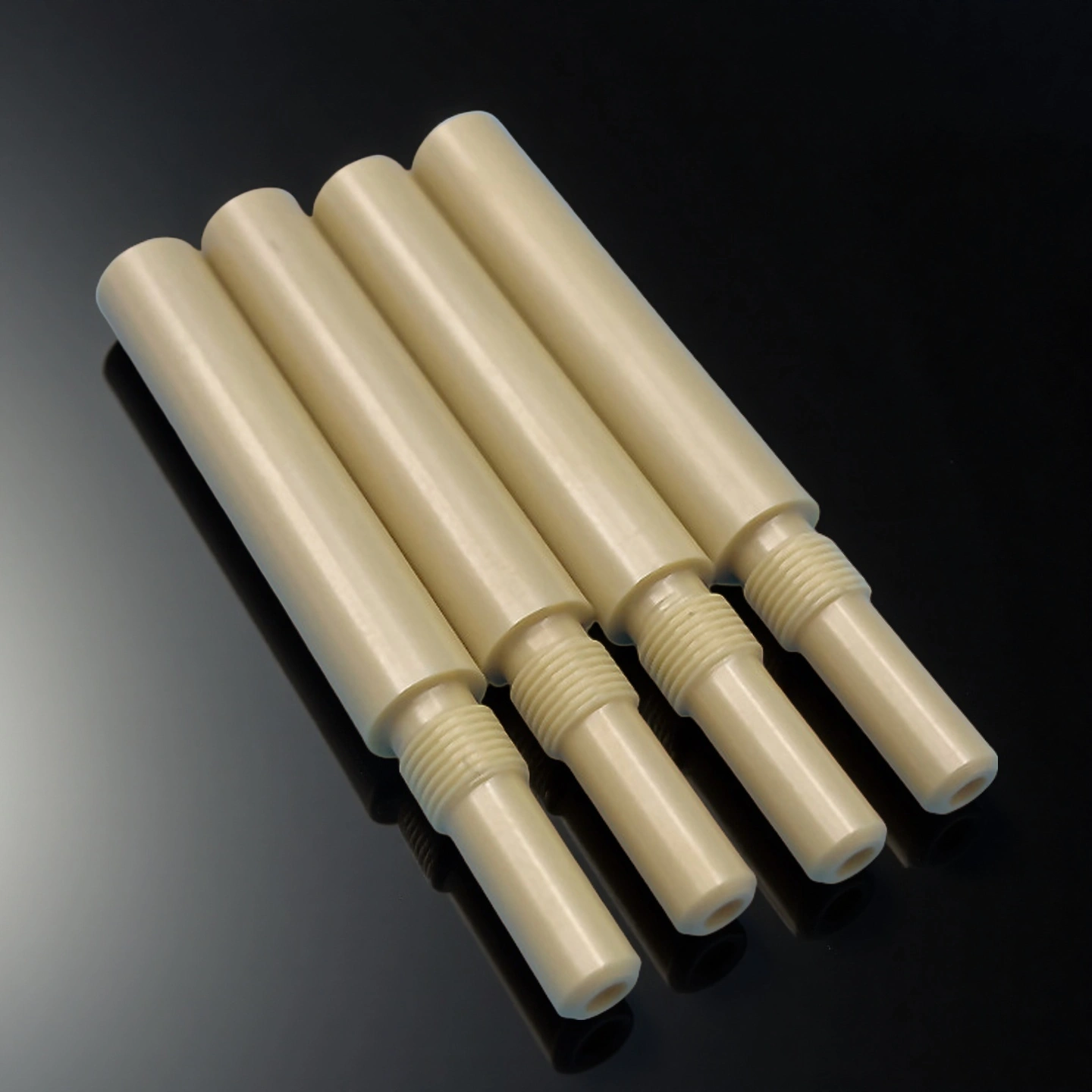

ADCERAX® Magnesia Stabilized Zirconia Ceramic Pin is engineered from a Mg‑PSZ microstructure that delivers high mechanical strength, wear resistance, and long‑term thermal stability in demanding industrial environments. Its material behavior ensures reliable positioning and fixation of components during machining, welding, and automated handling, preventing movement or rotation under repeated mechanical cycles. This stability contributes to consistent process accuracy and equipment reliability across automotive fixtures, robotic assembly systems, and corrosion‑exposed mechanical operations.

Product Features of Magnesia Stabilized Zirconia Ceramic Pin

-

Exceptional Mechanical Durability

The ceramic pin achieves a flexural strength above 900 MPa, offering mechanical resilience under repetitive shear or bending forces. Its fracture toughness exceeds that of alumina by over 30%, making it ideal for high-impact positioning tasks.

With a Vickers hardness of over 1300 HV, the surface resists abrasion during repeated tool contact and alignment cycles. In robotic jigs, this minimizes dimensional drift over 300,000+ cycles of operation.

Structural deformation is negligible due to a high elastic modulus of 205 GPa, allowing the pin to maintain precise engagement under continuous load without expansion or compression-related failure.

-

Thermal and Chemical Stability

Magnesia-stabilized zirconia retains mechanical properties up to 900°C, with dimensional variation below 0.02% in long-cycle high-temperature applications. This ensures fixture consistency in automotive welding or sintering processes.

In contact with acidic or alkaline media (pH 2–12), mass loss remains below 0.05 mg/cm² after 72 hours exposure, validating the pin's corrosion resistance for chemical plant installations.

No oxidation layer or spalling occurs even after 100 thermal cycles between room temperature and 800°C, ensuring longevity under repeated heating and cooling phases.

-

Electrical Insulation and Non-Magnetic Properties

The volume resistivity of the ceramic body exceeds 10¹² Ω·cm, enabling reliable insulation in high-voltage or sensor-sensitive environments. This protects adjacent equipment from electrochemical discharge issues.

It is entirely non-magnetic, with magnetic permeability μ ≈ 1.000, allowing usage near magnetic field sensors, transformers, or sensitive calibration stations without magnetic interference.

In testing environments, pins show zero metal particle attraction after exposure to 50 hours of grinding atmosphere, preserving the cleanliness of fixtures in microelectronics or cleanroom assembly lines.

Technical Specifications of Magnesia Stabilized Zirconia Ceramic Pin

Engineered for demanding industrial environments, Magnesia Stabilized Zirconia Ceramic Pin delivers reliable mechanical strength, high-temperature resilience, and long-term dimensional stability under corrosive and electrical isolation conditions.

| Property |

Specification |

| Material |

Magnesia Stabilized Zirconia (MSZ) |

| Color |

White or Ivory |

| Density |

5.70 – 5.85 g/cm³ |

| Flexural Strength |

>900 MPa |

| Vickers Hardness |

1100 – 1200 HV |

| Elastic Modulus |

~205 GPa |

| Fracture Toughness (K_IC) |

6 – 8 MPa·m¹ᐟ² |

| Thermal Conductivity |

~2.5 W/m·K @ 25°C |

| Maximum Operating Temperature |

Up to 1000°C (continuous use) |

| Thermal Expansion Coefficient |

10.3 × 10⁻⁶ /K (25–1000°C) |

| Electrical Resistivity |

>10¹² Ω·cm @ 20°C |

| Acid & Alkali Resistance |

Stable in pH <3 or >11 environments |

| Magnetic Permeability |

~1.000 (non-magnetic) |

| Surface Roughness (Ra) |

≤0.2 μm (fine ground) |

Dimensions of Magnesia Stabilized Zirconia Ceramic Pin

|

Mg-PSZ Ceramic Pin |

|

Item No. |

Diameter(mm) |

Height (mm) |

|

AT-MGO-X001 |

Customize |

Packaging for Magnesia Stabilized Zirconia Ceramic Pin

Magnesia Stabilized Zirconia Ceramic Pin is carefully packed using multi-layer protection to ensure safe international transit. Each unit is first placed in anti-static foam trays and sealed within moisture-resistant plastic boxes. The boxes are then cushioned with high-density insulation and secured inside custom-fit wooden crates for shock-proof export delivery.

ADCERAX® Magnesia Stabilized Zirconia Ceramic Pin Solves Precision Locating Challenges in Harsh Industrial Environments

ADCERAX® Magnesia Stabilized Zirconia Ceramic Pin ensures dimensional consistency and fixation integrity under severe thermal, mechanical, and vibrational stress, making it an ideal solution for automotive welding lines, pipeline valve assemblies, and high-heat furnace component fixtures.

-

Robust Locating in Automotive Resistance Welding Nut Fixtures

✅Key Advantages

1. Spatter Repulsion with Zero Adhesion Build-Up

The MSZ ceramic surface maintains <0.1 mg/cm² particle adhesion after 50,000 resistance welds under simulated BIW nut welding conditions. This eliminates the need for frequent manual cleaning or line pauses.

2. Cycle Stability Beyond 300,000 Welds

Zirconia pins retained dimensional tolerance within ±0.015 mm after 300,000 vertical clamping cycles at 800°C, outperforming hardened steel pins that failed after 80,000 cycles due to head wear and plastic deformation.

3. Heat-Driven Drift Elimination

With thermal expansion of only ~10.3×10⁻⁶/K, the pin avoids thermal drift and misalignment during projection welding sequences, reducing torque-induced hole shift by >70% compared to Cr-Mo dowels.

✅ ️Problem Solved

An Eastern European Tier-1 body shop experienced positional shift in BIW nut welding jigs every 3–5 weeks using steel pins, requiring jig rework and causing 2.5% rejections per day. After switching to ADCERAX® Magnesia Stabilized Zirconia Ceramic Pins, rework incidents dropped to near zero for over six months. Fixture downtime decreased by >60 hours per quarter, while weld alignment accuracy improved by 0.22 mm per pin per unit.

-

Stable Positioning in High-Vibration Oil & Gas Pipeline Valve Assembly

✅Key Advantages

1. Zero Loosening Under Axial Vibration

In endurance tests simulating ±1.2 mm displacement at 30 Hz for 100 hours, MSZ ceramic pins maintained positional deviation <0.03 mm. Steel dowels in comparison showed loosening torque reduction >50% and drift of 0.28 mm.

2. Inert Against Aggressive Pipeline Fluids

The pin’s corrosion rate was <0.005 mm/year in synthetic condensate blend (pH 4.2, NaCl + H₂S), outperforming 316L stainless steel by 18×. No microcracks or surface pitting were observed after 30 days.

3. Non-Magnetic for Sensor-Safe Environments

Magnetic permeability of ~1.000 ensures full EMI compatibility with nearby flow sensors, torque transducers, or induction-based actuators, preventing signal drift in intelligent valve blocks.

✅ ️Problem Solved

A pipeline actuator OEM in Alberta, Canada, reported frequent misalignment of spring-loaded flanges caused by steel dowel rotation under prolonged vibration, leading to over 20 unplanned shutdowns per year. ADCERAX® Magnesia Stabilized Zirconia Ceramic Pins were integrated across 40+ assembly stations. After 12 months, there were zero re-torque failures and average unit alignment deviation improved from 0.27 mm to 0.05 mm, reducing post-assembly correction costs by over USD 15,000 annually.

-

Dimensional Accuracy in High-Heat Industrial Furnace Component Fixtures

✅Key Advantages

1. Stable Geometry up to 1000°C

Magnesia-stabilized zirconia retains 98.7% flexural strength at 950°C, with dimensional deviation under ±0.01 mm across 120 thermal cycles. In contrast, SS304 pins expanded >0.12 mm per 100 mm length at the same temperature range.

2. No Oxidation Scaling or Surface Flaking

After 72-hour exposure to oxidizing furnace atmosphere at 980°C, zirconia pins exhibited zero mass loss or discoloration. Typical steel alternatives developed surface oxide layers >30 μm, impairing fit tolerance.

3. Long-Term Structural Holding Without Thermal Creep

No measurable creep was recorded for ADCERAX® MSZ pins under 6 MPa load at 850°C for 72 hours, while alloy steel pins showed 0.18 mm displacement. This ensures anchor integrity in refractory linings and support frames.

✅ ️Problem Solved

A metallurgy plant in Korea faced annual shutdowns due to anchor pin creep within gas-fired billet furnaces, disrupting the refractory grid and heat profile. ADCERAX® Magnesia Stabilized Zirconia Ceramic Pins were deployed in 180+ mounting points. Thermal creep was fully eliminated across 900+ cycles, reducing furnace chamber misalignment to under 0.02° per section, and saving over USD 70,000 in annual corrective maintenance.

Best Practices for Using ADCERAX® Magnesia Stabilized Zirconia Ceramic Pin in Industrial Fixtures

Proper handling and integration of Magnesia Stabilized Zirconia Ceramic Pin are essential to maximize service life, maintain dimensional accuracy, and ensure safe performance across various mechanical and thermal environments.

-

Installation Guidelines for Precision Fitment

1. Use alignment‑verified jigs during installation.

Always insert pins with verified coaxiality between mating holes and fixtures to avoid undue lateral force and fracture risk. Dry fitting without force tools is strongly recommended.

2. Avoid mechanical hammering or press-fitting.

Excessive impact can initiate micro-cracks at chamfer zones, especially in thin or stepped geometries. Only use soft-material pusher blocks under guided pressure.

3. Check slot tolerance before insertion.

Misaligned boreholes or excess deviation beyond design slot width can cause local stress accumulation, reducing long-term reliability.

-

Storage and Environmental Control Recommendations

1. Store in sealed, vibration‑free environments.

Unpacked ceramic pins should be kept in anti-static containers with foam padding, away from moisture and direct sunlight.

2. Avoid extreme humidity exposure.

Prolonged storage in environments above 60% RH can accelerate surface degradation when combined with contaminants or salt vapors.

3. Prevent direct contact with oily tools or solvents.

Some industrial cleaning residues can etch surface finishes, especially around polished diameter zones intended for guiding.

-

Maintenance and Inspection Protocols

1. Inspect every 100,000 cycles for wear or chipping.

High-frequency jigs may accumulate debris or micro-abrasions, affecting precision over time. Visual checks under 10x magnification are recommended.

2. Clean only with soft brushes and isopropyl alcohol.

Avoid using abrasive cloths or ultrasonic cleaners that could cause micro-surface erosion.

3. Log operational cycle time per fixture.

Tracking service hours or cycle count helps predict preventive replacement, reducing downtime from unexpected breakage.

-

Usage Conditions to Avoid Common Failures

1. Do not exceed 1000°C in continuous thermal use.

Though short bursts above 1000°C may not immediately fail the pin, structural fatigue accelerates rapidly after prolonged over-temp exposure.

2. Avoid placing near arc discharge without shielding.

Direct arc energy or spatter contact can pit or crack zirconia surfaces, especially under clamping tension.

3. Never rotate the pin after locking.

Rotational torque after interference fitting may cause hidden subsurface cracking, especially in shoulder-transition designs.