Insulator alumina beads are small, high-alumina ceramic components used to electrically isolate and mechanically guide metal leads (thermocouple wires, heater/resistance wires) in hot zones of furnaces, kilns, vacuum chambers, and lab equipment. They are supplied as single beads, short tube-type segments, or flexible fish-spine strands with controlled hole geometry to keep conductors separated, prevent shorting or arcing, and simplify routing through baffles and feed-throughs.

Insulator Alumina Beads Benefits

- Consistent hole geometry: Controlled ID/spacing reduces mis-threading and improves assembly yield.

- High-temperature stability: Al₂O₃ matrix resists softening and creep in prolonged hot-zone exposure.

- Clean edges and deburring: Smooth bore and chamfer options protect wire insulation and metal sheaths.

- Low open porosity options: Minimizes contamination traps; supports vacuum/inert environments.

- Multiple formats: Single bead, short segment, and fish-spine strands fit straight or flex routing.

Insulation Alumina Ceramic Beads Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Insulator Alumina Beads Specifications

Type 1: Single hole pass wire insulator alumina beads

| Item | Bottom outer diameter(mm) | Boss outer diameter (mm) | Height(mm) | Hole Dia (mm) |

| AT-YM-JY1001 | Ø20 | Ø14 | 11 | Ø8 |

| AT-YM-JY1002 | Ø22 | Ø15 | 13 | Ø9 |

| AT-YM-JY1003 | Ø9 | Ø6 | 6 | Ø3.5 |

| AT-YM-JY1004 | Ø9 | Ø5 | 12 | Ø3 |

| AT-YM-JY1005 | Ø15 | Ø10 | 12 | Ø7 |

| AT-YM-JY1006 | Ø17 | Ø11 | 13 | Ø7.5 |

| AT-YM-JY1007 | Ø18 | Ø12 | 13 | Ø7 |

| AT-YM-JY1008 | Ø18 | Ø12 | 11 | Ø6.5 |

| AT-YM-JY1009 | Ø8 | Ø6 | 5 | Ø2.5 |

Type 2: two holes pass wire insulator alumina beads

| Item | Bottom outer diameter(mm) | Boss outer diameter (mm) | Height(mm) | Hole Dia (mm) |

| AT-YM-JY2001 | Ø6 | Ø5 | 5.5 | Ø1 |

| AT-YM-JY2002 | Ø8 | Ø7 | 7 | Ø2 |

| AT-YM-JY2003 | Ø8 | Ø7 | 7 | Ø2.5 |

| AT-YM-JY2004 | Ø10 | Ø8 | 7 | Ø2.5 |

| AT-YM-JY2005 | Ø11 | Ø9 | 9 | Ø3 |

| AT-YM-JY2006 | Ø12 | Ø10 | 8 | Ø2.5 |

| AT-YM-JY2007 | Ø13 | Ø12 | 7 | Ø3.5 |

| AT-YM-JY2008 | Ø14 | Ø10 | 10 | Ø3.5 |

| AT-YM-JY2009 | Ø14 | Ø11 | 9 | Ø3 |

| AT-YM-JY2010 | Ø15 | Ø12.5 | 7 | Ø4 |

| AT-YM-JY2011 | Ø15 | Ø12 | 10 | Ø3.5 |

| AT-YM-JY2012 | Ø16 | Ø14 | 11 | Ø4 |

| AT-YM-JY2013 | Ø16 | Ø12 | 10 | Ø7.5 |

| AT-YM-JY2014 | Ø16 | Ø10 | 10 | Ø3 |

| AT-YM-JY2015 | Ø16 | Ø12 | 10 | Ø3.5 |

| AT-YM-JY2016 | Ø17 | Ø15 | 12 | Ø4 |

| AT-YM-JY2017 | Ø18 | Ø14 | 11 | Ø4 |

| AT-YM-JY2018 | Ø20 | Ø14 | 12 | Ø4.5 |

Type 3: Alumina Fish Spine Beads

| Item | Outer Dia (mm) | Inner Dia (mm) | Height (mm) |

| AT-YM-YJ1001 | 4 | 1.5 | 4 |

| AT-YM-YJ1002 | 4 | 2 | 4 |

| AT-YM-YJ1003 | 5 | 2.5 | 5 |

| AT-YM-YJ1004 | 6 | 2 | 6 |

| AT-YM-YJ1005 | 6 | 2.7 | 6.5 |

| AT-YM-YJ1006 | 7 | 3.5 | 7 |

| AT-YM-YJ1007 | 8 | 4 | 8 |

| AT-YM-YJ1008 | 9 | 4.5 | 8.5 |

| AT-YM-YJ1009 | 9.5 | 5.2 | 8 |

| AT-YM-YJ1010 | 10.5 | 5.5 | 9 |

| AT-YM-YJ1011 | 13 | 7.5 | 9 |

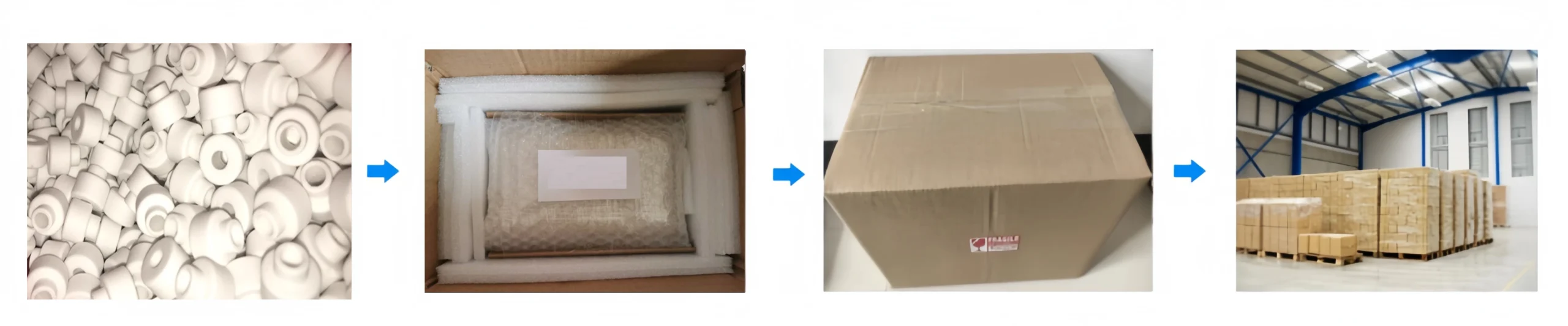

Alumina Insulator Beads Packaging

- China insulator alumina beads are are packed in poly-bagged or carton with inner cushioning