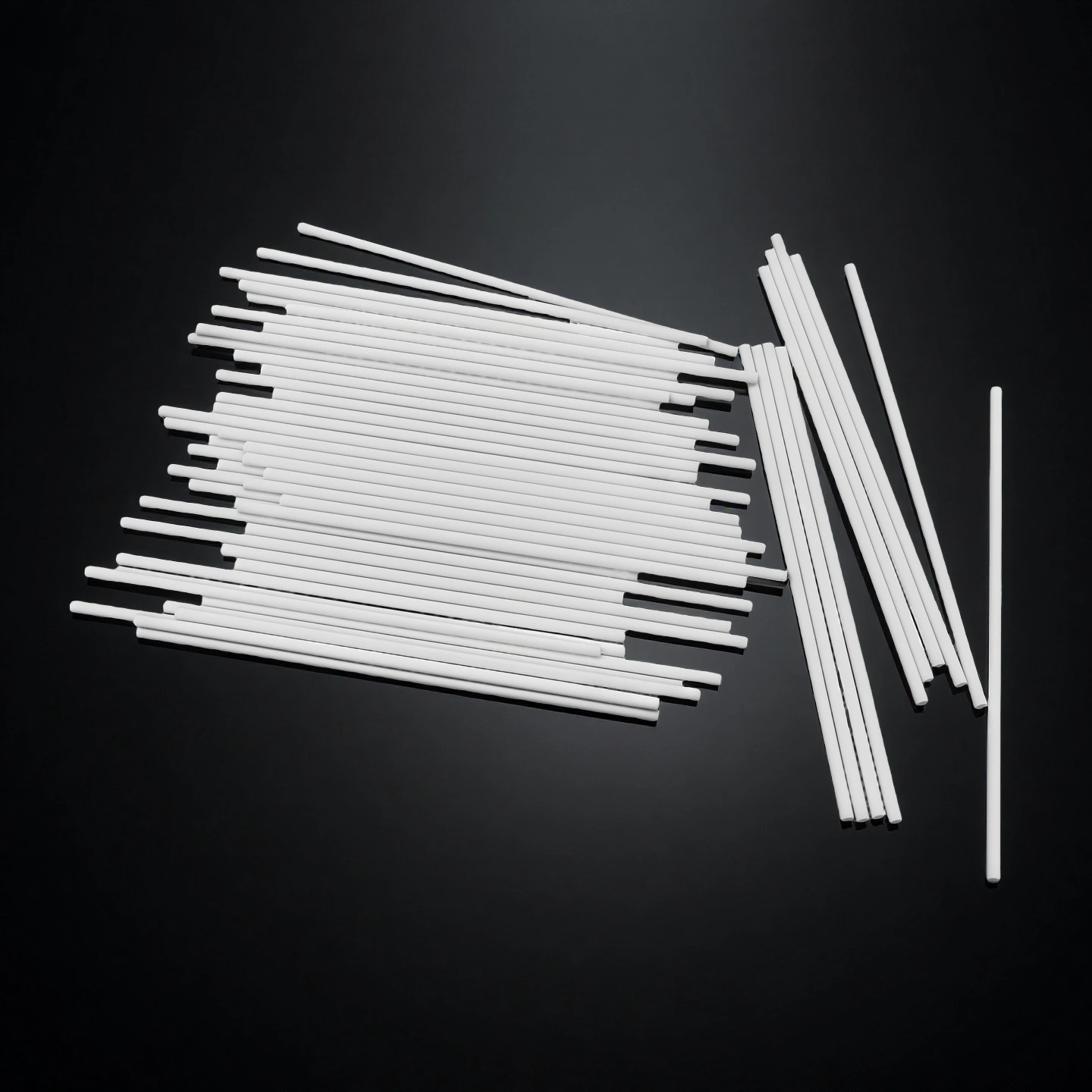

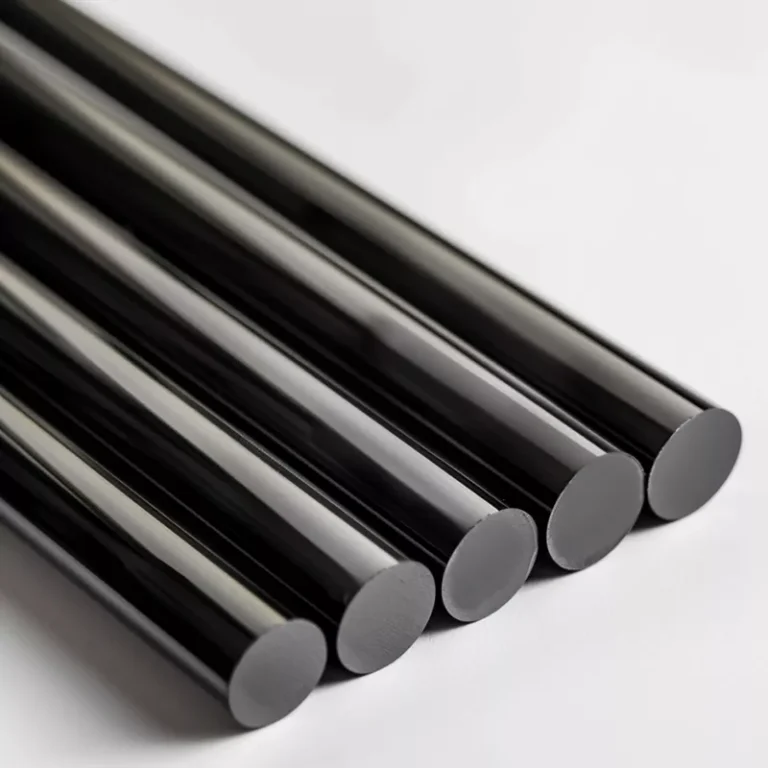

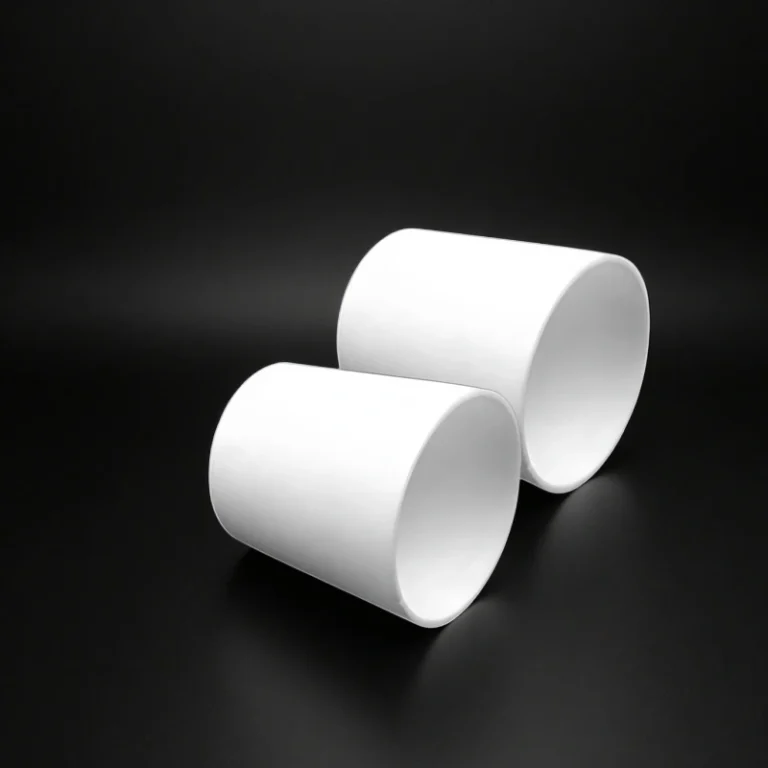

Beryllium Oxide (BeO) rod is a precision-machined, high-thermal-conductivity ceramic bar used as a heat-spreading, electrically insulating structural element in RF/microwave fixtures, optical benches, vacuum equipment, and precision jigs. It is produced from high-purity BeO powder by pressing, sintering, and finish machining (e.g., grinding, lapping, polishing) to tight dimensional tolerances.

Beryllium Oxide Rod Benefits

- Heat-moving insulator: combines high thermal conductivity with dielectric isolation in one part.

- Tight geometry control: OD/ID/length tolerances typically ±0.05–0.10 mm for stable assembly.

- Finish options: ground, lapped, or polished ends to defined Ra for contact repeatability.

- RF-grade dielectric: low loss tangent suitable for microwave fixtures and couplers.

- Vacuum-ready: dense microstructure and clean surface preparation for low outgassing integration.

Beryllium Oxide Rod Properties

|

Property |

Be-97 |

Be-99 |

|

BeO Purity |

≧97% |

≧99% |

|

Density (g/cm3) |

≧2.85 |

≧2.85 |

|

Hardness (Hv) |

1200 |

1250 |

|

Maximum Working Temperature (℃) |

1600 |

1650 |

|

Flexural Strength (MPa) |

170 |

190 |

|

Fracture Toughness (MPa*m1/2) |

2.5~3.5 |

2.5~3.5 |

|

Dielectric Constant (at 1MHz) |

6.5 |

7 |

|

Breakdown Voltage (kV/mm) |

15 |

20 |

|

Thermal Conductivity (W/m*K) |

220-240 |

260-310 |

|

Thermal Expansion Coefficient (/℃) |

7~8.5*10-6 |

7~8.5*10-6 |

Beo Ceramic Rods Specifications

|

Item No. |

Outer Dia(mm) |

Length(mm) |

Purity(%) |

|

AT-BeO-B1001 |

1.5 |

60 |

99 |

|

AT-BeO-B1002 |

1.5 |

93 |

99 |

|

AT-BeO-B1003 |

1.5 |

30-300 |

99 |

|

AT-BeO-B1004 |

2 |

30-300 |

99 |

|

AT-BeO-B1005 |

0.3-2 |

30-300 |

99 |

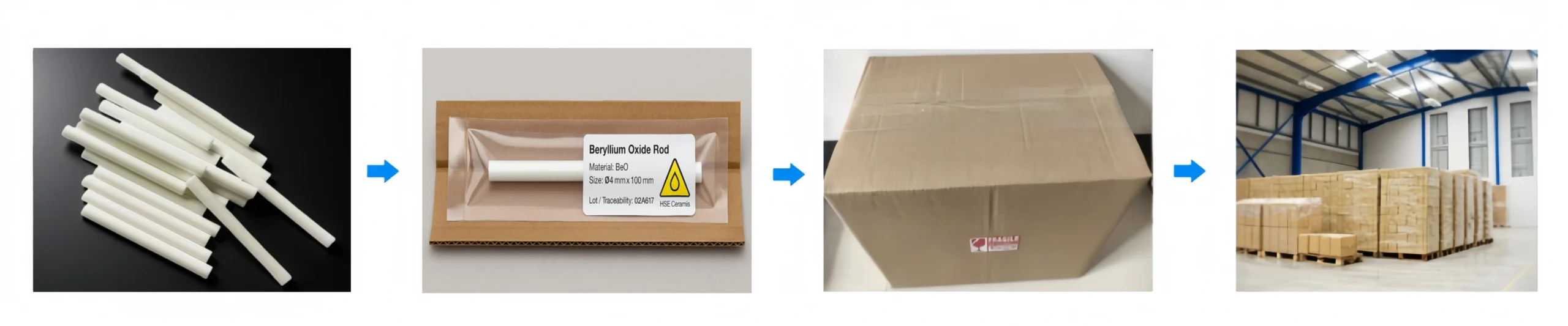

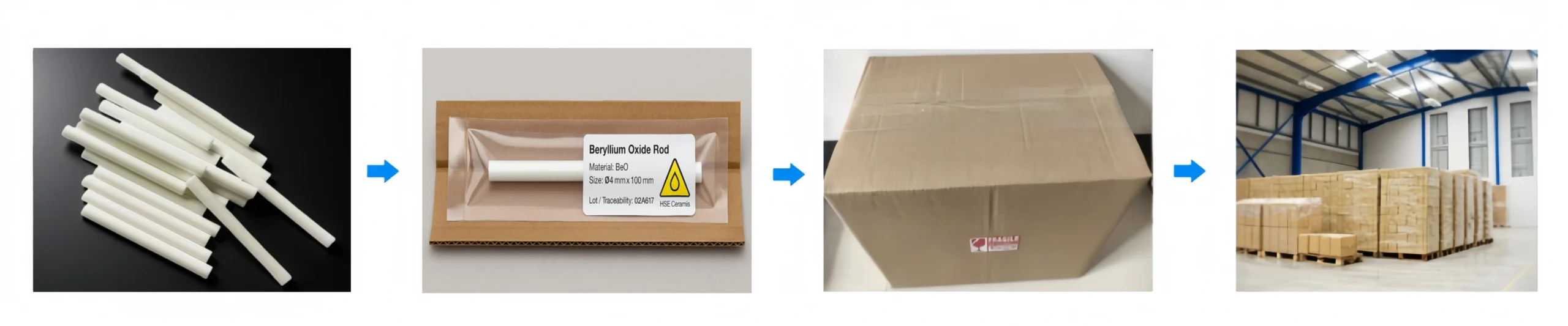

Beryllium Oxide Rod Packing

- Each Beryllium Oxide Rod is individually sleeved, cushioned, clearly labeled with material and lot details, and sealed with HSE hazard marking to ensure clean and safe delivery.

Beryllium Oxide Rods Usage Instructions

Proper handling and use of Beryllium Oxide (BeO) Rods ensure consistent performance, safety, and long service life. Follow these best practices during installation, operation, storage, and maintenance.

-

Install

1. Inspect each rod for chips, cracks, or edge defects before assembly.

2. Use soft clamps, torque-limited fasteners, or precision slots — avoid point loads or metal-to-ceramic contact pressure.

3. When alignment is critical, specify lapped or polished ends (Ra ≤ 0.2 µm) to ensure uniform contact and minimal tilt.

4. For brazed or bonded assemblies, confirm metallization system (e.g., Mo/Mn, TiW) and filler compatibility before heating.

5. Apply uniform pressure during assembly; misalignment may cause stress cracking during thermal cycles.

-

Use

1. Maintain smooth thermal transitions; avoid quenching or sudden temperature drops above 100 °C/min.

2. Keep parts clean and dry before powering high-voltage or RF systems to prevent arc discharge.

3. In vacuum or cleanroom setups, use gloves and lint-free holders to prevent surface contamination.

4. Do not exceed the rated service temperature for your BeO grade (typically ≤ 1000 °C continuous).

5. If the rod serves as an insulator, ensure clearances follow dielectric spacing requirements.

-

Store

1. Keep rods in sealed anti-static sleeves with desiccant packs to prevent moisture adsorption.

2. Separate by foam or corrugated partitions to avoid edge collisions.

3. Store flat on vibration-free shelves, away from chemical vapors and high humidity.

4. For long-term storage, retain the lot label and HSE hazard marking for traceability.

-

Clean

1. Use lint-free wipes and filtered isopropanol or deionized water for surface cleaning.

2. Avoid abrasive tools or ultrasonic baths that may alter the surface finish.

3. Dry with filtered compressed air or nitrogen; re-seal immediately after cleaning.

4. For vacuum use, perform a mild 120 °C bake-out before installation to remove adsorbed moisture.

-

Cautions

1. BeO is safe in solid form but hazardous as dust — do not cut, grind, or machine outside a controlled facility with dust extraction.

2. Dispose of damaged or contaminated rods through certified hazardous-material channels.

3. Always wear gloves when handling; avoid dropping or impacting the surface.

4. Include BeO safety data (MSDS) and warning labels in your internal documentation.

5. In case of accidental breakage, isolate the area, ventilate, and follow site HSE cleanup procedures.