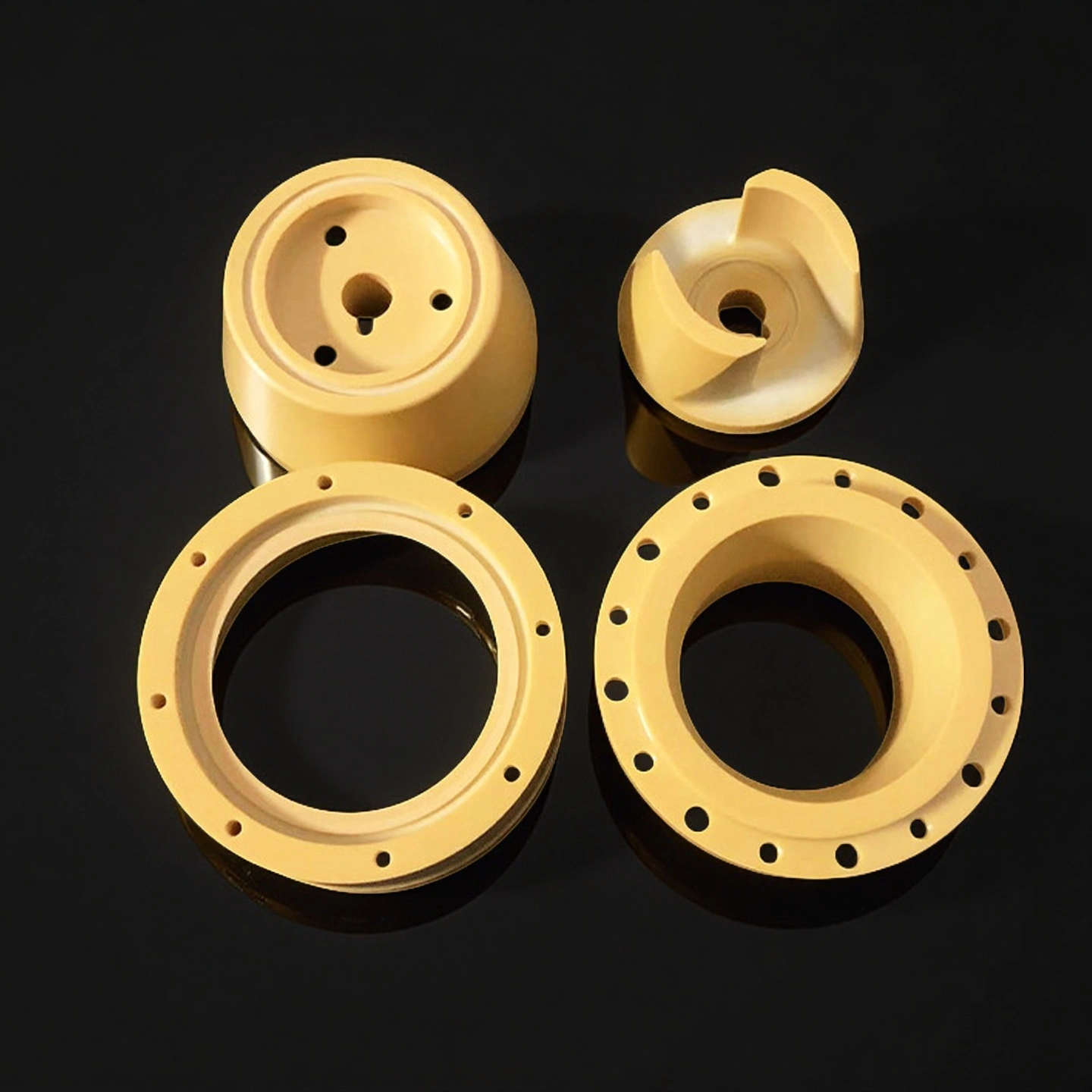

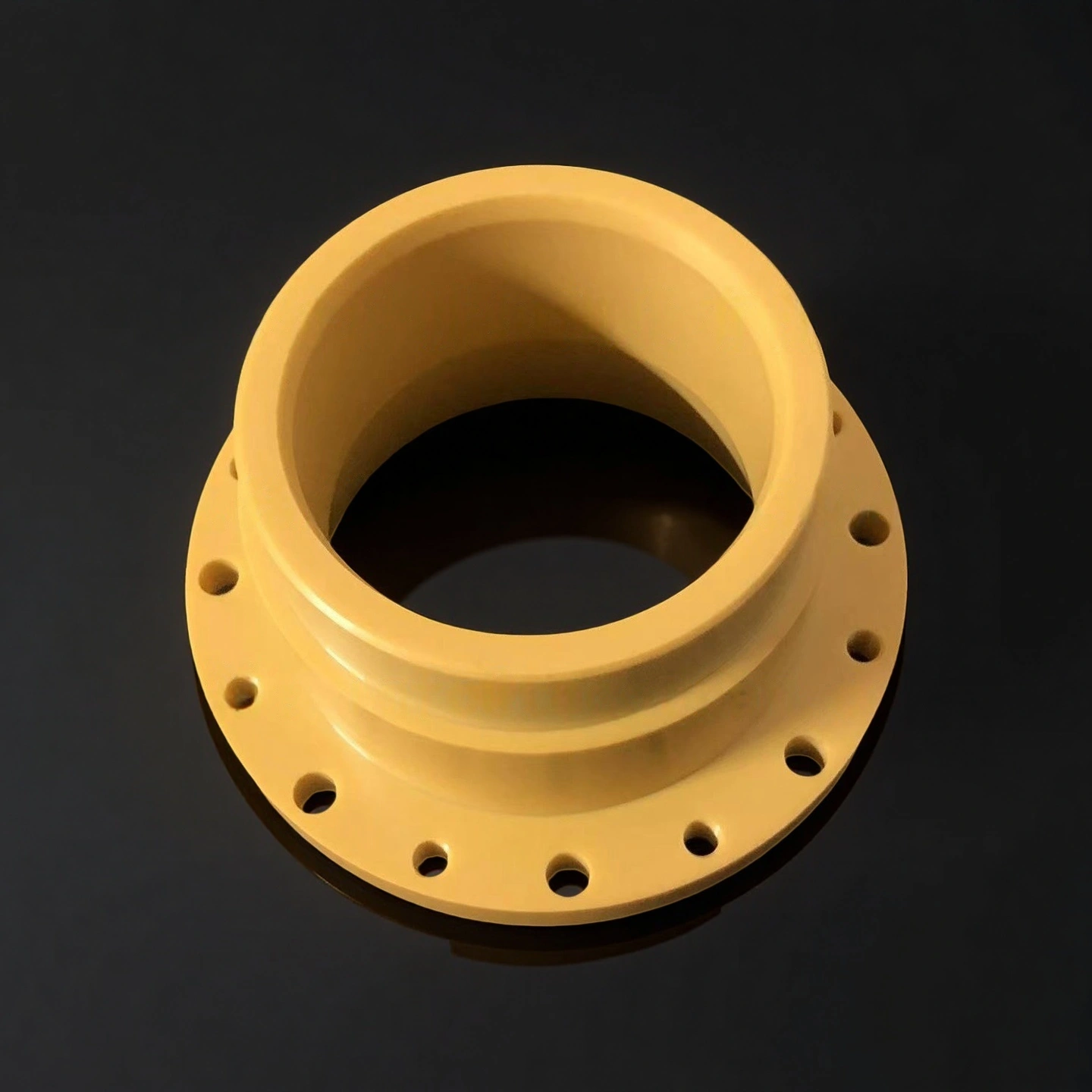

ADCERAX® Magnesia Stabilized Zirconia Ceramic Valve is designed for demanding flow control where corrosion, high temperature, and abrasion challenge traditional valve materials. It delivers strong mechanical performance and thermal stability, maintaining reliable sealing under continuous operation above 1000 °C. Combining chemical inertness with smooth, self‑lubricating surfaces, it ensures clean, maintenance‑free operation across petrochemical, power generation, water treatment, and pharmaceutical systems.

Key Performance Features of Magnesia Stabilized Zirconia Ceramic Valve

-

Flexural Strength ≥ 800 MPa

The valve body resists fracture and deformation under load, maintaining integrity in high-pressure pipelines. This level of flexural strength reduces mechanical failure during rapid pressure fluctuations.

-

Compressive Strength ≥ 2000 MPa

The ceramic structure supports long-term sealing under static or dynamic compression. It enables consistent performance in valves subject to high closing torque.

-

Wear Rate < 2 × 10⁻⁶ mm³/N·m

Tested with Al₂O₃ abrasives, the valve shows 8× longer service life than 316 stainless steel. This minimizes replacement frequency in slurry and solid-laden media.

-

Surface Roughness ≤ Ra 0.2 µm

Precision grinding produces ultra-smooth internal flow paths, reducing fluid turbulence and pressure drop. The mirror finish lowers energy loss during high-speed operation.

-

Seal Interface Flatness ≤ 0.01 mm

A flatness deviation under 10 microns ensures leak-free contact during repeated thermal cycling. It enhances the sealing lifespan across thousands of open-close cycles.

-

Frictionless Operation – Self-Lubricating Behavior

Ceramic contact surfaces exhibit natural lubrication under media flow, eliminating the need for grease. This reduces system contamination and maintenance labor.

-

Thermal Shock Tolerance ΔT ≥ 250 °C/min

The valve remains crack-free after 50+ cycles between ambient and 950 °C. It performs reliably in applications with abrupt heat exposure.

-

Acid and Alkali Resistance (H₂SO₄ ≤ 70%, NaOH ≤ 40%)

Material inertness prevents degradation when exposed to aggressive fluids. This makes it suitable for sulfuric, hydrochloric, and caustic systems without corrosion-induced failure.

Technical Properties for Magnesia Stabilized Zirconia Ceramic Valve

ADCERAX® Magnesia Stabilized Zirconia Ceramic Valve offers stable mechanical, thermal, and chemical behavior in aggressive media environments. Its performance is defined by high fracture strength, reliable thermal endurance, and proven inertness to acidic and alkaline exposure.

| Property |

Specification |

| Material Composition |

ZrO₂ + 8–10 mol% MgO |

| Density |

≥ 5.70 g/cm³ |

| Hardness |

HRA 88–90 (approx. 1250 HV) |

| Flexural Strength |

≥ 800 MPa |

| Compressive Strength |

≥ 2000 MPa |

| Thermal Expansion Coefficient |

8.5 × 10⁻⁶ /K (20–1000 °C) |

| Thermal Conductivity |

≈ 2.0 W/m·K |

| Operating Temperature Range |

−40 °C to +1000 °C |

| Thermal Shock Resistance |

ΔT ≥ 250 °C/min |

| Surface Roughness |

≤ Ra 0.2 µm |

| Seal Flatness Accuracy |

≤ 0.01 mm |

| Chemical Resistance |

Stable in H₂SO₄ (≤ 70%), NaOH (≤ 40%) |

| Wear Rate |

< 2 × 10⁻⁶ mm³/N·m (Al₂O₃ abrasive test) |

| Biocompatibility |

Non-toxic, non-contaminating |

| Leak Rate Standard |

≤ 10⁻⁶ mbar L/s (helium leak test) |

Dimensions of Magnesia Stabilized Zirconia Ceramic Valve

|

Magnesia Stabilized Zirconia Ceramic Valve |

|

Item No. |

Outer Diameter(mm) |

Inner Diameter(mm) |

Height(mm) |

|

AT-MSZV-0001 |

30 |

6 |

42 |

Secure Export Packaging for Magnesia Stabilized Zirconia Ceramic Valve

Magnesia Stabilized Zirconia Ceramic Valve is individually protected using anti-static wrap and cushioned with tailored foam inserts to prevent movement during transit. For batch shipments, reinforced cartons or plywood crates are used depending on part geometry and weight. Each box is sealed with tamper-evident labels and clearly marked for international handling compliance.

ADCERAX® Magnesia Stabilized Zirconia Ceramic Valve Resolves Critical Process Challenges in Corrosive, High-Temperature Flow Systems

Across multiple industrial sectors, the Magnesia Stabilized Zirconia Ceramic Valve from ADCERAX® plays a vital role in maintaining flow control stability where conventional metal or polymer valves fail. From abrasive slurries to thermal shock environments and corrosive pipelines, this engineered ceramic valve is applied where durability, chemical resistance, and system cleanliness are critical for operational reliability.

-

Magnesia Stabilized Zirconia Ceramic Valve in Chlor-Alkali Brine Injection Systems

✅Key Advantages

1. Alkaline Corrosion Immunity

The valve exhibits zero pitting after 500 hours of 30 % NaOH exposure under 80 °C continuous flow. Its magnesia-stabilized zirconia structure prevents hydroxide ion attack that typically degrades stainless steel valves.

2. High Thermal Gradient Tolerance

With ΔT ≥ 250 °C/min verified through cyclic testing, the valve endures abrupt heating and cooling during brine cell startups without structural distortion or microcrack propagation.

3. Anti-Scaling Surface Stability

A Ra ≤ 0.2 µm polished internal finish minimizes NaCl crystal adhesion, maintaining consistent flow even under supersaturated brine conditions, unlike metal valves that accumulate scaling layers.

✅ ️Problem Solved

A German chlor-alkali plant reported metal valve leakage after only 6 months due to scale-induced seal wear and alkaline corrosion. After replacing with ADCERAX® Magnesia Stabilized Zirconia Ceramic Valves, the operating life extended to over 24 months with zero pitting or pressure loss, reducing annual valve maintenance cost by 68 %. Operators confirmed improved flow consistency and eliminated brine contamination from corroded metal residues.

-

Magnesia Stabilized Zirconia Ceramic Valve in Power Plant Desulfurization Slurry Loops

✅Key Advantages

1. Abrasion Resistance in High-Solid Slurry

Tested wear rate of < 2 × 10⁻⁶ mm³/N·m under CaCO₃ slurry (60 wt%) ensures superior longevity versus metal valves, even at throttling zones with strong turbulence.

2. Compressive Strength for Pressure Stability

With ≥ 2000 MPa compressive strength, the valve maintains sealing integrity under high differential pressures typical in flue gas desulfurization recirculation loops.

3. Erosion-Free Flow Control

Internal surface maintains geometry after 10⁶ opening–closing cycles, preventing valve seat deformation and leakage during slurry recirculation.

✅ ️Problem Solved

A Polish coal-fired power plant experienced valve wall erosion within 9 months, causing 12 hours of forced shutdown per event and financial losses exceeding €25,000 per incident. Implementation of ADCERAX® Magnesia Stabilized Zirconia Ceramic Valves extended mean time between failures (MTBF) to > 3 years, eliminated slurry leaks, and reduced unplanned maintenance frequency by 80 %, ensuring stable SO₂ scrubbing efficiency and compliance with emission targets.

-

Magnesia Stabilized Zirconia Ceramic Valve in CIP Lines of Fermentation-Grade Sugar Processing

✅Key Advantages

1. Biocompatible and Ion-Free Flow Path

The valve’s chemically inert ceramic composition releases no detectable metallic ions (< 0.1 ppm) during alternating acid (H₂SO₄ ≤ 70%) and alkali (NaOH ≤ 40%) sterilization cycles, ensuring contamination-free production.

2. Smooth Mirror-Finish Interior

An internal polish of Ra ≤ 0.2 µm reduces microbial adhesion by 95 % compared to standard stainless steel valves, simplifying sterilization validation for CIP protocols.

3. Thermal and Chemical Cycling Durability

Endures over 500 cleaning cycles at 95 °C without surface degradation or seal delamination, maintaining consistent closure integrity across alternating acid-base rinses.

✅ ️Problem Solved

A Japanese sugar fermentation facility faced repeated contamination after acid rinse due to metal ion leaching from conventional valves, resulting in batch rejections worth $40,000 per occurrence. After installing ADCERAX® Magnesia Stabilized Zirconia Ceramic Valves, no ion residues were detected for 12 consecutive CIP cycles, and maintenance intervals extended from 3 to 12 months, ensuring regulatory compliance and uninterrupted product purity.

Operational Guidance for ADCERAX® Magnesia Stabilized Zirconia Ceramic Valve in Demanding Flow Systems

For optimal longevity and sealing performance, ADCERAX® Magnesia Stabilized Zirconia Ceramic Valve must be deployed in accordance with its thermo-mechanical characteristics, fluid compatibility range, and structural design limitations to avoid unnecessary damage or instability under harsh processing conditions.

-

Pre-Installation Recommendations

1. Surface Cleanliness Inspection

All valve contact surfaces should be free of oil, metal debris, or moisture before installation. Contaminants may cause seal irregularities and impact torque uniformity during actuator calibration.

2. Alignment and Gasket Matching

Flange faces must be aligned within ±0.1 mm flatness tolerance to prevent mechanical distortion of the ceramic body. Use graphite or PTFE gaskets rated for ≥1000 °C where thermal cycling is expected.

3. Torque Sequencing and Load Balancing

Follow a cross-bolt tightening sequence using a calibrated torque wrench to avoid uneven compression. Recommended torque values depend on flange size and gasket type, and over-torqueing must be avoided.

-

Startup and Commissioning Guidelines

1. Gradual Pressurization Protocol

Introduce fluid pressure in stages over 3–5 minutes to allow valve internals to adapt to differential expansion. Instant pressurization risks micro-crack formation.

2. Thermal Ramp Conditioning

For high-temperature fluids, increase system temperature at a rate <5 °C/min below 600 °C to prevent thermal shock. Maintain steady-state thermal environment for 30 minutes before dynamic flow adjustments.

3. Valve Cycling Validation

Run 10–20 open/close cycles under no-load conditions to validate seal integrity and stem alignment. Record any abnormal vibration or hysteresis in control signal response.

-

Maintenance and Wear Monitoring

1. Visual Seal Condition Audit

Every 1,000 operating hours, inspect the sealing surfaces for discoloration, scoring, or chemical deposits. Early signs of surface fatigue can indicate incorrect media compatibility or pressure surges.

2. Stem Torque Recheck

Measure stem torque under static conditions quarterly to detect progressive torsional loss or binding. Excess torque increase may indicate misalignment or seat wear.

3. Internal Surface Ultrasound or Borescope Scan

In corrosive or abrasive flows, perform an internal inspection every 6 months using a flexible borescope or ultrasound wall thickness gauge to detect sub-surface erosion or microfractures.

-

Media Compatibility and Limitations

1. Alkali and Acid Endurance Profile

The Magnesia Stabilized Zirconia Ceramic Valve is inert to pH 1–14 solutions, including NaOH, H₂SO₄, HCl, and H₃PO₄. Avoid media containing hydrofluoric acid (HF) or fluoride ions, which attack zirconia grain boundaries.

2. Particulate Suspension Tolerance

The valve tolerates solids up to 50 μm at <10% volume without flow instability. Larger particle slurries may require upstream filtration to prevent seat scoring.

3. Steam and Thermal Shock Boundary

Suitable for superheated steam ≤1000 °C with ramp rates below 5 °C/min. Sudden cold water contact on hot internals must be avoided to prevent crack propagation.