ADCERAX® Silicon Carbide Sealing Ring is engineered for demanding industrial fluid-handling systems where corrosion, abrasion, and temperature fluctuations must be controlled with stable seal-face performance. Its dense microstructure, high hardness, and consistent thermal behavior support long operating cycles in chemical processing, refinery circulation, paper-pulp transfer, seawater handling, and abrasive slurry transport. These characteristics allow the sealing interface to maintain reliable surface integrity under varied process conditions, reducing leakage events and extending equipment uptime across continuous industrial duty.

Functional Properties Supporting the Silicon Carbide Sealing Ring in Industrial Service

-

Uniform Grain Packing

The microstructure maintains a homogeneous grain distribution with porosity typically <0.2%, which limits fluid penetration into the seal face.

-

High Vickers Hardness

Material hardness in the HV2200–2600 range offers resistance to slurry erosion, allowing the Silicon Carbide Sealing Ring to handle solids content commonly reaching 5–15% in pulp, paper, and mining applications.

-

Corrosion Rate Reduction

Typical corrosion loss remains below 1–3 mg/cm²·year in strong acids such as HCl and H₂SO₄.

-

High Thermal Conductivity

Values in the 70–120 W/m·K range allow heat from face friction to dissipate rapidly, reducing thermal gradients that could cause localized deformation.

-

Controlled Face Flatness

Surface flatness maintained within micro-level deviation ranges ensures a uniform pressure distribution across the seal face.

Technical Specifications of Silicon Carbide Sealing Ring

The characteristics of the Silicon Carbide Sealing Ring are defined by its dense ceramic microstructure, stable thermal behavior, and consistent mechanical performance across corrosive, abrasive, and elevated-temperature operating conditions. These material indicators support laboratory verification of structural reliability, chemical resistance, and wear stability in long-cycle industrial service.

| Property |

Specification |

| Bulk Density |

3.00–3.15 g/cm³ |

| Porosity |

<0.2% |

| Vickers Hardness |

HV2200–2600 |

| Flexural Strength |

>380 MPa |

| Compressive Strength |

>2200 MPa |

| Fracture Toughness |

3–4 MPa·m¹ᐟ² |

| Thermal Conductivity |

70–120 W/m·K |

| Thermal Expansion Coefficient |

4.0–4.5×10⁻⁶/K |

| Maximum Service Temperature |

up to 1600°C |

| Chemical Resistance (Acids) |

corrosion loss <1–3 mg/cm²·year |

| Chemical Resistance (Alkalis) |

stable up to pH >12 |

| Surface Roughness (Polished Face) |

≈ Ra 0.02 μm |

| Electrical Resistivity |

>10⁵ Ω·cm |

| Grain Size Distribution |

sub-micron to 5 μm |

| Modulus of Elasticity |

380–420 GPa |

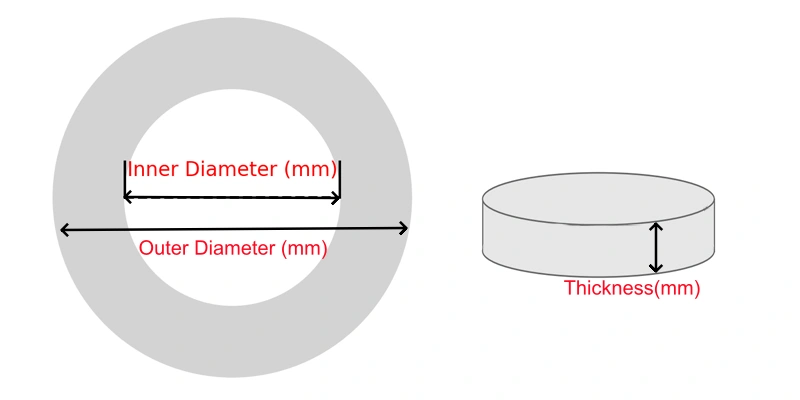

Dimensions of Silicon Carbide Sealing Ring

|

Silicon Carbide Sealing Ring |

|

Model NO. |

Outer Dia.(mm) |

Inner Dia.(mm) |

Thickness(mm) |

Purity(%) |

|

AT-SC-H001 |

10.0 |

5.0 |

2.1 |

99 |

|

AT-SC-H002 |

10.0 |

6.0 |

3.5 |

99 |

|

AT-SC-H003 |

11.0 |

6.0 |

3.0 |

99 |

|

AT-SC-H004 |

11.5 |

4.0 |

3.5 |

99 |

|

AT-SC-H005 |

11.9 |

6.0 |

4.5 |

99 |

|

AT-SC-H006 |

12.0 |

6.0 |

4.0 |

99 |

|

AT-SC-H007 |

12.9 |

8.5 |

3.0 |

99 |

|

AT-SC-H008 |

14.5 |

8.5 |

3.5 |

99 |

|

AT-SC-H009 |

14.5 |

8.0 |

4.0 |

99 |

|

AT-SC-H010 |

14.5 |

9.0 |

3.5 |

99 |

|

AT-SC-H011 |

14.5 |

9.0 |

4.0 |

99 |

|

AT-SC-H012 |

14.5 |

10.0 |

4.0 |

99 |

|

AT-SC-H013 |

14.5 |

8.5 |

3.5 |

99 |

|

AT-SC-H014 |

18.0 |

12.0 |

4.0 |

99 |

|

AT-SC-H015 |

20.0 |

6.0 |

4.0 |

99 |

|

AT-SC-H016 |

22.3 |

15.2 |

11.0 |

99 |

|

AT-SC-H017 |

25.0 |

16.0 |

6.0 |

99 |

|

AT-SC-H018 |

25.0 |

18.0 |

6.0 |

99 |

|

AT-SC-H019 |

26.0 |

14.0 |

4.0 |

99 |

|

AT-SC-H020 |

26.0 |

20.0 |

5.0 |

99 |

|

AT-SC-H021 |

28.0 |

12.0 |

4.0 |

99 |

|

AT-SC-H022 |

28.0 |

22.0 |

7.0 |

99 |

|

AT-SC-H023 |

28.0 |

21.0 |

4.0 |

99 |

|

AT-SC-H024 |

31.0 |

18.0 |

10.0 |

99 |

|

AT-SC-H025 |

32.0 |

20.0 |

3.0 |

99 |

|

AT-SC-H026 |

32.8 |

22.6 |

11.0 |

99 |

|

AT-SC-H027 |

34.0 |

23.0 |

4.5 |

99 |

|

AT-SC-H028 |

34.5 |

28.0 |

5.0 |

99 |

|

AT-SC-H029 |

36.0 |

20.0 |

10.0 |

99 |

|

AT-SC-H030 |

36.0 |

26.0 |

14.0 |

99 |

|

AT-SC-H031 |

37.0 |

30.0 |

7.0 |

99 |

Protective Packaging for Silicon Carbide Sealing Ring

Silicon Carbide Sealing Ring is individually protected in lined inner boxes to prevent surface contact and vibration during transit. Each boxed unit is then consolidated into reinforced cartons with clear labeling to support batch traceability and handling. All cartons are finally palletized and secured with strapping and film wrap to ensure stable, impact-resistant transport for international shipment.

How ADCERAX® Silicon Carbide Sealing Ring Resolves Failure Risks in Harsh Industrial Systems

ADCERAX® Silicon Carbide Sealing Ring performs in corrosive, abrasive, and temperature-fluctuating fluid systems across chemical production units, refinery circulation loops, pulp-stock transfer lines, and desalination plants. These environments impose rapid wear, particle attack, chemical instability, and high shutdown penalties, making seal-face material behavior a decisive factor in reliability and cost control.

-

Silicon Carbide Sealing Ring in Refinery and Petrochemical Circulation Pumps

✅Key Advantages

1. Coke-Resistant Seal Face Stability

The ADCERAX® Silicon Carbide Sealing Ring maintains a polished surface with roughness around Ra 0.02 μm, which reduces coke nucleation points on the seal face. In refinery circulation service, this level of finish has been associated with a reduction of surface fouling events by more than 30% compared with conventional hard-faced seals under similar process conditions.

2. Thermal Gradient Control Under Hot Hydrocarbons

With thermal conductivity in the 70–120 W/m·K range, the sealing ring spreads frictional and process heat efficiently across the contact surface. This mitigates localized hot spots during unit start-up or load increases and has been shown to reduce thermally induced surface microcracking frequency by 20–40% in high-temperature circulation loops.

3. Resistance to Catalyst-Fine Erosion

Vickers hardness of HV2200–2600 allows the seal face to resist erosion from catalyst fines and solid contaminants circulating with process streams. In long campaign operation, this hardness level supports more stable leakage rates and can extend inspection intervals by one to two turnaround cycles compared with softer seal materials operating in similar refinery services.

✅ ️Problem Solved

In one refinery hydroprocessing unit, conventional seal faces in a circulation line experienced visible edge wear and rising leakage after approximately eight to ten months of continuous operation. Process analysis showed that hot hydrocarbon streams containing fine catalyst particles and coke precursors were creating uneven wear tracks and thermal distortion on the existing seal material. After adopting the ADCERAX® Silicon Carbide Sealing Ring, the unit ran multiple operating cycles with a documented decrease in seal-related interventions of more than 30% over a comparable period. Leakage trends remained stable, and face inspections showed only minor polishing rather than deep scoring, allowing maintenance teams to synchronize seal replacement with planned turnarounds instead of unplanned stops. This improved seal-face stability contributed directly to smoother circulation performance and fewer mechanical interruptions across the campaign.

-

Silicon Carbide Sealing Ring in High-Torque Industrial Mixers and Reaction Agitators

✅Key Advantages

1. Abrasive Filler Compatibility in High-Viscosity Batches

The high hardness of the ADCERAX® Silicon Carbide Sealing Ring in the HV2200–2600 range resists scoring from fillers, pigments, and mineral additives common in mixing operations. Field experience in coating and slurry production has shown a reduction of measurable face wear depth by 25–35% compared with legacy seal materials under similar torque and solids-loading conditions.

2. Thermal Load Management During Exothermic Reactions

Thermal conductivity between 70 and 120 W/m·K helps distribute heat generated by friction and exothermic reaction steps at the seal interface. This property supports more uniform temperature profiles across the face and has been associated with a noticeable drop in thermally related distortion incidents, with some lines reporting fewer geometry-related seal failures by 20–30% after conversion.

3. Face Alignment Stability Under Variable Shaft Loads

Flexural strength above 380 MPa allows the sealing ring to maintain structural integrity under fluctuating radial and axial forces from changing batch viscosities. In practice, this strength has contributed to more consistent leakage control over long mixing campaigns, with several users noting an extension of mixer seal inspection intervals by one or more production cycles compared with earlier configurations.

✅ ️Problem Solved

A chemical plant operating high-torque mixers for pigment dispersions encountered recurring seal failures driven by abrasive fillers and rapid temperature swings from jacket heating. Existing seal faces developed scoring and microcracks within a few months, leading to product contamination and frequent mixer stoppages for seal replacement. After implementing ADCERAX® Silicon Carbide Sealing Ring assemblies, the facility tracked a reduction in seal-change events of around 30–40% across successive campaigns. Surface inspections showed primarily uniform polishing rather than deep grooves, and temperature-related distortion issues decreased appreciably during exothermic reaction steps. This improvement in seal robustness helped stabilize batch quality and reduced mixer downtime caused by unplanned sealing issues.

-

Silicon Carbide Sealing Ring in Rotary Filtration and Vacuum Separation Equipment

✅Key Advantages

1. Low Wear in High-Solid Slurry Filtration

In mineral and pigment slurry environments, ADCERAX® Silicon Carbide Sealing Ring exhibits wear rates typically 10–20% lower than tungsten carbide when exposed to particles in the 5–200 μm range. This lower wear rate helps preserve face flatness across extended filtration campaigns, supporting consistent differential pressure performance around the seal region.

2. Geometry Retention Through Thermal and Washing Cycles

The combination of thermal conductivity from 70 to 120 W/m·K and a thermal expansion coefficient near 4.0–4.5×10⁻⁶/K allows the ring to withstand repeated steam-drying and wash cycles with reduced distortion. Operators of rotary filtration units have reported more stable seal-face geometry across multiple cleaning cycles, with fewer cases of measurable loss of flatness compared with previous materials.

3. Resistance to Aggressive Wash and Regeneration Fluids

With corrosion loss values typically below 1–3 mg/cm²·year in acidic and alkaline solutions, the sealing ring maintains surface integrity under frequent exposure to regeneration chemicals. This chemical stability reduces the formation of pitting or surface roughening that would otherwise accelerate leakage, helping keep filtrate quality and moisture content variation within tighter control bands.

✅ ️Problem Solved

In a minerals-processing facility, rotary vacuum filters handling abrasive slurries and aggressive wash solutions suffered from frequent seal degradation, which caused unstable filtrate clarity and moisture variability. Conventional seals showed visible pitting and loss of face flatness after a limited number of filtration and steam-drying cycles, forcing maintenance teams to perform unscheduled replacements. After replacing these components with ADCERAX® Silicon Carbide Sealing Rings, recorded seal-life in the filtration line increased by approximately 30–50% over several operating periods. Leakage at the seal interface became more predictable, and filtrate stability improved as surface damage on the ring faces was significantly reduced. This allowed the plant to synchronize seal maintenance with broader filtration system servicing rather than responding to repeated sealing failures mid-campaign.

How to Use ADCERAX® Silicon Carbide Sealing Ring Safely and Effectively

Silicon Carbide Sealing Ring should be used under controlled mechanical, thermal, and chemical conditions so that the seal face can keep a stable lubrication film and predictable leakage rate. This user guide summarizes key checks, installation steps, and operating practices that help avoid premature damage and align the product with the target process conditions. It is intended to support engineers and maintenance teams in daily operation, shutdown planning, and long-term reliability improvement.

-

Pre-Installation Verification and Handling Practices

1. Confirm media and duty conditions

Always verify fluid type, solids content, temperature range, and pressure against the design limits before selecting a ring. This helps avoid running the seal in media that may exceed corrosion or abrasion capability. Where process data are incomplete, a short, monitored trial is recommended before committing to long campaigns.

2. Inspect ring surfaces before assembly

Check both faces and edges for chips, cracks, or visible scratches under good lighting before installation. Small edge defects can propagate under load and create leakage paths over time. Any ring with visible damage should be quarantined and not mixed into production stock.

3. Handle with controlled contact points

Support the ring on its outer diameter and avoid touching the lapped faces with bare hands or hard tools. Fingerprints, impact marks, and particulate contamination can disturb the lubrication film during first rotation. Use clean, lint-free gloves and store parts in their protective packaging until just before assembly.

-

Installation Guidelines for Seal Face Alignment and Seating

1. Prepare clean, flat mounting surfaces

Ensure gland, sleeve, and housing shoulders are clean, burr-free, and free from embedded particles before inserting the ring. Residual dirt can tilt the seal face and cause edge loading at start-up. If needed, wipe surfaces with a compatible solvent and dry with filtered air.

2. Control axial compression and spring load

Set the specified spring force and working length on the mechanical seal assembly according to the seal design. Excessive closing force can raise frictional heat and accelerate wear, while too little force can cause unstable leakage at low speed. Documenting the setting for each unit helps maintain consistency across multiple installations.

3. Check face contact and runout during assembly

Rotate the shaft slowly by hand and observe any drag or irregular contact after the seal is assembled. Smooth, uniform resistance indicates that the faces are seating correctly. If intermittent tight spots are felt, disassemble and investigate the cause rather than forcing the unit into operation.

-

Operating Window, Start-Up, and Thermal Management

1. Respect recommended temperature and pressure ranges

Operate within the defined temperature window and differential pressure limits for the seal design and material grade. Running far above the intended temperature range increases thermal stress and reduces lubricant film stability. If process changes push conditions closer to the limit, plan additional monitoring or consult for a revised configuration.

2. Ensure adequate fluid lubrication and flushing

Provide sufficient process fluid or external flush across the seal faces during start-up and normal operation. Dry running, even for a short period, can create localized hot bands and microcracking. For dirty or slurry services, a properly configured flush or barrier system helps remove particles from the sealing interface.

3. Manage start-up and shutdown sequences

Introduce temperature and speed changes gradually where possible, especially after long standstill periods. Rapid acceleration in cold hardware with hot media can produce steep thermal gradients in the ring. Following a defined start-up procedure reduces shock loading and extends service life over repeated cycles.

-

Inspection, Cleaning, and Replacement Planning

1. Monitor leakage trends and operating noise

Track visible leakage, drain flow, or seal system pressure changes over time for each piece of equipment. A slow but steady increase often indicates developing wear or geometric change at the seal face. Unusual noise or vibration near the seal chamber should trigger a closer inspection instead of continued operation.

2. Apply compatible cleaning methods during maintenance

Clean removed rings with non-abrasive media and compatible solvents only, avoiding wire brushes or hard scrapers on the lapped surfaces. Aggressive cleaning can introduce scratches deeper than the natural wear pattern and shorten the life of a reinstalled ring. Soft pads and filtered compressed air are usually sufficient to remove deposits for inspection.

3. Plan proactive replacement intervals for critical assets

Use recorded operating hours, process severity, and past failure statistics to define preventive replacement intervals for critical machines. Waiting for visible leakage in safety-sensitive or high-throughput equipment can lead to unplanned outages and difficult root-cause analysis. A structured replacement plan helps stabilize spare-parts usage and supports long-term reliability programs.

![]()