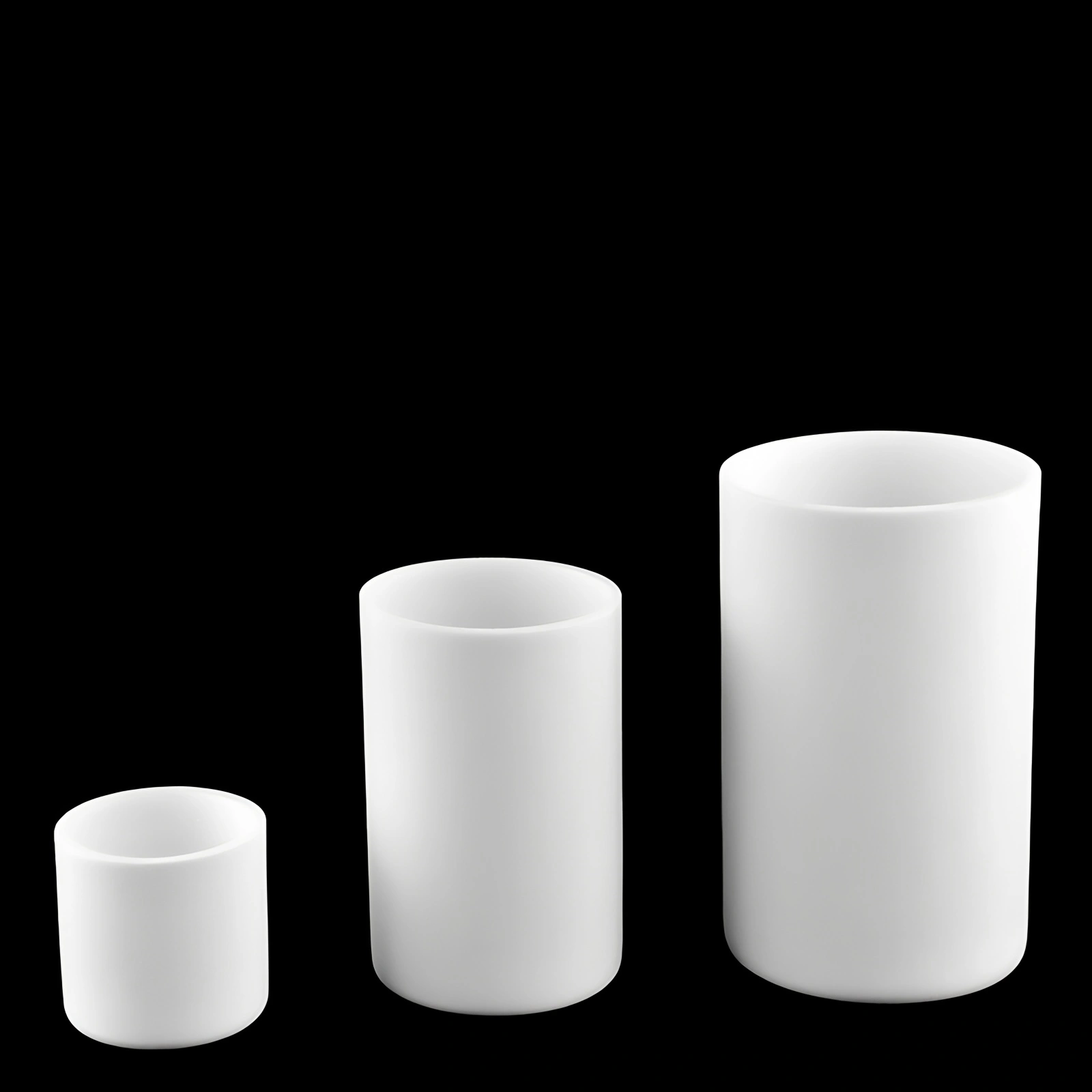

Alumina cylindrical crucible is a high-temperature container made from aluminum oxide (Al₂O₃) ceramic, shaped in a straight-walled cylinder. It is widely used in laboratories and industrial furnaces for heating, melting, ashing, and calcination processes.

Advantages of Cylindrical Alumina Crucible

- Uniform thermal envelope — The true cylinder minimizes edge effects compared to tapered shapes, supporting consistent melting, ashing, or calcination across batches.

- Dimensional repeatability — Tight concentricity and straight walls improve fixture fit and reproducibility in furnaces and high-temperature equipment.

- Contamination control — High-purity Al₂O₃ resists reaction with slags, salts, and atmospheres, helping to maintain sample integrity.

- Lid compatibility — Flat or cap lids reduce volatilization and support stable atmospheres during heating cycles.

- Service-life economics — Robust wall options (thin for rapid heating, thick for durability) allow users to balance cost and longevity according to application needs.

Alumina Cylindrical Crucibles Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

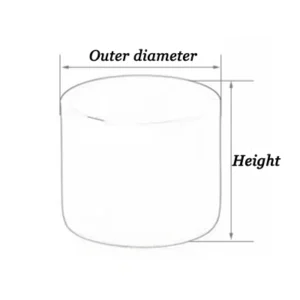

Specifications of Cylindrical Alumina Crucible

| Item NO. | Volume(ml) | Outer diameter(mm) | Height(mm) |

| TE-AC-070 | 0.5 | 20 | 4 |

| TE-AC-071 | 0.7 | 12 | 8 |

| TE-AC-071-1 | 0.8 | 12 | 12 |

| TE-AC-072 | 0.9 | 12 | 10 |

| TE-AC-073 | 1 | 20 | 5 |

| TE-AC-074 | 1 | 12 | 10 |

| TE-AC-075 | 1 | 18 | 5 |

| TE-AC-076 | 1 | 18 | 8 |

| TE-AC-077 | 1 | 10 | 15 |

| TE-AC-078 | 1 | 11 | 20 |

| TE-AC-079 | 1.5 | 12 | 20 |

| TE-AC-080 | 1.5 | 12 | 25 |

| TE-AC-081 | 1.5 | 9 | 40 |

| TE-AC-082 | 1.5 | 13 | 25 |

| TE-AC-083 | 2 | 10 | 25 |

| TE-AC-083-1 | 2 | 20 | 20 |

| TE-AC-085 | 2 | 30 | 5 |

| TE-AC-086 | 2 | 12 | 39 |

| TE-AC-083-2 | 2.5 | 22 | 20 |

| TE-AC-087 | 3 | 18 | 18 |

| TE-AC-088 | 3 | 16 | 28 |

| TE-AC-088-1 | 3 | 12.7 | 25 |

| TE-AC-088-2 | 3 | 14 | 31 |

| TE-AC-088-3 | 3 | 15 | 5 |

| TE-AC-088-5 | 3 | 15 | 20 |

| TE-AC-089 | 3 | 15 | 75 |

| TE-AC-090 | 3 | 10 | 30 |

| TE-AC-091 | 3.4 | 17 | 21 |

| TE-AC-091-1 | 4 | 14 | 44 |

| TE-AC-092 | 4 | 20 | 20 |

| TE-AC-093 | 5 | 32 | 10 |

| TE-AC-094 | 5 | 12 | 60 |

| TE-AC-094-1 | 5 | 10 | 40 |

| TE-AC-094-3 | 5 | 11.5 | 50 |

| TE-AC-094-4 | 5 | 11.5 | 15 |

| TE-AC-095 | 5 | 11 | 20 |

| TE-AC-096 | 5 | 10.5 | 20 |

| TE-AC-097 | 5 | 20 | 30 |

| TE-AC-098 | 5 | 15 | 50 |

| TE-AC-099 | 5 | 28 | 17 |

| TE-AC-099-1 | 5 | 35 | 8.5 |

| TE-AC-100 | 5 | 16 | 50 |

| TE-AC-101 | 5 | 54 | 8 |

| TE-AC-102 | 5.4 | 17 | 37 |

| TE-AC-103 | 6 | 16 | 60 |

| TE-AC-104 | 6 | 17 | 40 |

| TE-AC-104-1 | 6 | 16 | 56 |

| TE-AC-105 | 6 | 19 | 35 |

| TE-AC-105-1 | 6 | 16 | 80 |

| TE-AC-105-2 | 6 | 20 | 30 |

| TE-AC-108 | 7 | 22 | 25 |

| TE-AC-106 | 8 | 25 | 25 |

| TE-AC-109 | 9 | 20 | 40 |

| TE-AC-109-1 | 10 | 19 | 58 |

| TE-AC-109-2 | 10 | 20 | 50 |

| TE-AC-110-1 | 10 | 25 | 30 |

| TE-AC-110-2 | 10 | 30 | 28 |

| TE-AC-112 | 10 | 19 | 100 |

| TE-AC-113 | 10.2 | 22 | 36 |

| TE-AC-083-3 | 15 | 30 | 30 |

| TE-AC-114 | 15 | 47 | 13 |

| TE-AC-114-1 | 15 | 23 | 60 |

| TE-AC-115 | 15 | 30 | 30 |

| TE-AC-115-1 | 15 | 47 | 13 |

| TE-AC-115-2 | 15 | 30 | 30 |

| TE-AC-115-3 | 15 | 30 | 30 |

| TE-AC-116 | 20 | 35 | 35 |

| TE-AC-117 | 20 | 25 | 60 |

| TE-AC-118 | 20 | 25 | 60 |

| TE-AC-118-1 | 20 | 35 | 30 |

| TE-AC-119 | 20 | 28 | 58 |

| TE-AC-119-2 | 25 | 35 | 35 |

| TE-AC-121 | 25 | 28 | 58 |

| TE-AC-122 | 30 | 30 | 60 |

| TE-AC-123 | 30 | 36 | 45 |

| TE-AC-123-1 | 30 | 40 | 32 |

| TE-AC-124 | 30 | 40 | 35 |

| TE-AC-124-1 | 30 | 30 | 60 |

| TE-AC-124-3 | 34 | 26 | 82 |

| TE-AC-124-4 | 35 | 40 | 40 |

| TE-AC-125 | 35 | 40 | 40 |

| TE-AC-111 | 36 | 40 | 40 |

| TE-AC-124-7 | 40 | 40 | 50 |

| TE-AC-126 | 40 | 35 | 58 |

| TE-AC-126-1 | 40 | 50 | 30 |

| TE-AC-110 | 45 | 40 | 50 |

| TE-AC-127 | 45 | 42 | 45 |

| TE-AC-127-2 | 45 | 35 | 65 |

| TE-AC-127-3 | 45 | 40 | 50 |

| TE-AC-128 | 45 | 35 | 70 |

| TE-AC-131-2 | 45 | 50 | 100 |

| TE-AC-128-1 | 50 | 40 | 60 |

| TE-AC-129 | 50 | 30 | 100 |

| TE-AC-107 | 55 | 40 | 60 |

| TE-AC-130 | 60 | 40 | 70 |

| TE-AC-131 | 60 | 50 | 50 |

| TE-AC-132 | 65 | 35 | 100 |

| TE-AC-134 | 75 | 45 | 65 |

| TE-AC-136 | 80 | 75 | 27 |

| TE-AC-134-1 | 80 | 75 | 27 |

| TE-AC-135 | 80 | 37 | 69 |

| TE-AC-137 | 80 | 60 | 40 |

| TE-AC-135-4 | 85 | 50 | 60 |

| TE-AC-138 | 85 | 50 | 60 |

| TE-AC-135-5 | 90 | 35 | 120 |

| TE-AC-131-3 | 110 | 50 | 120 |

| TE-AC-138-1 | 110 | 60 | 60 |

| TE-AC-138-2 | 110 | 40 | 120 |

| TE-AC-119-4 | 115 | 40 | 120 |

| TE-AC-119-5 | 115 | 47 | 85 |

| TE-AC-141 | 120 | 90 | 35 |

| TE-AC-139 | 120 | 50 | 80 |

| TE-AC-140 | 120 | 60 | 60 |

| TE-AC-141 | 120 | 90 | 35 |

| TE-AC-142 | 125 | 41 | 137 |

| TE-AC-124-10 | 130 | 60 | 60 |

| TE-AC-131-6 | 130 | 60 | 60 |

| TE-AC-143 | 130 | 60 | 60 |

| TE-AC-143-1 | 130 | 65 | 45 |

| TE-AC-143-2 | 130 | 75 | 30 |

| TE-AC-144 | 130 | 45 | 110 |

| TE-AC-145 | 130 | 60 | 60 |

| TE-AC-145-1 | 130 | 45 | 110 |

| TE-AC-084 | 150 | 37 | 175 |

| TE-AC-146 | 150 | 50 | 100 |

| TE-AC-146-1 | 160 | 90 | 35 |

| TE-AC-124-5 | 170 | 90 | 35 |

| TE-AC-146-2 | 170 | 70 | 70 |

| TE-AC-146-3 | 170 | 48 | 120 |

| TE-AC-147 | 170 | 65 | 65 |

| TE-AC-160-8 | 175 | 90 | 35 |

| TE-AC-148 | 180 | 59 | 87 |

| TE-AC-124-11 | 195 | 60 | 90 |

| TE-AC-151 | 200 | 100 | 35 |

| TE-AC-152 | 200 | 100 | 40 |

| TE-AC-149 | 200 | 55 | 90 |

| TE-AC-149-1 | 200 | 100 | 40 |

| TE-AC-149-2 | 200 | 45 | 150 |

| TE-AC-150 | 200 | 60 | 100 |

| TE-AC-151 | 200 | 100 | 35 |

| TE-AC-152 | 200 | 100 | 40 |

| TE-AC-154-2 | 200 | 70 | 70 |

| TE-AC-124-12 | 215 | 60 | 100 |

| TE-AC-132-1 | 215 | 70 | 70 |

| TE-AC-153 | 215 | 70 | 70 |

| TE-AC-124-6 | 220 | 95 | 40 |

| TE-AC-152-1 | 220 | 50 | 150 |

| TE-AC-152-2 | 220 | 60 | 120 |

| TE-AC-152-3 | 220 | 55 | 120 |

| TE-AC-131-4 | 225 | 55 | 120 |

| TE-AC-160-9 | 230 | 95 | 40 |

| TE-AC-119-1 | 250 | 60 | 115 |

| TE-AC-154 | 250 | 60 | 120 |

| TE-AC-154-1 | 250 | 90 | 60 |

| TE-AC-124-13 | 260 | 60 | 120 |

| TE-AC-165-1 | 260 | 100 | 40 |

| TE-AC-165-4 | 260 | 105 | 40 |

| TE-AC-174-6 | 260 | 60 | 120 |

| TE-AC-124-14 | 270 | 70 | 90 |

| TE-AC-119-3 | 300 | 90 | 60 |

| TE-AC-131-5 | 300 | 55 | 170 |

| TE-AC-155 | 300 | 95 | 60 |

| TE-AC-156 | 300 | 70 | 100 |

| TE-AC-156-1 | 300 | 80 | 80 |

| TE-AC-157 | 300 | 80 | 80 |

| TE-AC-154-3 | 320 | 60 | 170 |

| TE-AC-124-16 | 330 | 75 | 95 |

| TE-AC-135-1 | 330 | 80 | 80 |

| TE-AC-158 | 330 | 80 | 80 |

| TE-AC-120 | 350 | 80 | 80 |

| TE-AC-159 | 350 | 80 | 80 |

| TE-AC-159-1 | 350 | 90 | 30 |

| TE-AC-159-2 | 350 | 70 | 120 |

| TE-AC-154-4 | 370 | 65 | 150 |

| TE-AC-160-5 | 380 | 80 | 100 |

| TE-AC-119-6 | 400 | 85 | 85 |

| TE-AC-160 | 400 | 70 | 120 |

| TE-AC-160-1 | 400 | 66 | 150 |

| TE-AC-160-4 | 400 | 85 | 85 |

| TE-AC-161 | 400 | 85 | 85 |

| TE-AC-160-2 | 450 | 90 | 90 |

| TE-AC-160-3 | 450 | 90 | 90 |

| TE-AC-135-2 | 480 | 90 | 90 |

| TE-AC-162 | 480 | 90 | 90 |

| TE-AC-124-8 | 500 | 95 | 90 |

| TE-AC-160-10 | 500 | 95 | 90 |

| TE-AC-164-1 | 500 | 80 | 130 |

| TE-AC-174-10 | 500 | 80 | 120 |

| TE-AC-165-10 | 510 | 95 | 95 |

| TE-AC-124-9 | 550 | 95 | 95 |

| TE-AC-160-11 | 550 | 95 | 95 |

| TE-AC-163 | 600 | 100 | 100 |

| TE-AC-164 | 600 | 100 | 100 |

| TE-AC-124-15 | 630 | 70 | 210 |

| TE-AC-165-11 | 630 | 100 | 100 |

| TE-AC-165 | 650 | 100 | 100 |

| TE-AC-165-2 | 650 | 100 | 100 |

| TE-AC-165-12 | 750 | 88 | 150 |

| TE-AC-165-5 | 800 | 110 | 100 |

| TE-AC-166 | 800 | 115 | 110 |

| TE-AC-167 | 800 | 80 | 200 |

| TE-AC-135-3 | 880 | 100 | 100 |

| TE-AC-168 | 880 | 110 | 110 |

| TE-AC-160-6 | 950 | 80 | 250 |

| TE-AC-123-2 | 1000 | 80 | 250 |

| TE-AC-168-1 | 1000 | 115 | 155 |

| TE-AC-169-5 | 1080 | 120 | 120 |

| TE-AC-165-7 | 1100 | 120 | 120 |

| TE-AC-169-1 | 1100 | 120 | 120 |

| TE-AC-160-7 | 1140 | 80 | 300 |

| TE-AC-169 | 1140 | 120 | 120 |

| TE-AC-124-2 | 1200 | 80 | 300 |

| TE-AC-169-6 | 1200 | 110 | 150 |

| TE-AC-169-7 | 1200 | 135 | 30 |

| TE-AC-169-8 | 1200 | 135 | 110 |

| TE-AC-165-3 | 1300 | 100 | 200 |

| TE-AC-170 | 1300 | 115 | 155 |

| TE-AC-178 | 1300 | 100 | 200 |

| TE-AC-170-1 | 1400 | 130 | 130 |

| TE-AC-169-2 | 1450 | 130 | 130 |

| TE-AC-170-2 | 1450 | 130 | 130 |

| TE-AC-165-6 | 1500 | 110 | 195 |

| TE-AC-171 | 1500 | 125 | 150 |

| TE-AC-165-8 | 1800 | 120 | 200 |

| TE-AC-171-1 | 1800 | 140 | 140 |

| TE-AC-169-3 | 1850 | 140 | 140 |

| TE-AC-172 | 1850 | 140 | 140 |

| TE-AC-173 | 2000 | 135 | 160 |

| TE-AC-174 | 2000 | 135 | 200 |

| TE-AC-174-1 | 2000 | 150 | 80 |

| TE-AC-174-2 | 2000 | 170 | 165 |

| TE-AC-180 | 2200 | 100 | 210 |

| TE-AC-169-4 | 2250 | 150 | 150 |

| TE-AC-173-1 | 2250 | 160 | 160 |

| TE-AC-174-11 | 2250 | 150 | 150 |

| TE-AC-181 | 2600 | 140 | 200 |

| TE-AC-174-3 | 2700 | 150 | 180 |

| TE-AC-165-9 | 3300 | 130 | 300 |

| TE-AC-175 | 3350 | 170 | 170 |

| TE-AC-176 | 4000 | 180 | 180 |

| TE-AC-174-8 | 5400 | 185 | 240 |

| TE-AC-174-9 | 5500 | 200 | 200 |

| TE-AC-177 | 5500 | 200 | 200 |

| TE-AC-174-5 | 5700 | 120 | 600 |

| TE-AC-174-7 | 6000 | 176 | 280 |

| TE-AC-173-2 | 7400 | 220 | 220 |

| TE-AC-178-1 | 7400 | 220 | 220 |

| TE-AC-179 | 9700 | 240 | 240 |

| TE-AC-174-4 | 23000 | 315 | 315 |

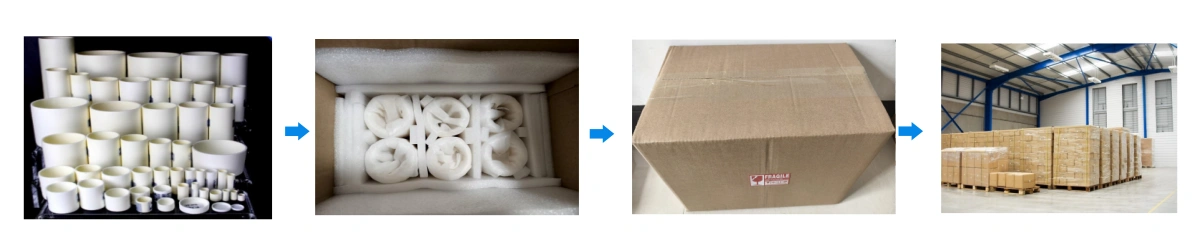

Cylindrical Alumina Crucible Packaging

- Unit pack: PE sleeve or blister + foam cradle; outer carton with corner protection

- Accessories: matching lids, tongs, support rings, crucible carriers, adapter stands