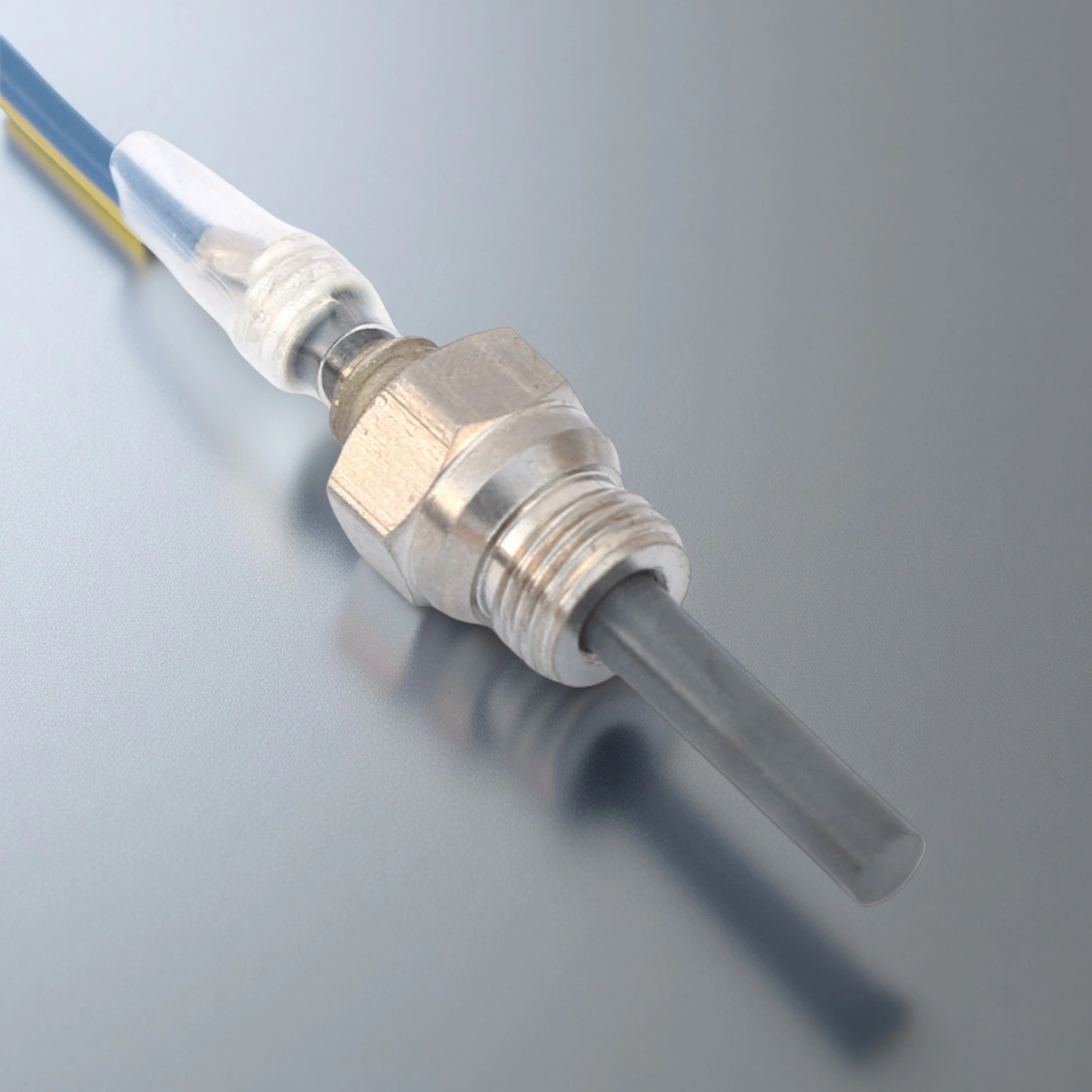

The silicon nitride electric plug is engineered for high-temperature environments where electrical insulation, thermal shock resistance, and mechanical strength are critical. Commonly used in gas ignition systems, industrial furnaces, and automotive exhaust sensors, this component ensures stable performance under extreme thermal and electrical loads.

Silicon Nitride Electric Plug Benefits

-

Fast surface heating for cold-start support

The silicon nitride electric plug reaches ignition temperature within seconds, helping diesel heaters and burners achieve reliable start-up in low-temperature environments. -

High operating temperature with a stable ceramic body

The Si₃N₄ ceramic body maintains mechanical strength at elevated temperature, allowing operation close to 1000–1100 °C at the hot zone without deformation. -

Resistance to thermal shock and cycling

The plug structure tolerates rapid heating and cooling, supporting repeated ignition cycles in parking heaters, boilers and pellet stoves throughout the heating season. -

Compact structure with efficient heat transfer

The electric plug integrates the heater and ceramic carrier in a small cross-section, so the hot surface sits directly in the fuel/air stream, reducing ignition delay. -

Geometry designed for sealed mounting

The front and rear sections can be shaped for threaded, flanged or clamped mounting, helping maintain the tightness of the combustion chamber and exhaust path.

Silicon Nitride Glow Plug Properties

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson's ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

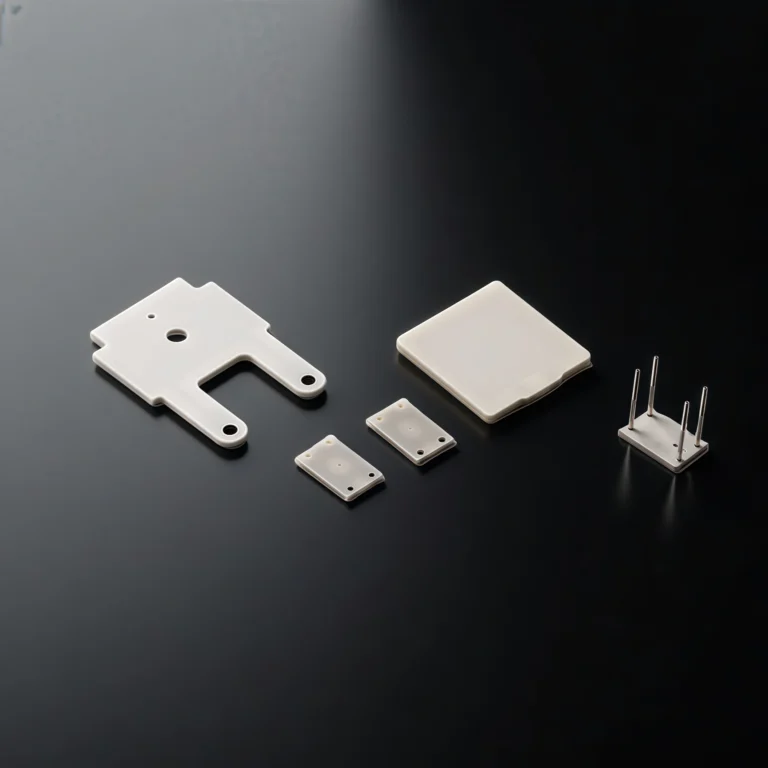

Si3N4 Electric Plug Specifications

| Si3N4 Electric Plug | ||

| Item No. | Diameter (mm) | Thickness (mm) |

| AT-DHG-DRS01 | Customize | |

Silicon Nitride Ceramic Glow Plug Packaging

- Each silicon nitride hot surface igniter is individually protected in a shock-absorbing inner tray or sleeve to prevent ceramic edge damage.

![]()