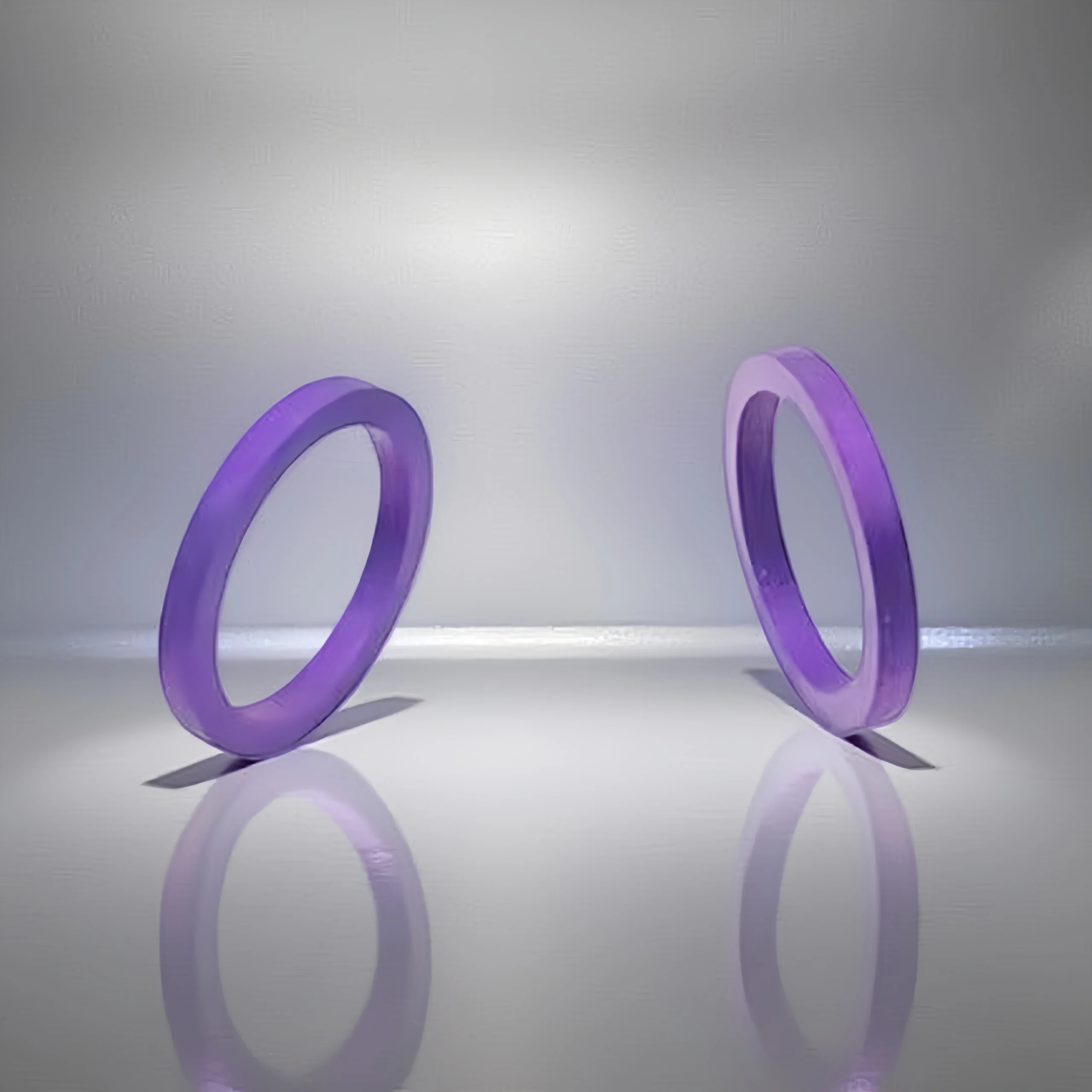

A Lanthanum Hexaboride Ring (LaB6) is a precision ceramic ring used in vacuum electron-source assemblies to provide repeatable OD/ID fit, clean seating, and stable geometry around the cathode or holder interface. It is commonly specified for thermionic electron guns and rebuild spares where alignment and contamination control matter.

Lanthanum Hexaboride Ring Benefits

LaB6 Ring Properties

| Lanthanum Hexaboride Ceramics (LaB6) | ||

| Property | Typical Value / Range | Performance Highlights / Notes |

| Melting Point | ≈ 2528 K (about 2250 °C) | Refractory ceramic that remains structurally stable at very high temperatures. |

| Density | ~4.7 g/cm³ | Compact, robust ceramic body suitable for small high-power cathodes and inserts. |

| Thermal Conductivity | ~47–60 W/m·K at 20 °C | Efficiently spreads heat across the emitter, reducing local hot spots. |

| Thermal Expansion (CTE) | ~6.2–6.5 ×10⁻⁶ /K (20–900 °C) | Good thermal shock resistance and predictable expansion for brazed or clamped assemblies. |

| Electrical Resistivity | ~15 μΩ·cm at 20 °C | High electrical conductivity, ideal for thermionic cathodes and other electron-emitting parts. |

| Typical Operating Temperature (Cathode) | ~1400–1800 °C in vacuum | Provides strong electron emission while maintaining long-term structural stability. |

| Emission Current Density | ~20–50 A/cm² at 1400–1800 °C | Delivers high beam brightness for electron microscopes, X-ray sources and plasma devices. |

| Work Function | ≈ 2.6–2.7 eV | Low work function enables high emission at lower temperatures than conventional tungsten cathodes. |

LaB6 Ring Specifications

| Lanthanum Hexaboride Ring | ||

| Item No. | Diameter (mm) | Thickness (mm) |

| AT-LB-A3001 | Customize | |

Lanthanum Hexaboride Ring Packaging

- Each LaB6 ring is individually protected to prevent edge contact and abrasion during transit.

- Double-layer sealed bagging is used to reduce dust exposure after final handling.