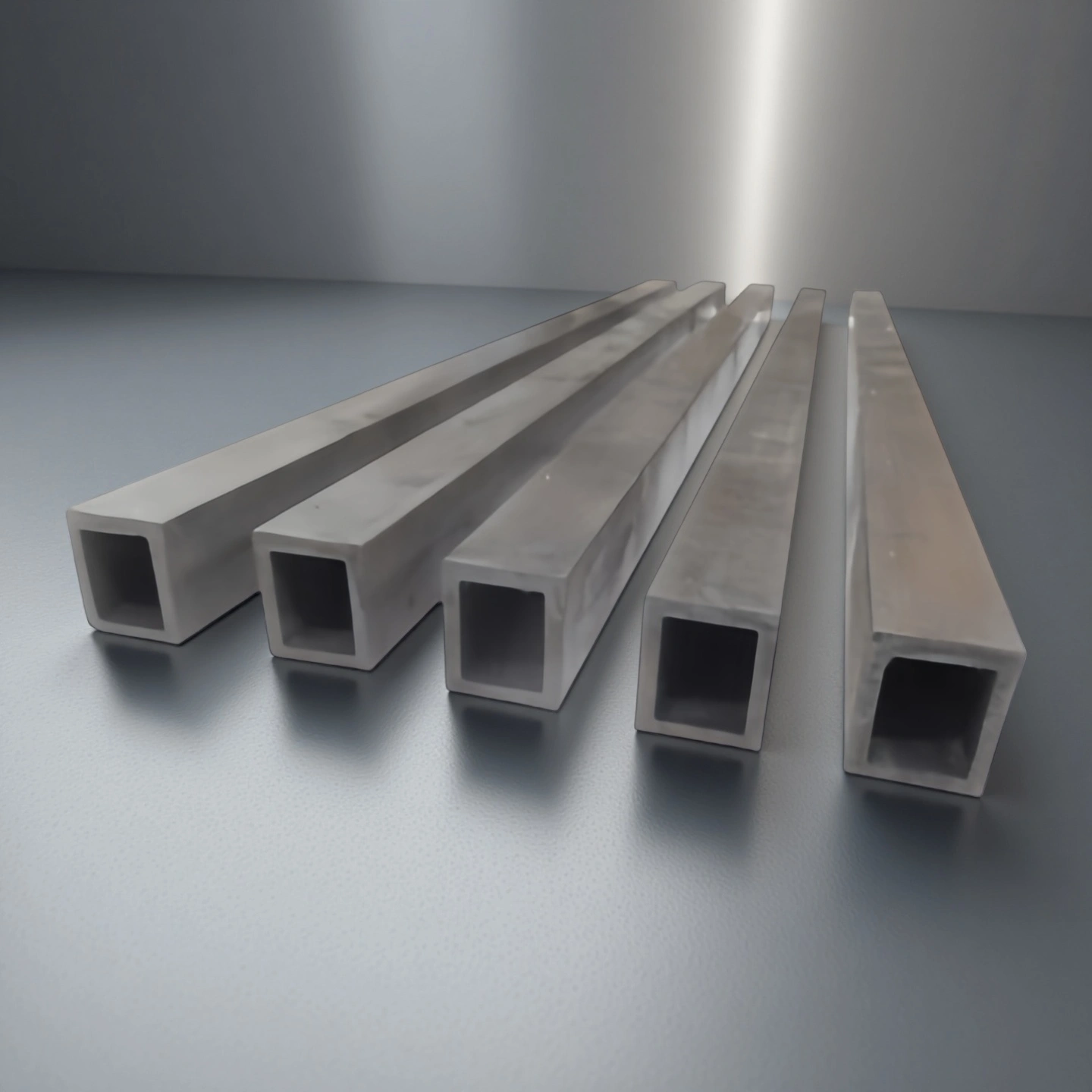

ADCERAX® SiC Square Beam is an advanced structural component designed for high-temperature kiln applications, particularly in tunnel, shuttle, and roller kilns. This product offers superior mechanical strength, thermal shock resistance, and oxidation stability, ensuring long-lasting performance even under the most demanding conditions. Ideal for industries such as sanitaryware and electrical porcelain, the SiC Square Beam contributes to energy efficiency and reduced downtime, making it an essential solution for high-performance kiln operations.

Core Functional Advantages of the ADCERAX® SiC Square Beam in Kiln Operations

-

High-Temperature Mechanical Strength

• SiC Square Beam maintains exceptional load-bearing stability under continuous furnace temperatures, supported by a high-temperature flexural strength exceeding 45–55 MPa at 1300–1380°C. This enables stable support for heavy sanitaryware and electrical porcelain products during long firing cycles.

• Its structural integrity remains consistent throughout extended thermal exposure, with strength degradation rates typically below 5–8% after 100 firing cycles. This ensures predictable mechanical performance and minimizes the risk of mid-cycle deformation.

• Longitudinal bending resistance is significantly improved by the RBSC/SiSiC matrix, which provides a room-temperature flexural strength of 240–300 MPa. This characteristic supports reliable kiln car configurations in demanding industrial environments.

-

Thermal Shock Resistance

• SiC Square Beam delivers strong resistance to rapid temperature changes, achieving thermal shock performance that withstands ΔT > 250°C without structural cracking. This behavior is critical for shuttle kilns and intermittent firing systems.

• The material's low thermal expansion coefficient, typically 4.5 × 10⁻⁶ /K, minimizes internal stress and prevents dimensional distortion during fast heating or cooling transitions. This stabilizes the overall kiln structure under fluctuating thermal conditions.

• High thermal conductivity values within the range of 25–35 W/m·K allow rapid heat dissipation, effectively reducing localized thermal gradients and improving firing uniformity for sensitive ceramic bodies.

-

Structural Stability Under Heavy Load

• SiC Square Beam offers extremely high load capacity, with compressive strength typically reaching 1800–2000 MPa at room temperature, enabling safe support of dense ceramic loads in multi-layer kiln car configurations.

• Deflection under load is minimal—measured bending displacement often remains below 1–2 mm after repeated firing cycles—ensuring precise alignment of kiln furniture and reducing mechanical stress on product layers.

• Static and dynamic load tests indicate that long-span beam sections retain more than 85–90% of their original stiffness after repeated heating cycles, positioning the design as a stable backbone of modern kiln cars.

Technical Specifications of SiC Square Beam

ADCERAX® SiC Square Beam exhibits a stable Si–SiC composite microstructure with high thermal conductivity, low expansion behavior, and long-term strength retention under continuous firing conditions, making it suitable for demanding kiln environments across sanitaryware, electrical porcelain, and advanced ceramic production.

| Property |

Specification |

| Material System |

RBSC / SiSiC |

| Density |

2.60–2.70 g/cm³ |

| Open Porosity |

< 15% |

| Max Working Temperature |

1380 °C (continuous) |

| Flexural Strength (RT) |

> 220 MPa |

| Flexural Strength (1300 °C) |

45–55 MPa |

| Thermal Conductivity |

25–35 W/m·K |

| Thermal Expansion (25–1000 °C) |

4.0–4.5 ×10⁻⁶ /K |

| Hardness |

Mohs 9–9.5 |

| Oxidation Weight Gain |

< 0.2% after 100 h at 1200 °C |

| Elastic Modulus |

> 250 GPa |

| Acid / Alkali Resistance |

Stable in most oxidizing and neutral atmospheres |

| Microstructure |

Fine SiC skeleton with Si infiltration |

| Surface Finish |

As-fired, dense, low-defect |

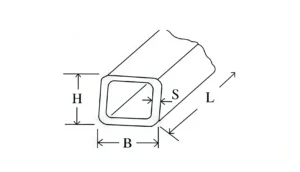

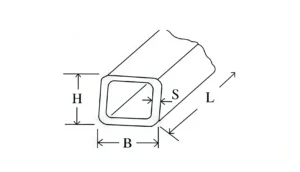

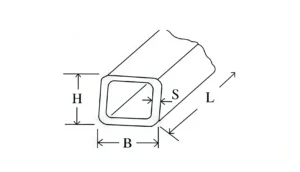

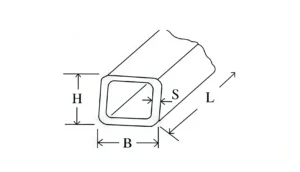

Dimensions of Silicon SiC Square Beam

| Beam Bearing Capacity Table |

Size of Section

(mm) |

Wall Thickness

(mm) |

Concentrated Loading

(Kg) |

Uniformly Distributed Loading

(Kg) |

| B side |

H side |

B side |

H side |

B side |

H side |

| 30 |

30 |

5 |

74 |

74 |

147 |

147 |

| 30 |

40 |

5 |

117 |

95 |

235 |

190 |

| 40 |

40 |

5 |

149 |

149 |

298 |

298 |

| 50 |

50 |

6 |

283 |

283 |

567 |

567 |

| 50 |

60 |

6 |

374 |

331 |

748 |

662 |

| 50 |

70 |

6 |

473 |

379 |

946 |

757 |

| 60 |

60 |

7 |

481 |

481 |

962 |

962 |

| 80 |

80 |

7 |

935 |

935 |

1869 |

1869 |

| 100 |

100 |

8 |

1708 |

1708 |

3416 |

3416 |

| 110 |

110 |

10 |

2498 |

2498 |

4997 |

4997 |

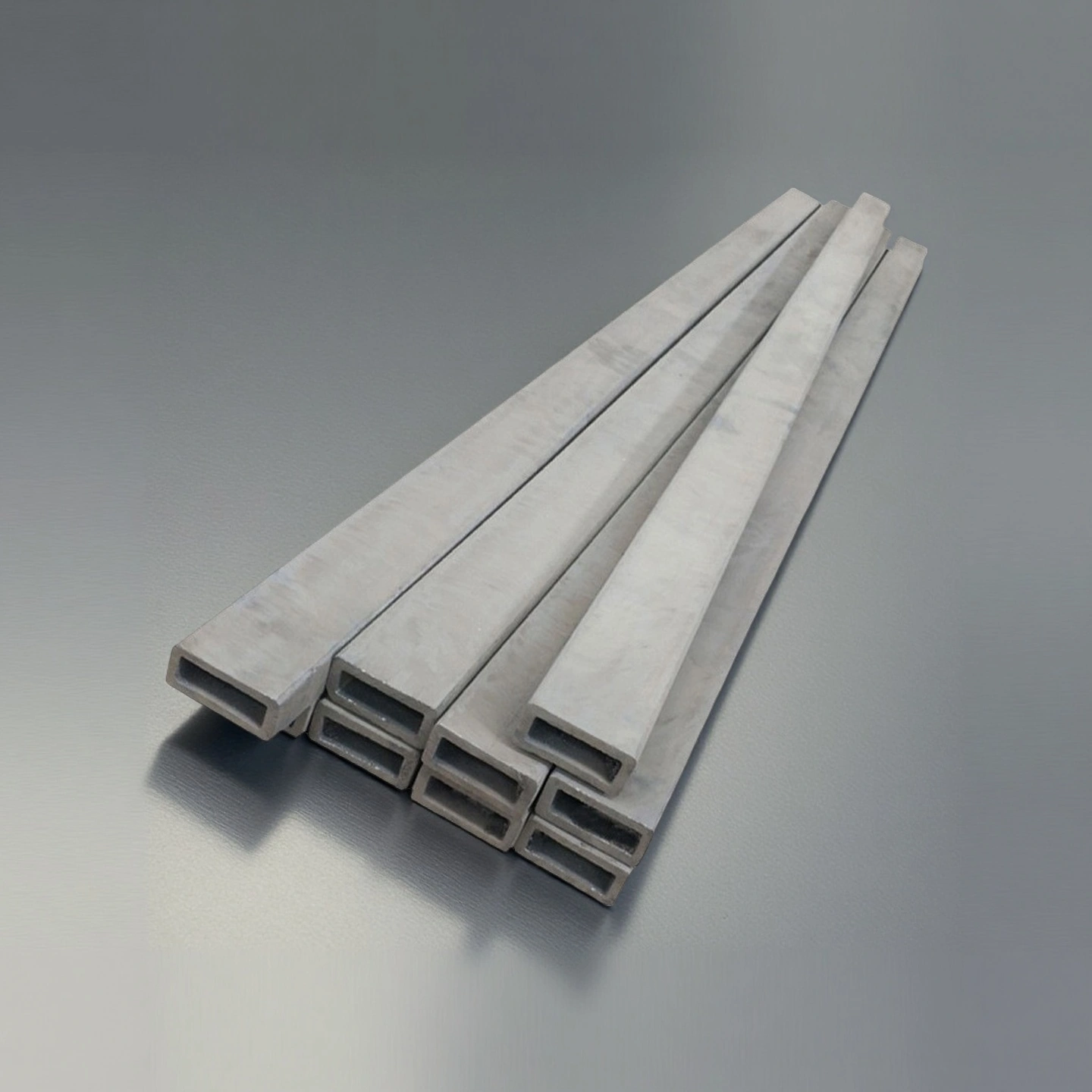

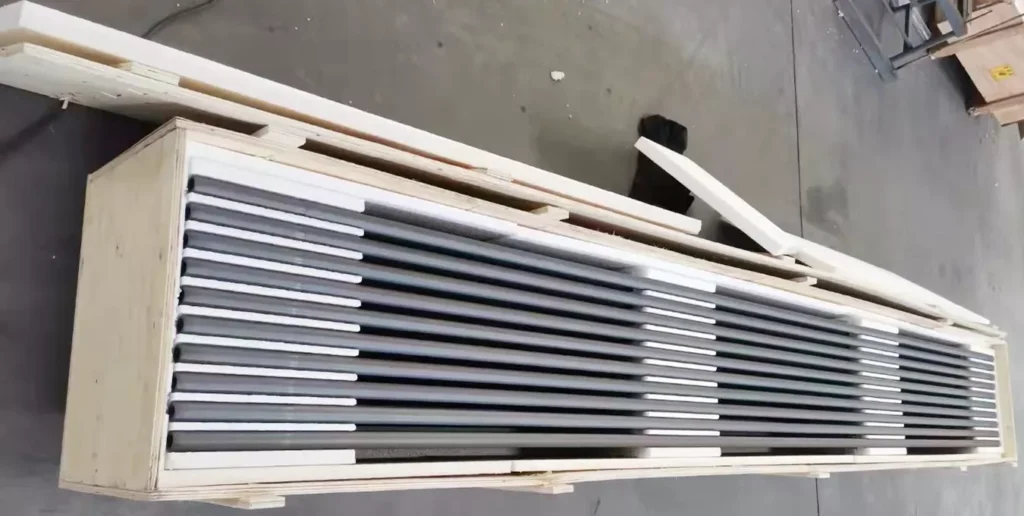

Packaging Overview for SiC Square Beam

SiC Square Beam is packaged in reinforced wooden crates with layered internal cushioning to prevent impact and vibration during transport. Each beam is separated with protective padding to avoid surface friction and ensure stable alignment throughout handling. The crate structure is optimized for long-distance export shipping, maintaining product integrity from factory dispatch to kiln installation.

Overcoming Industry-Specific Challenges with ADCERAX® SiC Square Beam

ADCERAX® SiC Square Beam is the ideal solution for industrial applications requiring high temperature, strength, and stability. With its superior mechanical and thermal properties, SiC Square Beam effectively solves performance issues across industries such as sanitaryware, electrical porcelain, and specialty ceramics. Designed to support demanding kiln environments, ADCERAX® delivers enhanced operational reliability, energy savings, and longer service life, addressing common challenges in high-temperature kiln operations.

-

Enhancing Kiln Efficiency in Sanitaryware Production

✅Key Advantages

1. Reduced Temperature Gradient Across Kiln Load

In sanitaryware tunnel kilns using ADCERAX® SiC Square Beam, typical temperature variation across the car can be reduced from about ±15–25 °C down to ±5–8 °C. This tighter control directly lowers warpage risk on large pieces and improves dimensional consistency across full car loads.

2. Lower Fuel Consumption per Fired Piece

Thanks to thermal conductivity in the range of 25–35 W/m·K, SiC Square Beam improves heat transfer and shortens soak times in the 1200–1280 °C range. Field data from comparable sanitaryware lines indicate fuel usage per piece can be cut by 10–18%, with no loss of firing quality.

3. Reduced Scrap Rate on Large Sanitary Units

By limiting beam deformation and maintaining a stable support plane, SiC Square Beam reduces differential shrinkage between supports and loaded products. In practice, reject rates for large toilets and tanks can fall from 8–10% to around 3–5%, especially on lines previously constrained by temperature imbalance and unstable supports.

✅ ️Problem Solved

A sanitaryware plant operating a 120 m tunnel kiln at 1220–1250 °C struggled with temperature gradients of ±20 °C, leading to an average scrap rate of 9% on large-format toilets and tanks. After replacing traditional refractory beams with ADCERAX® SiC Square Beam on all kiln cars, measured gradients decreased to approximately ±7 °C across the working width. Within three months of stable operation, the reject rate on heavy sanitary units dropped to 4%, and specific fuel consumption per fired piece improved by about 12%. The combined effect allowed the plant to recover the beam investment in less than 12 months, while simultaneously improving capacity stability and glaze quality.

-

Improving Stability in Electrical Porcelain Kilns

✅Key Advantages

1. High-Load Support Without Long-Term Creep

Electrical porcelain insulators can impose concentrated loads exceeding 150–250 kg per setting on kiln cars during firing at 1250–1350 °C. ADCERAX® SiC Square Beam maintains high-temperature flexural strength in the 45–55 MPa range, limiting long-span deflection to only 1–2 mm after repeated cycles and preventing misalignment of tall insulator bodies.

2. Oxidation-Stable Support in Oxygen-Rich Atmospheres

In oxy-rich firing conditions, low-grade beams tend to powder and weaken after a few hundred hours of exposure. SiC Square Beam shows oxidation weight gain typically below 0.3–0.5% after 500 h at 1200 °C, retaining >90% of its initial strength and preserving the flatness needed for precision electrical porcelain firing.

3. Extended Service Life Under Heavy-Duty Firing Schedules

Electrical porcelain kilns often run 300–330 days per year, with limited shutdown windows for maintenance. Under these conditions, SiC Square Beam can deliver a service life 2–3× longer than traditional refractory beams, significantly reducing unplanned replacements and associated kiln downtime.

✅ ️Problem Solved

An electrical porcelain manufacturer firing high-voltage post insulators at 1280–1300 °C experienced progressive beam creep, with conventional beams sagging by 4–6 mm over 18 months. This deformation forced extra grinding operations and contributed to a 6% failure rate at final dimensional inspection. After upgrading the kiln car support system to ADCERAX® SiC Square Beam, measured sag over comparable spans remained within 1–2 mm after a full year of operation. Dimensional rejection on finished insulators fell to about 2–3%, and beam replacement intervals were extended from roughly 18 months to more than 4 years, cutting maintenance-related downtime by over 40% on that line.

-

Supporting High-Demand Specialty Ceramic Kilns

✅Key Advantages

1. Reliable Performance Under Fast Heating Profiles

Specialty ceramic kilns for microcrystalline glass and engineered oxides often run ramp rates of 5–8 °C/min, which severely stress conventional supports. ADCERAX® SiC Square Beam, with a thermal expansion coefficient around 4.0–4.5 ×10⁻⁶ /K, tolerates repeated rapid ramps without cracking, maintaining structural integrity through hundreds of fast-fire cycles.

2. Stable Support for Dense and Large-Format Loads

Refractory bodies and large oxide ceramic plates can reach bulk densities of 2.8–3.0 g/cm³ and impose high distributed loads during sintering. With room-temperature flexural strength above 220 MPa and high stiffness, SiC Square Beam provides a rigid platform that minimizes bending under these dense loads, helping preserve flatness and microstructural consistency.

3. Improved Yield in Wide-Chamber Kilns

In wide-chamber specialty kilns, temperature gradients of 20–30 °C across the span can cause uneven microstructure and localized cracking. By enhancing lateral heat transfer and reducing hot–cold zones, SiC Square Beam helps narrow effective temperature spread to around ±8–10 °C, which can raise first-pass yield on critical products by 5–10 percentage points.

✅ ️Problem Solved

A producer of microcrystalline glass panels operated a wide-chamber kiln with aggressive firing curves, experiencing frequent beam cracking and panel warpage near the chamber edges. Temperature mapping showed lateral gradients close to 25–28 °C, and overall first-pass yield on large panels remained stuck at about 82%. After retrofitting the key load-bearing rows with ADCERAX® SiC Square Beam, the operator recorded a reduced gradient near 10–12 °C under identical firing profiles. Within several production campaigns, first-pass yield on large panels climbed to 90–92%, and beam breakage incidents dropped to near zero, stabilizing throughput while preserving the fast-cycle process window required by the specialty ceramics line.

Comprehensive User Guide for ADCERAX® SiC Square Beam

To ensure stable kiln performance and extend operational lifespan, the SiC Square Beam requires proper installation, loading control, and environmental management throughout firing cycles. This guide outlines essential procedures and precautions that help users maintain consistent support integrity, reduce deformation risks, and achieve predictable thermal behavior in long-cycle industrial kilns.

-

Installation and Alignment Requirements for SiC Square Beam

1. Ensure Level Support Points

Proper installation begins with verifying that all kiln car contact surfaces are uniform within ±1 mm across the span. This minimizes concentrated stress and prevents bending during firing. Maintaining level load distribution ensures predictable deformation control over repeated cycles.

2. Maintain Controlled Thermal Expansion Gaps

A thermal allowance gap should be preserved between beams and posts to accommodate expansion at 1200–1380 °C. Without this buffer, compression forces may accumulate and induce micro-cracks at the beam ends. Consistent thermal spacing protects the beam’s structural stability during long firing periods.

3. Confirm Secure but Non-Restrictive Positioning

Beam seating must be firm enough to avoid vibration yet loose enough to avoid clamping under thermal growth. Excessively tight seating may generate edge stress as temperatures rise. A balanced interface ensures smooth thermal response throughout each firing cycle.

-

Loading and Weight Distribution Practices

1. Distribute Weight Evenly Across the Kiln Car

Heavy sanitaryware or electrical porcelain should be arranged so that no single point exceeds 40–60% of the beam’s rated load zone. Uneven distribution accelerates creep and reduces lifespan. Balanced loading directly supports product dimensional accuracy.

2. Avoid Point-Load Contact on Beam Surfaces

Use setters, supports, or flat plates to spread contact pressure across a broader area, limiting localized forces that may exceed critical bending thresholds. Point loads introduce sharp stress gradients that compromise long-term rigidity. Proper load spreading preserves mechanical integrity.

3. Monitor Load Profiles During Batch Changes

Switching between lighter and heavier product types may alter the load center, affecting beam deflection behavior. Periodic checks can identify deviations early before they propagate into structural distortion. Stable load profiles reduce kiln cycle variability and firing defects.

-

Kiln Atmosphere and Thermal Management Guidelines

1. Maintain Stable Oxygen Levels Under High Temperatures

Exposure to fluctuating oxygen content at >1100 °C may influence oxidation patterns on conventional supports, but SiC beams remain stable under controlled atmospheres. Continuous monitoring reduces surface reactions that could affect overall kiln balance. Stable atmospheres enhance predictable heat transfer.

2. Adopt Controlled Heating and Cooling Curves

Rapid changes exceeding 5–8 °C/min may introduce thermal shock, stressing both the beam and supported ware. Smooth gradient control preserves beam microstructure and reduces crack initiation. Consistent ramp profiles support uniform sintering quality.

3. Minimize Temperature Gradients in Wide Kiln Chambers

Horizontal differences of >20–25 °C can impose asymmetric expansion forces along the beam length. Reducing these gradients contributes to better flatness retention during the firing cycle. Uniform temperature fields support higher product yield.

-

Maintenance, Inspection, and Handling Instructions

1. Inspect Beam Straightness on a Regular Cycle

Periodic checks every 4–6 weeks help detect early deviation trends, especially in high-load kilns. Identifying minor changes allows corrective action before significant warpage occurs. Routine straightness control maintains consistent support geometry.

2. Clean Residues and Debris After Firing

Accumulated glaze droplets or refractory dust can create thermal hot spots during subsequent cycles. Removing foreign material avoids localized overheating that stresses the beam surface. Clean contact zones improve thermal uniformity.

3. Handle and Store Beams With Protective Spacing

During off-kiln storage, leave fully cushioned gaps between beams to prevent friction marks or edge impacts. SiC beams are rigid but should be protected from sharp mechanical shocks. Proper storage contributes directly to long service life.

![]()