MgO Tube is a dense, sintered ceramic sleeve used to protect heating wires, thermocouple leads, or metal electrodes from electrical shorting and chemical attack under extreme heat. It maintains insulation integrity up to 1800 °C while allowing efficient heat transfer along the assembly.

Magnesia Tubes Benefits

- Stable electrical insulation resistance > 10¹³ Ω·cm at 500 °C.

- Maintains mechanical strength after > 100 thermal cycles between 25 °C and 1000 °C.

- Uniform microstructure ensures consistent heat transfer and low porosity (< 5 %).

- Chemical inertness to molten metals and alkalis — no contamination of heating elements.

- Precise tolerances down to ± 0.1 mm available for engineered assemblies.

Properties of Magnesia Tube

| Properties | Unit | Value |

| Material | % | 99 MgO |

| Density | g/m³ | 3.5 |

| Bulk Density | g/m³ | 2.8 |

| ApparentPorosity | % | 20 |

| Compressive Strength | MPa | 50 |

| FlexuralStrength | MPa | 16 |

| Refractoriness | SK | 42< |

| Thermal Conductivity | W/(m.K) | 5 |

| Coefficient of thermal expansion (20~1000℃) | 10-6/K | 13 |

| Operating temperature | Max (℃) | 2200 |

| Room temperature | Room temperature (℃) | 1800 |

Magnesia Tubes Specifications

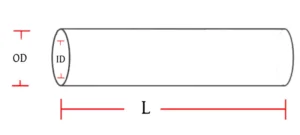

Type 1: Single Bore Mgo Tube

| Single Bore Magnesia Ceramic Tube | ||||

| Item NO. | OD (mm) | ID (mm) | L (mm) | Purity (%) |

| AT-MO-G1001 | 1.2 | 0.5 | 30 | 99.5 |

| AT-MO-G1002 | 3.7 | 2.0 | 30 | 99.5 |

| AT-MO-G1003 | 3.9 | 1.3 | 30 | 99.5 |

| AT-MO-G1004 | 5.0 | 2.0 | 30 | 99.5 |

| AT-MO-G1005 | 5.0 | 3.0 | 30 | 99.5 |

| AT-MO-G1006 | 5.5 | 2.0 | 30 | 99.5 |

| AT-MO-G1007 | 6.4 | 3.4 | 40 | 99.5 |

| AT-MO-G1008 | 7.0 | 4.0 | 40 | 99.5 |

| AT-MO-G1009 | 8.0 | 5.0 | 40 | 99.5 |

| AT-MO-G1010 | 9.0 | 6.0 | 40 | 99.5 |

| AT-MO-G1011 | 13.0 | 9.0 | 50 | 99.5 |

| AT-MO-G1012 | 14.0 | 8.0 | 50 | 99.5 |

| AT-MO-G1013 | 15.0 | 10.0 | 50 | 99.5 |

| AT-MO-G1014 | 16.0 | 9.0 | 50 | 99.5 |

| AT-MO-G1015 | 18.0 | 10.0 | 50 | 99.5 |

| AT-MO-G1016 | 19.0 | 19.0 | 50 | 99.5 |

| AT-MO-G1017 | 1.2-25 (Customize) | 0.5-20 (Customize) | 30-500 (Customize) | 99.5 |

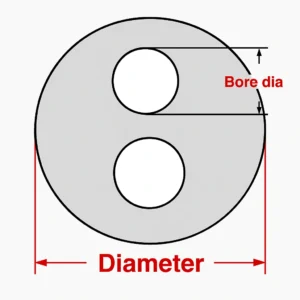

Type 2: Double Bores Mgo Tube

| Double Bores Magnesia Ceramic Tube | ||||

| Item NO. | Diameter (mm) | Bore Dia (mm) | Length (mm) | Purity (%) |

| AT-MO-G2001 | 5.3 | 1.6 | 25 | 99.5 |

| AT-MO-G2002 | 7.0 | 2.4 | 40 | 99.5 |

| AT-MO-G2003 | 9.0 | 3.0 | 50 | 99.5 |

| AT-MO-G2004 | 11.0 | 3.5 | 40 | 99.5 |

| AT-MO-G2005 | 15.0 | 4.5 | 40 | 99.5 |

| AT-MO-G2006 | 18.0 | 5.0 | 50 | 99.5 |

| AT-MO-G2007 | 13.0 | 4.5 | 40 | 99.5 |

| AT-MO-G2008 | 20.0 | 6.0 | 50 | 99.5 |

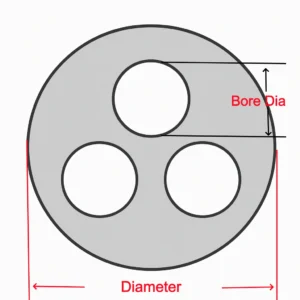

Type 3: Three Bores Mgo Tube

| Three Bores Magnesia Ceramic Tube | ||||

| Item NO. | Diameter (mm) | Bore Dia (mm) | Length (mm) | Purity (%) |

| AT-MO-G3001 | 6.6 | 1.3 | 50 | 99.5 |

| AT-MO-G3002 | 6.6 | 1.3 | 100 | 99.5 |

| AT-MO-G3003 | 9 | 3 | 50 | 99.5 |

| AT-MO-G3004 | 13.6 | 2.3 | 50 | 99.5 |

| AT-MO-G3005 | 18 | 5 | 100 | 99.5 |

| AT-MO-G3006 | 20 | 6 | 100 | 99.5 |

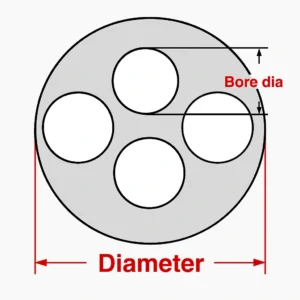

Type 4: Four Bores Mgo Tube

| Four Bores Magnesia Ceramic Tube | ||||

| Item NO. | Diameter (mm) | Bore Dia (mm) | Length (mm) | Purity (%) |

| AT-MO-G4001 | 4.0 | 1.1 | 20 | 99.5 |

| AT-MO-G4002 | 5.0 | 1.3 | 25 | 99.5 |

| AT-MO-G4003 | 6.0 | 1.4 | 25 | 99.5 |

| AT-MO-G4004 | 7.0 | 1.6 | 25 | 99.5 |

| AT-MO-G4005 | 8.0 | 1.8 | 25 | 99.5 |

| AT-MO-G4006 | 9.0 | 2.5 | 25 | 99.5 |

| AT-MO-G4007 | 11.0 | 3.0 | 40 | 99.5 |

| AT-MO-G4008 | 12.0 | 3.5 | 40 | 99.5 |

| AT-MO-G4009 | 13.0 | 4.0 | 40 | 99.5 |

| AT-MO-G4010 | 15.0 | 4.0 | 50 | 99.5 |

| AT-MO-G4011 | 16.0 | 4.0 | 40 | 99.5 |

| AT-MO-G4012 | 17.0 | 5.0 | 50 | 99.5 |

| AT-MO-G4013 | 18.0 | 5.0 | 50 | 99.5 |

| AT-MO-G4014 | 19.0 | 5.5 | 50 | 99.5 |

| AT-MO-G4015 | 20.0 | 5.5 | 50 | 99.5 |

| AT-MO-G4016 | 22.0 | 6.0 | 50 | 99.5 |

| AT-MO-G4017 | 24.0 | 6.8 | 50 | 99.5 |

| AT-MO-G4018 | 25.0 | 7.0 | 50 | 99.5 |

| AT-MO-G4019 | 26.0 | 7.0 | 50 | 99.5 |

| AT-MO-G4020 | 28.0 | 8.0 | 50 | 99.5 |

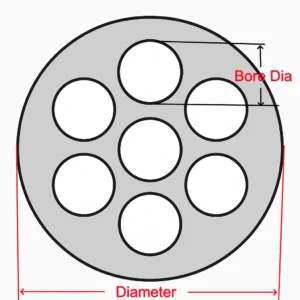

Type 5: Seven Bores Mgo Tube

| Seven Bores Magnesia Ceramic Tube | ||||

| Item NO. | Diameter (mm) | Bore Dia (mm) | Length (mm) | Purity (%) |

| AT-MO-G7001 | 9 | 1.8 | 25 | 99.5 |

| AT-MO-G7002 | 11 | 2.5 | 25 | 99.5 |

| AT-MO-G7003 | 13 | 3 | 30 | 99.5 |

| AT-MO-G7004 | 15 | 3.5 | 35 | 99.5 |

| AT-MO-G7005 | 17 | 4 | 40 | 99.5 |

| AT-MO-G7006 | 18 | 4.5 | 40 | 99.5 |

| AT-MO-G7007 | 20 | 4.5 | 50 | 99.5 |

| AT-MO-G7008 | 22 | 5 | 50 | 99.5 |

| AT-MO-G7009 | 25 | 5 | 50 | 99.5 |

| AT-MO-G7010 | 27 | 7 | 50 | 99.5 |

| AT-MO-G7011 | 29 | 7 | 50 | 99.5 |

| AT-MO-G7012 | 33 | 7 | 50 | 99.5 |

| AT-MO-G7013 | 48 | 8.3 | 50 | 99.5 |

Magnesium Oxide Tubes Packaging

- Each tube wrapped in foam sleeve → bubble bag → reinforced carton.

- Bulk orders use double-layer cartons or wood boxes