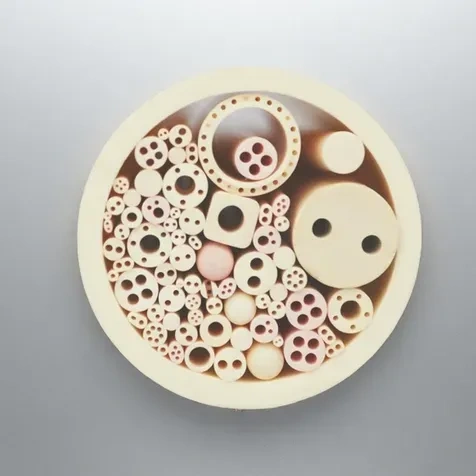

Multi-Bore Alumina Tube is a high-temperature ceramic component made from high-purity aluminum oxide (Al₂O₃), designed with multiple internal bores (like 6 holes,10 holes and more )running along its length. These tubes are engineered to meet specific dimensional and structural requirements provided by the customer, including the number of bores, bore diameter, outer diameter, length, and end configurations (open, closed, etc.).

Multi-Bore Alumina Tube Benefits

- High dimensional accuracy ensures reliable assembly in precision instruments.

- Multi-channel design enables simultaneous gas flow or multi-point temperature sensing.

- Excellent thermal shock resistance reduces failure risk in rapid heating environments.

- High electrical insulation prevents signal interference in sensor systems.

- Corrosion resistance supports use in aggressive chemical atmospheres.

Properties for Alumina Ceramic Multiple-Bore Tubes

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

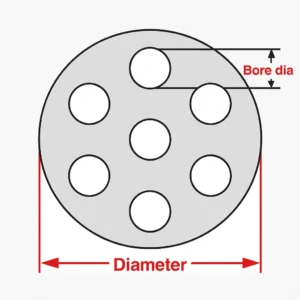

Specifications of Multi-Bore Alumina Tube

| SKU | Diameter(mm) | Bore Diameter(mm) | L(mm) |

| TE-AT-60001 | 1.85 | 0.2 | ≤3000 |

| TE-AT-60002 | 4.5 | 0.8 | ≤3000 |

| TE-AT-60003 | 4.6 | 0.8 | ≤3000 |

| TE-AT-60004 | 4.7 | 0.8 | ≤3000 |

| TE-AT-60005 | 5.8 | 1 | ≤3000 |

| TE-AT-60006 | 6 | 1 | ≤3000 |

| TE-AT-60007 | 7.8 | 1.25 | ≤3000 |

| TE-AT-60008 | 7.8 | 1.1 | ≤3000 |

| TE-AT-60009 | 8 | 0.8 | ≤3000 |

| TE-AT-60010 | 8 | 1.15 | ≤3000 |

| TE-AT-60011 | 8.2 | 1.15 | ≤3000 |

| TE-AT-60012 | 10 | 1.3 | ≤3000 |

| TE-AT-60013 | 15 | 1 | ≤3000 |

| TE-AT-60014 | 20 | 1.5 | ≤3000 |

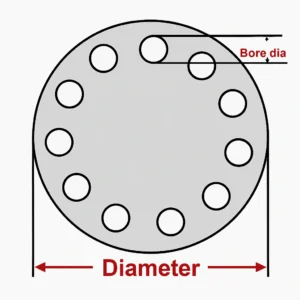

| SKU | Diameter(mm) | Bore Diameter(mm) | L(mm) |

| TE-AT-70015 | 6 | 0.8 | ≤1500 |

| TE-AT-70016 | 6.5 | 0.8 | ≤1500 |

| TE-AT-70017 | 6.5 | 0.9 | ≤1500 |

| TE-AT-70018 | 7 | 0.9 | ≤1500 |

| TE-AT-70019 | 7 | 1 | ≤2500 |

| TE-AT-70020 | 8 | 1.1 | ≤2500 |

| TE-AT-70021 | 14 | 1.5 | ≤2500 |

| TE-AT-70022 | 16 | 1.5 | ≤2500 |

| TE-AT-70023 | 20 | 1.5 | ≤2500 |

Alumina Multi-Hole Ceramic Tube Packaging:

- Each tube is individually packed in foam-lined boxes to prevent breakage.