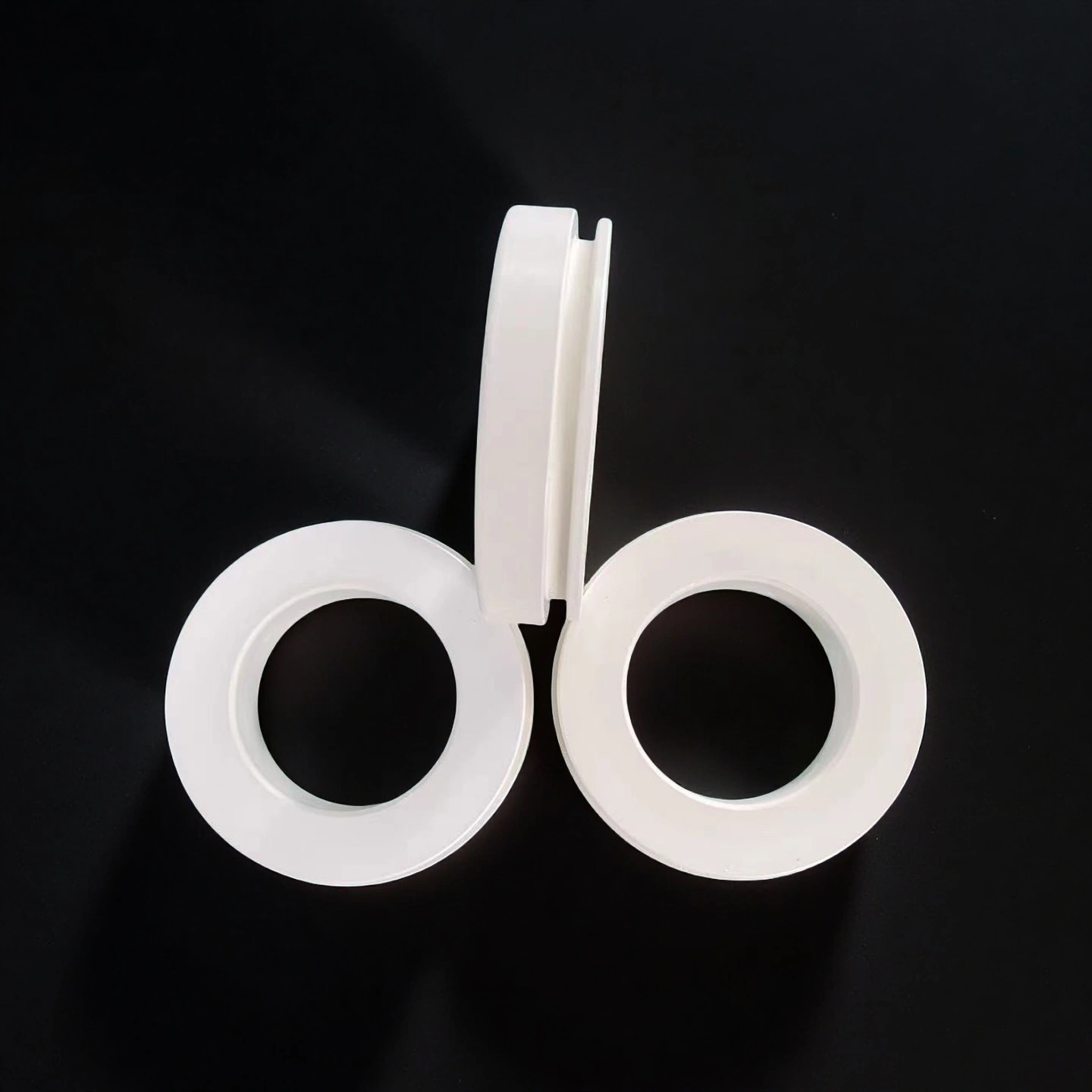

A hexagonal boron nitride ring is a toroidal ceramic component machined from hot-pressed hexagonal boron nitride (hBN). It combines high electrical resistivity, useful thermal conductivity and very low wettability to molten non-ferrous metals, so it can act as a high-temperature insulating and non-sticking interface between graphite, metals and other ceramics.

Hexagonal Boron Nitride Ring Benefits

-

High-temperature electrical insulation with usable thermal conductivity

The hexagonal boron nitride ring combines high electrical resistivity with thermal conductivity in a practical range, allowing it to insulate electrodes and supports while still distributing heat within furnace or casting assemblies. -

Non-wetting interface to molten aluminum and non-ferrous alloys

The BN ceramic ring shows low wettability toward molten aluminum and similar alloys, which helps reduce metal adhesion on nozzles, launder components and crucible lips, and supports longer intervals between cleaning operations. -

Machinable geometry and tight OD/ID tolerances

Hot-pressed hBN is machinable, so the ring can be produced with tight OD, ID and thickness tolerances, allowing it to locate graphite parts, feedthroughs and crucibles accurately without extensive on-site machining. -

Low thermal expansion and good thermal shock resistance

The hexagonal boron nitride ring has a low coefficient of thermal expansion and good thermal shock performance, which supports repeated heating and cooling cycles without excessive cracking when the mechanical design is appropriate. -

Low contamination for metal, glass and materials processing

High-purity BN material offers low reactivity with many molten metals and glass compositions, supporting clean processing where surface contamination, inclusion formation or discolouration must be controlled.

HBN Ceramic Ring Properties

| Property | Unit | Pyrolytic Boron Nitride | Hot Pressed Boron Nitride |

| Purity | 99.99% | 99.50% | |

| Density | g/cm3 | 2.15-2.19 | 1.96-2 |

| Hardness | HV0.5 | 651 | 62 |

| Volume resistivity | Ohm*cm | 2*1014 | 1.2*1014 |

| Dielectric strength | kV/mm | 55 | 76 |

| Maximum working temperature | ℃ | 1000 (air), 2300 (vacuum) | 900 (air), 1850 (vacuum) |

| Bending strength | MPa | 173 (A direction) | 310 |

| Thermal conductivity | W/m*K | 60 (A direction) | 55 |

| Tensile strength | MPa | 112 (A direction) | 110 |

| Thermal expansion coefficient | /℃ | 6*10-7 | 1.8*10-6 |

| Compressive strength | MPa | 154 (A direction) | 120 |

HBN Ring Specifications

| Hexagonal BN Insulating Ring | ||

| Item No. | Outer Diameter(mm) | Inner Diameter(mm) |

| AT-BN-H1001 | Customize | |

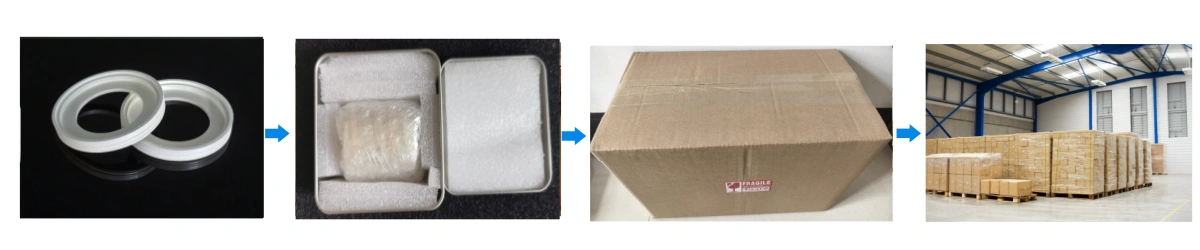

Hexagonal Boron Nitride Ring Packaging

- Each hexagonal boron nitride ring is separated in protective trays or soft compartments so that edges and faces do not contact each other during transport.