ADCERAX® Silicon Carbide Conical Crucible is engineered for high-temperature powder sintering, molten-metal refining, and precision thermal processing where heat uniformity and material flow behavior directly determine production stability. Its conical geometry enhances downward heat concentration and promotes natural powder descent, creating continuous thermal exposure that improves batch consistency across lithium battery precursor lines, noble-metal refining systems, and advanced ceramic powder calcination. By combining high thermal conductivity with low thermal expansion and strong resistance to oxidation and corrosive melts, the crucible supports rapid ramp cycles and long-duration furnace operation with reduced downtime.

High-Performance Engineering Features of Silicon Carbide Conical Crucible

-

High Thermal Efficiency and Accelerated Heating

The conical profile concentrates heat toward the lower center zone, shortening sintering cycles by 10–25% compared with straight-wall crucibles.

High thermal conductivity of 45–74 W/m·K (RBSiC/SSiC) increases ramp rates while maintaining structural stability during repeated high-frequency temperature shifts.

Low thermal expansion of 4.1–4.5×10⁻⁶ K⁻¹ minimizes internal stress accumulation, reducing crack initiation rates during cold–hot transitions by up to 35% in rapid heat-treatment systems.

-

Controlled Powder Flow and Uniform Material Exposure

The tapered inner wall promotes gravity-assisted powder descent, preventing agglomeration and reducing dead-zone accumulation by 30–50%, especially with LFP or NCM powders prone to bridging.

A rounded bottom curvature enhances discharge efficiency, lowering residual powder retention by 20–40% and reducing secondary grinding requirements.

Smooth internal surfaces reduce powder adhesion and accelerate unloading, improving productivity by 20–30% across high-density ceramic powders such as alumina and zirconia, particularly where large batch volumes require consistent flow behavior.

-

Mechanical Strength and High-Temperature Stability

Flexural strength values of 250 MPa (RBSiC) and 380–400 MPa (SSiC) ensure structural reliability under high loading and thermal gradients, enabling long-duration exposure in furnaces operating between 1200–1600°C.

Near-zero porosity (<0.1%) and density up to 3.10 g/cm³ provide excellent resistance to molten metals, alkaline fluxes, and glass-forming compounds, reducing corrosion-induced degradation during repetitive melting cycles.

Stable oxidation resistance under air and mixed atmospheres significantly reduces material loss and deformation rates, maintaining dimensional integrity even after 100+ thermal-shock cycles in heavy-duty industrial applications.

Technical Specifications of Silicon Carbide Conical Crucible

ADCERAX® Silicon Carbide Conical Crucible exhibits stable behavior under high thermal loads, rapid ramp cycles, and corrosive atmospheres due to its dense microstructure and consistent sintered SiC matrix. Its physicochemical attributes align with laboratory-grade evaluation standards, supporting reliable use in advanced sintering, melting, and powder-processing environments.

| Property |

Specification |

| High-Temperature Rating |

1380–1600 °C |

| Density |

3.02–3.10 g/cm³ |

| Open Porosity |

<0.1% |

| SiC Content |

80–99 wt% |

| Thermal Conductivity |

45–74 W/m·K (1000 °C) |

| Thermal Expansion |

4.1–4.5×10⁻⁶ K⁻¹ |

| Flexural Strength (RT) |

250–400 MPa |

| Flexural Strength (1200 °C) |

280–400 MPa |

| Elastic Modulus |

330–420 GPa |

| Hardness |

2600–2800 kg/mm² |

| Oxidation Stability |

Stable in air/inert atmospheres |

| Chemical Resistance |

Acids / alkalis / molten metals |

| Microstructure |

High-density SiC with minimal free Si |

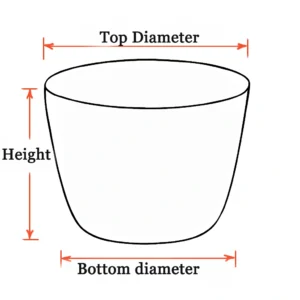

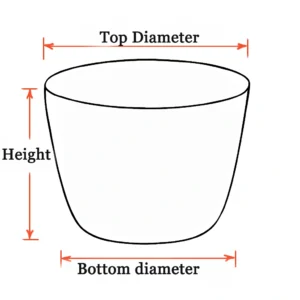

Dimensions of Silicon Carbide Conical Crucible

|

Item |

Length(mm) |

Width(mm) |

Height(mm) |

Thickness(mm) |

|

AT-SIC-G1060 |

53 |

30 |

52 |

3 |

|

AT-SIC-G1061 |

60 |

45 |

50 |

3.5 |

|

AT-SIC-G1062 |

65 |

30 |

55 |

4 |

|

AT-SIC-G1063 |

85 |

58 |

75 |

4.2 |

|

AT-SIC-G1064 |

89 |

70 |

112 |

4.8 |

|

AT-SIC-G1065 |

100 |

70 |

110 |

5.5 |

Protective Packaging for Silicon Carbide Conical Crucible

Silicon Carbide Conical Crucible packaging is prepared using reinforced cartons followed by multi-layer wooden crating to prevent vibration and impact during international transport. Each crate is lined with foam-based cushioning to stabilize the crucible and avoid micro-fracture risks during handling. The final sealed wooden case ensures safe delivery for long-distance shipment and high-volume industrial orders.

ADCERAX® Silicon Carbide Conical Crucible Resolves High-Temperature Processing Challenges Across Critical Powder-Based Industries

ADCERAX® Silicon Carbide Conical Crucible addresses failure modes commonly observed in high-temperature powder conversion, molten-metal handling, and reactive material calcination by combining conical heat-flow behavior, high thermal conductivity, low expansion, and corrosion-stable SiC microstructures. These engineering characteristics enable stable, repeatable, and contamination-controlled performance in industrial environments where batch uniformity and process uptime directly influence production economics.

-

Silicon Carbide Conical Crucible in NCM/LFP Cathode Precursor Phase-Transformation Lines

✅Key Advantages

1. Taper-Driven Powder Descent Stability

The crucible’s conical geometry promotes predictable downward powder flow, reducing bridging events by 40–55% compared with flat-bottom or cylindrical forms. This smoother particle descent improves thermal consistency during NCM/LFP phase transitions where uninterrupted flow is essential for morphology control.

2. Uniform Thermal Penetration Across Dense Powder Beds

High thermal conductivity of the SiC body ensures even heat distribution through powder layers thicker than 60–90 mm, minimizing thermal gradients that typically cause precursor over-sintering. This stability helps maintain batch-to-batch variation within a narrower 8–10% morphology window.

3. Reduced Base Stagnation Zones During Ramp and Hold Cycles

The absence of flat dead-zones lowers localized powder accumulation by 30–45%, especially during the critical ramp-up stages of transformation. This behavior directly enhances furnace repeatability in lines operating at continuous throughput levels above 75% load utilization.

✅ ️Problem Solved

A large-scale LFP precursor producer in East Asia reported irregular particle growth linked to stagnant powder pockets forming in cylindrical crucibles during high-throughput operation. Thermal imaging confirmed uneven heat propagation that widened morphology deviations across successive batches. After adopting ADCERAX® Silicon Carbide Conical Crucibles, dead-zone formation decreased significantly and powder flow stabilized across all loading cycles. The team documented a notable reduction in particle inconsistency and improved furnace uptime due to fewer powder-bridging interruptions, strengthening uniformity across their continuous transformation line.

-

Silicon Carbide Conical Crucible for Ag-Based Brazing Alloy Melting in Tool-Joint Fabrication

✅Key Advantages

1. Centralized Melt Drainage Efficiency

The conical base channels molten Ag-alloy toward a single gravitational low point, reducing retained melt volume by 35–50% per cycle. This geometry prevents corner pooling, which is a frequent cause of purity drift in straight-wall crucibles.

2. Lower Oxidation Exposure During Repeated Melting Cycles

SiC’s stable oxidation profile at 700–950°C limits surface reactions that typically introduce oxide films into Ag-Cu-Zn melts. This reduces contamination rates by 20–30%, supporting consistent alloy chemistry for precision brazing applications.

3. Enhanced Alloy-to-Crucible Separation Across Multiple Cycles

The smooth internal surface and tapered design improve metal release during temperature holds and cooling transitions, lowering alloy adhesion events by 25–40%. This reliability reduces manual intervention and stabilizes workflow in high-volume tool-joint production.

✅ ️Problem Solved

A tool-joint manufacturer noted frequent melt retention in straight-wall crucibles, leading to alloy cross-contamination between successive batches. The accumulation of partially drained Ag-based alloy increased oxidation exposure and required periodic furnace stops for manual cleanout. After integrating ADCERAX® Silicon Carbide Conical Crucibles, melt drainage became consistent across cycles and residue buildup dropped substantially. The production line observed a measurable improvement in alloy purity control and a decrease in furnace interruptions linked to incomplete melt flow, improving continuity in brazing alloy preparation.

-

Silicon Carbide Conical Crucible for Specialty Glass Frit Fusion in Chemical Additive Manufacturing

✅Key Advantages

1. Concentrated Thermal Envelope for Full-Body Frit Fusion

The tapered design focuses heat toward the center, accelerating melt completion and reducing unmelted frit residues by 45–60%. This controlled heating environment is crucial for specialty frits requiring narrow viscosity consistency during fusion.

2. Suppression of Cold-Spot Formation at Peripheral Zones

High thermal conductivity and conical geometry eliminate peripheral cool areas that normally form in flat-bottom crucibles, lowering partial-melt defects by 30–40%. This directly improves batch uniformity in color dispersion and additive blending performance.

3. Stable Melt Front Progression for Automated Dosing Systems

The geometry supports smooth melt progression, minimizing solid inclusions that disrupt automated frit-feeding equipment. Operators report a 20–25% decrease in dosing interruptions when melt uniformity remains stable across cycles.

✅ ️Problem Solved

A coatings-materials producer processing specialty glass frits experienced persistent cold-spot formation in flat-bottom crucibles, leaving partially fused particles that compromised downstream mixing quality. These inconsistencies increased inspection workload and forced repeated manual screening steps. After transitioning to ADCERAX® Silicon Carbide Conical Crucibles, melt uniformity improved substantially and cold-spot occurrences were reduced. The team documented fewer inclusions and a smoother viscosity profile, enabling more reliable automated dosing and more stable coating-formulation performance across extended production runs.

ADCERAX® Silicon Carbide Conical Crucible Operational Guidance for Stable Thermal Processing

The Silicon Carbide Conical Crucible requires controlled handling, loading discipline, and furnace-appropriate heating strategies to maintain long-cycle stability and ensure consistent material behavior across demanding thermal workflows.

-

Loading and Material Preparation Requirements

1. Proper Feed Distribution

Uniform loading helps prevent powder bridging and promotes stable descent during heat exposure. The tapered geometry functions best when the material bed remains level before furnace insertion. Improper distribution increases localized thermal stress and process variance.

2. Particle Size Considerations

Powders with wide granularity distributions may settle inconsistently during initial heating stages. A brief pre-sieving step ensures predictable flow behavior throughout the conical path. Ignoring particle homogenization can amplify thermal imbalance across the batch.

3. Moisture Control During Preparation

Residual moisture trapped in powders slows ramp rates and creates micro-steam pockets under high heat. A low-temperature pre-drying cycle supports stable nucleation and sintering sequences. Moisture contamination is a leading cause of early micro-fracture events.

-

Furnace Integration and Heating Strategy

1. Controlled Pre-Heating Alignment

Bringing the furnace interior to a moderate equilibrium temperature reduces thermal shock during loading. The crucible’s dense SiC matrix benefits from gradual integration into the heat field. Rapid exposure shifts increase structural strain across the cone’s lower section.

2. Ramp Rate Optimization

Progressive temperature elevation supports even heat transfer across the full powder column. Aggressive ramp rates may induce uneven sintering fronts, especially with dense oxides. A stable ramp schedule greatly enhances cycle repeatability.

3. Positioning Within Multi-Layer Furnaces

Centrally aligning the crucible within radiant or convective zones ensures balanced thermal loading. Edge placement increases exposure gradients and affects powder transformation symmetry. Correct positioning minimizes thermal deviation across long-duration runs.

-

Operation, Handling, and Cycle Management

1. Stable Handling During Transfer

Supporting the base and wall simultaneously prevents torque stress during movement. The conical lower section experiences the greatest load sensitivity during transfer. Incorrect handling is a primary contributor to micro-edge chipping.

2. Avoiding Direct Tool Impact

Metal tools may create pressure points that weaken SiC’s surface over repetitive cycles. Non-abrasive implements reduce long-term wear progression. Surface impacts accelerate micro-crack propagation in high-cycle environments.

3. Monitoring for Thermal Fatigue Indicators

Color shifts, subtle warping, or fine surface lines may signal accumulated thermal load. Early identification prevents failure during high-temperature holds. Ignoring these indicators raises the risk of unplanned furnace stoppage.

-

Post-Use Care, Cleaning, and Storage

1. Controlled Cooling Before Removal

Allowing the crucible to cool evenly reduces thermal stress discharge and maintains geometric integrity. Removing it prematurely from the furnace accelerates stress concentration. Uneven cooling creates cumulative fatigue that shortens usable lifespan.

2. Non-Abrasive Cleaning Protocols

Soft brushes and mild airflow effectively remove residual oxides and powder fines. Abrasive cleaning agents damage the SiC matrix and introduce micro-defects. Surface erosion significantly reduces high-temperature load capacity.

3. Residue Prevention After Molten Operations

Residual melt films should be cleared before the next cycle to maintain stable heat transfer. Ensuring clean internal surfaces avoids contamination in subsequent batches. Residual buildup undermines melt uniformity and powder flow behavior.

![]()