Hot Pressed Aluminum Nitride Plate is a dense, high-performance ceramic substrate used in thermal management and electrical insulation applications. With excellent thermal conductivity and low dielectric loss, it is widely used in power modules, laser systems, and high-temperature vacuum environments.

Hot-Pressed Aluminum Nitride Plate Benefits

-

High Thermal Conductivity in a Thick Plate Form

Hot-pressed aluminum nitride plate provides 180–230 W/m·K thermal conductivity through 0.5–30 mm thickness, enabling efficient heat spreading for high power density modules that cannot rely on thin substrates alone. -

High Density and Mechanical Robustness

With 3.25–3.30 g/cm³ density and fine microstructure, the hot-pressed AlN plate supports clamping, bolting and power cycling loads without excessive warpage or cracking in typical power and RF assemblies. -

Electrical Insulation with Low Dielectric Loss

The hot-pressed aluminum nitride plate combines high volume resistivity with low dielectric loss, allowing thermal management and electrical isolation in the same component for power, RF and high voltage designs. -

Stable Thermal Expansion for Power Cycling

The thermal expansion of hot-pressed AlN plate is close to many semiconductor and package metals, helping to reduce thermomechanical stress and extend module life under repeated on-off power cycling. -

Machinable to Complex Plate Geometries

Hot pressed aluminum nitride plates can be ground, drilled and profiled into complex plate geometries with openings, recesses and alignment features that match power modules, vacuum chucks and heater layouts.

Hot Pressed Aluminium Nitride Ceramic Plate Properties

| Property Content | Unit | Unit | ALN-170 | ALN-200 | ALN-230 |

| Basic Properties | Color | gray | light yellow | light yellow | |

| Density | g/cm³ | 3.2-3.3 | 3.2-3.3 | 3.2-3.3 | |

| Surface Roughness | μm | 0.2-0.75 | 0.2-0.75 | 0.2-0.8 | |

| Camber | length ‰ | ≤3‰ | ≤3‰ | ≤3‰ | |

| Hardness | HV | 1100 | 1100 | 1100 | |

| Thermal Properties | Max Operating Temperature | °C | 1100 | 1100 | 1100 |

| Thermal Conductivity | W/m·K | 170-190 | 190-220 | 220-230 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(20-400°c) | 4-5 | 4-5 | 4-5 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(400-800°c) | 5-6 | 5-6 | 5-6 | |

| Mechanical Properties | Flexural Strength | MPa | 300-400 | 350-450 | 400-500 |

| Tensile Strength | MPa | 200-300 | 250-350 | 280-380 | |

| Compressive Strength | MPa | 2000-3000 | 2200-3200 | 2500-3500 | |

| Electrical properties | Dielectric Constant | at 1MHz | 8-9 | 8-9 | 8-9 |

| Dielectric strength | KV/mm | ≥15 | ≥15 | ≥15 | |

| Volume resistivity | 20℃ Ω.cm | ≥1014 | ≥1014 | ≥1014 |

Hot Pressed Aluminium Nitride Plate Specifications

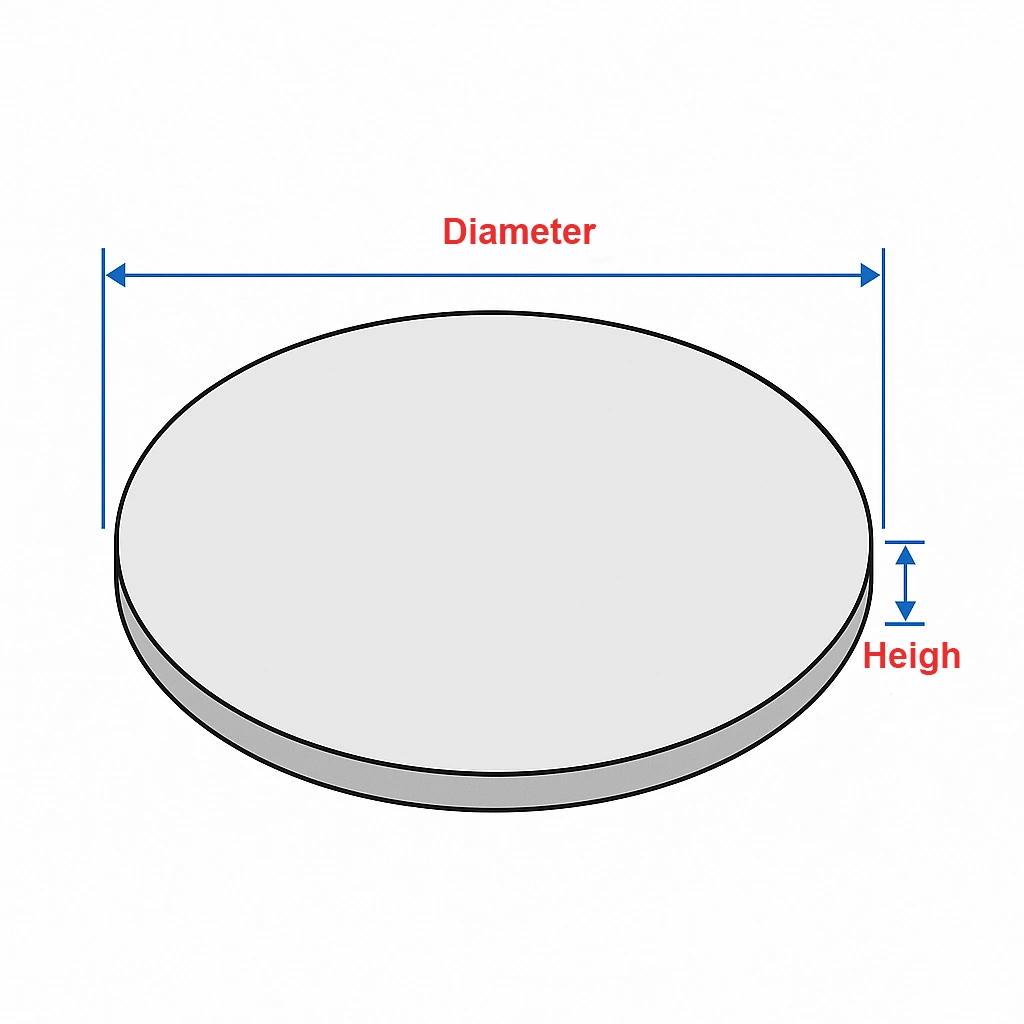

Type 1: Aluminum Nitride Plate Round

| Aluminum Nitride Plate Round | |||

| Item No. | Outer Diameter(mm) | Height (mm) | |

| AT-AIN-RY2001 | 500 | <500 | Max size |

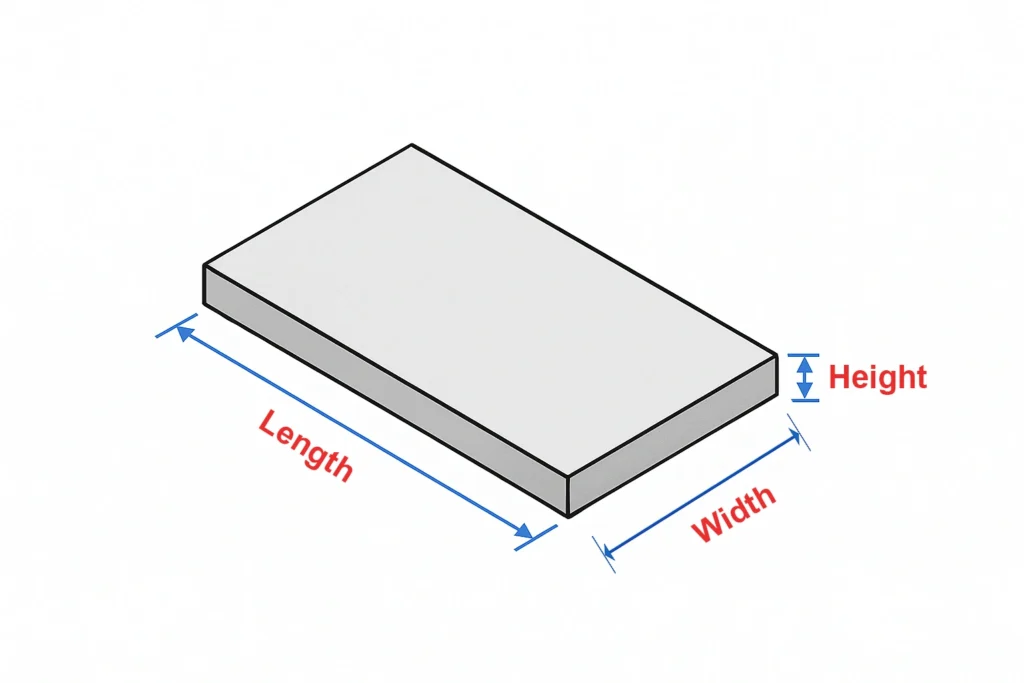

Type 2: Aluminum Nitride Plate Square

| Aluminum Nitride Plate Square | ||||

| Item No. | Length (mm) | Width (mm) | Height (mm) | |

| AT-AIN-RY1001 | 500 | 500 | <350 | Max Size |

Hot Pressed AlN Ceramic Plate Packing

- PE bags or antistatic bags enclose each tray to limit dust and handling contamination.