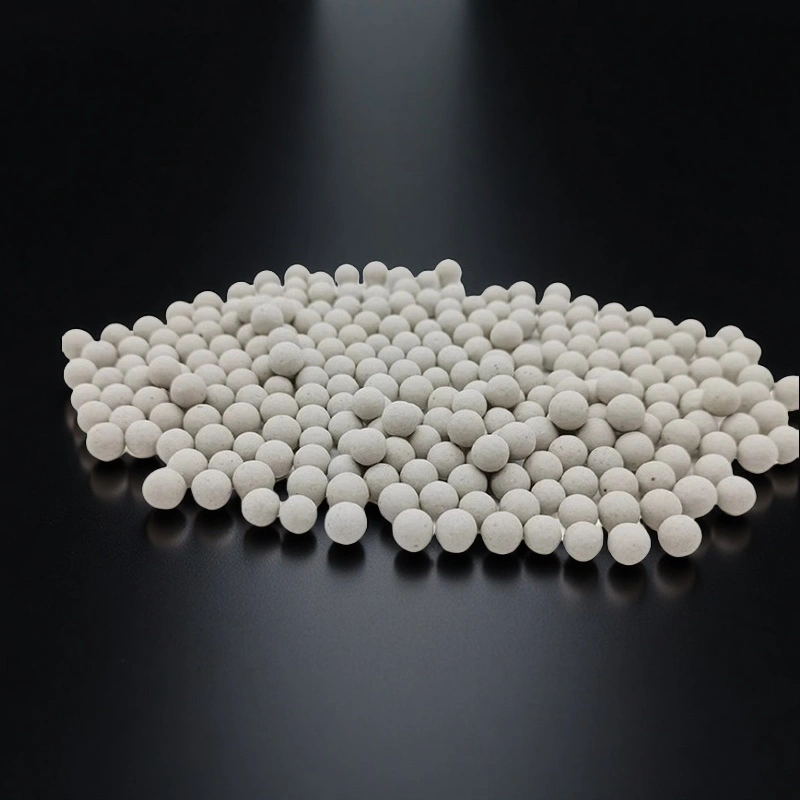

Inert alumina balls are dense, chemically stable spheres made primarily of Al₂O₃ (typically 92–99%+). They are used as catalyst bed support media / inert packing in reactors and adsorption dryers, as guard layers under molecular sieve or activated alumina, and as durable milling media in powder processing. Unlike adsorbents, they do not actively react or adsorb; their job is to distribute flow, support functional media, stabilize beds, and resist mechanical/thermal stress.

Inert Alumina Ceramic Balls Advantages

- Chemical inertness & purity: minimizes catalyst poisoning and product contamination in hydroprocessing and gas treatment.

- Mechanical robustness: high crushing strength and wear resistance stabilize bed geometry during cycles.

- Controlled size & sphericity: predictable pressure drop; easy layering with molecular sieve or activated alumina above.

- Thermal stability: suitable for elevated temperatures common to reactors and regeneration steps.

- Surface options: polished for low friction loading; micro-texture to assist bed interlocking where required.

Inert Alumina Ceramic Ball Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Inert Alumina Balls Specifications

| Inert Alumina Ceramic Balls | |||

| Item No. | Diameter (mm) | Purity (AI203)% | Tolerance |

| AT-YM-D001 | 2 | 92 | ±0.5 |

| AT-YM-D002 | 3 | 92 | ±1.0 |

| AT-YM-D003 | 6 | 92 | |

| AT-YM-D004 | 8 | 92 | |

| AT-YM-D005 | 10 | 92 | |

| AT-YM-D006 | 13 | 92 | ±1.5 |

| AT-YM-D007 | 16 | 92 | |

| AT-YM-D008 | 20 | 92 | |

| AT-YM-D009 | 25 | 92 | |

| AT-YM-D010 | 30 | 92 | ±2.0 |

| AT-YM-D011 | 38 | 92 | |

| AT-YM-D012 | 50 | 92 | |

| AT-YM-D013 | 60 | 92 | ±3.0 |

| AT-YM-D014 | 70 | 92 | |

| AT-YM-D015 | 80 | 92 | |

Inert Alumina Ball Packaging

- High purity inert alumina ceramic balls are packaged in 25 kg heavy-duty plastic bags, which are then placed inside 1-ton jumbo bags with inner waterproof liners. The jumbo bags are palletized and shrink-wrapped for secure, moisture-free international transport.