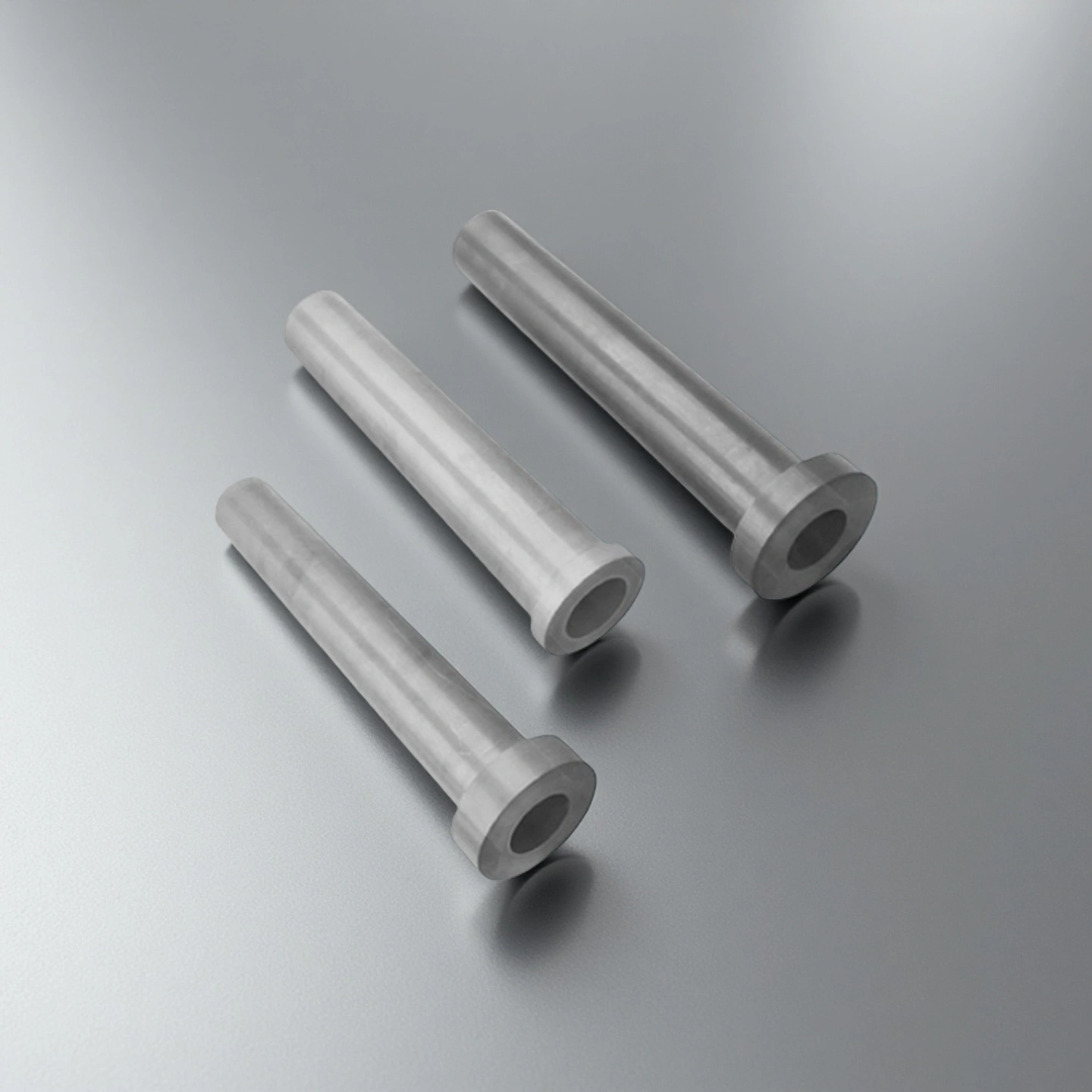

Silicon nitride riser tube is a precision ceramic tube (Si₃N₄) used in low-pressure die casting (LPDC) and selected gravity casting cells to lift molten aluminum from the holding furnace into the die cavity through a sealed, low-turbulence flow path. Its job is deceptively simple—move clean metal, at controlled velocity, every cycle—but the demands are high: wetting resistance to Al-Si alloys, thermal-shock tolerance through daily heat-up/cool-down, and dimensional stability so fill curves and casting quality remain repeatable.

Silicon Nitride Riser Tube Benefits

▪ Low wettability to Al–Si alloys

The Si₃N₄ surface forms a stable oxide–nitride layer that resists chemical bonding with molten aluminum. This reduces metal adhesion and dross accumulation, allowing cleaner bore surfaces and faster post-shutdown maintenance.

▪ Thermal-shock tolerance

Its interlocking β-Si₃N₄ grain structure dissipates thermal stress, allowing the tube to withstand rapid transitions from room temperature to 700–780 °C melt contact. This prevents cracking during daily heating cycles or emergency stops.

▪ Erosion-resistant inner bore

High hardness and <1 % open porosity limit aluminum infiltration and abrasion from alloy flow and oxide particles. The bore diameter stays consistent over long production runs, stabilizing metal throughput and fill-time consistency.

▪ Dimensional precision for sealing and mounting

Controlled sintering and finish machining ensure tight ID/OD concentricity and flat end faces. This improves sealing with the furnace base, reduces air ingress, and maintains accurate furnace-to-die alignment.

▪Consistent lifespan curve

Material stability and low wear rate allow predictable service life across batches, which supports scheduled maintenance instead of reactive tube replacement. This helps minimize downtime and unplanned casting interruptions.

Silicon Nitride Riser Tube Properties

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson's ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

Si3N4 Riser Tube Specifications

| Silicon Nitride Riser Tube | |||

| Item No. | Outer Diameter (mm) | Inner Diameter (mm) | Length (mm) |

| AT-DHG-G4001 | 70 | 50 | 500-1100mm |

| AT-DHG-G4002 | 75 | 54.8 | 500-1100mm |

| AT-DHG-G4003 | 80 | 59.5 | 500-1100mm |

| AT-DHG-G4004 | 82 | 61.8 | 500-1100mm |

| AT-DHG-G4005 | 85 | 64.5 | 500-1100mm |

| AT-DHG-G4006 | 90 | 69.5 | 500-1100mm |

| AT-DHG-G4007 | 100 | 79.5 | 500-1100mm |

| AT-DHG-G4008 | 115 | 94.4 | 500-1100mm |

| AT-DHG-G4009 | 130 | 109.5 | 500-1100mm |

| AT-DHG-G4010 | 142 | 121.5 | 500-1100mm |

| AT-DHG-G4011 | 150 | 129 | 500-1100mm |

| AT-DHG-G4012 | 180 | 159.2 | 500-1100mm |

| AT-DHG-G4013 | 200 | 179 | 500-1100mm |

| AT-DHG-G4014 | 215 | 194 | 500-1100mm |

| AT-DHG-G4015 | 221 | 200 | 500-1100mm |

Si3N4 Silicon Nitride Riser Tube Packaging

- Protection: each tube is in a closed-cell foam contour with full-length support; bore plugs to block dust.

![]()