Point bottom alumina crucible is a high-purity ceramic vessel made from alumina (Al₂O₃) that has a tapered or conical bottom ending in a point.Pointy alumina crucibles streamline small-volume fusion, evaporation, and calcination while reducing sample loss.

Benefits of Point Bottom Alumina Crucibles

Pointy alumina crucibles combine geometry and dense Al₂O₃ material for efficient, clean handling of high-temperature reactions.

- Focused pour-out: The tapered apex minimizes residue and ensures clean transfer.

- High-temperature resistance: Withstands continuous operation up to 1,680–1,730°C.(99%-99.7% alumina purity)

- Chemical durability: Stable against most acids and alkalis at room conditions.

- Geometry advantage: Pointy design improves recovery of valuable materials.

Alumina Crucible Pointed Bottom Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Point Bottom Alumina Crucible Specifications

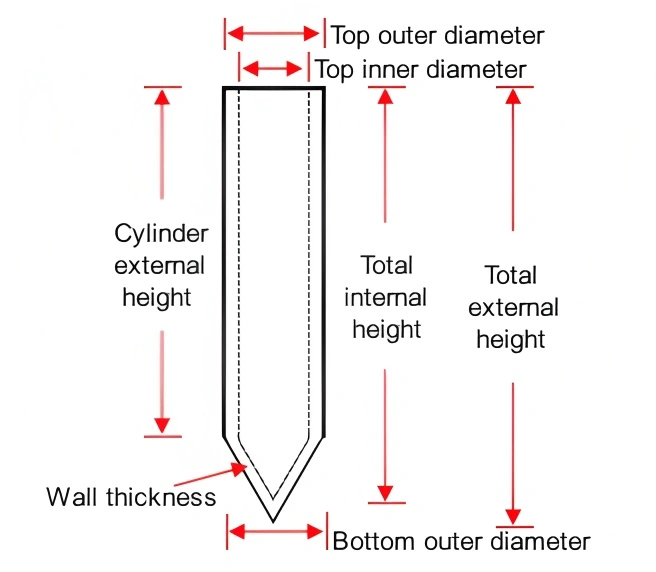

| Item NO. | Cylinder external height (mm) | Total external height (mm) | Total internal height (mm) | Bottom outer diameter (mm) | Top inner diameter (mm) | Top outer diameter (mm) | Wall thickness (mm) |

| TE-SS-001 | 70 | 81.3 | 69.5 | 10.4 | 7.7 | 10.9 | 1.6 |

| TE-SS-002 | 122 | 138 | 131 | 13.1 | 10.3 | 13.6 | 1.5 |

| TE-SS-003 | 63.5 | 77.6 | 62.8 | 18 | 14.3 | 18.2 | 1.8 |

| TE-SS-004 | 90 | 104 | 89 | 14.2 | 11 | 14.5 | 1.6 |

| TE-SS-005 | 76.6 | 97.8 | 76.3 | 24 | 20.7 | 24.4 | 1.8 |

| TE-SS-006 | 124 | 138 | 124 | 17.8 | 13.1 | 17.8 | 2.2 |

| TE-SS-007 | 113.5 | 129.5 | 112.3 | 24.5 | 20.7 | 25.2 | 2.1 |

| TE-SS-008 | 24 | 34 | 23 | 10 | 6 | 10 | 2 |

| TE-SS-009 | 70 | 85 | 69.5 | 15 | 12 | 15 | 1.5 |

| TE-SS-010 | 66 | 77 | 66 | 12 | 9 | 12 | 1.5 |

| TE-SS-011 | 80 | 94 | 79.5 | 9.5 | 7.5 | 9.5 | 1 |

| TE-SS-012 | 72 | 102 | 71 | 10 | 7.2 | 10 | 1.4 |

| TE-SS-013 | 45 | 60 | 45 | 12.5 | 9.7 | 12.5 | 1.4 |

Pointy Alumina Crucibles Packaging

- Each crucible is cushioned individually to prevent breakage.

- Outer carton reinforced with foam inserts for safe global shipping.

- Optional accessories include lids, ceramic boats, support rings, and crucible tongs.