Boron nitride fiber is a high-temperature insulating material made from fine BN filaments bonded into flexible sheets or felts. It combines excellent electrical insulation, non-wetting behavior to molten metals, and chemical inertness under vacuum or inert atmospheres.

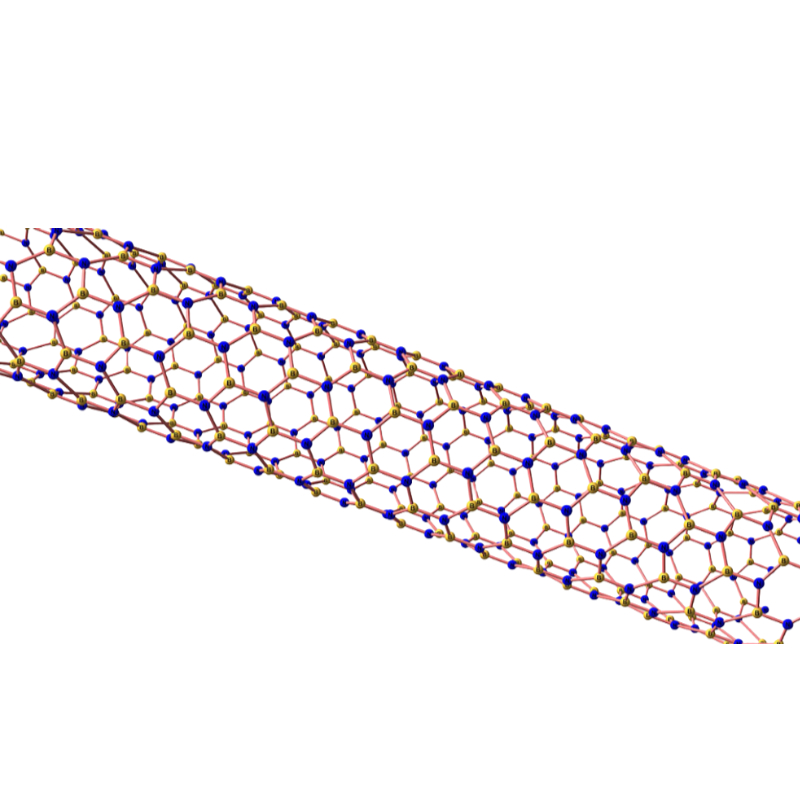

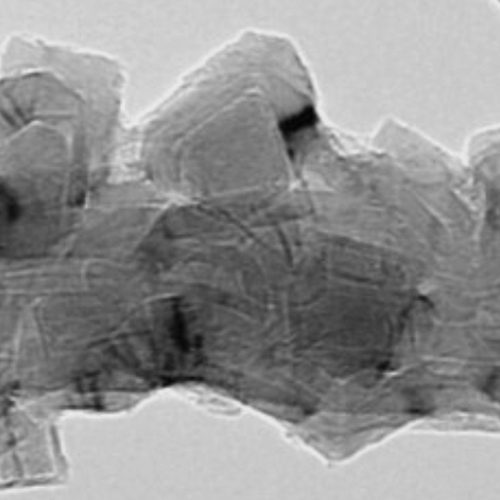

Structurally, BN fiber consists of hexagonal boron nitride microcrystals forming an interlocked fiber network. This gives it a unique balance of softness, thermal stability, and mechanical integrity. It remains stable up to 900–1000 °C in air and even higher (>1800 °C) under nitrogen, argon, or vacuum.

Boron Nitride Fiber Benefits

- High Purity Material: Manufactured from ≥99% BN powder, ensuring consistent thermal and electrical performance.

- Thermal Resistance: Operates reliably up to 1800°C in inert or vacuum environments.

- Electrical Insulation: Ideal for applications requiring high dielectric strength and low conductivity.

- Chemically Inert: Resistant to most acids, alkalis, and molten metals.

- Structural Reinforcement: Enhances mechanical strength in ceramic matrix composites (CMCs).

Boron Nitride Fiber properties

| Performance | Parameter |

|---|---|

| Appearance | White powder |

| Main Composition | Boron Nitride Nanotubes > 90% |

| Impurities | Hexagonal Boron Nitride (free floating) < 10%, Boron element < 1% |

| Number of Walls | 1-3 |

| Nanotube Width (Diameter) | 60nm |

| Nanotube Length | 20 μm |

| Barb Microcrystal (Hexagonal Boron Nitride Barb) | a=60nm, c=80nm (microcrystal size) |

| Density | 2.1 g/cm³ |

| Stability in Air | >900℃ |

| Melting Point | 2973℃ |

| Decomposition Melting Point | >4000℃ |

| Young's Modulus / Tensile Strength | 1.3TPa / 33GPa |

| Thermal Conductivity | 2400W/m·K |

| Resistivity | ρ > 109 Ω·cm |

| Band Gap | >5.5eV |

| Surface Roughness | Ra ~ 7.8nm |

| Thermal Neutron Absorption Cross-section | B11=767b (B10=~3800b), N=1.9b |

Boron Nitride Fiber Specifications

| Boron Nitride Fiber | ||||

| Item No. | Diameter(mm) | Length(mm) | Purity | Weight |

| AT-BNNT-001 | 60nm | 20um | 99 | 1g |

| AT-BNNT-002 | 0.5-1um | 1-10um | 99 | 1g |

| AT-BNNT-003 | 0.3-3um | 5-10um | 99 | 1g |

| AT-BNNT-004 | 0.3-3um | 10-20um | 99 | 1g |

Boron Nitride Nanotube Fiber Packaging

- sealed clean pouch; foam-slot carriers prevent edge compression.