ADCERAX® Electric Actuated ZrO2 Ceramic Knife Gate Valve is designed to provide reliable shut-off in abrasive, corrosive, and fiber-rich flow systems. Its zirconia ceramic sealing surfaces deliver high hardness and long service life, reducing unplanned downtime in demanding operations. With electric actuation, the valve integrates smoothly into PLC and SCADA systems, enabling automated control and monitoring. This combination of durability and automation makes it a dependable choice for power plants, mining, pulp, chemical, and municipal industries.

Features of Electric Actuated ZrO2 Ceramic Knife Gate Valve

- The Electric Actuated ZrO2 Ceramic Knife Gate Valve withstands exposure to pH 2–12 fluids, ensuring compatibility across acidic and alkaline environments.

- In chemical wastewater lines, zirconia valves maintained zero leakage over 12 months, compared with 15% leakage rates in stainless steel designs.

- Chloride stress tests at 200 ppm Cl⁻ concentration demonstrated no measurable degradation of zirconia surfaces after 500 hours.

- Independent abrasion trials confirm zirconia valves lose <0.05 mm material after 100,000 cycles, maintaining stable sealing integrity.

- Testing in fly ash pipelines showed a service life extension of 2.5× compared to metal valves, reducing annual replacement costs significantly.

- The zirconia seat of the Electric Actuated ZrO2 Ceramic Knife Gate Valve achieves HRA ≥ 88, nearly 8× harder than carbon steel, which minimizes surface wear during abrasive slurry flow.

- Equipped with electric actuators, the Electric Actuated ZrO2 Ceramic Knife Gate Valve supports 4–20 mA feedback signals, ensuring integration with >90% of PLC/SCADA systems in industrial plants.

- Power plant trials show downtime reductions of 30% annually when replacing manual valves with electric actuated zirconia knife gate valves.

- Lifecycle cost analysis indicates a 40% lower total cost of ownership across a 5-year period due to extended maintenance intervals and reduced leakage incidents.

Technical Properties for Electric Actuated ZrO2 Ceramic Knife Gate Valve

The Electric Actuated Zirconia Ceramic Knife Gate Valve is engineered with zirconia ceramic sealing components that deliver proven reliability under abrasive, corrosive, and high-temperature conditions.

| Property | Pure Zirconia (Monoclinic) - Unstabilized | Yttria-Stabilized Zirconia (YSZ) | Magnesia-stabilized zirconia (Mg-PSZ) |

| Typical Purity | High-purity raw material, but unstabilized for the final product | High purity | High purity |

| Crystal Phases (at RT) | Monoclinic (stable up to ~1170°C); Tetragonal and Cubic at higher temperatures. | Primarily, Metastable Tetragonal can have a Cubic phase. | Partially stabilized with tetragonal precipitates in a cubic matrix. |

| Density (g/cm³) | 5.65–6.05 | 5.85-6.1 | ~5.7 |

| Melting Point (°C) | ~2700-2715 | Very High (similar to pure zirconia, but phase stability is key) | Very High |

| Thermal Conductivity (W/m·K) | Low (approx. 2-3) | Low (approx. 2.5-3) | Low (approx. 3) |

| Thermal Expansion Coefficient (10⁻⁶/K) | ~10 | 9.5-10 | 10 |

| Flexural Strength (MPa) | Poor (due to phase transformation and brittleness) | Up to 1000, 710-900 | 500 |

| Compressive Strength (MPa) | Not typically used structurally | ~2000 | ~2500 |

| Fracture Toughness (MPa·m^0.5) | Low (inherently brittle) | Up to 10 (exceptionally high for ceramics due to transformation toughening), 8-9 | 6 |

| Hardness (Vickers, HV1) | Moderate | 11-13 GPa, 1100-1220 kg/mm² | 1100 kg/mm² |

| Chemical Inertness | Excellent in acids and alkalis | Excellent | Excellent |

| Biocompatibility | Generally good, but stabilized forms are preferred for medical use | Excellent, widely used in dental and medical implants | Good |

| Typical Applications | Refractories (at high temperatures) | Structural ceramics, dental implants, oxygen sensors, cutting tools, thermal barrier coatings | Refractories, structural components requiring specific thermal properties |

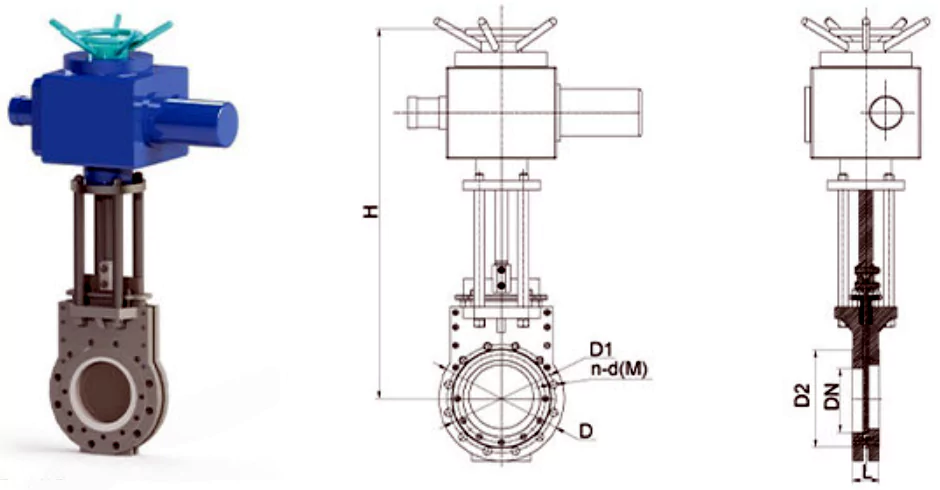

Specifications of Electric Actuated ZrO2 Ceramic Knife Gate Valve

| Item Name | Model | DN(mm) | L | D | D1 | D2 | n-d(M) | H |

| Electric Actuated ZrO2 Knife Gate Valve-P10 | AT-ZV1-D024 | 50 | 60 | 165 | 125 | 100 | 4-18(16) | 635 |

| Electric Actuated ZrO2 Knife Gate Valve-P10 | AT-ZV1-D025 | 65 | 60 | 185 | 145 | 120 | 4-18(16) | 655 |

| Electric Actuated ZrO2 Knife Gate Valve-P10 | AT-ZV1-D026 | 80 | 65 | 200 | 160 | 135 | 8-18(16) | 675 |

| Electric Actuated ZrO2 Knife Gate Valve-P10 | AT-ZV1-D027 | 100 | 65 | 220 | 180 | 135 | 8-18(16) | 725 |

| Electric Actuated ZrO2 Knife Gate Valve-P10 | AT-ZV1-D028 | 125 | 65 | 250 | 210 | 185 | 8-18(16) | 760 |

| Electric Actuated ZrO2 Knife Gate Valve-P10 | AT-ZV1-D029 | 150 | 65 | 285 | 240 | 210 | 8-22(20) | 780 |

| Electric Actuated ZrO2 Knife Gate Valve-P10 | AT-ZV1-D030 | 200 | 75 | 340 | 295 | 265 | 8-22(20) | 910 |

| Electric Actuated ZrO2 Knife Gate Valve-P10 | AT-ZV1-D031 | 250 | 75 | 395 | 350 | 320 | 12-22(20) | 1115 |

| Electric Actuated ZrO2 Knife Gate Valve-P10 | AT-ZV1-D032 | 300 | 80 | 445 | 400 | 370 | 12-22(20) | 1230 |

| Electric Actuated ZrO2 Knife Gate Valve-P10 | AT-ZV1-D033 | 350 | 85 | 505 | 460 | 428 | 16-22(20) | 1320 |

| Electric Actuated ZrO2 Knife Gate Valve-P10 | AT-ZV1-D034 | 400 | 85 | 565 | 515 | 480 | 16-26(22) | 1410 |

| Electric Actuated ZrO2 Knife Gate Valve-P10 | AT-ZV1-D035 | 450 | 95 | 615 | 565 | 530 | 20-26(22) | 1550 |

| Electric Actuated ZrO2 Knife Gate Valve-P10 | AT-ZV1-D036 | 500 | 100 | 670 | 620 | 582 | 20-26(22) | 1700 |

| Electric Actuated ZrO2 Knife Gate Valve-P16 | AT-ZV1-D037 | 50 | 60 | 165 | 125 | 100 | 4-18(16) | 635 |

| Electric Actuated ZrO2 Knife Gate Valve-P16 | AT-ZV1-D038 | 65 | 60 | 185 | 145 | 120 | 4-18(16) | 655 |

| Electric Actuated ZrO2 Knife Gate Valve-P16 | AT-ZV1-D039 | 80 | 65 | 200 | 160 | 135 | 8-18(16) | 675 |

| Electric Actuated ZrO2 Knife Gate Valve-P16 | AT-ZV1-D040 | 100 | 65 | 220 | 180 | 135 | 8-18(16) | 725 |

| Electric Actuated ZrO2 Knife Gate Valve-P16 | AT-ZV1-D041 | 125 | 65 | 250 | 210 | 185 | 8-18(16) | 760 |

| Electric Actuated ZrO2 Knife Gate Valve-P16 | AT-ZV1-D042 | 150 | 65 | 285 | 240 | 210 | 8-22(20) | 780 |

| Electric Actuated ZrO2 Knife Gate Valve-P16 | AT-ZV1-D043 | 200 | 75 | 340 | 295 | 265 | 12-22(20) | 910 |

| Electric Actuated ZrO2 Knife Gate Valve-P16 | AT-ZV1-D044 | 250 | 75 | 405 | 355 | 320 | 12-26(22) | 1115 |

| Electric Actuated ZrO2 Knife Gate Valve-P16 | AT-ZV1-D045 | 300 | 80 | 460 | 410 | 370 | 12-26(22) | 1230 |

| Electric Actuated ZrO2 Knife Gate Valve-P16 | AT-ZV1-D046 | 350 | 85 | 520 | 470 | 428 | 16-26(22) | 1320 |

| Electric Actuated ZrO2 Knife Gate Valve-P16 | AT-ZV1-D047 | 400 | 85 | 580 | 525 | 480 | 16-30(27) | 1410 |

| Note: Nominal Diameter: DN50–DN500; Nominal Pressure: 1.0 MPa–1.6 MPa; Operating Temperature: -20 °C–250 °C; Connection Type: Wafer; Actuation Method: Electric | ||||||||

Packaging of Electric Actuated ZrO2 Ceramic Knife Gate Valve

Each Electric Actuated ZrO2 Ceramic Knife Gate Valve is first packed in reinforced cartons and placed on pallets for stability. The cartons are then enclosed in strong plywood cases to protect against moisture and impact during shipping.