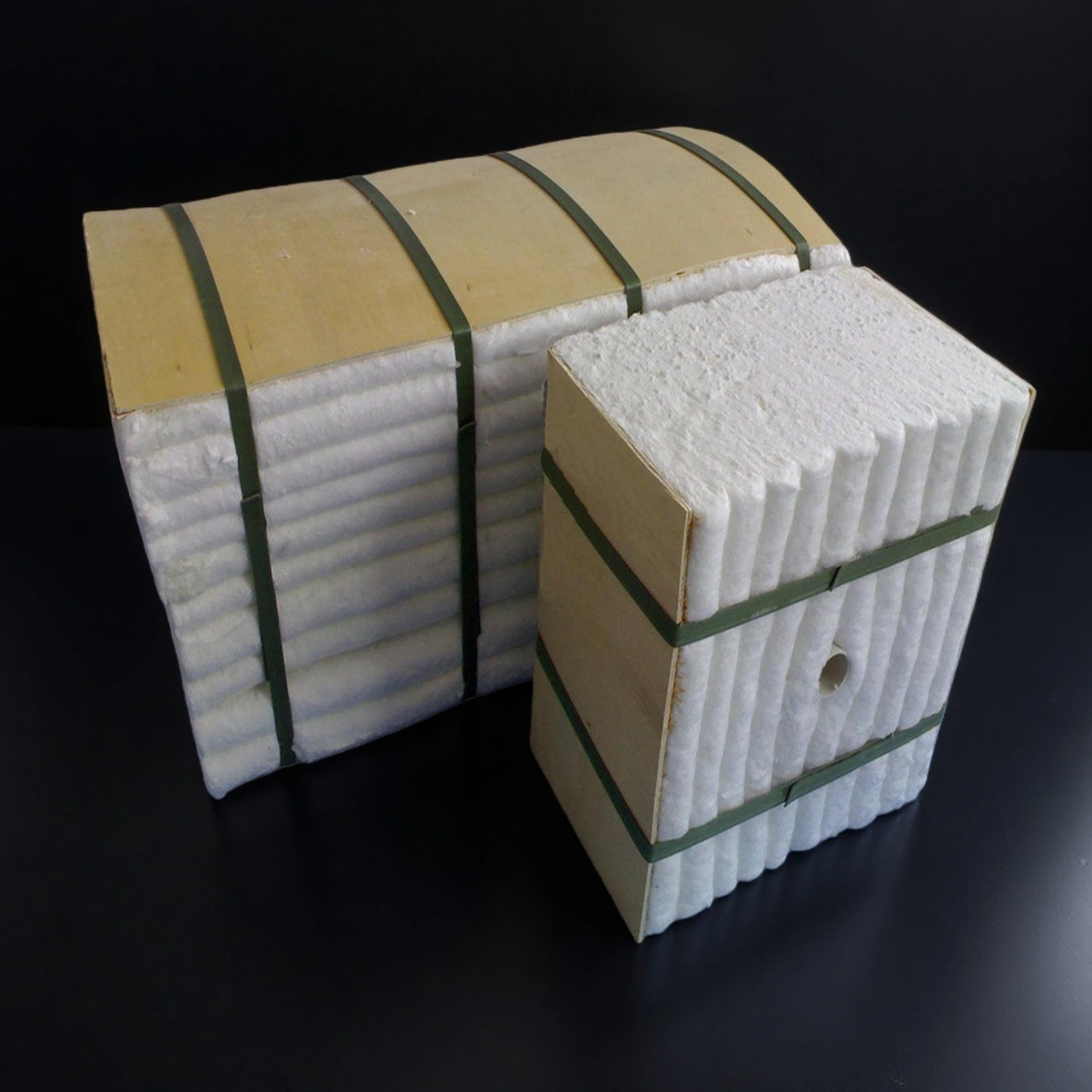

Compressed modular construction – Pre-compressed modules expand slightly after untying, helping to close joints between blocks and reduce hot spots and through-gaps in the aluminum silicate fiber module lining.

-

Integrated anchor design – Built-in metallic anchoring systems allow aluminum silicate fibre modules to be fixed directly to the furnace shell, improving installation speed and making thick linings easier to build in confined spaces.

-

Good thermal shock resistance – The fiber-based structure tolerates frequent heating and cooling cycles better than many brick or monolithic linings in comparable conditions, reducing cracking and spalling risk in repeated cycling.

Aluminum Silicate Ceramic Fiber Modules Properties

| Item | General Grade | Standard Grade | High Purity Grade | High Alumina Grade | Zirconia-Containing Grade |

| Classification Temperature (°C) | 1100 | 1260 | 1260 | 1360 | 1430 |

| Service Temperature (°C) | <1000 | 1050 | 1100 | 1200 | 1350 |

| Color | White | Off-white | Off-white | Off-white | Off-white |

| Bulk Density (kg/m³) | 260–320 | 260–320 | 260–320 | 260–320 | 260–320 |

| Permanent Linear Shrinkage (%) (24 h holding; based on 128 kg/m³) | <2.5 (1000°C) | <2.5 (1050°C) | <2.5 (1100°C) | <2.5 (1100°C) | <2.5 (1350°C) |

| Thermal Conductivity (W/m·K) (bulk density 128 kg/m³) | 0.085 (400°C) | 0.085 (400°C) | 0.085 (400°C) | 0.085 (400°C) | 0.085 (400°C) |

| 0.132 ( 800°C) | 0.132 ( 800°C) | 0.132 ( 800°C) | 0.132 ( 800°C) | 0.132 ( 800°C) | |

| 0.180 (1000°C) | 0.180 (1000°C) | 0.180 (1000°C) | 0.180 (1000°C) | ||

| Tensile Strength (MPa) (bulk density 128 kg/m³) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Chemical Composition (wt%) | |||||

| Al₂O₃ | 44 | 46 | 47–49 | 52–55 | 39–40 |

| Al₂O₃ + SiO₂ | 96 | 97 | 99 | 99 | – |

| Al₂O₃ + SiO₂ + ZrO₂ | – | – | – | – | 99 |

| ZrO₂ | – | – | – | – | 15–17 |

| Fe₂O₃ | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 |

| Na₂O + K₂O | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 |

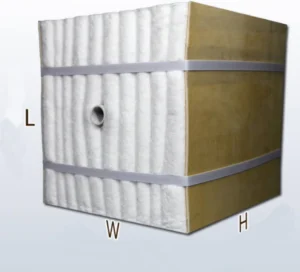

Aluminum Silicate Fiber Modules Specifications

| Item | L*W*H(mm) | Classification Temperature(℃) | Note |

| AT-GSL-MK1001 | 300*300*150 | 1260 | standard |

| AT-GSL-MK1002 | 300*300*200 | 1260 | standard |

| AT-GSL-MK1003 | 300*300*250 | 1260 | standard |

| AT-GSL-MK1004 | 300*300*300 | 1260 | standard |

| AT-GSL-MK1005 | 300*300*150 | 1300 | High aluminum |

| AT-GSL-MK1006 | 300*300*200 | 1300 | High aluminum |

| AT-GSL-MK1007 | 300*300*250 | 1300 | High aluminum |

| AT-GSL-MK1008 | 300*300*300 | 1300 | High aluminum |

| AT-GSL-MK1009 | 300*300*300 | 1430 | Zirconium-containing |

| AT-GSL-MK1010 | 600*300*200 | 1430 | Zirconium-containing |

| AT-GSL-MK1011 | 600*300*250 | 1430 | Zirconium-containing |

| AT-GSL-MK1012 | 600*300*300 | 1430 | Zirconium-containing |

Aluminum Silicate Fiber Modules Packaging

- Each aluminum silicate fiber module is strapped or film-wrapped in its compressed state to maintain pre-compression during transport.