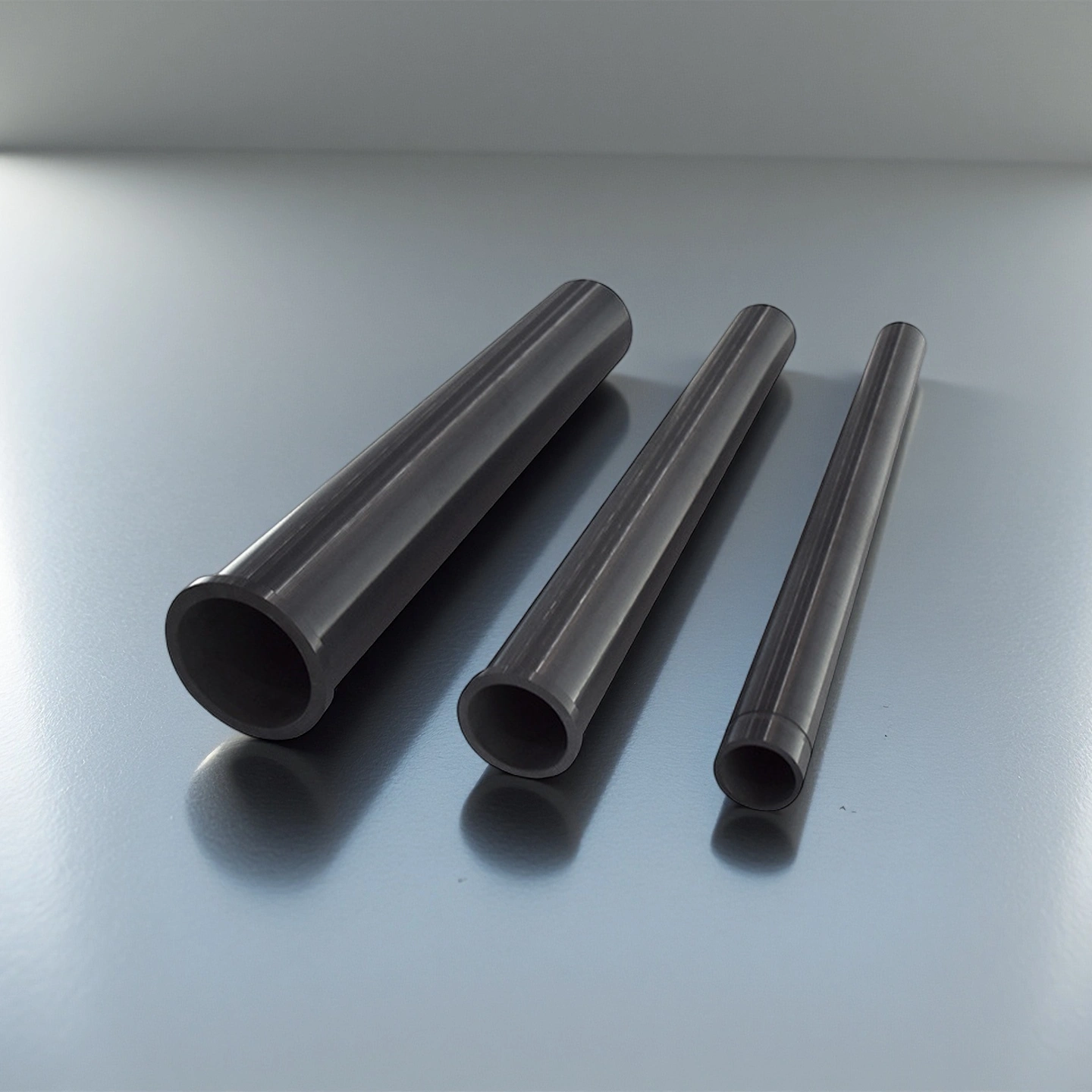

Silicon nitride heater protection tube is a ceramic component designed to isolate and protect heating elements or thermocouples when they are immersed in molten metals such as aluminum or zinc. It prevents direct contact between the heater and the metal, allowing stable heat transmission while avoiding chemical reaction, oxidation, or metal corrosion.

Silicon Nitride Heater Tube Benefits

-

Non-Wetting to Molten Aluminum:

Silicon nitride forms no intermetallic reaction layer with molten aluminum, preventing adhesion of metal and oxide dross. This reduces cleaning frequency and keeps heater surfaces exposed for consistent thermal efficiency during long-term immersion. -

Thermal Shock Resistance:

The low thermal expansion coefficient (~2.8 × 10⁻⁶/K) allows the tube to transition from room temperature to molten aluminum at 700–800 °C without cracking. It endures repeated heating and cooling cycles in daily furnace operations without structural fatigue. -

Corrosion and Erosion Resistance:

Si₃N₄ maintains mechanical strength in chloride salt, flux, and aluminum oxide-rich melt environments. Surface degradation rates are significantly lower than SiC or mullite, which helps reduce tube wall thinning and heater exposure. -

Gas-Tight and Dense Microstructure:

The fully dense ceramic body (<1% open porosity) prevents molten aluminum or furnace gas from penetrating the tube. This isolation protects internal heater wires or thermocouples from oxidation and electrical failure. -

Extended Service Life:

In molten aluminum applications, silicon nitride heater protection tubes operate 3–5 times longer than silicon carbide or alumina tubes under equal thermal and chemical conditions. Lower replacement frequency reduces furnace downtime and maintenance costs.

Silicon Nitride Heater Protection Tube Properties

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson's ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

Silicon Nitride Heater Tube Specifications

| No. | Comparison Item | Radiant Holding Furnace | Immersion Holding Furnace | Immersion Advantages |

|---|---|---|---|---|

| 1 | Heating Method | The heating rod radiates heat from the aluminum liquid surface | The heating rod heats inside the aluminum liquid | |

| 2 | Thermal Efficiency | 40-50% | 90-95% | High thermal efficiency |

| 3 | Heating Power | 90Kw (1000Kg) | 16Kw (1000Kg) | Significant power saving |

| 4 | Furnace Gas Temperature | 850-950℃ | 650-700℃ | Low aluminum loss |

| 5 | Aluminum Liquid Burn Loss Rate | 1.5-2% | 0.30% | Few impurities |

| 6 | Slagging Phenomenon on Liquid Surface | Severe | Very little | High-quality aluminum liquid |

| 7 | Aluminum Liquid Gas Absorption Phenomenon | Severe | Lower | |

| 8 | Heating Rate | Slow | Fast | Fast heating |

| 9 | Slagging and Aluminum Creeping in Furnace Lining | Severe | Not easy to slag | Easy maintenance |

| 10 | Aluminum Liquid Depth | Less than 400mm | Unlimited | More flexible |

| 11 | Temperature Uniformity | Top-bottom temperature difference 10-20℃ | Less than 5℃ | Good quality |

| 12 | Furnace Lining Life | Low | High | Long life |

| Si3N4 Heater Protection Tube | |||

| Item No. | Outer Diameter (mm) | Inner Diameter (mm) | Length (mm) |

| AT-DHG-G2001 | 20 | 9 | 500-1500 |

| AT-DHG-G2002 | 30 | 18 | 500-1500 |

| AT-DHG-G2003 | 40 | 20 | 500-1500 |

| AT-DHG-G2004 | 70 | 45 | 800-1500 |

| AT-DHG-G2005 | 100 | 75 | 800-1500 |

| AT-DHG-G2006 | 112 | 86 | 800-1500 |

| AT-DHG-G2007 | 125 | 100 | 800-1500 |

| AT-DHG-G2008 | 132 | 108 | 800-1500 |

| AT-DHG-G2009 | 160 | 135 | 800-1500 |

| AT-DHG-G2010 | 192 | 168 | 800-1500 |

| AT-DHG-G2011 | 200 | 175 | 800-1500 |

Silicon Nitride Heater Protection Tube Packaging

- Each tube is individually packed in foam-lined boxes to prevent damage during transit.

![]()