Pyrolytic Boron Nitride (PBN) crucible is a high-purity evaporation or containment vessel produced not by sintering powder, but by chemical vapor deposition (CVD) of boron and nitrogen gases onto a heated graphite mold. This process forms a fully dense, layered boron nitride structure with a purity typically above 99.99%, and in some grades up to 99.999% (5N).

PBN Crucible Benefits

- Beam & Flux Stability: matched geometry and wall profile enable predictable thermal fields and stable emission.

- Non-Wetting Interior: reduces material adhesion and improves changeover cleanliness across common source chemistries.

- Low Outgassing Surface: supports clean baselines in UHV / high vacuum to protect film purity.

- Anisotropic Thermal Response: PBN’s in-plane conductivity helps tune heat paths for consistent evaporation.

- Repeatable Dimensions: tight-tolerance machining on IDs/ODs, lips, and cones for source-to-source interchange.

Pyrolytic Boron Nitride Crucible Properties

| Property | Unit | Pyrolytic Boron Nitride | Hot Pressed Boron Nitride |

| Purity | 99.99% | 99.50% | |

| Density | g/cm3 | 2.15-2.19 | 1.96-2 |

| Hardness | HV0.5 | 651 | 62 |

| Volume resistivity | Ohm*cm | 2*1014 | 1.2*1014 |

| Dielectric strength | kV/mm | 55 | 76 |

| Maximum working temperature | ℃ | 1000 (air), 2300 (vacuum) | 900 (air), 1850 (vacuum) |

| Bending strength | MPa | 173 (A direction) | 310 |

| Thermal conductivity | W/m*K | 60 (A direction) | 55 |

| Tensile strength | MPa | 112 (A direction) | 110 |

| Thermal expansion coefficient | /℃ | 6*10-7 | 1.8*10-6 |

| Compressive strength | MPa | 154 (A direction) | 120 |

Types of PBN Crucible

1. MBE Crucible

Molecular Beam Epitaxy (MBE) is a mainstream epitaxial growth method for multilayers, heterostructures, superlattices, and high-purity compound films. MBE crucibles are used as source containers in the process.

Key features: It can be made in large sizes (typical maximum diameter about 12 inches and maximum height about 17 inches). It offers high density (up to about 2.20 g/cm³). The material purity reaches ≥99.99%. It shows non-wetting behavior and good dimensional stability.

Typical application: It is mainly used for MBE growth of III–V compound semiconductors.

2. VGF Crucible

The Vertical Gradient Freeze (VGF) technique grows single crystals by solidifying the melt under a controlled vertical temperature gradient. VGF crucibles are matched to that furnace style.

Key features: It supports large sizes (up to about 8 inches in diameter and about 17 inches in height). It provides high density and high purity (≥99.99%). It maintains uniform temperature fields for directional solidification.

Typical application: It is used for growing GaAs and InP single crystals for the semiconductor industry.

3. LEC Crucible

The Liquid Encapsulated Czochralski (LEC) method is suitable for pulling volatile III–V single crystals under a protective encapsulant.

Key features: It accepts large sizes (typical maximum diameter about 12 inches and maximum height about 17 inches). The purity is ≥99.99%. With an encapsulant at high temperature (above ~1500 °C), it suppresses volatile loss and helps maintain stable composition during growth.

Typical application: It is used to grow GaAs, InP, and GaP single crystals and related III–V materials.

4. OLED Crucible

OLED vacuum thermal evaporation requires clean, stable sources; OLED crucibles serve as the primary containers for organic or metal materials during deposition.

Key features: The material purity is typically ≥99.999%. It withstands high temperature, maintains uniform thickness, and offers good anisotropic thermal behavior for stable heating. It has non-wetting and easy-to-clean interiors. It resists chemical attack and does not react with common evaporation materials.

Typical application: It is used as the main source container in OLED and CIGS evaporation processes.

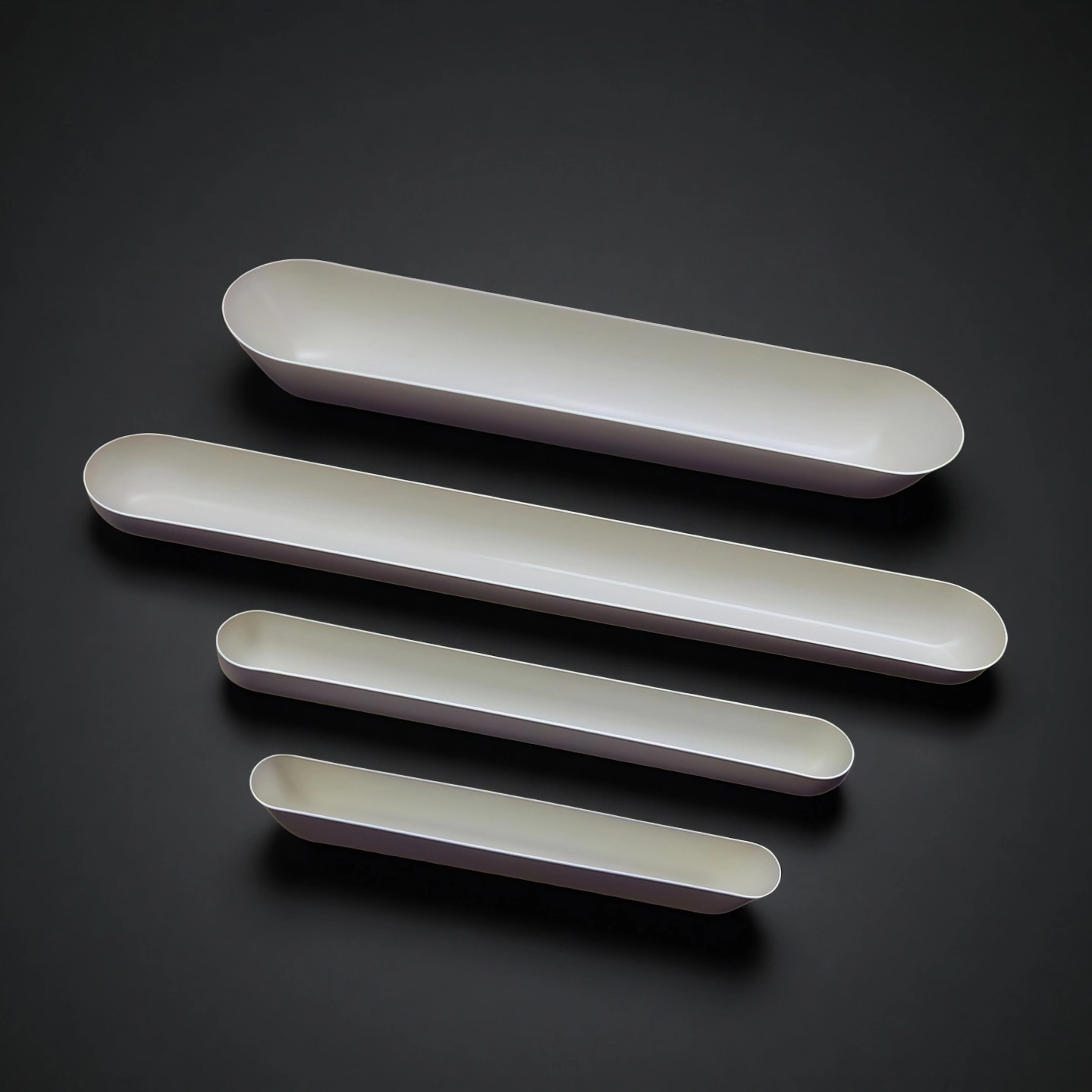

5. PBN Boat

The horizontal directional solidification method uses a multi-zone furnace to create a thermal gradient and control crystal growth; PBN boats are the carriers for the melt in this process.

Key features: It can be made in large formats (maximum diameter about 17 inches). The density can reach about 2.20 g/cm³. The purity is ≥99.99%. It is non-wetting and shows excellent high-temperature performance (up to about 2300 °C in inert atmospheres). It has good oxidation resistance and stable geometry.

Typical application: It is used for horizontal directional solidification of III–V compound crystals.

Pyrolytic Boron Nitride Crucible Specifications

Type 1: VGF Crucible

| VGF Crucible | ||||

| Item NO. | Inner Diameter(inch) | Height(inch) | Thickness(inch) | Purity |

| AAT-PBN-VGF1001 | 2" | 10 " | 0.035" | 99.99% |

| AAT-PBN-VGF1002 | 3" | 10 " | 0.035" | 99.99% |

| AAT-PBN-VGF1003 | 4" | 8 " | 0.035" | 99.99% |

| AAT-PBN-VGF1004 | 5 " | 8 " | 0.04" | 99.99% |

| AAT-PBN-VGF1005 | 6 " | 7 " | 0.04" | 99.99% |

| AAT-PBN-VGF1006 | 8 " | 20 " | 99.99% | |

Type 2: MBE Crucible

| MBE Crucible | ||||

| Item NO. | Inner Diameter(mm) | Lip Diameter(mm) | Height(mm) | Purity |

| AAT-PBN-MBE1001 | 19 | 50 | 59.2 | 99.99% |

| AAT-PBN-MBE1002 | 34 | 51 | 59.9 | 99.99% |

| AAT-PBN-MBE1003 | 32.5 | 51 | 110.3 | 99.99% |

| AAT-PBN-MBE1004 | 44 | 59.9 | 115 | 99.99% |

| AAT-PBN-MBE1005 | 35 | 59.9 | 167 | 99.99% |

| AAT-PBN-MBE1006 | 13 | 27 | 77 | 99.99% |

| AAT-PBN-MBE1007 | 19.7 | 32 | 88.9 | 99.99% |

| AAT-PBN-MBE1008 | 23.6 | 36.8 | 88.9 | 99.99% |

| AAT-PBN-MBE1009 | 23.6 | 36.83 | 30 | 99.99% |

| AAT-PBN-MBE1010 | 18.5 | 36.3 | 83 | 99.99% |

| AAT-PBN-MBE1011 | 20.8 | 36.3 | 83 | 99.99% |

| AAT-PBN-MBE1012 | 20.8 | 36.3 | 141 | 99.99% |

| AAT-PBN-MBE1013 | 38.1 | 54.2 | 108 | 99.99% |

| AAT-PBN-MBE1014 | 37.1 | 54.1 | 108 | 99.99% |

| AAT-PBN-MBE1015 | 10.5 | 17.2 | 26 | 99.99% |

| AAT-PBN-MBE1016 | 16.7 | 28.7 | 77 | 99.99% |

| AAT-PBN-MBE1017 | 38.1 | 53.3 | 89 | 99.99% |

Type 3: OLED Crucible

| OLED Crucible | ||||

| Item NO. | Inner Diameter(mm) | Lip Diameter (mm) | Height(mm) | Purity |

| AAT-PBN-OLED1001 | 55 | 70 | 160 | 99.99% |

| AAT-PBN-OLED1002 | 55 | 82 | 190 | 99.99% |

| AAT-PBN-OLED1003 | 62 | 84 | 186 | 99.99% |

| AAT-PBN-OLED1004 | 61 | 85 | 240 | 99.99% |

| AAT-PBN-OLED1005 | 78 | 115 | 240 | 99.99% |

Type 4: LEC Crucible

| LEC Crucible | ||||

| Item NO. | Inner Diameter(inch) | Height(inch) | Thickness(inch) | Purity |

| AAT-PBN-LEC1001 | 3" | 3" | 0.03" | 99.99% |

| AAT-PBN-LEC1002 | 4" | 4" | 0.035" | 99.99% |

| AAT-PBN-LEC1003 | 5 " | 5 " | 0.035" | 99.99% |

| AAT-PBN-LEC1004 | 6 " | 6 " | 0.04" | 99.99% |

| AAT-PBN-LEC1005 | 7 " | 7 " | 0.04" | 99.99% |

| AAT-PBN-LEC1006 | 8 " | 8 " | 0.04" | 99.99% |

| AAT-PBN-LEC1007 | 14 " | 14 " | 0.08" | 99.99% |

Type 5: PBN Boat

| PBN Boat | ||||

| Item NO. | Length(inch) | Height(inch) | Thickness(inch) | Purity |

| AAT-PBN-ZH1001 | 2"~15" | 0.5"~1" | 0.035"~0.08" | 99.99% |

| AAT-PBN-ZH1002 | 6"~20" | 1" | 0.035"~0.08" | 99.99% |

| AAT-PBN-ZH1003 | 6"~20" | 1.5" | 0.035"~0.08" | 99.99% |

| AAT-PBN-ZH1004 | 6"~20" | 2" | 0.035"~0.08" | 99.99% |

Pyrolytic Boron Nitride (PBN) Crucible Packaging

- Each BN liner is individually wrapped in soft foam or EPE padding to protect edges

- Placed in firm cardboard or plywood box with fixed positioning to prevent movement